Customizedlikarolo tsa tšepeli bohlokoa bakeng sa ho khanna katleho ea khoebo. Liindasteri tse kang tsa likoloi li itšetlehile ka boima bo bobebe, bo tšoarellangmetal die castlikarolo tsa ho ntlafatsa ts'ebetso le ts'ebetso. Lefatšeng ka bopharametal die casting parts foundrymaraka, e hakantsoeng ho fihla ho USD 112.27 bilione ka 2033, e totobatsa tlhokahalo e ntseng e eketseha ea litharollo tse lokiselitsoeng. Ho nepahala le ho sebetsa hantle ha e 'ngoe le e 'ngoemetal die casting partetsa hore e be tsa bohlokoa. Ho feta moo,centrifugal metal die castingmekhoa e ntlafatsa tlhahiso le ho feta, ho netefatsa liphetho tsa boleng bo holimo.

Lintlha tsa bohlokoa

- Custom metal die casting partsthusa likhoebo ho atleha. Ba fana ka ho nepahala le ho boloka chelete. Meetso e khethehileng e lumellana hantle le litlhoko, ho matlafatsa mosebetsi le liphoso tsa ho itšeha.

- Liindasteri tse kang likoloi le lifofane li fumana chelete e ngata ho tsoa ho metal die casting. Likarolo tsena li etsa hore lintho li sebetse hantle, li sireletsehe, 'me li sebelise mafura a fokolang. Li bohlokoa bakeng sa tšebeliso ea boleng bo holimo.

- Ho khetha sehlopha se nepahetsenge bohlokoa haholo. Lekola bokhoni ba bona, lisebelisoa le ts'ehetso ea bona ho aha likamano tse matla tse thusang khoebo ea hau ho hola.

Ho utloisisa likarolo tsa Metal Die Casting

Metal Die Casting Parts ke Life?

Metal die casting partske likarolo tse entsoeng ka mokhoa oa ho etsa tlhahiso o kenyelletsang ho qobella tšepe e qhibilihisitsoeng ka har'a mokoti oa hlobo tlas'a khatello e phahameng. Mokhoa ona o tiisa ho nepahala le ho tsitsisa ha ho hlahisa libopeho tse rarahaneng. Hangata mokhoa ona o sebelisa li-alloys tse kang aluminium, zinki le magnesium, e 'ngoe le e' ngoe e fana ka litšobotsi tse ikhethang.

| Mofuta oa Alloy | Maemo/Litšobotsi |

|---|---|

| Zinki | Qetello e ntle ea bokaholimo, ho tsitsana ha dimensional |

| Aluminium | AA 380, AA 384, AA 386, AA 390 |

| Magnesium | AZ91D |

| Koporo | Hangata e sebelisoa bakeng sa ho lahla |

Likarolo tsa moralo oa maano, joalo ka botenya ba lebota bo ts'oanang, li ntlafatsa ts'ebetso le ho tšoarella ha likarolo tsena. Ho pholisa ka mokhoa o tšoanang ho fokotsa likoli joalo ka warping, ho netefatsa botsitso ba sebopeho. Mekhoa e matla ea ho hlahloba e boetse e tiisa tlhahiso ea boleng bo holimo.

Likopo ho Key Industries

Likarolo tsa tšepe tsa tšepe li bapala karolo ea bohlokoa indastering e kang ea likoloi, sefofane le lisebelisoa tsa elektroniki. Ka mohlala, lefapha la likoloi le ne le nka karolo ea 41.7% ea karolo ea lekeno la lefats'e ka 2023. Thepa e phahameng ea khatello ea motlakase e hlahisa likarolo tse bobebe tse kang li-engine blocks le linyeoe tsa phetisetso, ho ntlafatsa ts'ebetso ea mafura le polokeho.

Sebakeng sa sefofane, theknoloji ena e theha likarolo tse matla haholo joalo ka mahare a turbine le likarolo tsa gearbox. Likarolo tsena li mamella maemo a feteletseng, ho netefatsa ho tšepahala. Ho feta moo, baetsi ba lisebelisoa tsa elektroniki ba sebelisa die casting ho hlahisa matlo le likhokahano tse rarahaneng, ho fihlela tlhoko ea meralo e kopaneng le e tšoarellang.

| Sebaka sa Kopo | Tlhaloso | Lintlha tsa Nomoro |

|---|---|---|

| Tsa makoloi | Li-block tsa enjine tse bobebe, linyeoe tsa phetisetso | Karolo ea 41.7% ea lekhetho ka 2023 |

| Sepakapaka | Li-blades tsa turbine, likarolo tsa gearbox | Matla a phahameng, ts'ebetso ea boemo bo feteletseng |

| Tsa elektroniki | Matlo, likhokahanyo | Meetso e tiileng, e tšoarellang |

Bohlokoa Ts'ebetsong ea Khoebo

Metal die casting parts kenya letsoho haholo hokatleho ea khoebo. Mmaraka oa lefats'e oa ho lahla tšepe, o boleng ba $ 177.28 bilione ka 2024, ho hakanngoa hore o tla fihla ho $ 325.69 bilione ka 2033, o hola ho CAGR ea 6.94%. Kholo ena e bonts'a tlhokahalo e ntseng e eketseha ea likarolo tse bobebe le tse tšoarellang.

Lintlha tsa bohlokoa tsa ts'ebetso li totobatsa bohlokoa ba tsona. Ho boloka sekhahla sa sekoli se ka tlase ho 2% ho netefatsa taolo ea boleng, athe tšebeliso e nepahetseng ea lisebelisoa e kaholimo ho 85% e fokotsa nako ea ho theoha. Litefiso tsa tlhahiso ea thepa ea makhetlo a 6-8 ka selemo li fokotsa litšenyehelo tsa ho ts'oara, 'me ho latela li-KPI tsa ho tsamaisa thepa ho ka matlafatsa litaelo tse pheta-phetoang ka 20%. Li-metrics tsena li bonts'a kamoo likarolo tsa tšepe li ntlafatsang ts'ebetso le ho ntlafatsa khotsofalo ea bareki.

| Metric | Tlhaloso |

|---|---|

| Litefiso tsa ho lahla | Ka tlase ho 2% ho netefatsa taolo ea boleng le khotsofalo ea bareki. |

| Tšebeliso ea Lisebelisoa | Ka holimo ho 85% e fokotsa nako ea ho theoha 'me e ntlafatsa tšebeliso ea lisebelisoa. |

| Inventory Turnover | Linako tsa 6-8 ka selemo li fokotsa litšenyehelo tsa ho tšoara le ho thibela ho lieha. |

| Khotsofalo ea Bareki | Li-KPI tsa thomello li ka eketsa litaelo tse pheta-phetoang ka 20%. |

| Li-KPI tsa lichelete | Melemo ea phaello e fetang 25% ka tlhahlobo ea litšenyehelo le lekeno. |

Melemo ea ho Customizing Metal Die Casting Parts

Nepahetseng le Boleng

Customizing metal die casting partse netefatsa ho nepahala ho sa bapisoang le boleng bo phahameng. Meetso e hlophisitsoeng e lumella bahlahisi ho fihlela lintlha tse nepahetseng, ho fokotsa liphoso le ho ntlafatsa ts'ebetso. Lithuto li totobatsa melemo ea ho itlhophisa:

- Phuputso ea 2022 hoJournal of Manufacturing Processese tlalehile ntlafatso ea 35% molemong oa likarolo le ts'ebetso bakeng sa lik'hamphani tse amohelang mokhoa o tloaelehileng oa lefu.

- TheInternational Journal of Advanced Manufacturing Technology(2023) e senotse phokotso ea 25% ea litšenyehelo tsa thepa e tala ka lebaka la meralo e ntlafalitsoeng.

Liphuputso tsena li bonts'a kamoo ho itlhophisa ho ntlafatsang ts'ebetso le ts'ebetso e ntle ea litšenyehelo. Ho feta moo, mekhoa e tsoetseng pele ea tlhahlobo e netefatsa hore karolo e 'ngoe le e' ngoe e kopana le litekanyetso tse thata tsa boleng, e fokotsa mefokolo le ho holisa ts'epo.

Katleho le Tshebetso

Ho iketsetsa likarolo tsa tšepe tsa tšepe ho matlafatsa ts'ebetso le ts'ebetso haholo. Meetso ea hlobo e sebetsang hantle le lits'ebetso tse lokiselitsoeng li fokotsa litšila le ho ntlafatsa lebelo la tlhahiso. Lintlha tse ka sehloohong tse tlatsetsang katlehong li kenyelletsa:

- Moqapi oa Mold: Li-mold tse ntlafalitsoeng li ntlafatsa ho nepahalale ho fokotsa tšebeliso ea thepa.

- Ho Felisa Likhahla le Limathi: Meralo e hlophisitsoeng e fokotsa litšila.

- Koetliso ea Basebetsi: Basebetsi ba nang le tsebo ba fokotsa litšenyehelo tsa ho sebetsa le ho ntlafatsa boleng ba tlhahiso.

Theknoloji ea sejoale-joale joalo ka hlobo e hatisitsoeng ea 3D e ntlafatsa ts'ebetso. Mefuta ena e thusa popo e potlakileng ea prototype, e fokotsa linako tsa potoloho ea moralo ka 50%. Meetso ea hlobo ea modular le eona e fana ka maemo a bonolo, e lumellang bahlahisi ho ikamahanya le litlhoko tse fapaneng tsa tlhahiso. Linako tse fokotsehileng tsa ho etella pele li tsamaisana le litlhoko tsa tlhahiso ea nako, ho netefatsa ho tsamaisoa ka nako le khotsofalo ea bareki.

Litšenyehelo-Ka katleho

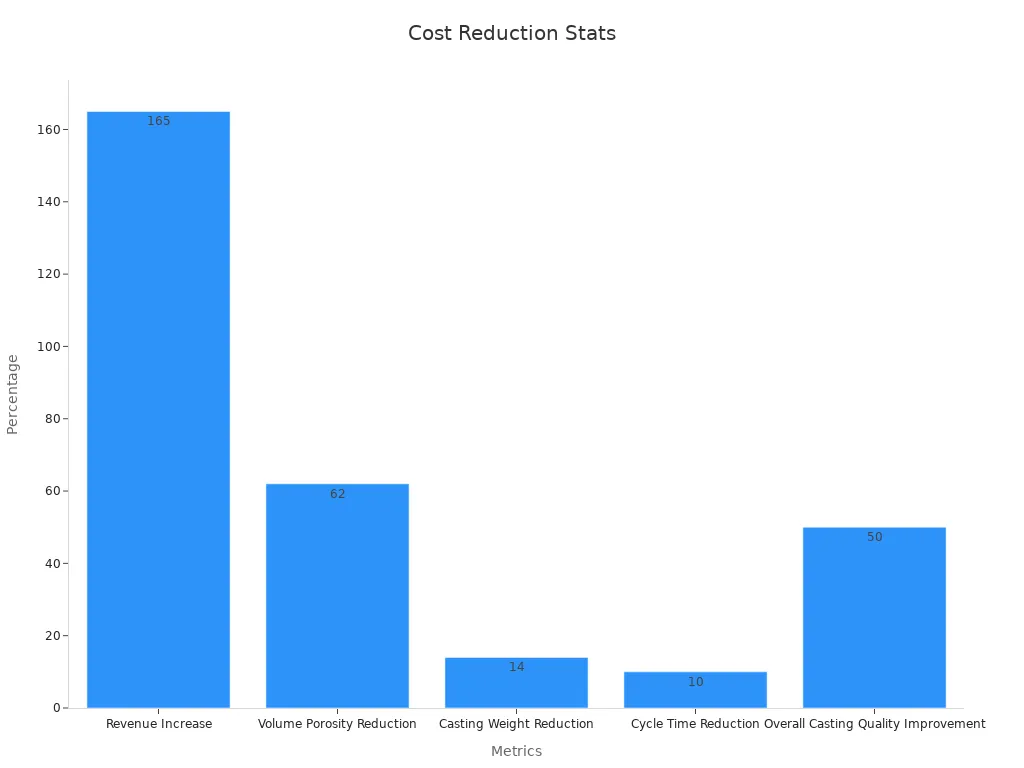

Ho iketsetsa likarolo tsa tšepe tsa tšepe ho fana ka chelete e ngata ea ho boloka. Ka ho ntlafatsa meralo le lits'ebetso, bahlahisi ba ka fokotsa tšebeliso ea thepa, tšebeliso ea matla le nako ea tlhahiso. Tafole e latelang e totobatsa melemo ea bohlokoa ea litšenyehelo:

| Metric | Sephetho |

|---|---|

| Keketso ea Lekeno | keketseho ea 165%. |

| Phokotso ea Tšebeliso ea Mochini oa Casting | Ho fokotsa matla a ho koala ho lithane tse 1200 |

| Phokotso ea Porosity ea Molumo | Phokotso ea 62%. |

| Ho fokotsa boima ba 'mele | Phokotso ea 14%. |

| Pokotso ea Nako ea Potoloho | Phokotso ea 10%. |

| Kakaretso ea Ntlafatso ea Boleng ba ho Lahlela | 50% ntlafatso |

Lintlafatso tsena li fetolela phaellong e holimo le litheko tsa tlholisano, e leng se etsang hore litharollo tse ikhethileng e be matsete a bohlale bakeng sa likhoebo.

Litharollo tse Taired bakeng sa Litlhoko tse Ikhethang

Khoebo e 'ngoe le e' ngoe e na le litlhoko tse ikhethang, 'me likarolo tse ikhethileng tsa tšepe li fana ka tharollo e lumellanang le litlhoko tse itseng. Ho tloha ho khetho ea thepa ho ea ho ntlafatso ea moralo, ho itlhophisa ho netefatsa hore likarolo li lumellana hantle le lipheo tsa ts'ebetso. Litlaleho tsa katleho tse tlalehiloeng li bontša phello ea litharollo tse ikamahanyang le maemo:

| Lebitso la moreki | Tlhaloso ea Tailored Solution |

|---|---|

| Boutique e ikhethang | E sebelisitse litharollo tse hlophisitsoeng tsa Aircall ho hlahella 'marakeng o nang le batho ba bangata. |

| Ba Tharollo | Litharollo tse amohetsoeng tse tsoang ho Aircall ho lumellana le litlhoko tsa bona tsa puisano hantle. |

Ts'ebetso ea mohato ka mohato e netefatsa hore projeke ka 'ngoe e fihlela litlhoko tse nepahetseng:

- Tlhahlobo ea Pele le Tlhahlobo ea Moralo: Buisanang ka merero ea morero le ho ntlafatsa meralo.

- Khetho ea Lintho: Khetha lisebelisoa ho latela litlhoko tsa ts'ebetso.

- Moralo & Boenjiniere: Sebelisa lisebelisoa tsa CAD ho theha meralo e tloaelehileng.

- Prototyping & Mohlala Testing: Netefatsa ho nepahala le ho etsa liteko tsa prototypes.

- Tlhahiso ea Tlhahiso & Tlhahiso ea Pele: Netefatsa ho seta le boleng nakong ea ho matha qalong.

- Tlhahiso ea ho qetela le Taolo ea Boleng: Etsa tlhahiso e feletseng ka ho hlahloba boleng bo tsoelang pele.

Mokhoa ona o tiisa hore likhoebo li fumana likarolo tse ntlafatsang ts'ebetso, tse fokotsang litšenyehelo, le ho fihlela maemo a indasteri.

Mokhoa oa ho Customize Metal Die Casting Parts

Moralo le Therisano

Ts'ebetso ea ho itlhophisa e qala ka moralo o phethahetseng le mohato oa lipuisano. Baenjiniere le baqapi ba sebelisana 'moho ho etsa polane e lumellanang le litlhoko tse khethehileng tsa moreki. Mothati ona o kenyelletsa ho sekaseka ts'ebeliso e reriloeng, ho khetha lisebelisoa tse loketseng, le ho khetha mekhoa e sebetsang hantle ea tlhahiso.

Mehato ea bohlokoa mokhahlelong ona e kenyelletsa:

- Tlhokahalo Analysis: Ho utloisisa litlhoko tsa ts'ebetso le lipheo tsa ts'ebetso.

- Khetho ea Lintho: Ho khetha li-alloys tse kang aluminium kapa zinki ho latela litlhoko tsa nako e telele le boima ba 'mele.

- Ntlafatso ea Moqapi: Ho sebelisa software ea CAD ho ntlafatsa meralo bakeng sa ho nepahala le ho etsa lintho hantle.

Puisano e atlehileng pakeng tsa moreki le sehlopha sa meralo e netefatsa hore lintlha tsohle li rarolloa. Mokhoa ona oa tšebelisano o fokotsa liphoso le ho theha motheo oa ts'ebetso e atlehileng ea tlhahiso.

Prototyping le Teko

Prototyping le liteko li bohlokoa bakeng sa ho netefatsa moralo le ho netefatsa ts'ebetso. Nakong ena, bahlahisi ba theha li-prototypes ho lekola ts'ebetso le ho tseba mathata a ka bang teng. Maikutlo a tsoang ho ba amehang a thusa ho ntlafatsa moralo pele tlhahiso e felletseng e qala.

Mesebetsi ea bohlokoa mokhahlelong ona e kenyelletsa:

- Ho theha sebopeho sa moetso kapa sebopeho sa sebopeho.

- Ho bokella maikutlo ho tsoa ho bamameli ba shebiloeng.

- Ho khetholla mathata a ka bang teng kapa ho netefatsa liqeto tsa sehlahisoa.

Ho hloleha ho hong le ho hong nakong ea prototyping ho fana ka leseli la bohlokoa mabapi le moralo le lits'ebetso tsa tlhahiso. Ka mohlala, tlhahlobo e qaqileng ea ho hlōleha e thusa ho tseba lisosa tsa ho hlōleha le litekanyetso tse lebeletsoeng tsa ho hlōleha. Lethathamo le latelang le bontša bohlokoa ba tlhahlobo:

| Palo ea li-Prototypes | Palo ea ho Hlōleha | Sekhahla sa ho hloleha (%) |

|---|---|---|

| 100 | 1 | 1 |

| 10 | 1 | 10 |

| 2 | 1 | 50 |

Lintlha tsena li totobatsa tlhokahalo ea tlhahlobo e matla ho netefatsa hore sehlahisoa sa ho qetela se finyella litekanyetso tsa boleng.

Tlhahiso le Taolo ea Boleng

Hang ha moralo o phethiloe, mohato oa tlhahiso oa qala. Baetsi ba sebelisa lisebelisoa tse tsoetseng pele le mekhoa ea ho hlahisa likarolo tsa tšepe tsa boleng bo holimo. Mehato ea taolo ea boleng e kengoa tšebetsong mohatong o mong le o mong ho boloka botsitso le ho ts'epahala.

Lintlha tsa bohlokoa tsa tlhahiso li kenyelletsa:

- Litefiso tsa Bofokoli: Ho beha leihlo palo ea likarolo tse nang le phoso ka kakaretso e hlahisoang.

- Peresente ea Lihlahisoa tse sa Lumellaneng: Ho netefatsa hore lihlahisoa li kopana le litlhaloso.

- Nako ea ho Rarolla Mathata a Boleng: Ho rarolla mathata ka potlako ho qoba tieho.

Tafole e ka tlase e bontša metrics ea bohlokoa ea tlhahiso:

| Metric | Tlhaloso |

|---|---|

| Litefiso tsa Sekoli | Palo ea li-unit tse nang le phoso ka kakaretso e hlahisitsoeng. |

| Peresente ea Lihlahisoa tse sa Lumellaneng | Karolelano ea lihlahisoa ha e kopane le litlhaloso. |

| Nako ea ho Rarolla Mathata a Boleng | Nako e nkuoang ho rarolla mathata a boleng. |

Litifikeiti tse kang ISO 9001 le Six Sigma li tiisa ho tiea ha ts'ebetso ea tlhahiso. Litekanyetso tsena li netefatsa hore bahlahisi ba lula ba fana ka likarolo tse fihlelang kapa tse fetang tebello ea indasteri.

Phano le Tšehetso

Mohato oa ho qetela o kenyelletsa ho fana ka likarolo tse phethiloeng ho mofani le ho fana ka tšehetso e tsoelang pele. Mekhoa e metle ea ho fana ka thepa e netefatsa hore litaelo li fihla ka nako 'me li le boemong bo phethahetseng. Lihlopha tsa tšehetso ea bareki li rarolla mathata leha e le afe 'me li fana ka thuso ha ho hlokahala.

Lintlha tsa bohlokoa tsa ts'ebetso ea thomello li kenyelletsa:

- Thoriso ka Nako: Peresente ea liodara tse phethetsoeng ka nako e lebelletsoeng ea delibari.

- Ho Nepaha ha Odara: Peresente ea litaelo tse fanoeng ntle le liphoso.

- Lintlha tsa Khotsofalo ea Bareki: E lekanya khotsofalo ea bareki mabapi le boiphihlelo ba ho tsamaisa thepa.

Tafole e ka tlase e totobatsa metrics ena:

| Metric | Tlhaloso |

|---|---|

| Phano ka Nako | Peresente ea liodara tse phethetsoeng ka nako e lebelletsoeng ea ho fihla. |

| Ho Nepaha ha Taelo | Peresente ea litaelo tse fanoeng ntle le liphoso ha li bapisoa le litaelo tsohle. |

| Lintlha tsa Khotsofalo ea Bareki | E lekanya khotsofalo ea bareki mabapi le boiphihlelo ba phano, ea bohlokoa bakeng sa ho lekola litšebeletso. |

Puisano e hlakileng le bareki e netefatsa hore ba lula ba tsebisitsoe ka thepa ea bona. Mekhoa ea ho fana ka maikutlo e thusa ho sebetsana le liphihlelo tse mpe le ho ntlafatsa boleng ba litšebeletso. Mokhoa ona o akaretsang o tiisa boiphihlelo bo se nang moeli ho tloha tlhahiso ho isa ho phano.

Mokhoa oa ho Khetha Mofani ea Nepahetseng bakeng sa Metal Die Casting Parts

Ho Lekola Boiphihlelo le Boitsebelo

Ho khetha mofani ea nang le boiphihlelo bo netefalitsoeng ho netefatsa ho ts'epahala le boleng. Bafani ba nang le histori e telele indastering hangata ba bontša kutloisiso e tebileng ea mekhoa ea tlhahiso. Mohlala, Form Technologies, e nang le boiphihlelo ba lilemo tse fetang 80 le merero e atlehileng ea 270+, e fana ka mohlala oa botsebi. Tlhahiso ea bona ea selemo le selemo ea li-unit tse limilione tse likete tse 5 le bareki ba fetang 2,000 ba totobatsa bokhoni ba bona ba ho sebetsana le litlhoko tse fapaneng.

- Lintlha tsa bohlokoa tse lokelang ho hlahlojoa li kenyelletsa:

- Litšebeletso li etselitsoe liindasteri tse khethehileng.

- Bokhoni ba boenjiniere ba moralo bakeng sa merero e rarahaneng.

- Litšebeletso tsa morao-rao tse kang ho qeta le ho kopanya.

Lithuto tsa mohlala li boetse li fana ka lintlha tsa bohlokoa. Mofani oa thepa ho baetsi ba likoloi o ile a fokotsa litefiso tsa maqheku ho tloha ho 20-40% ka ho kenya ts'ebetsong tsamaiso ea boleng bo boletsoeng esale pele. Ntlafatso ena e totobatsa bohlokoa ba boitseanape ba tekheniki mabapi le ho ntlafatsa sephetho sa tlhahiso.

Ho Lekola Theknoloji le Bokhoni

Ho amoheloa ha theknoloji e tsoetseng pele ho bohlokoa bakeng sa tlhahiso e sebetsang hantle le e nepahetseng. Bafani ba sebelisang theknoloji ea IoT ba ntlafatsa tlhahlobo le taolo ea ts'ebetso. Tlaleho ea morao tjena e bontša hore 62% ea bahlahisi ba kentse IoT ts'ebetsong ea bona, 'me ba bararo ho ba bahlano ba lemoha bokhoni ba eona.

Bokhoni bo kang mold flow simulation,Mechine ea CNC, le taolo ea boleng bo felletseng e boetse e khetholla bafani ba maemo a holimo. Theknoloji ena e netefatsa boleng bo tsitsitseng le potoloho ea tlhahiso e potlakileng. Bafani ba fanang ka meralo ea hlobo ea modular le prototyping e potlakileng le bona ba bonts'a ho ikamahanya le maemo a fetohang litlhoko tsa khoebo.

| Palopalo | Tlhaloso |

|---|---|

| 62% | Liperesente tsa bahlahisi ba sebelisang mahlale a IoT. |

| 3-ho-5 | Karolelano e bonts'ang kananelo e ntseng e hola ea IoT tlhahisong. |

Bohlokoa ba Tšebeletso ea Bareki

Litšebeletso tsa bareki li bapala karolo ea bohlokoa ho boloka likamano tsa nako e telele. Bafani ba nang le lihlopha tse nang le litsebo tsa ts'ehetso ba netefatsa puisano e bonolo le ho rarolla mathata kapele. Patlisiso e senotse hore 88% ea likhoebo li hokahanya litšebeletso tse ntle tsa bareki le ts'ebetso e holimo, athe 85% ea bareki ba fetola mabitso ka mor'a phihlelo e le 'ngoe e mpe.

| Palopalo | Temohisiso |

|---|---|

| 88% ea likhoebo | Lumellana hore tšebeletso e ntle ea bareki e amana le ts'ebetso e phahameng. |

| 85% ea bareki | E tla fetola mabitso ka mor'a hore ho be le bothata bo le bong. |

| 35% ea bareki | Ba ikemiselitse ho sebelisa chelete e ngata bakeng sa litšebeletso tse ikhethang tsa bareki. |

Bafani ba fanang ka puisano e pepeneneng le ts'ehetso ea ka mor'a ho fana ba khothalletsa botšepehi le botšepehi. Litšobotsi tsena li ama ka kotloloho ho boloka le khotsofalo ea bareki.

Ho hlahloba Maikutlo le Litlhahlobo

Maikutlo le bopaki li fana ka leseli la botumo ba mofani oa thepa. Maikutlo a matle a tsoang ho bareki ba nakong e fetileng a bonts'a boleng bo ts'oanang le ho ts'epahala. Li-platform tse kang Google Reviews le liforamu tsa indasteri hangata li fana ka litlhaloso tse qaqileng tsa bafani. Batla maikutlo mabapi le linako tsa ho fihla, boleng ba sehlahisoa, le karabelo.

Ho feta moo, lisebelisoa tse hlophisitsoeng joalo ka matrices a tlhahlobo ea barekisi li thusa ho bapisa bafani ka nepo. Likōpo tsa Tlhahisoleseding (RFI) le Litšoaneleho (RFQ) li tsoela pele ho ntlafatsa mokhoa oa ho khetha ka ho shebana le botsebi le boleng.

| Mokhoa oa ho Hlahloba | Tlhaloso |

|---|---|

| Matrix ea Tlhahlobo ea Bafani | Sesebelisoa se hlophisitsoeng sa ho bapisa barekisi ho latela mekhoa e mengata. |

| Likopo tsa Tlhahisoleseding (RFI) | E bokella lintlha tse akaretsang ho tsoa ho barekisi bakeng sa ho bapisa habonolo. |

| Likopo tsa Litšoaneleho (RFQ) | E tsepamisitse maikutlo holim'a botsebi le boleng ba barekisi ho netefatsa hore ho na le barekisi ba tšoanelehang ka ho fetesisa. |

Mekhoa ena e nolofatsa ho etsa liqeto, ho netefatsa hore likhoebo li khetha bafani ba tsamaellanang le lipheo tsa bona.

Likarolo tse ikhethileng tsa tšepe li bapala karolo ea bohlokoa molemong oa katleho ea khoebo. Ho nepahala ha tsona, ho baballa litšenyehelo, le ho feto-fetoha ha lintho tse bonahalang li etsa hore e be tsa bohlokoa haholo indastering.

| Tshebetso | Melemo | Lisebelisoa |

|---|---|---|

| Die Casting | Tšebeliso ea litšenyehelo, ho nepahala, ho feto-fetoha ha lintho tse bonahalang | Litlhoko tse phahameng tse nepahetseng le tse sebetsang hantle |

| Metal Ente Molding | Li-geometri tse rarahaneng, matla a holimo, le nako e telele | Lisebelisoa tse khethehileng tse nang le litlhoko tse thata |

Litharollo tse hlophisitsoeng li kopana le litlhoko tse ikhethang tsa ts'ebetso, ho ntlafatsa khotsofalo ea bareki le meputso ea matsete. Likhoebo li fumana monyetla oa tlholisano ka ho sebelisa mekhoa ena e mecha. Lekola ho itloaetsa ho bula menyetla e mecha le ho fihlela bokhabane ba ts'ebetso.

LBH

Ke melemo efe ea ho sebelisa likarolo tsa tšepe tsa tšepe?

Likarolo tsa tšepe tsa tšepe li fana ka ho nepahala, ho tšoarella nako e telele, le ho boloka litšenyehelo. Li lumellana le liindasteri tse hlokang lisebelisoa tse bobebe, tse matla haholo bakeng sa lisebelisoa tse rarahaneng.

Customization e ntlafatsa likarolo tsa tšepe tsa tšepe joang?

Ho itloaetsa ho ntlafatsa ts'ebetso ka ho hlophisa meralo ho latela litlhoko tse ikhethileng. E fokotsa litšila tsa thepa, e ntlafatsa boleng, 'me e netefatsa ho lumellana le litlhoko tse ikhethang tsa ts'ebetso.

Ke liindasteri life tse ruang molemo haholo ka likarolo tsa tšepe?

Liindasteri tse kang tsa makoloi, sefofane, le lisebelisoa tsa elektroniki li itšetlehile haholo ka likarolo tsa tšepe bakeng sa likarolo tse bobebe, tse tšoarellang, le tse sebetsang hantle haholo.

Ka: haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Mohala:

Lithekiso: 0086-134 8641 8015

Tšehetso: 0086-574 8669 1714

Nako ea poso: Apr-23-2025