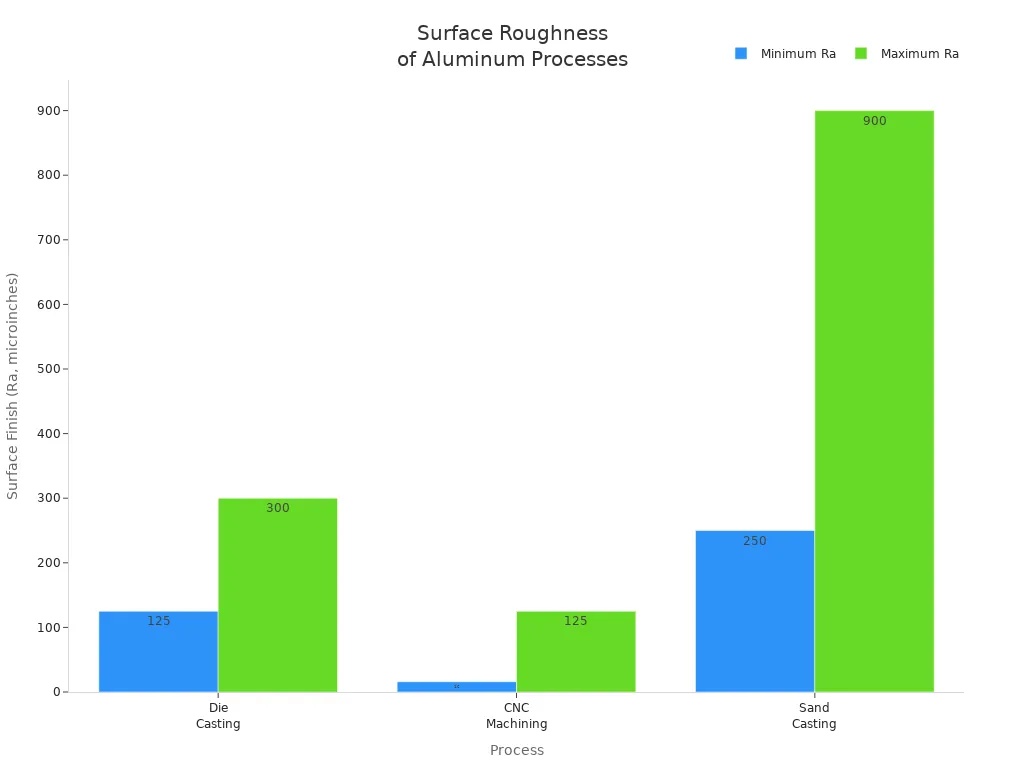

When you look at cast aluminum parts used in automobile or telecommunication industries, you want a smooth, flawless finish. CNC machining gives you that edge. It takes rough, as-cast surfaces and makes them sleek and precise. Just check out the difference:

| Process | Typical Surface Finish (Ra) |

|---|---|

| Die Casting | 125-300 microinches |

| CNC Machining | 16-125 microinches |

| Sand Casting | 250-900 microinches |

You can see how CNC machining helps you achieve a much finer finish, making every component look and perform better.

Key Takeaways

- CNC machining significantly improves the surface finish of cast aluminum parts, achieving smoother finishes between 16 and 125 microinches Ra.

- Using CNC milling and turning processes enhances the accuracy and consistency of parts, ensuring tight tolerances and better performance.

- Advanced finishing techniques like polishing and anodizing not only improve appearance but also increase durability and corrosion resistance.

Surface Finish Limitations in Cast Aluminum Die Casting

Common Imperfections in Cast Aluminum

When you work with cast aluminum, you might notice some flaws on the surface. These imperfections can affect how your parts look and perform. Here are a few issues you may see:

- Surface finishing plays a big role in how long your part lasts.

- If the finish is not right, corrosion resistance drops.

- Sometimes, the part just doesn’t look as good as you want.

You may also spot two types of porosity. Gas porosity happens when air or hydrogen gets trapped in the metal, leaving small, round holes. Shrinkage porosity shows up as bigger, odd-shaped cavities when the metal cools and shrinks.

Tolerance and Consistency Challenges

You want your parts to fit perfectly every time. Standard aluminum die casting usually gives you tolerances between ±0.05 mm and ±0.10 mm. For really precise jobs, you can get down to ±0.01 mm. Industry standards like ISO 8062-3 and NADCA help guide what’s possible. Still, hitting those tight tolerances can be tough, especially if you need the same results for every part.

Geometric Restrictions in Die Casting

Die casting works best for certain shapes. If you need sharp corners, deep holes, or thin walls, you might run into trouble. The process limits how complex your part can be. Sometimes, you have to change your design or add extra steps to get the features you want.

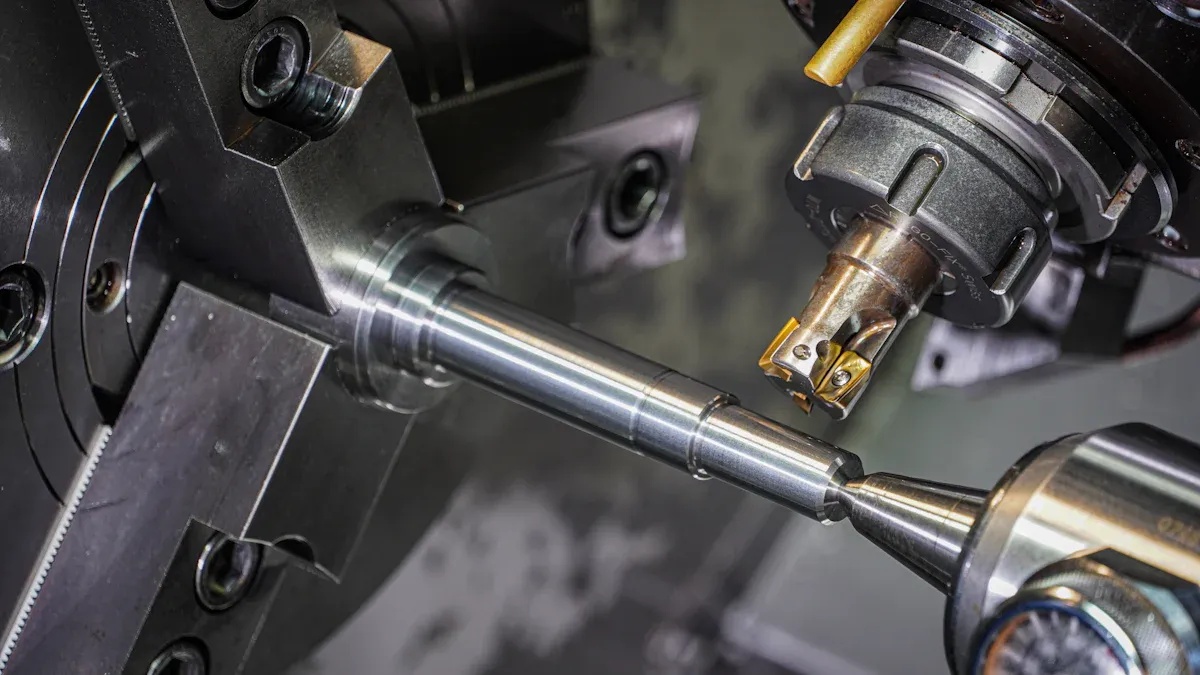

CNC Machining Processes for Cast Aluminum Enhancement

Milling for Flatness and Smooth Surfaces

When you want your cast aluminum parts to look and feel smooth, CNC milling is your go-to process. Milling machines use sharp, spinning tools to shave away rough spots and create flat, even surfaces. You can count on CNC milling to fix uneven areas and make sure your parts fit together perfectly. This process can reach tight tolerances, sometimes as precise as ±0.005 mm. That means your parts will have a consistent thickness and smoothness, which is important for things like engine covers or machine brackets.

Flatness is a big deal. It tells you how smooth and even a surface is. If you need two parts to fit together without gaps, you want both to be as flat as possible. CNC milling helps you get there by removing bumps and dips left from casting. MIC-6 aluminum, for example, has a special grain structure that makes it even easier to achieve a super-flat finish when you machine it.

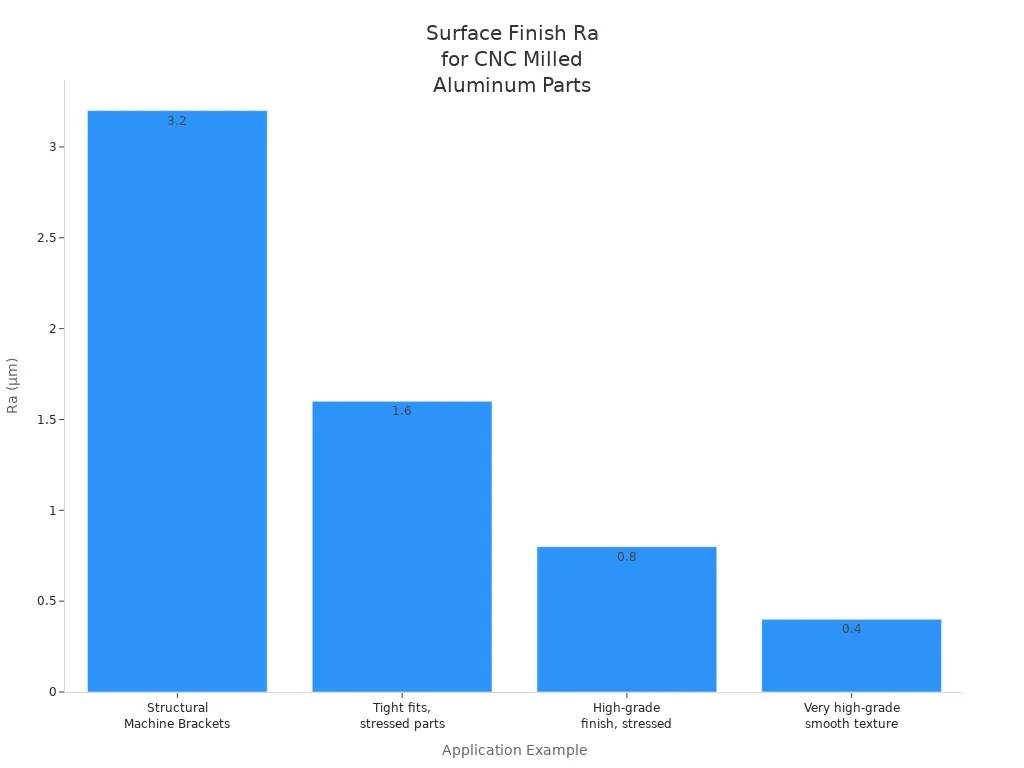

You can choose different levels of surface finish, depending on what your part needs. Here’s a quick look at what’s possible:

| Ra (µm) | Application Examples | Key Characteristics |

|---|---|---|

| 3.2 | Structural Machine Brackets, Automotive Engine Covers, General Tooling Fixtures, Machine Chassis | Functional use, moderate stress |

| 1.6 | Tight fits, parts under stress | Slightly visible cut marks, increased production cost by 2.5% |

| 0.8 | High-grade finish for stressed parts | Requires finishing passes, adds 5% to production cost |

| 0.4 | Very high-grade smooth texture | No observable cut marks, adds up to 15% to production cost |

If you need a part that looks great and works well, CNC milling gives you the control to get the finish you want.

Turning for Cylindrical Accuracy

CNC turning is the best way to make round or cylindrical parts from cast aluminum. The machine spins your part while a cutting tool shapes it. This process is perfect for making things like shafts, bushings, or any part that needs to be perfectly round.

You get amazing accuracy with CNC turning. The machine can hold tolerances as tight as ±0.0001 inches (2.54 microns). That means every part you make will be almost exactly the same. You don’t have to worry about mistakes from human hands, because the computer controls everything. This is a big deal for industries like automotive and aerospace, where even tiny errors can cause problems.

Here’s a quick comparison:

| Feature | CNC Turning | Traditional Turning |

|---|---|---|

| Tolerances | ±0.0001 inches (2.54 microns) | Generally looser tolerances |

| Repeatability | High, consistent quality | Variable, prone to human error |

| Surface Finish | Superior, often no secondary | May require additional finishing |

| Human Error | Reduced | Higher risk of errors |

With CNC turning, you get smooth, accurate, and repeatable results every time.

Polishing and Advanced Finishing Methods

After milling or turning, you might want your cast aluminum parts to look even better. That’s where polishing and advanced finishing come in. These methods can make your parts shiny, smooth, or give them a special texture.

Here are some popular finishing options:

- Mechanical polishing: Machines grind and polish the surface to remove tiny bumps and burrs.

- Chemical polishing: Chemicals smooth the surface by removing the oxide layer.

- Electrochemical polishing: Uses electricity and chemicals for a super-smooth finish.

- Precision mechanical polishing: Multiple steps with high-precision tools for extra smoothness.

- Ultra-precision polishing: Advanced tech like lasers or ion beams for the smoothest finish possible.

- Surface passivation: Restores corrosion resistance after polishing, often using anodizing.

You can also use methods like vibratory finishing and shot blasting. Vibratory finishing puts your parts in a bowl with special media that gently polishes and deburrs them. Shot blasting uses high-speed particles to create a uniform, matte surface. These techniques help prepare your parts for coatings or just make them look great.

If you want to add color or extra protection, you can try:

- Anodizing: Adds a tough, colorful layer that resists wear and corrosion.

- Powder coating: Gives a strong, even finish in almost any color.

- Sandblasting: Creates a matte look and preps the surface for more finishing.

Mechanical and chemical finishes each have their own look and benefits. Here’s a quick guide:

| Mechanical Finish | Surface Appearance | Application Method | Common Uses |

|---|---|---|---|

| Brushing | Directional, satin finish | Abrasive brushes/pads | Architectural designs |

| Polishing | Smooth, reflective | Progressive abrasives | Decorative and protective applications |

| Blast finishing | Uniform matte | High-velocity particles | Pre-treatment for coatings |

Correcting Casting Defects with CNC Machining

Sometimes, cast aluminum parts come out of the mold with small flaws. CNC machining can fix many of these issues, so you don’t have to throw away the part.

The most common defects you can correct include:

- Porosity: Tiny holes or pockets caused by trapped gas. CNC machining can remove these from the surface, making the part stronger and leak-proof.

- Shape defects: Problems like misaligned features or rough edges. CNC machines can trim and reshape these areas for a perfect fit.

| Casting Defect | Description |

|---|---|

| Porosity | Occurs when gas entrapment creates pockets or pits, leading to leaks. |

| Shape Defects | Arise from misalignment or distortion, resulting in incomplete features. |

By using CNC machining, you can turn a flawed cast aluminum part into a high-quality component that meets your exact needs.

Benefits of CNC Machining for Cast Aluminum Parts

Enhanced Appearance and Visual Quality

You want your parts to look sharp and professional. CNC machining helps you achieve that. With advanced finishing techniques, you can choose the exact look you want for your cast aluminum components. Check out some popular options:

| Technique | Description | Benefits |

|---|---|---|

| Bead Blasting | Uses abrasive media for a matte finish | Removes tool marks, improves paint adhesion, smooth feel |

| Powder Coating | Applies polymer powder and cures with heat | Great corrosion resistance, strong adhesion, many finishes |

| Mirror Polishing | Precision finishing for a shiny, reflective surface | Reduces friction, boosts corrosion resistance, optical clarity |

| Brushed Finishing | Creates a uniform grain pattern | Unique texture, keeps dimensions stable |

| Anodizing | Builds up the oxide layer on aluminum | More corrosion resistance, harder surface, color options |

These methods make your parts stand out and last longer.

Improved Fit, Function, and Performance

You need your parts to fit together perfectly. CNC machining delivers tight tolerances and precise fits, which means fewer assembly problems and better performance. Here’s how CNC machining helps:

| Contribution of CNC Machining | Description |

|---|---|

| Tight Tolerances | Parts meet exact measurements for smooth assembly |

| Precise Fits | Components fit seamlessly, reducing errors |

| High-Precision CAD Modeling | Ensures your design matches the final product |

When your parts fit right, your machines run better and last longer.

Increased Durability and Service Life

You want your cast aluminum parts to handle tough jobs and keep working. CNC machining helps by controlling heat, tool wear, and machining parameters. This keeps your parts strong and reliable. Here are some ways CNC machining boosts durability:

- Uses cutting fluid to manage heat and protect surfaces

- Maintains high cutting speeds with proper cooling

- Adjusts machining settings to prevent warping or distortion

Tip: When you use CNC machining, you get parts that last longer and perform better, even in demanding environments.

CNC machining gives you smoother, more reliable cast aluminum parts. You get better looks, tighter fits, and longer-lasting components. Many industries rely on this process:

| Industry | Reason for Use |

|---|---|

| Automotive | Lightweight, durable engine and chassis parts |

| Aerospace | High strength-to-weight ratio for aircraft |

| Construction | Corrosion resistance for structures |

| Marine | Lightweight, corrosion-resistant components |

| Electronics | Precision parts for devices |

| Consumer Goods | Versatile uses in many products |

| Medical Equipment | Non-toxic, easy-to-sterilize instruments |

Investing in CNC finishing helps you meet the highest standards every time.

FAQ

What surface finish can you expect after CNC machining cast aluminum?

You usually get a smooth finish between 16 and 125 microinches Ra. CNC machining removes rough spots and leaves your parts looking polished.

Tip: You can choose finer finishes for special projects.

Does CNC machining improve the strength of cast aluminum parts?

Yes, you get stronger parts. CNC machining removes weak areas and defects, so your components last longer and perform better.

Can you combine CNC machining with other finishing methods?

Absolutely! You can use CNC machining first, then add anodizing, powder coating, or polishing. This gives you a custom look and extra protection.

| Finishing Method | Benefit |

|---|---|

| Anodizing | Corrosion resistance |

| Powder Coating | Color options |

| Polishing | Shiny surface |

Post time: Sep-03-2025