Customized metal die casting parts are essential for driving business success. Industries such as automotive depend on lightweight, durable metal die cast components to enhance performance and efficiency. The global metal die casting parts foundry market, projected to reach USD 112.27 billion by 2033, underscores the increasing demand for tailored solutions. The precision and cost-effectiveness of each metal die casting part make them indispensable. Additionally, centrifugal metal die casting techniques further optimize production, ensuring high-quality results.

Key Takeaways

- Custom metal die casting parts help businesses succeed. They offer accuracy and save money. Special designs fit exact needs, boosting work and cutting mistakes.

- Industries like cars and airplanes gain a lot from metal die casting. These parts make things work better, safer, and use less fuel. They are key for top-quality uses.

- Picking the right company is very important. Check their skills, tools, and support to build strong partnerships that help your business grow.

Understanding Metal Die Casting Parts

What Are Metal Die Casting Parts?

Metal die casting parts are components created through a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method ensures precision and consistency in producing complex shapes. The process often uses alloys like aluminum, zinc, and magnesium, each offering unique characteristics.

| Alloy Type | Standards/Characteristics |

|---|---|

| Zinc | Good surface finish, dimensional consistency |

| Aluminum | AA 380, AA 384, AA 386, AA 390 |

| Magnesium | AZ91D |

| Copper | Commonly used in die casting |

Strategic design features, such as uniform wall thickness, enhance the performance and durability of these parts. Uniform cooling reduces defects like warping, ensuring dimensional stability. Rigorous inspection methods further guarantee high-quality production.

Applications in Key Industries

Metal die casting parts play a vital role in industries like automotive, aerospace, and electronics. The automotive sector, for instance, accounted for 41.7% of the global revenue share in 2023. High-pressure die casting equipment produces lightweight components like engine blocks and transmission cases, improving fuel efficiency and safety.

In aerospace, this technology creates high-strength parts such as turbine blades and gearbox components. These parts withstand extreme conditions, ensuring reliability. Additionally, electronics manufacturers use die casting to produce intricate housings and connectors, meeting the demand for compact and durable designs.

| Application Area | Description | Numerical Data |

|---|---|---|

| Automotive | Lightweight engine blocks, transmission cases | 41.7% revenue share in 2023 |

| Aerospace | Turbine blades, gearbox components | High-strength, extreme condition performance |

| Electronics | Housings, connectors | Compact, durable designs |

Importance in Business Operations

Metal die casting parts contribute significantly to business success. The global metal casting market, valued at USD 177.28 billion in 2024, is projected to reach USD 325.69 billion by 2033, growing at a CAGR of 6.94%. This growth reflects the increasing demand for lightweight and durable components.

Key performance metrics highlight their importance. Maintaining a defect rate below 2% ensures quality control, while efficient equipment utilization above 85% minimizes downtime. Inventory turnover rates of 6-8 times per year reduce holding costs, and tracking delivery KPIs can boost repeat orders by 20%. These metrics demonstrate how metal die casting parts optimize operations and enhance customer satisfaction.

| Metric | Description |

|---|---|

| Casting Defect Rates | Below 2% ensures quality control and customer satisfaction. |

| Equipment Utilization | Above 85% minimizes downtime and optimizes resource use. |

| Inventory Turnover | 6-8 times per year reduces holding costs and prevents delays. |

| Customer Satisfaction | Delivery KPIs can increase repeat orders by 20%. |

| Financial KPIs | Profit margins exceeding 25% through cost and revenue monitoring. |

Benefits of Customizing Metal Die Casting Parts

Precision and Quality

Customizing metal die casting parts ensures unmatched precision and superior quality. Tailored designs allow manufacturers to meet exact specifications, reducing errors and improving functionality. Studies highlight the advantages of customization:

- A 2022 study in the Journal of Manufacturing Processes reported a 35% improvement in component fit and function for companies adopting custom die casting.

- The International Journal of Advanced Manufacturing Technology (2023) revealed a 25% reduction in raw material costs due to optimized designs.

These findings demonstrate how customization enhances both performance and cost efficiency. Additionally, advanced inspection techniques ensure that each part meets stringent quality standards, minimizing defects and maximizing reliability.

Efficiency and Performance

Customizing metal die casting parts significantly boosts operational efficiency and performance. Effective mold designs and streamlined processes reduce waste and improve production speed. Key factors contributing to efficiency include:

- Mold Design: Optimized molds enhance precision and reduce material usage.

- Eliminating Overflows and Runners: Streamlined designs minimize waste.

- Workforce Training: Skilled workers lower processing costs and improve output quality.

Modern technologies like 3D-printed molds further enhance efficiency. These molds enable faster prototype creation, cutting design cycle times by 50%. Modular mold designs also provide flexibility, allowing manufacturers to adapt to varying production needs. Reduced lead times align with just-in-time manufacturing demands, ensuring timely delivery and customer satisfaction.

Cost-Effectiveness

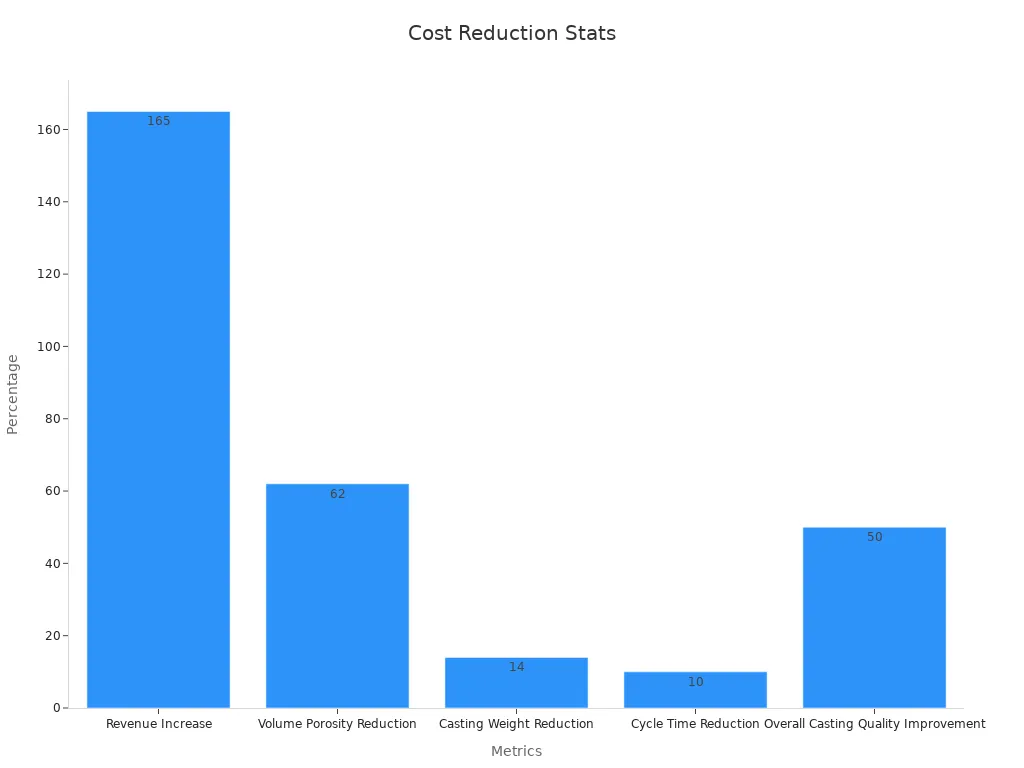

Customizing metal die casting parts offers substantial cost savings. By optimizing designs and processes, manufacturers can reduce material usage, energy consumption, and production time. The following table highlights key cost benefits:

| Metric | Result |

|---|---|

| Revenue Increase | 165% increase |

| Casting Machine Usage Reduction | Reduced closing force to 1200 tons |

| Volume Porosity Reduction | 62% reduction |

| Casting Weight Reduction | 14% reduction |

| Cycle Time Reduction | 10% reduction |

| Overall Casting Quality Improvement | 50% improvement |

These improvements translate into higher profit margins and competitive pricing, making customized solutions a smart investment for businesses.

Tailored Solutions for Unique Needs

Every business has unique requirements, and customized metal die casting parts provide solutions tailored to specific needs. From material selection to design optimization, customization ensures that parts align perfectly with operational goals. Documented success stories illustrate the impact of tailored solutions:

| Client Name | Description of Tailored Solution |

|---|---|

| Unique Boutique | Utilized Aircall’s tailored solutions to stand out in a crowded market. |

| The Solutionists | Adopted custom solutions from Aircall to fit their communication needs perfectly. |

A step-by-step customization process ensures that each project meets exact requirements:

- Initial Consultation & Design Review: Discuss project goals and optimize designs.

- Material Selection: Choose materials based on performance needs.

- Design & Engineering: Use CAD tools to create custom designs.

- Prototyping & Sample Testing: Verify accuracy and test prototypes.

- Production Setup & Initial Production: Confirm setup and quality during initial runs.

- Final Production & Quality Control: Conduct full-scale production with continuous quality checks.

This approach guarantees that businesses receive parts that enhance performance, reduce costs, and meet industry standards.

The Process of Customizing Metal Die Casting Parts

Design and Consultation

The customization process begins with a thorough design and consultation phase. Engineers and designers collaborate to create a blueprint that aligns with the client’s specific requirements. This stage involves analyzing the intended application, selecting suitable materials, and determining the most efficient manufacturing methods.

Key steps in this phase include:

- Requirement Analysis: Understanding the operational needs and performance goals.

- Material Selection: Choosing alloys like aluminum or zinc based on durability and weight requirements.

- Design Optimization: Using CAD software to refine designs for precision and manufacturability.

Effective communication between the client and the design team ensures that every detail is addressed. This collaborative approach minimizes errors and sets the foundation for a successful production process.

Prototyping and Testing

Prototyping and testing are critical for validating the design and ensuring functionality. During this phase, manufacturers create prototypes to evaluate the performance and identify potential issues. Feedback from stakeholders helps refine the design before full-scale production begins.

Key activities in this phase include:

- Creating a design mock-up or feature prototype.

- Gathering feedback from the target audience.

- Identifying potential issues or validating product decisions.

Every failure during prototyping provides valuable insights into the design and manufacturing processes. For example, a detailed failure analysis helps identify root causes and expected failure rates. The following table illustrates the importance of testing:

| Number of Prototypes | Number of Failures | Failure Rate (%) |

|---|---|---|

| 100 | 1 | 1 |

| 10 | 1 | 10 |

| 2 | 1 | 50 |

This data highlights the necessity of rigorous testing to ensure the final product meets quality standards.

Production and Quality Control

Once the design is finalized, the production phase begins. Manufacturers use advanced equipment and techniques to produce high-quality metal die casting parts. Quality control measures are implemented at every stage to maintain consistency and reliability.

Key production metrics include:

- Defect Rates: Monitoring the number of defective units per total produced.

- Percentage of Non-Conforming Products: Ensuring products meet specifications.

- Time to Resolve Quality Issues: Addressing problems promptly to avoid delays.

The table below outlines essential production metrics:

| Metric | Description |

|---|---|

| Defect Rates | Number of defective units per total produced. |

| Percentage of Non-Conforming Products | Ratio of products not meeting specifications. |

| Time to Resolve Quality Issues | Duration taken to address quality problems. |

Certifications like ISO 9001 and Six Sigma further validate the robustness of the production process. These standards ensure that manufacturers consistently deliver parts that meet or exceed industry expectations.

Delivery and Support

The final stage involves delivering the finished parts to the client and providing ongoing support. Efficient delivery systems ensure that orders arrive on time and in perfect condition. Customer support teams address any concerns and provide assistance as needed.

Key delivery performance metrics include:

- On-Time Delivery: Percentage of orders fulfilled within the expected delivery date.

- Order Accuracy: Percentage of orders delivered without errors.

- Customer Satisfaction Score: Measures customer satisfaction regarding delivery experiences.

The table below highlights these metrics:

| Metric | Description |

|---|---|

| On-Time Delivery | Percentage of orders fulfilled within the expected delivery date. |

| Order Accuracy | Percentage of orders delivered without errors compared to total orders. |

| Customer Satisfaction Score | Measures customer satisfaction regarding delivery experiences, critical for evaluating service. |

Clear communication with customers ensures they remain informed about their deliveries. Feedback mechanisms help address negative experiences and improve service quality. This comprehensive approach guarantees a seamless experience from production to delivery.

How to Choose the Right Provider for Metal Die Casting Parts

Evaluating Experience and Expertise

Selecting a provider with proven experience ensures reliability and quality. Providers with a long history in the industry often demonstrate a deep understanding of manufacturing processes. For example, Form Technologies, with over 80 years of experience and 270+ successful projects, exemplifies expertise. Their annual production of 5 billion units and a customer base exceeding 2,000 highlight their capability to handle diverse requirements.

- Key factors to evaluate include:

- Service offerings tailored to specific industries.

- Design engineering capabilities for complex projects.

- Post-production services like finishing and assembly.

Case studies also provide valuable insights. A supplier to car manufacturers reduced scrap rates from 20-40% by implementing predictive quality management. This improvement underscores the importance of technical expertise in optimizing production outcomes.

Assessing Technology and Capabilities

Advanced technology adoption is critical for efficient and precise manufacturing. Providers leveraging IoT technologies enhance process monitoring and control. A recent report shows that 62% of manufacturers have integrated IoT into their operations, with three in five recognizing its potential.

Capabilities like mold flow simulation, CNC machining, and total quality management further distinguish top providers. These technologies ensure consistent quality and faster production cycles. Providers offering modular mold designs and rapid prototyping also demonstrate adaptability to changing business needs.

| Statistic | Description |

|---|---|

| 62% | Percentage of manufacturers adopting IoT technologies. |

| 3-in-5 | Ratio indicating IoT’s growing recognition in manufacturing. |

Importance of Customer Service

Customer service plays a pivotal role in maintaining long-term partnerships. Providers with skilled support teams ensure smooth communication and quick issue resolution. A survey revealed that 88% of businesses link excellent customer service to peak performance, while 85% of customers switch brands after a single negative experience.

| Statistic | Insight |

|---|---|

| 88% of businesses | Agree that excellent customer service correlates with peak performance. |

| 85% of customers | Will switch brands after a single negative encounter. |

| 35% of customers | Are willing to spend more for exceptional customer service. |

Providers offering transparent communication and post-delivery support foster trust and loyalty. These qualities directly impact customer retention and satisfaction.

Checking Reviews and Testimonials

Reviews and testimonials provide a glimpse into a provider’s reputation. Positive feedback from past clients reflects consistent quality and reliability. Platforms like Google Reviews and industry forums often feature detailed evaluations of providers. Look for comments on delivery timelines, product quality, and responsiveness.

Additionally, structured tools like supplier evaluation matrices help compare providers objectively. Requests for Information (RFI) and Qualifications (RFQ) further refine the selection process by focusing on expertise and quality.

| Evaluation Method | Description |

|---|---|

| Supplier Evaluation Matrix | A structured tool for comparing suppliers based on multiple criteria. |

| Requests for Information (RFI) | Collects general information from suppliers for easier comparisons. |

| Requests for Qualifications (RFQ) | Focuses on suppliers’ expertise and quality to ensure the best-qualified vendors are considered. |

These methods streamline decision-making, ensuring businesses choose providers aligned with their goals.

Customized metal die casting parts play a crucial role in driving business success. Their precision, cost-effectiveness, and material versatility make them indispensable across industries.

| Process | Advantages | Applications |

|---|---|---|

| Die Casting | Cost-effectiveness, precision, material versatility | High precision and efficiency needs |

| Metal Injection Molding | Complex geometries, high strength, and durability | Specific applications with strict demands |

Tailored solutions meet unique operational needs, improving client satisfaction and investment returns. Businesses gain a competitive edge by adopting these innovative approaches. Explore customization to unlock new opportunities and achieve operational excellence.

FAQ

What are the advantages of using metal die casting parts?

Metal die casting parts offer precision, durability, and cost-efficiency. They suit industries requiring lightweight, high-strength components for complex applications.

How does customization improve metal die casting parts?

Customization enhances performance by tailoring designs to specific needs. It reduces material waste, improves quality, and ensures compatibility with unique operational requirements.

Which industries benefit most from metal die casting parts?

Industries like automotive, aerospace, and electronics rely heavily on metal die casting parts for lightweight, durable, and high-performance components.

By:haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Phone:

Sales: 0086-134 8641 8015

Support: 0086-574 8669 1714

Post time: Apr-23-2025