Customizediindawo zokugalela isinyithizibalulekile ekuqhubeni ushishino impumelelo. Amashishini afana neemoto axhomekeke kubunzima, omelelemetal die castamacandelo okuphucula ukusebenza kunye nokusebenza kakuhle. Ihlabathi jikelelemetal die ekujuleni iindawo foundryimakethi, kuqikelelwa ukuba ifikelele kwi-USD 112.27 yebhiliyoni ngo-2033, igxininisa imfuno ekhulayo yezisombululo ezilungiselelwe. Ukuchaneka kunye nokusebenza kakuhle kweendleko nganyeintsimbi die ukuphosa inxalenyezizenze zibe yimfuneko. Ukongeza,centrifugal metal die castingubuchule bokwenza ngcono ngakumbi imveliso, ukuqinisekisa iziphumo ezikumgangatho ophezulu.

Izinto eziphambili zokuThatha

- iindawo zokujula zentsimbi yesikonceda amashishini aphumelele. Banikezela ngokuchaneka kunye nokugcina imali. Uyilo olukhethekileyo luhambelana neemfuno ezichanekileyo, ukunyusa umsebenzi kunye nokusika iimpazamo.

- Imizi-mveliso efana neemoto kunye neenqwelomoya zizuza kakhulu kwi-metal die casting. Ezi ndawo zenza izinto zisebenze ngcono, zikhuseleke, kwaye zisebenzise amafutha amancinci. Zingundoqo kusetyenziso olukumgangatho ophezulu.

- Ukukhetha inkampani efanelekileyoibaluleke kakhulu. Jonga izakhono zabo, izixhobo, kunye nenkxaso yokwakha intsebenziswano eyomeleleyo enceda ishishini lakho likhule.

Ukuqonda iMetal Die Casting Parts

Yintoni iMetal Die Casting Parts?

Intsimbi yokuphosa iinxalenye zokuphosangamalungu adalwe ngenkqubo yokuvelisa ebandakanya ukunyanzeliswa kwesinyithi esinyibilikisiweyo kumgodi wokungunda phantsi koxinzelelo oluphezulu. Le ndlela iqinisekisa ukuchaneka kunye nokuhambelana ekuveliseni imilo enzima. Inkqubo ihlala isebenzisa i-alloys njenge-aluminiyam, i-zinc, kunye ne-magnesium, nganye inika iimpawu ezizodwa.

| Uhlobo lwe-alloy | Imigangatho/Iimpawu |

|---|---|

| Zinc | Ukugqitywa kakuhle komphezulu, ukuhambelana kwe-dimensional |

| Aluminiyam | AA 380, AA 384, AA 386, AA 390 |

| Magnesium | I-AZ91D |

| Ubhedu | Ngokuqhelekileyo isetyenziswa kwi-die casting |

Iimpawu zoyilo lweqhinga, ezifana nobukhulu bodonga obufanayo, bongeza ukusebenza kunye nokuqina kwezi nxalenye. Ukupholisa okufanayo kunciphisa iziphene ezifana ne-warping, ukuqinisekisa uzinzo lwe-dimensional. Iindlela zokuhlola ngokungqongqo ziqinisekisa ngakumbi imveliso ekumgangatho ophezulu.

Usetyenziso kuMashishini aPhambili

Amalungu okujula ngesinyithi adlala indima ebalulekileyo kumashishini afana neemoto, i-aerospace, kunye ne-elektroniki. Icandelo leemoto, umzekelo, libalelwa kwi-41.7% yesabelo sengeniso yehlabathi ngo-2023. Isixhobo sokuphosa i-high-pressure die cast sivelisa amacandelo alula afana neebhloko ze-injini kunye neemeko zokuhambisa, ukuphucula ukusebenza kakuhle kwamafutha kunye nokhuseleko.

Kwi-aerospace, obu buchwephesha budala iindawo ezomeleleyo ezifana neeblade ze-iturbine kunye nezixhobo zebhokisi yegiya. Ezi nxalenye zimelana neemeko ezinzima, ziqinisekisa ukuthembeka. Ukongeza, abavelisi bezinto zombane basebenzisa i-die casting ukuvelisa izindlu ezintsonkothileyo kunye neziqhagamshelo, ukuhlangabezana nemfuno yoyilo olubambeneyo noluhlala ixesha elide.

| Indawo yesicelo | Inkcazo | Idatha yamanani |

|---|---|---|

| Iimoto | Iibhloko zenjini ezikhaphukhaphu, iimeko zokuhambisa | 41.7% isabelo sengeniso ngo-2023 |

| I-Aerospace | I-turbine blades, amacandelo ebhokisi yegiya | Amandla aphezulu, imeko egqithisileyo yokusebenza |

| Electronics | Izindlu, izihlanganisi | Uyilo olubambeneyo, oluhlala ixesha elide |

Ukubaluleka kwiMisebenzi yoShishino

Metal die ukujula iindawo igalelo kakhuluimpumelelo yoshishino. Imakethi yehlabathi yokuphosa isinyithi, exabisa i- $ 177.28 yezigidigidi ngo-2024, kulindeleke ukuba ifikelele kwi-325.69 yeebhiliyoni zeedola ngo-2033, ikhula kwi-CAGR ye-6.94%. Oku kukhula kubonisa imfuno ekhulayo yezinto ezikhaphukhaphu kunye nezihlala ixesha elide.

Iimetriki zokwenziwa komsebenzi eziphambili zibalaselisa ukubaluleka kwazo. Ukugcina izinga lesiphene elingaphantsi kwe-2% liqinisekisa ulawulo lomgangatho, ngelixa ukusetyenziswa kwezixhobo ngokufanelekileyo ngaphezu kwe-85% kunciphisa ixesha lokuphumla. Amazinga okuthengiswa kwempahla ye-6-8 ngamaxesha ngonyaka anciphisa iindleko zokubamba, kwaye ukulandelela ukuhanjiswa kwe-KPIs kunokunyusa ii-odolo eziphindaphindiweyo nge-20%. Ezi metrics zibonisa indlela intsimbi yokuphosa iinxalenye eziphucula ukusebenza kunye nokuphucula ukwaneliseka kwabathengi.

| Metric | Inkcazo |

|---|---|

| Ukuphosa Amaxabiso eSiphene | Ngaphantsi kwe-2% iqinisekisa ukulawula umgangatho kunye nokwaneliseka kwabathengi. |

| Ukusetyenziswa kweZixhobo | Ngaphezulu kwe-85% inciphisa ixesha lokuphumla kwaye yandisa ukusetyenziswa kobutyebi. |

| Inventory Turnover | Amaxesha angama-6-8 ngonyaka anciphisa iindleko zokubamba kunye nokuthintela ukulibaziseka. |

| Ukwaneliseka koMthengi | Ukuhanjiswa kwe-KPIs kunokunyusa iiodolo eziphindayo nge-20%. |

| Ii-KPIs zemali | Imida yenzuzo engaphezulu kwe-25% ngokujongwa kweendleko kunye nengeniso. |

Izibonelelo zokuLungiselela iiNdawo zokuCasa iMetal Die

Ukuchaneka kunye noMgangatho

Ukwenza ngokwezifiso iindawo zokulahla isinyithiiqinisekisa ukuchaneka okungahambelaniyo kunye nomgangatho ophezulu. Uyilo olulungelelanisiweyo luvumela abavelisi ukuba bahlangabezane neenkcukacha ezichanekileyo, ukunciphisa iimpazamo kunye nokuphucula ukusebenza. Izifundo ziqaqambisa iingenelo zokwenza ngokwezifiso:

- Uphononongo luka-2022 kwiIjenali yeeNkqubo zoMvelisoingxelo ye-35% yophuculo lokulungelelaniswa kwecandelo kunye nomsebenzi kwiinkampani ezamkela i-diecasting yesiko.

- IIjenali yaMazwe ngaMazwe yeTekhnoloji yoMveliso ePhakamileyo(2023) ibonakalise ukucutha kwe-25% kwiindleko zempahla ekrwada ngenxa yoyilo olulungisiweyo.

Ezi ziphumo zibonisa ukuba ukwenza ngokwezifiso kuphucula ukusebenza kunye nokusebenza kakuhle kweendleko. Ukongeza, iindlela zokuhlola eziphambili ziqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho engqongqo yobulunga, ukunciphisa iziphene kunye nokwandisa ukuthembeka.

Ubuchule kunye nokusebenza kakuhle

Ukwenza ngokwezifiso iindawo zokulahla isinyithi kukhulisa kakhulu ukusebenza kakuhle kunye nokusebenza. Uyilo lokungunda olusebenzayo kunye neenkqubo ezilungelelanisiweyo zinciphisa inkunkuma kunye nokuphucula isantya semveliso. Imiba ephambili enegalelo kwimpumelelo ibandakanya:

- Uyilo lokungunda: Ukungunda okulungiselelwe kuphucula ukuchanekakunye nokunciphisa ukusetyenziswa kwezinto.

- Ukuphelisa ukuZiphuphuma kunye neeMbaleki: Uyilo olulungelelanisiweyo lunciphisa inkunkuma.

- Uqeqesho lwabasebenzi: Abasebenzi abanezakhono bathoba iindleko zokusetyenzwa kunye nokuphucula umgangatho wemveliso.

Itekhnoloji yale mihla efana ne-3D-printed molds iphucula ngakumbi ukusebenza kakuhle. Ezi zibumba zivumela ukudala iprototype ngokukhawuleza, ukusika amaxesha omjikelezo woyilo ngama-50%. Uyilo lokungunda lwemodyuli lukwabonelela ngokuguquguquka, ukuvumela abavelisi ukuba baziqhelanise neemfuno zemveliso ezahlukeneyo. Ukuncitshiswa kwamaxesha okukhokela ahambelana neemfuno zokwenziwa kwangexesha, ukuqinisekisa ukuhanjiswa kwangexesha kunye nokwaneliseka kwabathengi.

Iindleko-Ukusebenza

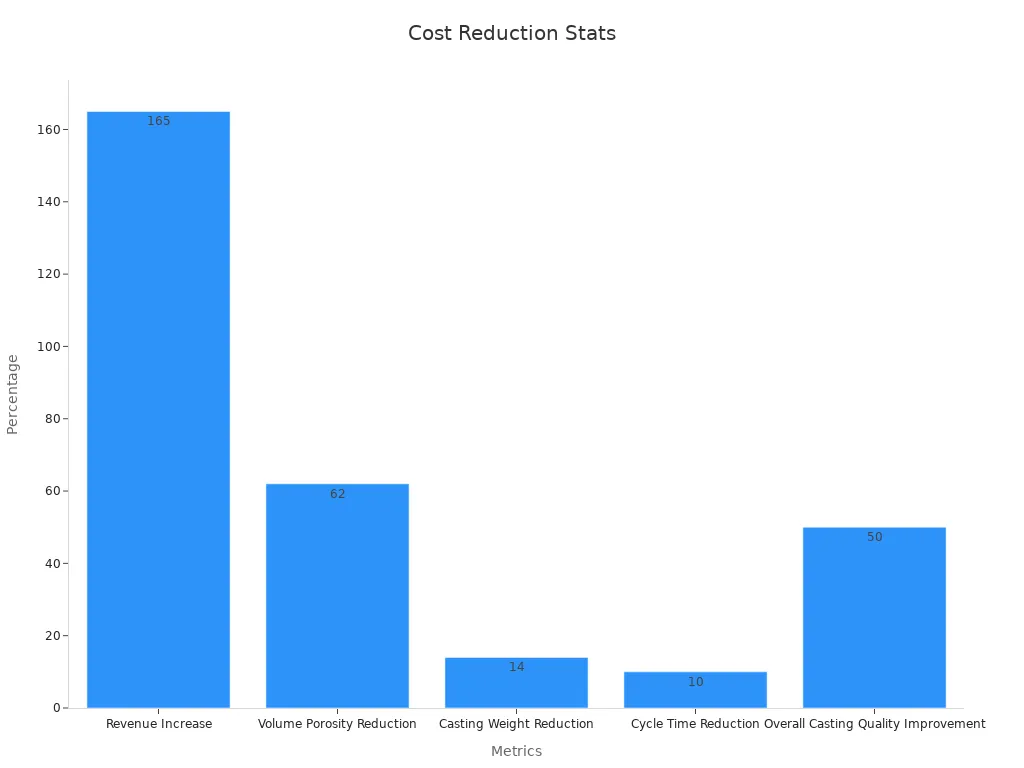

Ukwenza iinxalenye zokujula zentsimbi zibonelela ngogcino lweendleko ezinkulu. Ngokulungisa uyilo kunye neenkqubo, abavelisi banokunciphisa ukusetyenziswa kwezinto, ukusetyenziswa kwamandla kunye nexesha lokuvelisa. Le theyibhile ilandelayo igxininisa kwiinzuzo eziphambili zeendleko:

| Metric | Isiphumo |

|---|---|

| Ukunyuka kweNgeniso | 165% ukwanda |

| UkuNcitshiswa kokusetyenziswa komatshini wokuphosa | Ukunciphisa amandla okuvala ukuya kwiitoni ze-1200 |

| UkuNcitshiswa koMqulu wePorosity | I-62% yokunciphisa |

| Ukunciphisa Ubunzima bokuphosa | I-14% yokunciphisa |

| UkuNcitshiswa kwexesha lomjikelo | I-10% yokunciphisa |

| UkuPhuculwa koMgangatho wokuCasa ngokubanzi | Uphuculo lwe-50%. |

Olu phuculo luguqulela kwimida yengeniso ephezulu kunye namaxabiso akhuphisanayo, okwenza izisombululo ezilungelelanisiweyo zibe lutyalo-mali oluhlakaniphile kumashishini.

Izisombululo ezilungiselelwe iiMfuno eziZodwa

Ishishini ngalinye lineemfuno ezizodwa, kwaye iinxalenye zokuphosa zentsimbi ezilungiselelweyo zibonelela ngezisombululo ezilungiselelwe iimfuno ezithile. Ukusuka ekukhethweni kwezinto ezibonakalayo ukuya kuyilo loyilo, ukwenziwa ngokwezifiso kuqinisekisa ukuba iinxalenye zihambelana ngokugqibeleleyo neenjongo zokusebenza. Amabali empumelelo ashicilelweyo abonisa impembelelo yezisombululo ezilungiselelweyo:

| Igama loMthengi | Inkcazo yeSicombululo esilungiselelweyo |

|---|---|

| Unique Boutique | Kusetyenziswe izisombululo ezilungiselelwe i-Aircall ukuze ibonakale kwimarike exineneyo. |

| AbaSombululi | Izisombululo ezimkelweyo ezivela kwi-Aircall ukuze zilungele iimfuno zabo zonxibelelwano ngokugqibeleleyo. |

Inkqubo yokwenza inyathelo ngenyathelo iqinisekisa ukuba iprojekthi nganye ihlangabezana neemfuno ezichanekileyo:

- Uthethwano lokuqala kunye noPhononongo loYilo: Xoxa ngeenjongo zeprojekthi kunye nokwandisa uyilo.

- Ukukhethwa kwezinto: Khetha izinto ezisekelwe kwiimfuno zokusebenza.

- Uyilo kunye nobunjineli: Sebenzisa izixhobo zeCAD ukwenza uyilo lwesiko.

- Iprototyping kunye noVavanyo lweSampulu: Qinisekisa ukuchaneka kunye nokuvavanya iiprototypes.

- Ukuseta iMveliso kunye neMveliso yokuQala: Qinisekisa ukuseta kunye nomgangatho ngexesha lokuqhuba kokuqala.

- Imveliso yokugqibela kunye noLawulo loMgangatho: Ukuqhuba imveliso epheleleyo kunye nokutshekisha umgangatho oqhubekayo.

Le ndlela iqinisekisa ukuba amashishini afumana iinxalenye eziphucula ukusebenza, ukunciphisa iindleko, kunye nokuhlangabezana nemigangatho yoshishino.

Inkqubo yokwenza iMetal Die Casting Parts

Uyilo kunye nothethwano

Inkqubo yokwenza ngokwezifiso iqala ngoyilo olucokisekileyo kunye nesigaba sokubonisana. Iinjineli kunye nabayili bayasebenzisana ukwenza iplani ehambelana neemfuno ezikhethekileyo zomthengi. Eli nqanaba libandakanya ukuhlalutya usetyenziso olucetywayo, ukukhetha izinto ezifanelekileyo, kunye nokumisela iindlela ezisebenzayo zokuvelisa.

Amanyathelo aphambili kwesi sigaba abandakanya:

- Uhlalutyo lweeMfuneko: Ukuqonda iimfuno zokusebenza kunye neenjongo zokusebenza.

- Ukukhethwa kwezinto: Ukukhetha i-alloys njenge-aluminium okanye i-zinc ngokusekelwe ekuqina kunye neemfuno zobunzima.

- UPhuculo loYilo: Ukusebenzisa isoftwe yeCAD ukucokisa uyilo lokuchaneka kunye nokwenziwa.

Unxibelelwano olusebenzayo phakathi komxhasi kunye neqela loyilo liqinisekisa ukuba zonke iinkcukacha zibhekiswe. Le ndlela yokubambisana inciphisa iimpazamo kwaye ibeka isiseko senkqubo yemveliso eyimpumelelo.

Prototyping kunye noVavanyo

Iprototyping kunye novavanyo zibalulekile ekuqinisekiseni uyilo kunye nokuqinisekisa ukusebenza. Ngeli nqanaba, abavelisi benza iiprototypes zokuvavanya ukusebenza kunye nokuchonga imiba enokubakho. Ingxelo evela kwabachaphazelekayo inceda ukucokisa uyilo ngaphambi kokuba imveliso epheleleyo iqale.

Imisebenzi ephambili kwesi sigaba ibandakanya:

- Ukudala i-design-up-up okanye iprototype yesici.

- Ukuqokelela ingxelo evela kubaphulaphuli ekujoliswe kubo.

- Ukuchonga imiba enokwenzeka okanye ukuqinisekisa izigqibo zemveliso.

Yonke into engaphumeleliyo ngexesha leprototyping inika ulwazi oluxabisekileyo kuyilo kunye neenkqubo zokuvelisa. Ngokomzekelo, uhlalutyo oluneenkcukacha lokungaphumeleli lunceda ukuchonga izizathu ezisisiseko kunye namazinga okusilela alindelekileyo. Le theyibhile ilandelayo ibonisa ukubaluleka kovavanyo:

| Inani leePrototypes | Inani leentsilelo | Inqanaba lokusilela (%) |

|---|---|---|

| 100 | 1 | 1 |

| 10 | 1 | 10 |

| 2 | 1 | 50 |

Le datha igxininisa imfuneko yovavanyo olungqongqo ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigangatho yomgangatho.

Imveliso kunye noLawulo loMgangatho

Emva kokuba uyilo lugqityiwe, isigaba sokuvelisa siqala. Abavelisi basebenzisa izixhobo eziphambili kunye nobuchule bokuvelisa iindawo ezikumgangatho ophezulu zokuphosa iintsimbi. Amanyathelo okulawula umgangatho aphunyezwa kwinqanaba ngalinye ukugcina ukuhambelana nokuthembeka.

Iimetriki eziphambili zemveliso ziquka:

- Amazinga eSiphene: Ukubeka iliso kwinani leeyunithi ezineziphene ngokwetotali eveliswayo.

- Ipesenti yeeMveliso ezingangqinelaniyo: Ukuqinisekisa ukuba iimveliso ziyahlangabezana nemigaqo.

- Ixesha Lokusombulula Imiba Yomgangatho: Ukujongana neengxaki ngokukhawuleza ukuphepha ukulibaziseka.

Le theyibhile ingezantsi ichaza iimetrics zemveliso ezibalulekileyo:

| Metric | Inkcazo |

|---|---|

| Imilinganiselo yesiphene | Inani leeyunithi ezineziphene ngokwetotali nganye evelisiweyo. |

| Ipesenti yeeMveliso ezingangqinelaniyo | Umyinge weemveliso ezingadibananga nemigaqo. |

| Ixesha lokusombulula imiba esemgangathweni | Ixesha elithathiweyo ukulungisa iingxaki zomgangatho. |

Iziqinisekiso ezifana ne-ISO 9001 kunye neSix Sigma ziqinisekisa ngakumbi ukomelela kwenkqubo yemveliso. Le migangatho iqinisekisa ukuba abavelisi bahlala behambisa iinxalenye ezihlangabezanayo okanye ezingaphezulu kolindelo lweshishini.

Ukuhanjiswa kunye neNkxaso

Inqanaba lokugqibela libandakanya ukuhambisa iinxalenye ezigqityiweyo kumxhasi kunye nokubonelela ngenkxaso eqhubekayo. Iisistim zokuhanjiswa ezisebenzayo ziqinisekisa ukuba iiodolo zifika ngexesha kwaye zikwimeko egqibeleleyo. Amaqela axhasayo abathengi ajongana nayo nayiphi na inkxalabo kwaye anike uncedo njengoko lufuneka.

Iimetrics eziphambili zonikezelo ziquka:

- Ukuhanjiswa kwangexesha: Ipesenti yee-odolo ezizalisekileyo phakathi komhla olindelekileyo wokuziswa kwazo.

- Ukuchaneka koMyalelo: Ipesenti yee-odolo ezizisiweyo ngaphandle kweempazamo.

- Ukwaneliseka koMthengi iNqaku: Ilinganisa ukwaneliseka kwabathengi malunga namava okuhanjiswa.

Itheyibhile engezantsi iqaqambisa ezi metrics:

| Metric | Inkcazo |

|---|---|

| Ukuhanjiswa kwangexesha | Ipesenti yee-odolo ezizalisekileyo ngexesha ebekulindeleke ukuba liziswe ngalo. |

| Ukuchaneka Komyalelo | Ipesenti yee-odolo ezizisiweyo ngaphandle kweempazamo xa kuthelekiswa nee-odolo zizonke. |

| Ukwaneliseka koMthengi inqaku | Ilinganisa ukwaneliseka kwabathengi malunga namava okuhanjiswa, okubaluleke kakhulu kuvavanyo lwenkonzo. |

Unxibelelwano olucacileyo nabathengi luqinisekisa ukuba bahlala benolwazi malunga nokuhanjiswa kwabo. Iindlela zokunika ingxelo zinceda ukulungisa amava angalunganga kunye nokuphucula umgangatho wenkonzo. Le ndlela ibanzi iqinisekisa amava angenamthungo ukusuka kwimveliso ukuya kunikezelo.

Indlela yokukhetha uMboneleli oLungileyo weMetal Die Casting Parts

Ukuvavanya amava kunye nobuGcisa

Ukukhetha umnikezeli onamava aqinisekisiweyo kuqinisekisa ukuthembeka kunye nomgangatho. Ababoneleli abanembali ende kwishishini bahlala bebonisa ukuqonda okunzulu kweenkqubo zokuvelisa. Umzekelo, iFom Technologies, engaphezulu kweminyaka engama-80 yamava kunye neeprojekthi eziyimpumelelo ezingama-270+, ngumzekelo wobuchule. Imveliso yabo yonyaka yeeyunithi ezibhiliyoni ezi-5 kunye nesiseko sabathengi esingaphaya kwama-2,000 sigxininisa amandla abo okujongana neemfuno ezahlukeneyo.

- Imiba ephambili ekufuneka ivavanywe ibandakanya:

- Unikezelo lwenkonzo olulungiselelwe amashishini athile.

- Ukuyila ubunjineli bokukwazi ukwenza iiprojekthi ezinzima.

- Iinkonzo ze-post-production ezifana nokugqiba kunye nokudibanisa.

Izifundo ezingumzekelo zikwabonelela ngeembono ezixabisekileyo. Umthengisi kubavelisi beemoto banciphisa amaxabiso okulahlwa ukusuka kwi-20-40% ngokuphumeza ulawulo lomgangatho oqikelelweyo. Olu phuculo lugxininisa ukubaluleka kobuchule bobugcisa ekwandiseni iziphumo zemveliso.

Ukuvavanya iTekhnoloji kunye neZakhono

Ukwamkelwa kwetekhnoloji ekwinqanaba eliphezulu kubalulekile kwimveliso esebenzayo kunye nechanekileyo. Ababoneleli abasebenzisa itekhnoloji ye-IoT baphucula inkqubo yokubeka iliso kunye nolawulo. Ingxelo yakutshanje ibonisa ukuba i-62% yabavelisi badibanise i-IoT kwimisebenzi yabo, kunye nabathathu kwabahlanu baqaphela amandla ayo.

Izakhono ezinjengokulinganisa kokungunda,CNC machining, kunye nolawulo olupheleleyo lomgangatho ngakumbi ukwahlula ababoneleli abaphezulu. Ezi teknoloji ziqinisekisa umgangatho ohambelanayo kunye nemijikelezo yokuvelisa ngokukhawuleza. Ababoneleli abanikezela ngoyilo lwemodyuli yokubumba kunye neprototyping ekhawulezayo nabo babonisa ukuziqhelanisa nokutshintsha kweemfuno zeshishini.

| Ubalo | Inkcazo |

|---|---|

| 62% | Ipesenti yabavelisi abamkela itekhnoloji ye-IoT. |

| 3-in-5 | Umlinganiselo obonisa ukukhula kokuqondwa kwe-IoT kwimveliso. |

Ukubaluleka kweNkonzo yoMthengi

Inkonzo yabathengi idlala indima ebalulekileyo ekugcineni ubuhlakani bexesha elide. Ababoneleli abanamaqela enkxaso anezakhono baqinisekisa unxibelelwano oluhle kunye nokusombulula imiba ekhawulezileyo. Uphando lubonise ukuba i-88% yamashishini idibanisa inkonzo ebalaseleyo yabathengi ukuya kwincopho yokusebenza, ngelixa i-85% yabathengi batshintsha iimpawu emva kokufumana amava angalunganga.

| Ubalo | Ingqiqo |

|---|---|

| I-88% yamashishini | Vumelana ukuba inkonzo ebalaseleyo yabathengi ihambelana nokusebenza okuphezulu. |

| I-85% yabathengi | Izakutshintsha iibrendi emva kokudibana okungalunganga okunye. |

| I-35% yabathengi | Ukulungele ukuchitha ngaphezulu kwinkonzo yabathengi ekhethekileyo. |

Ababoneleli abanikezela ngonxibelelwano olungafihliyo kunye nenkxaso emva kokunikezelwa bakhuthaza ukuthembana nokunyaniseka. Ezi mpawu zichaphazela ngokuthe ngqo ukugcinwa kwabathengi kunye nokwaneliseka.

Ukujonga uPhononongo kunye noBungqina

Uphononongo kunye nobungqina bubonelela ngesidima somboneleli. Ingxelo eyakhayo evela kubathengi bexesha elidlulileyo ibonisa umgangatho ongaguqukiyo kunye nokuthembeka. Amaqonga afana noPhononongo lukaGoogle kunye neeforam zeshishini zihlala zibonakalisa uvandlakanyo oluneenkcukacha lwababoneleli. Jonga amagqabantshintshi ngamaxesha okuhanjiswa, umgangatho wemveliso, kunye nokuphendula.

Ukongeza, izixhobo ezicwangcisiweyo ezifana neematriki zovavanyo lomthengisi zinceda ukuthelekisa ababoneleli ngokufanelekileyo. Izicelo zoLwazi (RFI) kunye neziQinisekiso (RFQ) ziphucula ngakumbi inkqubo yokhetho ngokujolisa kubuchule kunye nomgangatho.

| Indlela yoVavanyo | Inkcazo |

|---|---|

| Supplier Evaluation Matrix | Isixhobo esicwangcisiweyo sokuthelekisa ababoneleli ngokusekwe kwiikhrayitheriya ezininzi. |

| Izicelo zoLwazi (RFI) | Uqokelela ulwazi oluphangaleleyo kubaboneleli-nkonzo ukwenzela uthelekiso olulula. |

| Izicelo zeziqinisekiso (RFQ) | Ijolisa kubuchule babaxhasi kunye nomgangatho wokuqinisekisa ukuba abathengisi abagqwesileyo bayaqwalaselwa. |

Ezi ndlela zilungelelanisa ukuthathwa kwezigqibo, ziqinisekisa ukuba amashishini akhetha ababoneleli abahambelana neenjongo zabo.

Amalungu okujula enziwe ngentsimbi adlala indima ebalulekileyo ekuqhubeni impumelelo yeshishini. Ukuchaneka kwabo, ukusebenza kakuhle kweendleko, kunye nokuguquguquka kwezinto eziphathekayo kubenza babaluleke kakhulu kuwo onke amashishini.

| Inkqubo | Iingenelo | Usetyenziso |

|---|---|---|

| Die Casting | Ukusebenza kweendleko, ukuchaneka, ukuguquguquka kwezinto eziphathekayo | Ukuchaneka okuphezulu kunye neemfuno ezifanelekileyo |

| Metal Isitofu Molding | Iijometri ezintsonkothileyo, ukomelela okuphezulu, kunye nokuqina | Usetyenziso olukhethekileyo oluneemfuno ezingqongqo |

Izisombululo ezilungiselelweyo zihlangabezana neemfuno zokusebenza ezizodwa, ukuphucula ukwaneliseka kwabathengi kunye nembuyekezo yotyalo-mali. Amashishini afumana ithuba lokukhuphisana ngokwamkela ezi ndlela zintsha. Phonononga ukwenza ngokwezifiso ukuvula amathuba amatsha kunye nokufezekisa ukugqwesa kokusebenza.

FAQ

Ziziphi iingenelo zokusebenzisa iinxalenye zokuphosa isinyithi?

Amalungu okujula ngesinyithi anika ukuchaneka, ukuqina, kunye nokuphumelela kweendleko. Zifanelana namashishini afuna i-lightweight, i-high-high-power components kwizicelo ezinzima.

Ngaba ukwenza ngokwezifiso kuyiphucula njani indawo yokujula yentsimbi?

Ukwenziwa ngokwezifiso konyusa ukusebenza ngokulungelelanisa uyilo ngokweemfuno ezithile. Inciphisa inkunkuma yezinto, iphucula umgangatho, kwaye iqinisekisa ukuhambelana neemfuno zokusebenza ezizodwa.

Ngawaphi amashishini azuza kakhulu kwiindawo zokuphosa iintsimbi?

Imizi-mveliso efana neemoto, i-aerospace, kunye ne-electronics zithembele kakhulu kwintsimbi yokuphosa iinxalenye zokukhanya, ukuqina, kunye nokusebenza okuphezulu.

Ngu:haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Ifowuni:

Iintengiso: 0086-134 8641 8015

Inkxaso: 0086-574 8669 1714

Ixesha lokuposa: Apr-23-2025