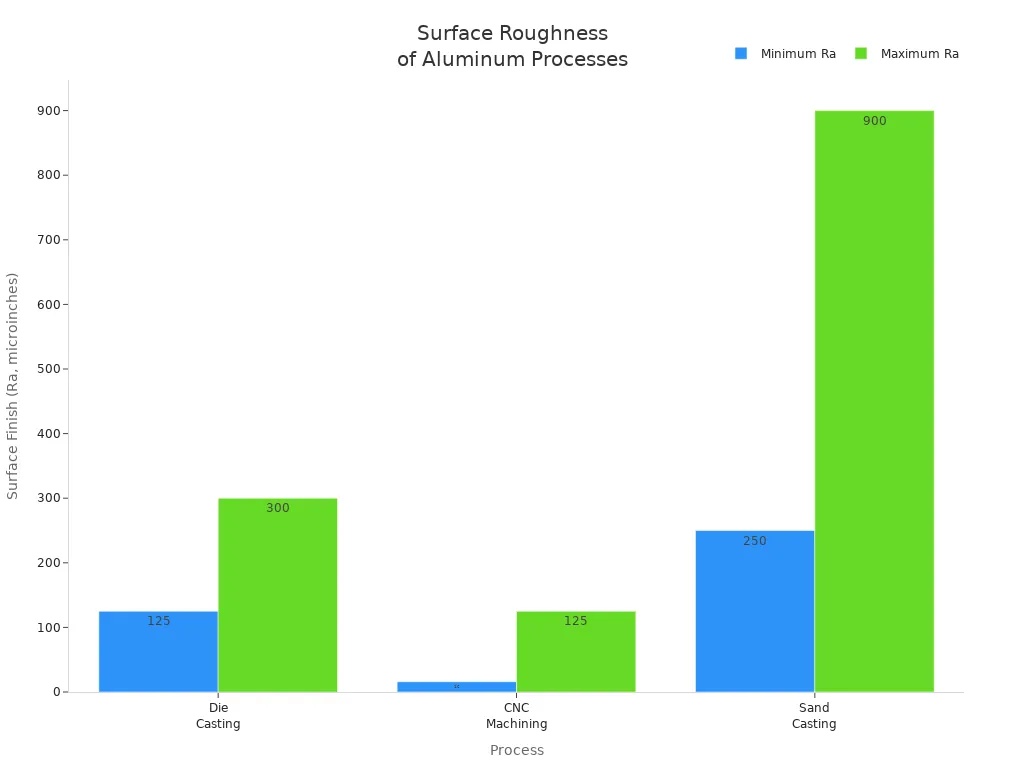

Thaum koj saib cam khwb cia txhuas qhov chaw siv nyob rau hauvtsheb or kev sib txuas lusindustries, koj xav tau ib tug du, flawless tiav. CNC machining muab koj qhov ntug. Nws yuav siv cov ntxhib, zoo li-casting nto thiab ua rau lawv sleek thiab meej. Tsuas yog xyuas qhov txawv:

| Txheej txheem | Hom nto tiav (Ra) |

|---|---|

| Tuag Casting | 125-300 microinches |

| CNC Machining | 16-125 microinches |

| Xuab zeb Casting | 250-900 microinches |

Koj tuaj yeem pom yuav ua li cas CNC machining pab koj ua tiav qhov zoo dua, ua kom txhua yam zoo thiab ua tau zoo dua.

Ntsiab Cai

- CNC machining tseem ceeb heevtxhim kho qhov chaw tiavntawm cam khwb cia txhuas qhov chaw, ua tiav smoother tiav ntawm 16 thiab 125 microinches Ra.

- Siv CNC milling thiab xa cov txheej txheemtxhim kho qhov tseebthiab sib xws ntawm cov khoom, kom ntseeg tau nruj tolerances thiab kev ua tau zoo dua.

- Cov txheej txheem zoo tshaj plaws xws li polishing thiab anodizing tsis tsuas yog txhim kho cov tsos, tab sis kuj ua rau kom durability thiab corrosion kuj.

Nto Finish txwv nyob rau hauv Cast Aluminium Tuag Casting

Common Imperfections nyob rau hauv Cast Aluminium

Thaum koj ua hauj lwm nrog cam khwb cia txhuas, koj yuav pom ib co flaws ntawm qhov chaw. Cov kev tsis zoo no tuaj yeem cuam tshuam li cas koj cov khoom saib thiab ua haujlwm. Nov yog qee qhov teeb meem koj tuaj yeem pom:

- Nto finishing plays lub luag hauj lwm lojntev npaum li cas koj feem kav.

- Yog tias qhov ua tiav tsis raug, corrosion kuj poob.

- Qee zaum, ntu tsuas yog tsis zoo li koj xav tau.

Koj tuaj yeem pom ob hom porosity. Gas porosity tshwm sim thaum huab cua lossis hydrogen nkag mus rau hauv cov hlau, tawm hauv qhov me me, puag ncig. Shrinkage porosity qhia tau tias loj dua, khib-zoo li kab noj hniav thaum cov hlau txias thiab shrinks.

Tolerance thiab Consistency Challenges

Koj xav kom koj cov khoom kom haum zoo txhua lub sijhawm. Txheem txhuas tuag casting feem ntau muab rau koj kam rau ua ntawm ± 0.05 hli thiab ± 0.10 hli. Rau cov hauj lwm meej tiag tiag, koj tuaj yeem nqis mus rau ± 0.01 hli. Cov qauv kev lag luam xws li ISO 8062-3 thiab NADCA pab qhia qhov ua tau. Tseem,ntaus cov nruj kam rau uatuaj yeem nyuaj, tshwj xeeb tshaj yog tias koj xav tau cov txiaj ntsig zoo ib yam rau txhua qhov.

Geometric txwv hauv Tuag Casting

Tuag casting ua haujlwm zoo tshaj plaws rau qee yam duab. Yog tias koj xav tau cov ces kaum ntse, qhov tob, lossis cov phab ntsa nyias, koj yuav khiav mus rau qhov teeb meem. Cov txheej txheem txwv qhov nyuaj npaum li cas koj feem tuaj yeem ua tau. Qee zaum, koj yuav tsum hloov koj tus qauv tsim lossis ntxiv cov kauj ruam ntxiv kom tau txais cov yam ntxwv koj xav tau.

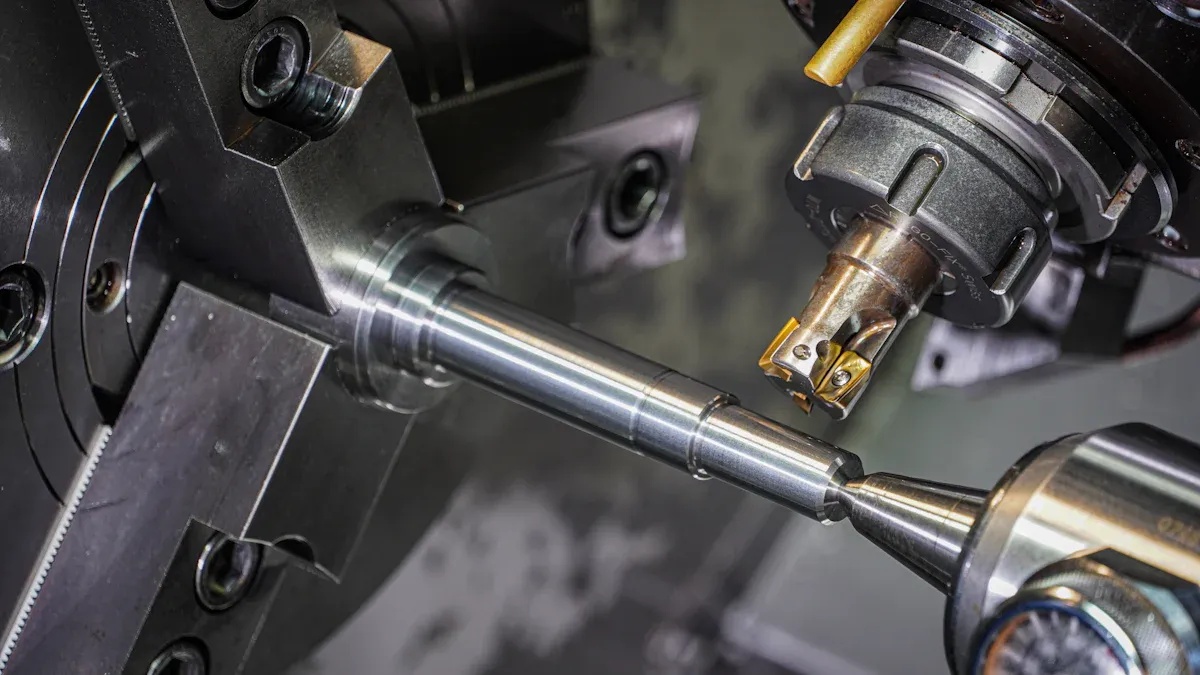

CNC Machining txheej txheem rau Cast Aluminium Enhancement

Milling rau Flatness thiab Smooth nto

Thaum koj xav tau kojcam khwb cia aluminium qhov chawkom saib thiab xav tias du, CNC milling yog koj mus-rau txheej txheem. Cov tshuab milling siv cov cuab yeej ntse, spinning kom chais tawm qhov chaw ntxhib thiab tsim cov tiaj tus, txawm tias qhov chaw. Koj tuaj yeem suav rau CNC milling los kho qhov tsis sib xws thiab xyuas kom koj cov khoom haum ua ke zoo kawg nkaus. Cov txheej txheem no tuaj yeem ncav cuag qhov siab ntev, qee zaum ua raws li ± 0.005 hli. Qhov ntawd txhais tau hais tias koj cov khoom yuav muaj cov tuab tuab thiab du, uas yog qhov tseem ceeb rau cov khoom xws li lub cav npog lossis lub tshuab brackets.

Flatness yog qhov loj. Nws qhia koj li cas du thiab txawm tias ib qho chaw. Yog tias koj xav tau ob ntu kom haum ua ke yam tsis muaj qhov khoob, koj xav kom ob qho tib si tiaj tus li sai tau. CNC milling pab koj mus txog qhov ntawd los ntawm kev tshem tawm cov pob thiab dips sab laug ntawm casting. MIC-6 aluminium, piv txwv li, muaj cov qauv tshwj xeeb uas ua rau nws yooj yim dua kom ua tiav lub tiaj tiaj thaum koj tshuab nws.

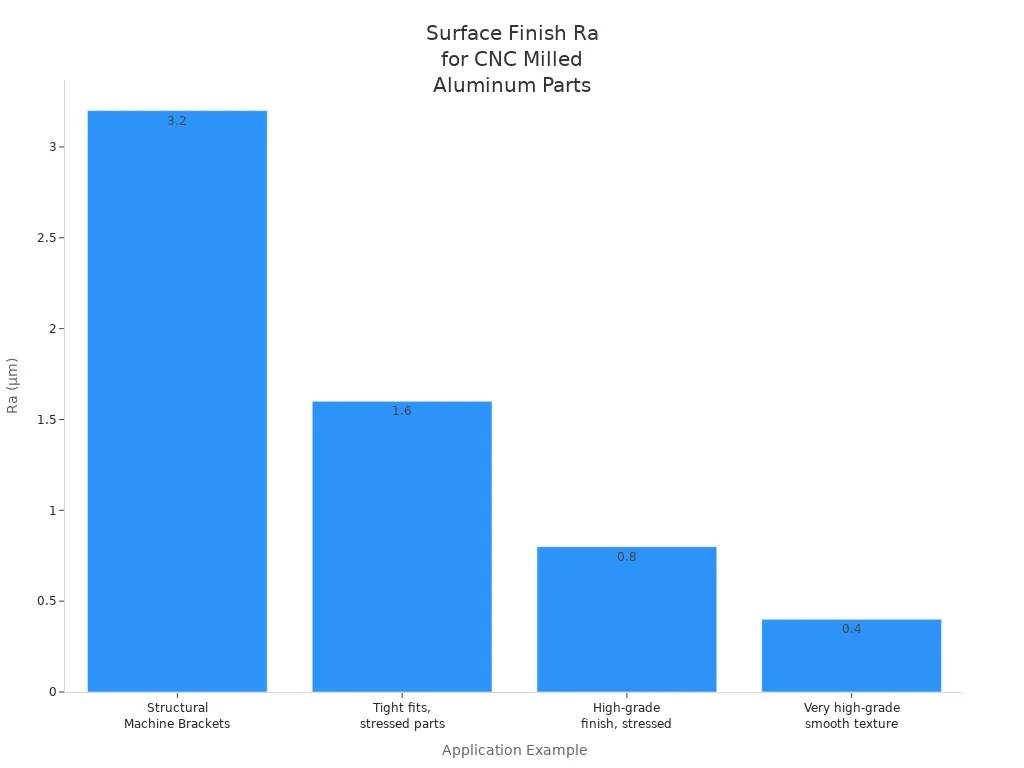

Koj tuaj yeem xaiv ntau theem ntawm qhov chaw tiav, nyob ntawm seb koj xav tau dab tsi. Nov yog kev saib sai ntawm qhov ua tau:

| Rau (µm) | Piv txwv daim ntawv thov | Cov yam ntxwv tseem ceeb |

|---|---|---|

| 3.2 | Cov qauv siv tshuab brackets, Automotive cav npog, General Tooling Fixtures, Tshuab Chassis | Kev siv ua haujlwm, kev ntxhov siab me ntsis |

| 1.6 | Tight fits, qhov chaw nyob rau hauv kev ntxhov siab | Me ntsis pom cov cim txiav, nce nqi ntau lawm los ntawm 2.5% |

| 0.8 ua | High-qib tiav rau qhov nyuaj siab | Yuav tsum tau ua tiav tiav, ntxiv 5% rau cov nqi tsim khoom |

| 0.4 | High-qib smooth kev ntxhib los mos | Tsis muaj cov cim txiav uas pom tau, ntxiv txog 15% rau cov nqi tsim khoom |

Yog tias koj xav tau ib feem uas zoo nkaus li zoo thiab ua haujlwm zoo, CNC milling muab rau koj tswj kom tau qhov koj xav tau.

Tig rau Cylindrical raug

CNC tig yog txoj hauv kev zoo tshaj plaws los ua ib puag ncig lossis cylindrical qhov chaw los ntawm cam khwb cia txhuas. Lub tshuab tig koj ntu thaum lub cuab yeej txiav nws. Cov txheej txheem no zoo meej rau kev ua tej yam xws li shafts, bushings, lossis ib feem uas yuav tsum tau ua kom zoo kawg nkaus.

Koj tau txais qhov tseeb qhov tseeb nrog CNC tig. Lub tshuab muaj peev xwm tuav tau nruj raws li ± 0.0001 nti (2.54 microns). Qhov ntawd txhais tau tias txhua qhov koj ua yuav luag zoo ib yam. Koj tsis tas yuav txhawj xeeb txog kev ua yuam kev los ntawm tib neeg txhais tes, vim tias lub computer tswj txhua yam. Qhov no yog qhov loj rau kev lag luam xws li tsheb thiab aerospace, qhov twg txawm tias me me yuam kev tuaj yeem ua teeb meem.

Nov yog qhov sib piv ceev:

| Feature | CNC tig | Ib txwm tig |

|---|---|---|

| Ua siab ntev | ± 0.0001 nti (2.54 microns) | Feem ntau looser tolerances |

| Rov ua dua | High, zoo ib yam | Variable, nquag rau tib neeg yuam kev |

| Nto tiav | Superior, feem ntau tsis muaj theem nrab | Tej zaum yuav xav tau kev ua tiav ntxiv |

| Tib neeg yuam kev | Txo | Muaj kev pheej hmoo siab dua |

Nrog CNC tig, koj tau txais kev sib tw, raug, thiab rov ua dua txhua zaus.

Polishing thiab Advanced Finishing Methods

Tom qab milling los yog tig, koj yuav xav kom koj cov cam khwb cia txhuas qhov chaw kom zoo dua. Qhov ntawd yog qhov uas polishing thiab kev ua tiav qib siab tuaj rau hauv. Cov txheej txheem no tuaj yeem ua rau koj qhov chaw ci ntsa iab, du, lossis muab qhov tshwj xeeb zoo nkauj rau lawv.

Nov yog qee qhov kev xaiv ua tiav nrov:

- Mechanical polishing:Cov tshuab zom thiab txhuam qhov saum npoo kom tshem tawm cov pob me me thiab burrs.

- Tshuaj polishing:Cov tshuaj ua kom du nto los ntawm kev tshem tawm cov oxide txheej.

- Electrochemical polishing:Siv hluav taws xob thiab tshuaj lom neeg rau kev ua tiav zoo heev.

- Precision mechanical polishing:Ntau cov kauj ruam nrog cov cuab yeej ua haujlwm siab kom ua kom du ntxiv.

- Ultra-precision polishing:Advanced thev naus laus zis zoo li lasers lossis ion beams rau qhov ua tiav zoo tshaj plaws.

- Nto passivation:Restores corrosion kuj tom qab polishing, feem ntau siv anodizing.

Koj tuaj yeem siv txoj hauv kev zoo li vibratory xov thiab tua blasting. Vibratory finishing muab koj cov khoom nyob rau hauv ib lub tais nrog tshwj xeeb xov xwm uas maj mam polishes thiab deburrs lawv. Kev txhaj tshuaj blasting siv cov khoom siv ceev ceev los tsim kom muaj qhov sib xws, matte nto. Cov tswv yim no pab npaj koj qhov chaw rau txheej txheej lossis tsuas yog ua kom lawv zoo nkauj.

Yog tias koj xav ntxiv xim lossis kev tiv thaiv ntxiv, koj tuaj yeem sim:

- Anodizing:Ntxiv cov tawv tawv, xim txheej uas tiv taus hnav thiab corrosion.

- Hmoov txheej:Muab ib tug muaj zog, txawm tag nyob rau hauv yuav luag txhua yam xim.

- Sandblasting:Tsim kom pom matte zoo thiab npaj rau saum npoo kom tiav ntau dua.

Mechanical thiab chemical finishes txhua tus muaj lawv tus kheej saib thiab cov txiaj ntsig. Nov yog phau ntawv qhia ceev:

| Mechanical tiav | Nto Zoo | Txoj kev thov | Siv dav |

|---|---|---|---|

| txhuam hniav | Directional, satin tiav | Abrasive txhuam / pads | Architectural tsim |

| Polishing | Smooth, reflective | Progressive abrasives | Kho kom zoo nkauj thiab tiv thaiv daim ntaub ntawv |

| Blast tiav | Uniform matte | High-velocity hais | Kev kho mob ua ntej rau coatings |

Kho qhov Casting Defects nrog CNC Machining

Qee zaum, cam khwb cia txhuas qhov chaw tuaj tawm ntawm cov pwm nrog qhov tsis zoo me me.CNC machining tuaj yeem khontau qhov teeb meem no, yog li koj tsis tas yuav pov tseg ib feem.

Cov kev tsis zoo tshaj plaws uas koj tuaj yeem kho tau suav nrog:

- Porosity:Cov qhov me me los yog cov hnab tshos tshwm sim los ntawm cov pa roj. CNC machining tuaj yeem tshem tawm cov no los ntawm qhov chaw, ua rau qhov muaj zog thiab tsis muaj pov thawj.

- Cov yam ntxwv tsis xws luag:Teeb meem xws li misaligned nta lossis cov npoo ntxhib. CNC tshuab tuaj yeem txiav thiab kho cov chaw no kom haum zoo.

| Casting Defect | Kev piav qhia |

|---|---|

| Porosity | Muaj tshwm sim thaum gas entrapment tsim hnab ris los yog pits, ua rau kom xau. |

| Cov duab tsis zoo | Tawm los ntawm misalignment los yog distortion, ua rau cov yam ntxwv tsis tiav. |

Los ntawm kev siv CNC machining, koj tuaj yeem tig qhov tsis zoo cam khwb cia txhuas rau hauv cov khoom zoo uas ua tau raws li koj cov kev xav tau.

Cov txiaj ntsig ntawm CNC Machining rau Cast Aluminium Parts

Txhim kho qhov tshwm sim thiab pom qhov zoo

Koj xav kom koj cov khoom zoo li ntse thiab kev tshaj lij. CNC machining pab koj ua tiav qhov ntawd. Nrog cov txheej txheem tiav tiav, koj tuaj yeem xaiv qhov zoo meej uas koj xav tau rau koj cov khoom siv aluminium. Tshawb xyuas qee qhov kev xaiv nrov:

| Cov txheej txheem | Kev piav qhia | Cov txiaj ntsig |

|---|---|---|

| Bead Blasting | Siv cov xov xwm abrasive rau matte tiav | Tshem tawm cov cuab yeej cim, txhim kho xim adhesion, du zoo |

| Hmoov Txheej | Siv cov hmoov polymer thiab kho nrog cua sov | Zoo corrosion kuj, muaj zog adhesion, ntau tiav |

| Daim iav Polishing | Precision finishing rau ib ci iab, reflective nto | Txo kev sib txhuam, boosts corrosion kuj, optical clarity |

| Txhuam txhuam | Tsim ib qho qauv zoo ib yam | Kev ntxhib los mos tshwj xeeb, ua kom qhov ntev ruaj khov |

| Anodizing | Tsim cov oxide txheej ntawm aluminium | Ntau dua corrosion kuj, nyuaj nto, xim xaiv |

Cov txheej txheem no ua rau koj qhov chaw sawv ntsug thiab kav ntev dua.

Txhim kho haum, muaj nuj nqi, thiab kev ua tau zoo

Koj xav tau koj cov khoom kom haum ua ke zoo kawg nkaus. CNC machining muab nruj kam rau ua thiab haum haum, uas txhais tau hais tias tsawg dua kev sib dhos teeb meem thiab kev ua tau zoo dua. Nov yog yuav ua li cas CNC machining pab:

| Kev koom tes ntawm CNC Machining | Kev piav qhia |

|---|---|

| Tight Tolerances | Cov khoom ua tau raws li qhov ntsuas qhov tseeb rau kev sib dhos du |

| Precise Fits | Cheebtsam haum seamlessly, txo qhov yuam kev |

| High-Precision CAD Modeling | Xyuas kom koj tus qauv tsim yog cov khoom kawg |

Thaum koj cov khoom haum zoo, koj cov tshuab ua haujlwm zoo dua thiab kav ntev dua.

Ntxiv Durability thiab Service Life

Koj xav kom koj cov cam khwb cia txhuas qhov chaw los tuav cov haujlwm nyuaj thiab ua haujlwm. CNC machining pab los ntawm kev tswj cov cua sov, cuab yeej hnav, thiab machining tsis. Qhov no ua rau koj qhov chaw muaj zog thiab txhim khu kev qha. Nov yog qee txoj hauv kev CNC machining boosts durability:

- Siv cov kua txiav los tswj cov cua sov thiab tiv thaiv qhov chaw

- Ua kom muaj kev kub ceev nrog kev txias kom zoo

- Kho qhov chaw machining los tiv thaiv warping lossis distortion

Tswv yim: Thaum koj siv CNC machining, koj tau txais qhov chaw uas kav ntev dua thiab ua tau zoo dua, txawm nyob rau hauv qhov xav tau ib puag ncig.

CNC machining muab koj smoother, txhim khu kev qha cam khwb cia txhuas qhov chaw. Koj tau txais kev saib zoo dua, nruj dua, thiab cov khoom siv ntev dua. Ntau qhov kev lag luam vam khom rau cov txheej txheem no:

| Kev lag luam | Yog vim li cas siv |

|---|---|

| Automotive | Lub teeb yuag, ruaj khov cav thiab chassis qhov chaw |

| Aerospace | Siab zog-rau-hnyav piv rau aircraft |

| Kev tsim kho | Corrosion tsis kam rau cov qauv |

| Tubrog nkoj | Lub teeb, corrosion-resistant Cheebtsam |

| Electronics | Precision qhov chaw rau cov khoom siv |

| Cov khoom siv | Kev siv ntau yam hauv ntau cov khoom |

| Khoom siv kho mob | Non-toxic, yooj yim-rau-sterilize seev |

Kev nqis peev hauv CNC ua tiav pab koj ua tau raws li cov qauv siab tshaj plaws txhua lub sijhawm.

FAQ

Dab tsi saum npoo tiav koj tuaj yeem xav tau tom qab CNC machining cam khwb cia txhuas?

Koj feem ntau tau txais kev ua tiav ntawm 16 thiab 125 microinches Ra. CNC machining tshem tawm cov chaw ntxhib thiab tawm ntawm koj qhov chaw saib polished.

Tswv yim: Koj tuaj yeem xaiv qhov ua tiav tiav rau cov haujlwm tshwj xeeb.

Puas yog CNC machining txhim kho lub zog ntawm cam khwb cia txhuas qhov chaw?

Yog, koj tau txais cov khoom muaj zog. CNC machining tshem tawm cov chaw tsis muaj zog thiab qhov tsis xws luag, yog li koj cov khoom siv tau ntev dua thiab ua tau zoo dua.

Koj puas tuaj yeem ua ke CNC machining nrog lwm txoj kev ua tiav?

kiag li! Koj tuaj yeem siv CNC machining ua ntej, tom qab ntawd ntxiv anodizing, hmoov txheej, lossis polishing. Qhov no muab koj tus kheej saib thiab kev tiv thaiv ntxiv.

| Txoj kev ua tiav | Cov txiaj ntsig |

|---|---|

| Anodizing | Corrosion kuj |

| Hmoov Txheej | Xim xaiv |

| Polishing | ci ntsa iab |

Post lub sij hawm: Sep-03-2025