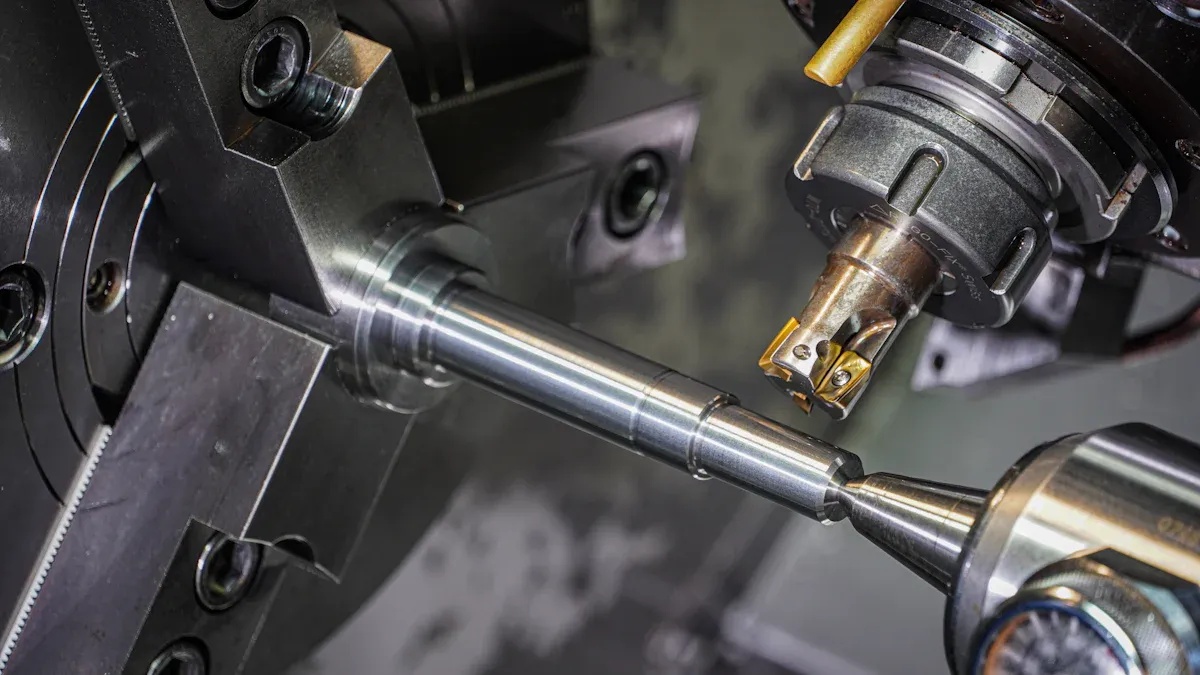

Paunotarisa zvikamu zvealuminium zvakakandwa zvinoshandiswa mukatimotokari or telecommunicationmaindasitiri, iwe unoda kupera kwakatsetseka, kusina mhosva. CNC machining inokupa iyo muganho. Zvinotora rough, as-cast surfaces uye inoita kuti ive yakapfava uye chaiyo. Ingotarisa mutsauko:

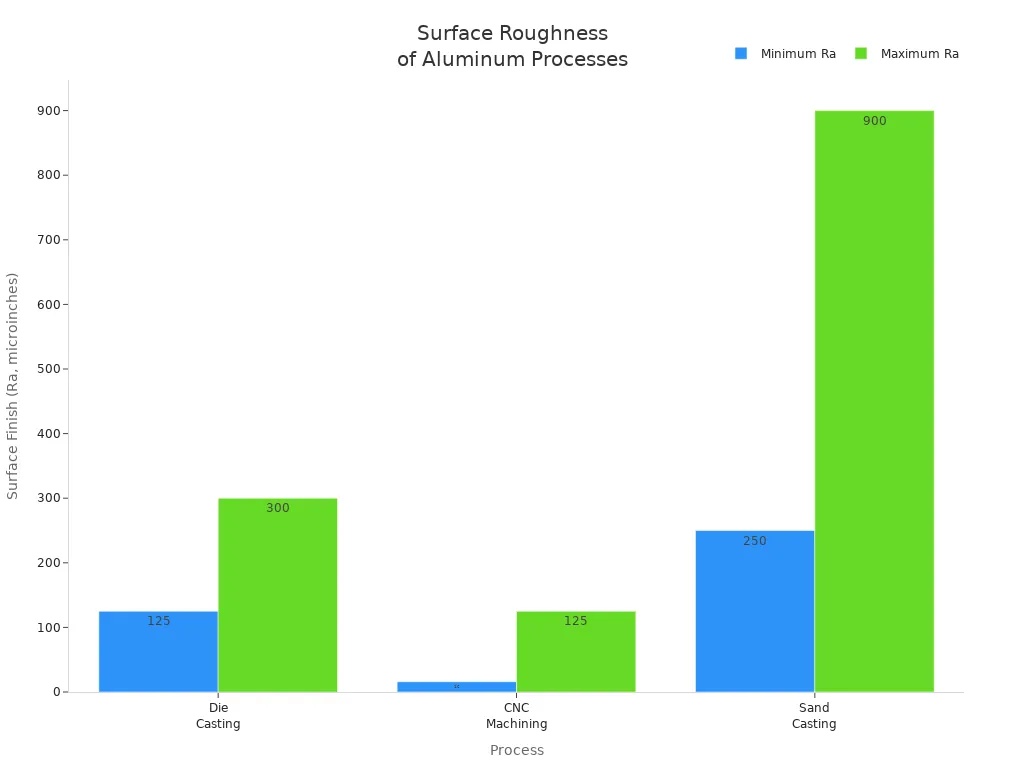

| Process | Typical Surface Finish (Ra) |

|---|---|

| Die Casting | 125-300 microinches |

| CNC Machining | 16-125 microinches |

| Sand Casting | 250-900 microinches |

Iwe unogona kuona kuti CNC machining inokubatsira sei kuti uwane kupedzisa kwakanyatsonaka, uchiita kuti chikamu chose chitaridzike uye chiite zvirinani.

Key Takeaways

- CNC machining zvakanyanyainovandudza kupera kwepamusoroyeakakandirwa aruminiyamu zvikamu, kuwana akatsetseka kupera pakati pe16 ne125 microinches Ra.

- Kushandisa CNC milling uye kutendeuka maitirokunowedzera chokwadiuye kuenderana kwezvikamu, kuve nechokwadi kushivirira kwakasimba uye kuita kuri nani.

- Maitiro ekupedzisa epamberi senge polishing uye anodizing haingonatsiridza chitarisiko chete asi zvakare inowedzera kusimba uye kusakara.

Surface Pedzisa Kugumira muCast Aluminium Die Casting

Zvakajairwa Kusakwana muCast Aluminium

Paunenge uchishanda ne cast aluminium, unogona kuona kumwe kukanganisa pamusoro. Kusakwana uku kunogona kukanganisa matarisiro nekuita nhengo dzako. Heano mamwe mashoma aunogona kuona:

- Kupedzisa kwepamusoro kunoita basa gurukwenguva yakareba sei chikamu chako chinotora.

- Kana kupera kusina kunaka, corrosion resistance inodonha.

- Dzimwe nguva, chikamu chacho hachitaridziki zvakanaka sezvaunoda.

Iwe unogona zvakare kuona maviri marudzi e porosity. Gasi porosity inoitika kana mweya kana hydrogen yabatwa musimbi, ichisiya maburi madiki, akatenderera. Shrinkage porosity inoratidzika semakomba makuru, asinganzwisisike apo simbi inotonhora uye inoderera.

Kushivirira uye Kusagadzikana Matambudziko

Iwe unoda kuti zvikamu zvako zvikwane zvakakwana nguva dzese. Standard aluminum die casting kazhinji inokupa kushivirira pakati pe ± 0.05 mm uye ± 0.10 mm. Kune mabasa chaiwo, unogona kudzika kusvika ± 0.01 mm. Maindasitiri zviyero se ISO 8062-3 uye NADCA anobatsira kutungamira izvo zvinogoneka. Zvakadaro,kurova zviya zvekushingirirainogona kuoma, kunyanya kana iwe uchida mibairo yakafanana kune yega yega chikamu.

Geometric Restrictions mu Die Casting

Die casting inoshanda zvakanyanya kune mamwe maumbirwo. Kana uchida makona akapinza, makomba akadzika, kana madziro matete, unogona kupinda mudambudziko. Maitiro acho anoganhura kuti chikamu chako chingave chakaoma sei. Dzimwe nguva, iwe unofanirwa kushandura dhizaini yako kana kuwedzera mamwe matanho kuti uwane maficha aunoda.

CNC Machining Matanho eCast Aluminium Enhancement

Kugaya kweFlatness uye Smooth Surfaces

Paunoda yakozvikamu zvealuminiumkuti utarise uye unzwe wakatsetseka, CNC milling ndiko kuenda kwako-kuita maitiro. Michina yekugaya inoshandisa yakapinza, yekuruka maturusi ekuveura nzvimbo dzakakasharara uye kugadzira sandara, kunyangwe nzvimbo. Iwe unogona kuvimba neCNC milling kugadzirisa nzvimbo dzisina kuenzana uye ita shuwa kuti zvikamu zvako zvinokwana pamwechete zvakakwana. Iyi nzira inogona kusvika kushivirira kwakasimba, dzimwe nguva senge ± 0.005 mm. Izvi zvinoreva kuti zvikamu zvako zvichave neukobvu hunoenderana uye kutsvedzerera, izvo zvakakosha kune zvinhu zvakaita semavhavha einjini kana mabhureki emuchina.

Kufuratira chinhu chikuru. Inokuudza kuti wakatsetseka sei uye kunyange nepamusoro. Kana iwe uchida zvikamu zviviri kuti zvikwane pamwe chete pasina mapeji, unoda kuti zvose zvive zvakatsetseka sezvinobvira. CNC milling inokubatsira kuti usvike ipapo nekubvisa mabumps uye dips kubva pakukanda. MIC-6 aluminium, semuenzaniso, ine yakakosha zviyo chimiro chinoita kuti zvive nyore kuwana super-flat kupedzisa kana uchinge waigadzira.

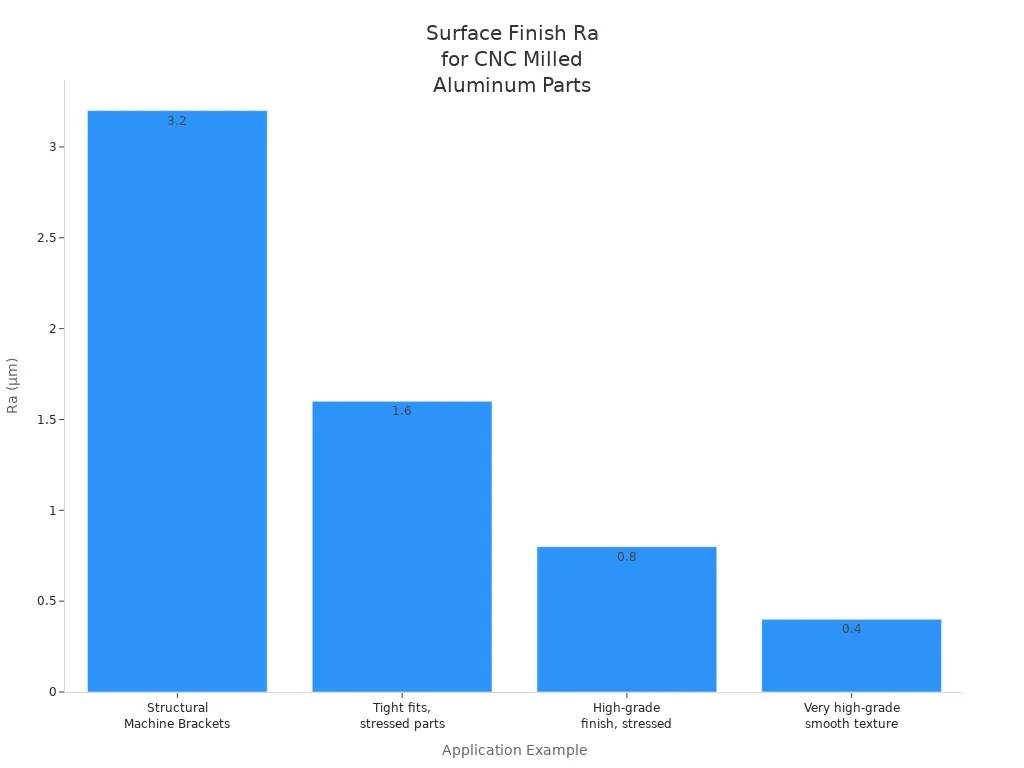

Iwe unogona kusarudza mazinga akasiyana ekupedzisa kwepamusoro, zvichienderana nekuti chikamu chako chinoda chii. Heino kutarisa nekukurumidza kune izvo zvinogoneka:

| Ra (µm) | Mienzaniso Yekushandisa | Hunhu Hunokosha |

|---|---|---|

| 3.2 | Structural Machine Brackets, Mavhavha Enjini Yemotokari, General Tooling Fixtures, Machine Chassis | Kushanda kushandiswa, kushushikana kuri pakati nepakati |

| 1.6 | Yakasimba inokwana, zvikamu pasi pekunetseka | Zvishoma zvinooneka kucheka mamaki, yakawedzera mutengo wekugadzira ne2.5% |

| 0.8 | High-giredhi kupera kwezvikamu zvakasimbiswa | Inoda kupedzisa kupasa, inowedzera 5% kumutengo wekugadzira |

| 0.4 | Yakanyanya yepamusoro-giredhi yakatsetseka maitiro | Hapana anocherechedzwa akachekwa mamaki, anowedzera kusvika ku15% kumutengo wekugadzira |

Kana iwe uchida chikamu chinotaridzika zvakanaka uye chinoshanda nemazvo, CNC milling inokupa iwe kutonga kuti uwane kupedzisa kwaunoda.

Kushandura kuCylindrical Accuracy

CNC kutendeuka ndiyo yakanakisa nzira yekugadzira yakatenderera kana cylindrical zvikamu kubva pakakanda aluminium. Muchina wacho unotenderedza chikamu chako apo chishandiso chekucheka chinochiumba. Iyi nzira yakanakira kugadzira zvinhu senge shafts, bushings, kana chero chikamu chinoda kunyatso kutenderera.

Iwe unowana kunoshamisa kurongeka neCNC kutendeuka. Muchina uyu unogona kubata kushivirira kwakasimba se ± 0.0001 inches (2.54 microns). Izvi zvinoreva kuti chikamu chese chaunogadzira chinenge chakangofanana. Iwe haufanirwe kunetseka nezvekukanganisa kubva mumaoko emunhu, nekuti komputa inodzora zvese. Ichi chinhu chikuru kune maindasitiri akaita semotokari uye aerospace, uko kunyangwe zvikanganiso zvidiki zvinogona kukonzera matambudziko.

Heino kuenzanisa nekukurumidza:

| Feature | CNC Turning | Traditional Turning |

|---|---|---|

| Kushivirira | ± 0.0001 inches (2.54 microns) | Kazhinji looser tolerances |

| Kudzokorora | Hunhu hwepamusoro, hunoenderana | Zvinosiyana, zvinowanzoitika kukanganisa kwevanhu |

| Surface Finish | Superior, kazhinji kwete yechipiri | Inogona kuda kuwedzera kupedzisa |

| Kukanganisa Kwevanhu | Yakaderedzwa | Dambudziko repamusoro rekukanganisa |

Ne CNC kutendeuka, iwe unowana yakatsetseka, yakarurama, uye inodzokororwa mhedzisiro nguva dzese.

Kukwenenzvera uye Nepamusoro Kupedzisa Nzira

Mushure mekugaya kana kutendeuka, ungangoda kuti zvikamu zvealuminium zvakakandwa zvitaridzike zvirinani. Ndipo panouya kukwenenzverwa nekupedzwa kwepamusoro. Nzira idzi dzinogona kuita kuti nhengo dzako dzipenye, dzitsvedzerere, kana kuti dzipe chimiro chakakosha.

Heano mamwe akakurumbira ekupedzisa sarudzo:

- Mechanical polishing:Michina inokuya nekukwenenzvera pamusoro kuti ibvise tumapundu tudiki.

- Kemikari polishing:Makemikari anotsvedzerera pamusoro nekubvisa iyo oxide layer.

- Electrochemical polishing:Inoshandisa magetsi nemakemikari kune super-yakapfava kupera.

- Precision mechanical polishing:Matanho akawanda ane yakakwirira-chaiyo maturusi ekuwedzera kutsvedzerera.

- Ultra-precision polishing:Yepamberi tekinoroji senge lasers kana ion matanda kune yakatsetseka kupera inogoneka.

- Surface passivation:Inodzoreredza kusagadzikana kwekuora mushure mekupukuta, kazhinji uchishandisa anodizing.

Iwe unogona zvakare kushandisa nzira senge vibratory kupedzisa uye kupfura kuputika. Vibratory kupedzisa kunoisa zvikamu zvako mundiro ine yakakosha midhiya inopenya zvinyoro nyoro nekuibvisa. Shot blasting inoshandisa high-speed particles kugadzira yunifomu, matte pamusoro. Aya maitiro anobatsira kugadzirira zvikamu zvako zvekupfeka kana kungoita kuti zvitaridzike zvakanaka.

Kana iwe uchida kuwedzera ruvara kana imwe dziviriro, unogona kuedza:

- Anodizing:Inowedzera yakaoma, ine ruvara runyoro inoramba kusakara nekuora.

- Powder coating:Inopa yakasimba, kunyange kupedzisa munenge chero ruvara.

- Sandblasting:Inogadzira chitarisiko che matte uye inogadzirira pasi kuti iwedzere kupedzisa.

Mechanical uye makemikari anopedzisa chimwe nechimwe chine chitarisiko chavo uye mabhenefiti. Heino gwara rekukurumidza:

| Mechanical Finish | Surface Kuonekwa | Maitiro Okushandisa | Common Use |

|---|---|---|---|

| Kukwesha | Directional, satin kupera | Abrasive brushes/pads | Architectural designs |

| Kupukuta | Smooth, inofungisisa | Progressive abrasives | Kushongedza uye kudzivirira zvikumbiro |

| Blast finishing | Uniform matte | High-velocity particles | Pre-kurapwa kwemajasi |

Kugadzirisa Kukanganisa Kukandira neCNC Machining

Dzimwe nguva, zvikamu zvealuminium zvakakandwa zvinobuda muforoma zvine zvikanganiso zvidiki.CNC machining inogona kugadzirisadzakawanda dzenyaya idzi, saka haufanirwe kurasa chikamu.

Izvo zvinonyanya kukanganisa zvaunogona kugadzirisa zvinosanganisira:

- Porosity:Makomba madiki kana homwe zvinokonzerwa negasi rakavharirwa. CNC machining inogona kubvisa izvi kubva pamusoro, zvichiita kuti chikamu chacho chive chakasimba uye chinodonhedza-chiratidzo.

- Shape defects:Matambudziko akaita seasina kurongeka zvimiro kana mipendero yakaoma. CNC michina inogona kucheka uye kuumbazve nzvimbo idzi kuti dzikwane.

| Kukandira Kukanganisa | Tsanangudzo |

|---|---|

| Porosity | Zvinoitika kana gasi rakanyura richigadzira homwe kana makomba, zvichiita kuti pave nekudonha. |

| Shape Defects | Simuka kubva mukusarongeka kana kukanganisa, zvichikonzera kusakwana kwezvinhu. |

Nekushandisa CNC machining, unogona kushandura chakakanganisika chakakandwa aruminiyamu chikamu kuita chemhando yepamusoro chikamu chinosangana nezvido zvako chaizvo.

Mabhenefiti eCNC Machining yeCast Aluminium Parts

Chitarisiko Chakawedzerwa uye Hunhu Hwekuonekwa

Iwe unoda kuti nhengo dzako dzitaridzike dzakapinza uye nyanzvi. CNC machining inokubatsira kuti uite izvozvo. Nemaitiro epamusoro ekupedzisa, unogona kusarudza iyo chaiyo yekutarisa yaunoda kune yako cast aluminium zvikamu. Tarisa dzimwe sarudzo dzakakurumbira:

| Technique | Tsanangudzo | Benefits |

|---|---|---|

| Bead Blasting | Inoshandisa abrasive media kupedzisa matte | Inobvisa mamaki ezvishandiso, inonatsiridza kunamatira kwepende, kunzwa kwakatsetseka |

| Powder Coating | Isa polima poda uye inorapa nekupisa | Great corrosion resistance, kunamatira kwakasimba, akawanda anopera |

| Mirror Polishing | Kunyatso kupedzisa kwenzvimbo inopenya, inopenya | Inoderedza kukweshera, inowedzera corrosion resistance, optical clarity |

| Brushed Finishing | Inogadzira yunifomu yezviyo pateni | Unique texture, inochengeta zviyero zvakagadzikana |

| Anodizing | Inovaka iyo oxide layer paaluminium | Kuwedzera corrosion kuramba, kuoma kwepamusoro, sarudzo dzemavara |

Idzi nzira dzinoita kuti zvikamu zvako zvioneke uye zvinogara kwenguva refu.

Yakavandudzwa Kukwana, Basa, uye Kuita

Unoda zvikamu zvako kuti zvienderane zvakakwana. CNC machining inopa kushivirira kwakasimba uye kuenderana chaiko, zvinoreva mashoma matambudziko egungano uye kuita zvirinani. Heano maitiro eCNC machining anobatsira:

| Mupiro weCNC Machining | Tsanangudzo |

|---|---|

| Tight Tolerances | Zvikamu zvinosangana kuyerwa chaiko kwekusangana kwakatsetseka |

| Precise Inokodzera | Zvikamu zvinokwana zvisina musono, zvichideredza zvikanganiso |

| High-Precision CAD Modelling | Ita shuwa kuti dhizaini yako inoenderana nechigadzirwa chekupedzisira |

Kana zvikamu zvako zvakwana, michina yako inoshanda zvirinani uye inogara kwenguva refu.

Kuwedzera Kusimba uye Hupenyu Hwebasa

Iwe unoda kuti zvikamu zvealuminium zvakakandwa zvibate mabasa akaoma uye urambe uchishanda. CNC machining inobatsira nekudzora kupisa, kupfeka chishandiso, uye machining paramita. Izvi zvinoita kuti nhengo dzako dzirambe dzakasimba uye dzakavimbika. Heano dzimwe nzira dzeCNC machining dzinowedzera kusimba:

- Inoshandisa mvura yekucheka kugadzirisa kupisa uye kudzivirira nzvimbo

- Inochengetedza kumhanya kwekucheka kwakanyanya nekutonhora kwakakodzera

- Inogadzirisa marongero emuchina kudzivirira warping kana kukanganisa

Zano: Paunoshandisa CNC machining, unowana zvikamu zvinogara kwenguva refu uye kuita zvirinani, kunyangwe munzvimbo dzinodiwa.

CNC machining inokupa yakapfava, yakavimbika yakakanda aluminium zvikamu. Iwe unowana kutaridzika kuri nani, kusimba kwakasimba, uye zvinhu zvinogara kwenguva refu. Maindasitiri mazhinji anovimba nemaitiro aya:

| Indasitiri | Chikonzero Chokushandisa |

|---|---|

| Automotive | Yakareruka, yakasimba injini uye chassis zvikamu |

| Aerospace | High simba-ku-kurema reshiyo nokuda ndege |

| Kuvaka | Corrosion resistance yezvivakwa |

| Marine | Zvikamu zvisingaremi, zvisingadziviriri |

| Electronics | Precision zvikamu zvemidziyo |

| Consumer Goods | Kushandiswa kwakasiyana-siyana muzvigadzirwa zvakawanda |

| Midziyo Yezvokurapa | Zvishandiso zvisina muchetura, zviri nyore kuuraya simbi |

Kudyara muCNC kupedzisa kunobatsira kuti usangane neakanyanya mwero nguva dzese.

FAQ

Ndeipi kupera kwepamusoro kwaungatarisira mushure meCNC machining cast aluminium?

Iwe kazhinji unowana kupera kwakatsetseka pakati pe16 ne125 microinches Ra. CNC machining inobvisa rough spots uye inosiya nhengo dzako dzichiita kunge dzakakwenenzverwa.

Zano: Unogona kusarudza anopedzisa mapurojekiti akakosha.

Ko CNC machining inovandudza simba reakakanda aluminium zvikamu?

Hongu, unowana zvikamu zvakasimba. CNC machining inobvisa nzvimbo dzisina simba uye hurema, saka zvikamu zvako zvinogara kwenguva refu uye kuita zvirinani.

Unogona here kusanganisa CNC machining nedzimwe nzira dzekupedzisa?

Ndizvozvo! Unogona kushandisa CNC machining kutanga, wobva wawedzera anodizing, poda coating, kana polishing. Izvi zvinokupa chitarisiko chetsika uye kuchengetedzwa kwakawedzerwa.

| Kupedzisa Nzira | Benefit |

|---|---|

| Anodizing | Corrosion resistance |

| Powder Coating | Zvisarudzo zvemavara |

| Kupukuta | Shiny pamusoro |

Nguva yekutumira: Sep-03-2025