Ngokwezifisometal die cast izingxenyezibalulekile ekushayeleni impumelelo yebhizinisi. Izimboni ezifana nezezimoto zincike kokungasindi, okuqinilemetal die castizingxenye zokuthuthukisa ukusebenza nokusebenza kahle. Umhlaba jikelelemetal die casting izingxenye foundryimakethe, okulindeleke ukuthi ifinyelele ku-USD 112.27 billion ngo-2033, igcizelela isidingo esikhulayo sezixazululo eziklanyelwe. Ukunemba kanye nempumelelo yezindleko zayo ngayinyemetal die casting ingxenyezenze zibe semqoka. Ngaphezu kwalokho,i-centrifugal metal die castingamasu athuthukisa futhi ukukhiqiza, aqinisekisa imiphumela yekhwalithi ephezulu.

Okuthathwayo Okubalulekile

- Izingxenye zokuphonswa kwensimbi ngokwezifisosiza amabhizinisi aphumelele. Banikeza ukunemba futhi bonga imali. Imiklamo ekhethekile ifanelana nezidingo eziqondile, ithuthukisa umsebenzi namaphutha okusika.

- Izimboni ezifana nezimoto nezindiza zithola okuningi ngokufaka insimbi. Lezi zingxenye zenza izinto zisebenze kangcono, ziphephe, futhi zisebenzise uphethiloli omncane. Ziwukhiye wokusetshenziswa kwekhwalithi ephezulu.

- Ukukhetha inkampani efanelekubaluleke kakhulu. Hlola amakhono abo, amathuluzi, kanye nokwesekwa ukuze wakhe ubambiswano oluqinile olusiza ibhizinisi lakho ukuthi likhule.

Ukuqonda Izingxenye Zokusakaza Ze-Metal Die

Yiziphi Izingxenye Zokusakaza Ze-Metal Die?

Izingxenye zokuphonsa zensimbiziyizingxenye ezidalwe ngenqubo yokukhiqiza ehlanganisa ukuphoqelela insimbi encibilikisiwe ibe yisikhunta ngaphansi kwengcindezi ephezulu. Le ndlela iqinisekisa ukunemba nokuvumelana ekukhiqizeni izimo eziyinkimbinkimbi. Inqubo ivamise ukusebenzisa ama-alloys afana ne-aluminium, i-zinc, ne-magnesium, ngalinye linikeza izici ezihlukile.

| Uhlobo lwe-alloy | Amazinga/Izici |

|---|---|

| Zinc | Ukuqedwa okuhle kwendawo, ukungaguquguquki kwe-dimensional |

| I-Aluminium | I-AA 380, AA 384, AA 386, AA 390 |

| Magnesium | I-AZ91D |

| Ithusi | Ngokuvamile isetshenziswa ekulingiseni die |

Izici zedizayini yamaqhinga, njengokuqina kodonga olufanayo, zithuthukisa ukusebenza nokuqina kwalezi zingxenye. Ukupholisa okufanayo kunciphisa amaphutha afana ne-warping, kuqinisekisa ukuzinza kwe-dimensional. Izindlela zokuhlola eziqinile ziqhubeka ziqinisekisa ukukhiqizwa kwekhwalithi ephezulu.

Izicelo Ezimbonini Ezibalulekile

Izingxenye zokuphonsa ezinsimbi zidlala indima ebalulekile ezimbonini ezifana nezezimoto, i-aerospace, ne-electronics. Umkhakha wezimoto, ngokwesibonelo, ubambe u-41.7% wesabelo semali engenayo emhlabeni wonke ngo-2023. Imishini yokukhipha umfutho ophakeme ikhiqiza izingxenye ezingasindi njengamabhulokhi enjini namakesi okudlulisa, ukuthuthukisa ukusebenza kahle kukaphethiloli nokuphepha.

Kwi-aerospace, lobu buchwepheshe bakha izingxenye eziqine kakhulu njengama-turbine blades kanye nezingxenye ze-gearbox. Lezi zingxenye zimelana nezimo ezimbi kakhulu, ziqinisekisa ukwethembeka. Ukwengeza, abakhiqizi bezinto zikagesi basebenzisa i-die casting ukukhiqiza izindlu eziyinkimbinkimbi nezixhumi, ezihlangabezana nesidingo semiklamo ehlangene nehlala isikhathi eside.

| Indawo Yesicelo | Incazelo | Idatha Yezinombolo |

|---|---|---|

| Ezezimoto | Amabhulokhi enjini angasindi, amakesi okudlulisela | Isabelo semali esingu-41.7% ngo-2023 |

| I-Aerospace | Ama-turbine blades, izingxenye ze-gearbox | Amandla aphezulu, ukusebenza kwesimo esidlulele |

| Ezogesi | Izindlu, izixhumi | Imiklamo emincane, ehlala isikhathi eside |

Ukubaluleka Kwemisebenzi Yebhizinisi

Izingxenye zokuphonsa zensimbi zifaka isandla kakhuluimpumelelo yebhizinisi. Imakethe yokusakazwa kwensimbi yomhlaba wonke, enenani lama- $ 177.28 billion ngo-2024, kulindeleke ukuthi ifinyelele ku-USD 325.69 billion ngo-2033, ikhula ku-CAGR ka-6.94%. Lokhu kukhula kukhombisa ukukhula kwesidingo sezingxenye ezingasindi nezihlala isikhathi eside.

Amamethrikhi okusebenza angukhiye agqamisa ukubaluleka kwawo. Ukugcina izinga lokungasebenzi lingaphansi kuka-2% kuqinisekisa ukulawulwa kwekhwalithi, kuyilapho ukusetshenziswa kahle kwemishini engaphezu kwama-85% kunciphisa isikhathi sokuphumula. Izilinganiso zokutholwa kwempahla izikhathi ezingu-6-8 ngonyaka zinciphisa izindleko zokubamba, futhi ukulandelela ukulethwa kwama-KPI kungakhuphula ama-oda aphindaphindiwe ngo-20%. Lawa mamethrikhi akhombisa ukuthi izingxenye ze-metal die casting zithuthukisa kanjani ukusebenza futhi zithuthukise ukwaneliseka kwamakhasimende.

| Imethrikhi | Incazelo |

|---|---|

| Ukusakaza Izilinganiso Zokukhubazeka | Ngaphansi kuka-2% kuqinisekisa ukulawulwa kwekhwalithi nokwaneliseka kwamakhasimende. |

| Ukusetshenziswa Kwezisetshenziswa | Ngaphezulu kuka-85% kunciphisa isikhathi sokuphumula futhi kukhulisa ukusetshenziswa kwezinsiza. |

| Inventory Turnover | Izikhathi ezingu-6-8 ngonyaka kunciphisa izindleko zokubamba futhi kuvimbele ukubambezeleka. |

| Ukwaneliseka Kwekhasimende | Ama-KPI wokulethwa angakhuphula ama-oda aphindayo ngo-20%. |

| Ama-KPI ezezimali | Izilinganiso zenzuzo ezedlula ama-25% ngokuqapha izindleko kanye nenzuzo. |

Izinzuzo Zokwenza Ngokwezifiso Izingxenye Zokusakaza Ze-Metal Die

Ukunemba kanye Nekhwalithi

Ukwenza ngokwezifiso izingxenye zokusakaza zensimbiiqinisekisa ukunemba okungenakuqhathaniswa kanye nekhwalithi ephezulu. Imiklamo eklanyelwe ivumela abakhiqizi ukuthi bahlangabezane nokucaciswa okuqondile, ukunciphisa amaphutha nokuthuthukisa ukusebenza. Ucwaningo lugqamisa izinzuzo zokwenza ngokwezifiso:

- Ucwaningo lwango-2022 kuIjenali Yezinqubo Zokukhiqizaibike ukuthuthuka okungama-35% kokulingana kwengxenye nokusebenza kwezinkampani ezisebenzisa ukusakaza okuzenzakalelayo kwefa.

- IIjenali yamazwe ngamazwe ye-Advanced Manufacturing Technology(2023) iveze ukwehliswa okungama-25% kwezindleko zempahla eluhlaza ngenxa yemiklamo ethuthukisiwe.

Lokhu okutholakele kubonisa ukuthi ukwenza ngendlela oyifisayo kuthuthukisa kanjani kokubili ukusebenza nokusebenza kahle kwezindleko. Ukwengeza, amasu okuhlola athuthukile aqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziqinile zekhwalithi, inciphisa amaphutha futhi ikhulise ukwethembeka.

Ukusebenza kahle kanye nokusebenza

Ukwenza ngokwezifiso izingxenye zokusakaza zensimbi kuthuthukisa kakhulu ukusebenza kahle nokusebenza. Imiklamo yesikhunta ephumelelayo nezinqubo ezilula zinciphisa ukungcola futhi zithuthukise isivinini sokukhiqiza. Izici ezibalulekile ezinomthelela ekusebenzeni kahle zihlanganisa:

- Isikhunta Design: Isikhunta esilungiselelwe sithuthukisa ukunembafuthi unciphise ukusetshenziswa kwezinto.

- Ukuqeda Ukuchichima kanye Abagijimi: Imiklamo elula inciphisa imfucuza.

- Ukuqeqeshwa Kwabasebenzi: Abasebenzi abanamakhono banciphisa izindleko zokucubungula futhi bathuthukise ikhwalithi yokuphumayo.

Ubuchwepheshe besimanje obufana nokubunjwa okuphrintiwe kwe-3D buthuthukisa ukusebenza kahle. Lezi zibunjwa zinika amandla ukudalwa kwe-prototype ngokushesha, ukusika izikhathi zomjikelezo wokuklama ngo-50%. Imiklamo yesikhunta se-Modular iphinde inikeze ukuguquguquka, okuvumela abakhiqizi ukuthi bazivumelanise nezidingo ezihlukahlukene zokukhiqiza. Izikhathi zokuhola ezincishisiwe zihambisana nezidingo zokukhiqiza ezifika ngesikhathi, okuqinisekisa ukulethwa okufika ngesikhathi kanye nokwaneliseka kwamakhasimende.

Izindleko-Ngempumelelo

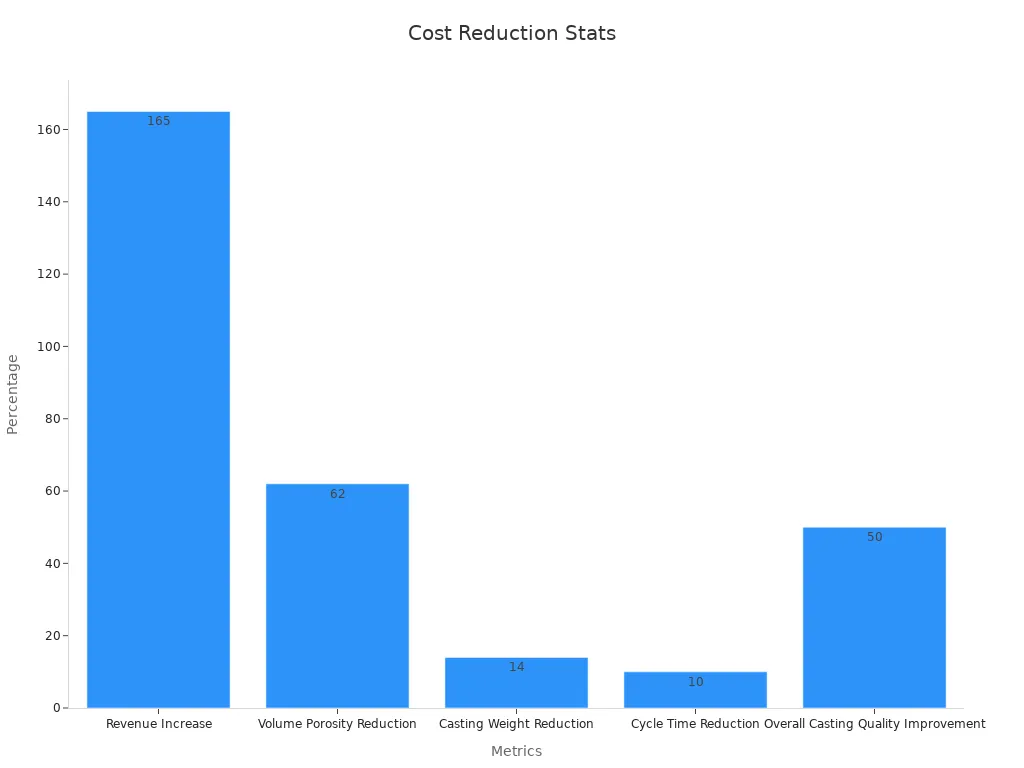

Ukwenza ngokwezifiso izingxenye zensimbi kunikeza ukonga kwezindleko ezinkulu. Ngokulungiselela imiklamo nezinqubo, abakhiqizi banganciphisa ukusetshenziswa kwezinto ezibonakalayo, ukusetshenziswa kwamandla, nesikhathi sokukhiqiza. Ithebula elilandelayo ligqamisa izinzuzo zezindleko ezibalulekile:

| Imethrikhi | Umphumela |

|---|---|

| Ukunyuka Kwemali Engenayo | ukwanda ngo-165%. |

| Ukwehliswa Kokusetshenziswa Komshini Wokusakaza | Amandla okuvala ancishisiwe abe ngamathani ayi-1200 |

| Ukuncishiswa kwe-Volume Porosity | 62% ukwehliswa |

| Ukunciphisa Isisindo Sokusakaza | Ukwehliswa ngo-14%. |

| Ukunciphisa Isikhathi Somjikelezo | 10% ukuncishiswa |

| Sekukonke Ukuthuthukiswa Kwekhwalithi Yokusakaza | 50% ukuthuthukiswa |

Lokhu kuthuthukiswa kuhumushela kumamajini enzuzo ephezulu kanye namanani ancintisanayo, okwenza izixazululo ezenziwe ngokwezifiso zibe ukutshalwa kwezimali okuhlakaniphile kwamabhizinisi.

Izixazululo Ezihlanganisiwe Zezidingo Eziyingqayizivele

Ibhizinisi ngalinye linezidingo ezihlukile, futhi izingxenye zensimbi ezenziwe ngezifiso zinikeza izixazululo ezihambisana nezidingo ezithile. Kusukela ekukhethweni kwezinto ezibonakalayo kuya ekuthuthukisweni kwedizayini, ukwenza ngendlela oyifisayo kuqinisekisa ukuthi izingxenye zihambisana kahle nemigomo yokusebenza. Izindaba zempumelelo ezibhalwe phansi zibonisa umthelela wezixazululo ezenzelwe wena:

| Igama Leklayenti | Incazelo ye-Tailored Solution |

|---|---|

| I-Boutique Eyingqayizivele | Kusetshenziswe izixazululo ezenzelwe i-Aircall ukuze zigqame emakethe egcwele abantu. |

| Abaxazululi | Izixazululo ezenziwe ngokwezifiso ezithathwe ku-Aircall ukuze zilingane nezidingo zabo zokuxhumana ngokuphelele. |

Isinyathelo ngesinyathelo inqubo yokwenza ngokwezifiso iqinisekisa ukuthi iphrojekthi ngayinye ihlangabezana nezidingo eziqondile:

- Ukubonisana Kokuqala Nokubuyekezwa Kwedizayini: Xoxa ngezinhloso zephrojekthi futhi ulungiselele imiklamo.

- Ukukhetha Okubalulekile: Khetha izinto ezisekelwe ezidingweni zokusebenza.

- Idizayini nobunjiniyela: Sebenzisa amathuluzi e-CAD ukuze udale imiklamo yangokwezifiso.

- I-Prototyping nokuhlolwa kwesampula: Qinisekisa ukunemba kanye nama-prototypes wokuhlola.

- Ukusetha Ukukhiqiza Nokukhiqiza Kokuqala: Qinisekisa ukusetha kanye nekhwalithi phakathi nokuqalisa kokuqala.

- Ukukhiqizwa Kokugcina Nokulawulwa Kwekhwalithi: Yenza ukukhiqizwa kwesikali esigcwele ngokuhlolwa kwekhwalithi okuqhubekayo.

Le ndlela iqinisekisa ukuthi amabhizinisi athola izingxenye ezithuthukisa ukusebenza, ezinciphisa izindleko, futhi ezihlangabezana nezindinganiso zomkhakha.

Inqubo yokwenza ngokwezifiso izingxenye zokusakaza ze-Metal Die

Ukuklama Nokubonisana

Inqubo yokwenza ngokwezifiso iqala ngokuklama okuphelele nesigaba sokubonisana. Onjiniyela nabaklami bayasebenzisana ukuze bakhe ipulani ehambisana nezidingo eziqondile zeklayenti. Lesi sigaba sibandakanya ukuhlaziya uhlelo oluhlosiwe, ukukhetha izinto ezifanele, kanye nokuthola izindlela zokukhiqiza ezisebenza kahle kakhulu.

Izinyathelo ezibalulekile kulesi sigaba zihlanganisa:

- Ukuhlaziywa Kwezidingo: Ukuqonda izidingo zokusebenza nezinjongo zokusebenza.

- Ukukhetha Okubalulekile: Ukukhetha ama-alloys afana ne-aluminium noma i-zinc ngokusekelwe ukuqina nezidingo zesisindo.

- Ukuthuthukisa Idizayini: Ukusebenzisa isofthiwe ye-CAD ukucwenga imiklamo ukuze uthole ukunemba kanye nokwenziwa.

Ukuxhumana okuphumelelayo phakathi kweklayenti nethimba lokuklama kuqinisekisa ukuthi yonke imininingwane iyabhekwa. Le ndlela yokuhlanganyela inciphisa amaphutha futhi ibeke isisekelo senqubo yokukhiqiza eyimpumelelo.

I-Prototyping nokuhlola

I-Prototyping nokuhlola kubalulekile ekuqinisekiseni ukuklama nokuqinisekisa ukusebenza. Ngalesi sigaba, abakhiqizi benza ama-prototypes ukuhlola ukusebenza nokukhomba izinkinga ezingaba khona. Impendulo evela kubabambiqhaza isiza ukucolisa idizayini ngaphambi kokuthi kuqale ukukhiqiza ngezinga eligcwele.

Imisebenzi esemqoka kulesi sigaba ihlanganisa:

- Ukudala i-design-up-up noma i-prototype yesici.

- Iqoqa impendulo ezithamelini eziqondiwe.

- Ukuhlonza izinkinga ezingaba khona noma ukuqinisekisa izinqumo zomkhiqizo.

Konke ukwehluleka ngesikhathi se-prototyping kunikeza imininingwane ebalulekile mayelana nokuklama nezinqubo zokukhiqiza. Isibonelo, ukuhlaziya okunemininingwane yokwehluleka kusiza ukukhomba izimbangela kanye namazinga okuhluleka alindelekile. Ithebula elilandelayo libonisa ukubaluleka kokuhlola:

| Inombolo yama-Prototypes | Inombolo Yokuhluleka | Izinga Lokuhluleka (%) |

|---|---|---|

| 100 | 1 | 1 |

| 10 | 1 | 10 |

| 2 | 1 | 50 |

Le datha igqamisa isidingo sokuhlolwa okuqinile ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zekhwalithi.

Ukukhiqiza kanye Nokulawulwa Kwekhwalithi

Uma umklamo usuphothuliwe, isigaba sokukhiqiza siyaqala. Abakhiqizi basebenzisa imishini ethuthukisiwe kanye namasu ukuze bakhiqize izingxenye zensimbi ezifayo zekhwalithi ephezulu. Izinyathelo zokulawula ikhwalithi zisetshenziswa kuzo zonke izigaba ukuze kugcinwe ukungaguquguquki nokwethembeka.

Amamethrikhi angukhiye okukhiqiza afaka:

- Izilinganiso Zephutha: Ukuqapha inani lamayunithi anesici ngesamba ngasinye esikhiqizwayo.

- Iphesenti Lemikhiqizo Engavumelani: Ukuqinisekisa ukuthi imikhiqizo iyahlangabezana nezicaciso.

- Isikhathi Sokuxazulula Izinkinga Zekhwalithi: Ukubhekana nezinkinga ngokushesha ukuze kugwenywe ukubambezeleka.

Ithebula elingezansi libonisa amamethrikhi okukhiqiza abalulekile:

| Imethrikhi | Incazelo |

|---|---|

| Izilinganiso Zephutha | Inani lamayunithi anesici ngesamba ngasinye esikhiqiziwe. |

| Iphesenti Lemikhiqizo Engavumelani | Isilinganiso semikhiqizo esingahlangabezani nezicaciso. |

| Isikhathi Sokuxazulula Izinkinga Zekhwalithi | Isikhathi esithathwayo ukulungisa izinkinga zekhwalithi. |

Izitifiketi ezifana ne-ISO 9001 kanye ne-Six Sigma ziqinisekisa futhi ukuqina kwenqubo yokukhiqiza. Lawa mazinga aqinisekisa ukuthi abakhiqizi bahlala beletha izingxenye ezihlangabezana noma ezeqa okulindelwe yimboni.

Ukulethwa Nokusekela

Isigaba sokugcina sibandakanya ukuletha izingxenye eziqediwe kuklayenti nokuhlinzeka ngokusekela okuqhubekayo. Amasistimu okulethwa asebenza kahle aqinisekisa ukuthi ama-oda afika ngesikhathi futhi esesimweni esifanele. Amathimba okusekela amakhasimende abhekana nanoma yikuphi ukukhathazeka futhi anikeze usizo njengoba kudingeka.

Amamethrikhi okuletha okubalulekile ahlanganisa:

- Ukulethwa Ngesikhathi: Iphesenti lama-oda agcwaliswe phakathi nedethi yokulethwa elindelwe.

- Ukunemba Kwe-oda: Iphesenti lama-oda alethwa ngaphandle kwamaphutha.

- Isikolo Sokwaneliseka Kwekhasimende: Ikala ukwaneliseka kwekhasimende mayelana nokuzizwisa kokulethwa.

Ithebula elingezansi ligqamisa lawa mamethrikhi:

| Imethrikhi | Incazelo |

|---|---|

| Ukulethwa Ngesikhathi | Iphesenti lama-oda agcwaliswe phakathi nedethi yokulethwa elindelwe. |

| Ukunemba Kwe-oda | Amaphesenti ama-oda alethwayo ngaphandle kwamaphutha uma kuqhathaniswa nama-oda aphelele. |

| Isikolo Sokwaneliseka Kwekhasimende | Ikala ukwaneliseka kwekhasimende mayelana nokuzizwisa kokulethwa, okubalulekile ekuhloleni isevisi. |

Ukuxhumana okucacile namakhasimende kuqinisekisa ukuthi bahlala benolwazi mayelana nokulethwa kwabo. Izindlela zempendulo zisiza ukubhekana nesipiliyoni esibi futhi zithuthukise ikhwalithi yesevisi. Le ndlela ebanzi iqinisekisa umuzwa ongenazihibe kusukela ekukhiqizeni kuye ekulethweni.

Ungamkhetha Kanjani Umhlinzeki Ofanele Wezingxenye Zokusakaza Ze-Metal Die

Ukuhlola Okuhlangenwe nakho Nobungcweti

Ukukhetha umhlinzeki onokuhlangenwe nakho okuqinisekisiwe kuqinisekisa ukwethembeka nekhwalithi. Abahlinzeki abanomlando omude embonini bavame ukubonisa ukuqonda okujulile kwezinqubo zokukhiqiza. Isibonelo, i-Form Technologies, enesipiliyoni seminyaka engaphezu kwengama-80 kanye namaphrojekthi aphumelele angama-270+, ayisibonelo sobuchwepheshe. Ukukhiqizwa kwabo kwaminyaka yonke kwamayunithi ayizigidi eziyizinkulungwane ezingu-5 kanye nesizinda samakhasimende esingaphezu kuka-2,000 sigqamisa amandla abo okusingatha izidingo ezihlukahlukene.

- Izici ezibalulekile okufanele zihlolwe zihlanganisa:

- Iminikelo yesevisi eyenzelwe izimboni ezithile.

- Amakhono onjiniyela aklama amaphrojekthi ayinkimbinkimbi.

- Izinsizakalo zangemuva kokukhiqiza njengokuqeda nokuhlanganisa.

Izibonelo zezifundo nazo zinikeza imininingwane ebalulekile. Umphakeli kubakhiqizi bezimoto wehlise izilinganiso zokulahlwa kusuka ku-20-40% ngokusebenzisa ukuphathwa kwekhwalithi okubikezelwayo. Lokhu kuthuthukiswa kugcizelela ukubaluleka kobuchwepheshe bokwenza ngcono imiphumela yokukhiqiza.

Ukuhlola Ubuchwepheshe Namakhono

Ukwamukelwa kobuchwepheshe obusezingeni eliphezulu kubalulekile ekukhiqizeni okuphumelelayo nokunembayo. Abahlinzeki abasebenzisa ubuchwepheshe be-IoT bathuthukisa ukuqapha nokulawula inqubo. Umbiko wakamuva ukhombisa ukuthi abakhiqizi abangama-62% bahlanganise i-IoT emisebenzini yabo, kanti abathathu kwabahlanu babona amandla ayo.

Amakhono afana nokulingisa ukugeleza kwesikhunta,CNC imishini, kanye nokuphathwa kwekhwalithi ephelele kuphinde kuhlukanise abahlinzeki abaphezulu. Lobu buchwepheshe buqinisekisa ikhwalithi engaguquki kanye nemijikelezo yokukhiqiza esheshayo. Abahlinzeki abahlinzeka ngemiklamo yesikhunta se-modular kanye ne-prototyping esheshayo nabo babonisa ukuguquguquka kwezidingo zebhizinisi ezishintshayo.

| Izibalo | Incazelo |

|---|---|

| 62% | Amaphesenti abakhiqizi abasebenzisa ubuchwepheshe be-IoT. |

| 3-ku-5 | Isilinganiso esibonisa ukuqashelwa okukhulayo kwe-IoT ekukhiqizeni. |

Ukubaluleka Kwesevisi Yekhasimende

Isevisi yamakhasimende idlala indima ebalulekile ekugcineni ubambiswano lwesikhathi eside. Abahlinzeki abanamaqembu asekelayo anamakhono baqinisekisa ukuxhumana okushelelayo nokuxazulula izinkinga ngokushesha. Inhlolovo iveze ukuthi amabhizinisi angama-88% axhumanisa isevisi yamakhasimende enhle kakhulu ekusebenzeni okuphezulu, kanti amakhasimende angama-85% ashintsha amabhrendi ngemuva kwesipiliyoni esisodwa esibi.

| Izibalo | Ukuqonda |

|---|---|

| 88% wamabhizinisi | Vumelana ukuthi isevisi yamakhasimende enhle kakhulu ihambisana nokusebenza okuphezulu. |

| Amakhasimende angu-85%. | Izoshintsha amabhrendi ngemva kokuhlangana okungalungile okukodwa. |

| Amakhasimende angu-35%. | Uzimisele ukusebenzisa imali eningi ukuze uthole isevisi yamakhasimende ehlukile. |

Abahlinzeki abanikeza ukuxhumana okusobala nosekelo lwangemva kokulethwa bakhuthaza ukwethenjwa nokwethembeka. Lezi zimfanelo zithinta ngokuqondile ukugcinwa nokwaneliseka kwamakhasimende.

Ihlola Izibuyekezo kanye Nobufakazi

Ukubuyekeza nobufakazi kunikeza amazwibela esithunzini somhlinzeki. Impendulo eyakhayo evela kumakhasimende adlule ibonisa ikhwalithi engaguquki nokwethembeka. Amapulatifomu afana nokubuyekezwa kwe-Google kanye nezinkundla zemboni ngokuvamile zifaka ukuhlolwa okuningiliziwe kwabahlinzeki. Bheka amazwana mayelana nezikhathi zokulethwa, ikhwalithi yomkhiqizo, nokuphendula.

Ukwengeza, amathuluzi ahlelekile afana namatrices okuhlola abahlinzeki asiza ukuqhathanisa abahlinzeki ngendlela efanele. Izicelo Zolwazi (i-RFI) kanye Neziqu (RFQ) ziphinde zicolise inqubo yokukhetha ngokugxila kulwazi kanye nekhwalithi.

| Indlela Yokuhlola | Incazelo |

|---|---|

| I-Supplier Evaluation Matrix | Ithuluzi elihlelekile lokuqhathanisa abahlinzeki ngokusekelwe kumibandela eminingi. |

| Izicelo Zolwazi (RFI) | Iqoqa ulwazi olujwayelekile kubahlinzeki ukuze kube lula ukuqhathanisa. |

| Izicelo Zeziqu (RFQ) | Igxile ekwazisweni nabahlinzeki kanye nekhwalithi yokuqinisekisa ukuthi abathengisi abafaneleke kakhulu bayacatshangelwa. |

Lezi zindlela zilula ukwenza izinqumo, ziqinisekisa ukuthi amabhizinisi akhetha abahlinzeki abahambisana nezinhloso zabo.

Izingxenye zokuphonsa zensimbi ezenziwe ngokwezifiso zidlala indima ebalulekile ekushayeleni impumelelo yebhizinisi. Ukunemba kwazo, ukusebenza kahle kwezindleko, kanye nokuguquguquka kwezinto ezibonakalayo kuzenza zibaluleke kakhulu kuzo zonke izimboni.

| Inqubo | Izinzuzo | Izinhlelo zokusebenza |

|---|---|---|

| I-Die Casting | Ukusebenza kwezindleko, ukunemba, ukuguquguquka kwezinto | Izidingo zokunemba okuphezulu nokusebenza kahle |

| Metal Umjovo Molding | Amajiyometri ayinkimbinkimbi, amandla aphezulu, nokuqina | Izinhlelo zokusebenza eziqondile ezinezidingo eziqinile |

Izixazululo eziklanyelwe ukuhlangabezana nezidingo zokusebenza eziyingqayizivele, zithuthukisa ukwaneliseka kwamakhasimende kanye nezinzuzo zokutshala izimali. Amabhizinisi azuza umkhawulo wokuncintisana ngokusebenzisa lezi zindlela ezintsha. Hlola ukwenza ngokwezifiso ukuze uvule amathuba amasha futhi uzuze ukusebenza kahle kakhulu.

FAQ

Yiziphi izinzuzo zokusebenzisa izingxenye ze-metal die casting?

Izingxenye zokuphonsa zensimbi zinikeza ukunemba, ukuqina, nokusebenza kahle kwezindleko. Zifanele izimboni ezidinga izinto ezingasindi, ezinamandla aphezulu ezisetshenziswa eziyinkimbinkimbi.

Ukwenza ngokwezifiso kuzithuthukisa kanjani izingxenye zensimbi zokuphonsa?

Ukwenza ngokwezifiso kuthuthukisa ukusebenza ngokuhlanganisa imiklamo ngokwezidingo ezithile. Yehlisa udoti wezinto ezibonakalayo, ithuthukisa ikhwalithi, futhi iqinisekise ukuhambisana nezidingo zokusebenza ezihlukile.

Yiziphi izimboni ezizuza kakhulu ezingxenyeni zokuphonswa kwensimbi?

Izimboni ezifana nezezimoto, i-aerospace, kanye ne-electronics zithembele kakhulu ezingxenyeni zensimbi zensimbi ukuze uthole izinto ezingasindi, eziqinile, nezisebenza kahle kakhulu.

By: haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Ucingo:

Ukuthengisa: 0086-134 8641 8015

Ukusekela: 0086-574 8669 1714

Isikhathi sokuthumela: Apr-23-2025