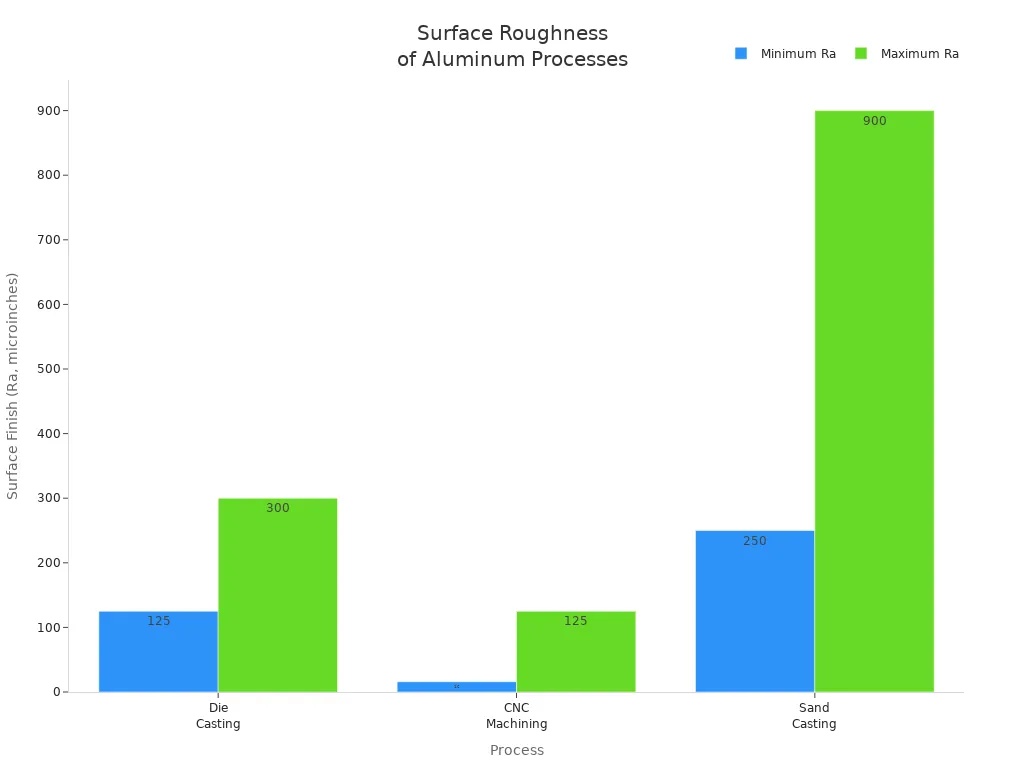

Xa ujonga iindawo ezisetyenzisiweyo ze-aluminiumimoto or uthungelwano ngomnxebakumashishini, ufuna isiphelo esigudileyo, esingenasiphako. CNC machining ikunika ukuba edge. Kuthatha umphezulu orhabaxa, njengoko uphoswe kwaye ubenze bubenethe kwaye bachaneke. Jonga nje umahluko:

| Inkqubo | Ukugqitywa komphezulu oqhelekileyo (Ra) |

|---|---|

| Die Casting | 125-300 microintshi |

| CNC Machining | 16-125 microintshi |

| Isanti yokuphosa | 250-900 microintshi |

Uyakwazi ukubona indlela iCNC Machining ikunceda ngayo ukuba ufikelele kwisiphelo esigqwesileyo, esenza ukuba yonke into ibonakale kwaye isebenze ngcono.

Izinto eziphambili zokuThatha

- CNC machining kakhuluiphucula ukugqitywa komphezuluyamacandelo aluminiyam ephosiweyo, ukuphumeza ukugqiba agudileyo phakathi 16 kunye 125 microinches Ra.

- Ukusebenzisa i-CNC yokugaya kunye neenkqubo zokujikakwandisa ukuchanekakunye nokuhambelana kwamalungu, ukuqinisekisa ukunyamezelana okuqinileyo kunye nokusebenza okungcono.

- Iindlela zokugqibezela ezikumgangatho ophezulu ezifana nokupholisha kunye ne-anodizing ayiphuculi nje inkangeleko kodwa ikwanyusa ukuqina kunye nokumelana nomhlwa.

Umphezulu wokuGqibela imida kwiCast Aluminium Die Casting

Ukungafezeki okuqhelekileyo kwi-Cast Aluminium

Xa usebenza nge-aluminium ephosiweyo, unokuqaphela iimpazamo kumphezulu. Oku kungafezeki kunokuchaphazela indlela amalungu akho abukeka ngayo kwaye asebenza ngayo. Nantsi imiba embalwa onokuyibona:

- Ukugqitywa komphezulu kudlala indima enkuluixesha elingakanani inxalenye yakho.

- Ukuba ukugqiba akulungile, ukuxhathisa ukubola kuyehla.

- Ngamanye amaxesha, inxalenye ayibonakali ilungile njengoko ufuna.

Unokubona kwakhona iindidi ezimbini ze-porosity. Irhasi porosity yenzeka xa umoya okanye ihydrogen ivaleleke kwintsimbi, ishiya imingxunya emincinci engqukuva. I-shrinkage porosity ibonakala njengemingxuma emikhulu, emile okwenqaba xa intsimbi iphola kwaye iyancipha.

Unyamezelo kunye neMingeni engaguqukiyo

Ufuna iindawo zakho zilingane ngokugqibeleleyo ngalo lonke ixesha. Standard aluminiyam die casting ngokuqhelekileyo kukunika tolerances phakathi ± 0.05 mm kunye ± 0.10 mm. Ngemisebenzi echanekileyo ngenene, ungehla uye ku-±0.01 mm. Imigangatho yoshishino efana ne-ISO 8062-3 kunye ne-NADCA inceda ukukhokela oko kunokwenzeka. Sekunjalo,ukubetha ezo zinyamezelo eziqinileyokunokuba nzima, ngakumbi ukuba ufuna iziphumo ezifanayo kuzo zonke iindawo.

Izithintelo zeJometri kwiDie Casting

I-Die casting isebenza ngcono kwiimilo ezithile. Ukuba ufuna iikona ezibukhali, imingxuma enzulu, okanye iindonga ezibhityileyo, ungangena engxakini. Inkqubo iyanciphisa indlela enokubanzima ngayo inxalenye yakho. Ngamanye amaxesha, kufuneka utshintshe uyilo lwakho okanye wongeze amanyathelo ongezelelweyo ukufumana iimpawu ozifunayo.

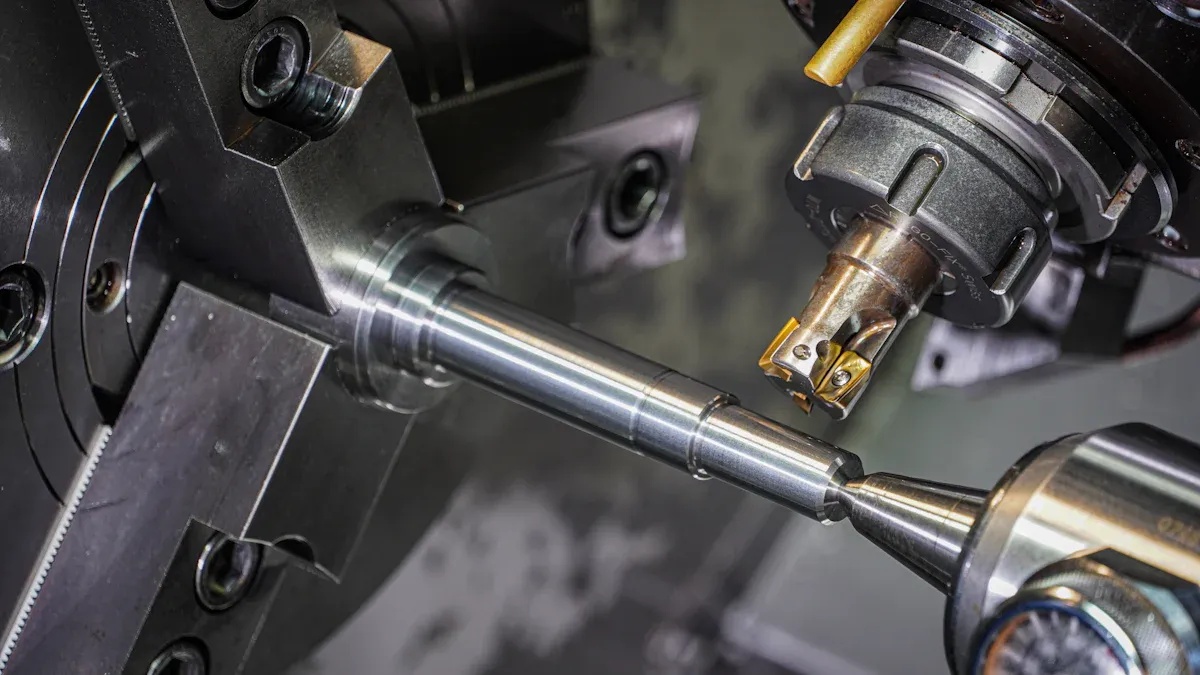

Iinkqubo ze-CNC zoMatshini woPhuculo lweAluminiyam yeCast

Ukugalela ukuMtyaba kunye neMigangatho egudileyo

Xa ufuna eyakhoiinxalenye ze-aluminiumukujonga kwaye uzive ugudile, i-CNC milling yinkqubo yakho yokuhamba. Oomatshini bokugaya basebenzisa izixhobo ezibukhali, zokusonta ukucheba iindawo ezirhabaxa kwaye benze umphezulu othe tyaba. Ungathembela kwi-CNC yokusila ukulungisa iindawo ezingalinganiyo kwaye uqinisekise ukuba iindawo zakho zihambelana ngokugqibeleleyo. Le nkqubo inokufikelela kukunyamezelana okuqinileyo, ngamanye amaxesha ngokuthe ngqo njenge ± 0.005 mm. Oko kuthetha ukuba iindawo zakho ziya kuba nobukhulu obungaguqukiyo kunye nokuguda, okubalulekileyo kwizinto ezifana nezigqubuthelo zenjini okanye izibiyeli zoomatshini.

I-flatness yinto enkulu. Ikuxelela indlela egudileyo kunye nomphezulu ocacileyo. Ukuba ufuna iindawo ezimbini ukuze zihlangane ngaphandle kwezithuba, ufuna ukuba zombini zibe tyaba kangangoko. I-CNC milling ikunceda ukuba ufike khona ngokususa amaqhuma kunye neediphu ezishiywe ekujuleni. I-aluminium ye-MIC-6, umzekelo, inokwakheka okuziinkozo okukhethekileyo okwenza kube lula ukufezekisa i-super-flat finish xa uyimatshini.

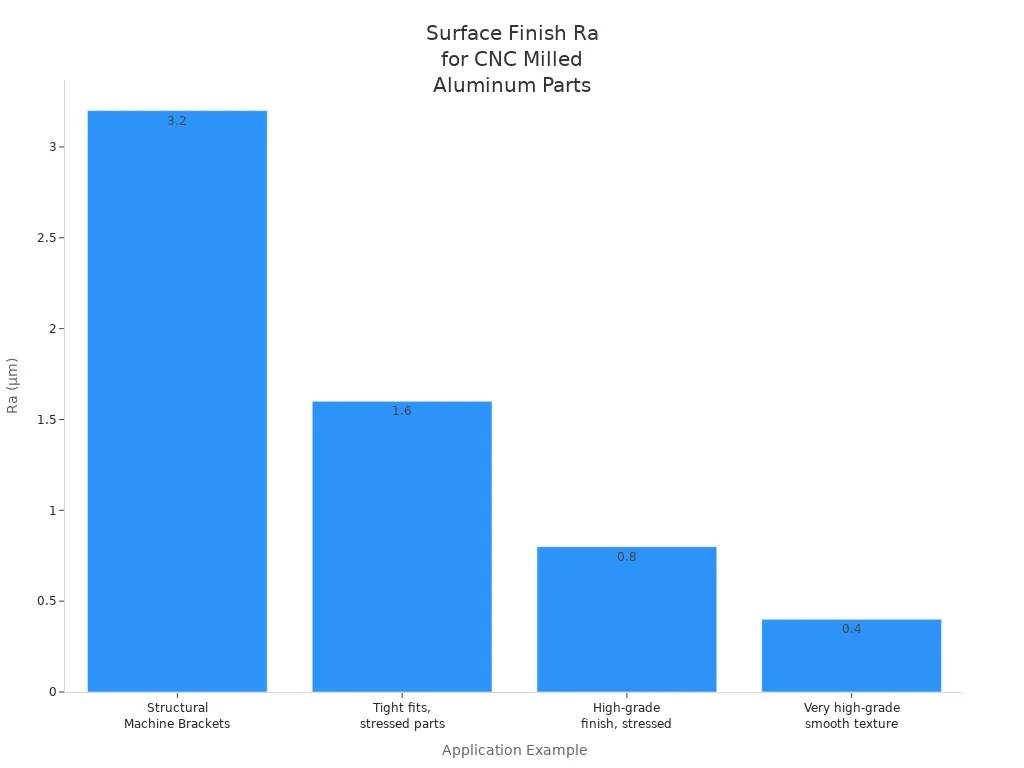

Unokukhetha amanqanaba ahlukeneyo okugqiba umphezulu, kuxhomekeke kwinto efunwa yinxalenye yakho. Nanku ujongo olukhawulezileyo kwinto enokwenzeka:

| Ra (µm) | Imizekelo yosetyenziso | Iimpawu eziphambili |

|---|---|---|

| 3.2 | Izibiyeli zoomatshini boLwakhiwo, amaQhuva eNjini yeZithuthi, uLungiso lweziXhobo ngokubanzi, iChassis yoomatshini | Ukusetyenziswa okusebenzayo, uxinzelelo oluphakathi |

| 1.6 | Ukuqina okuqinileyo, iinxalenye eziphantsi koxinzelelo | Amanqaku okusika abonakala kancinci, ukunyuka kweendleko zemveliso nge-2.5% |

| 0.8 | Ukugqiba umgangatho ophezulu kwiindawo ezigxininisiweyo | Ifuna ukupasa kokugqiba, yongeza i-5% kwiindleko zemveliso |

| 0.4 | Ubume obugudileyo obuphezulu kakhulu | Akukho manqaku aqaphelekayo, adibanisa ukuya kutsho kwi-15% kwiindleko zemveliso |

Ukuba ufuna inxalenye ekhangeleka kakuhle kwaye isebenza kakuhle, i-CNC milling ikunika ulawulo lokugqiba oyifunayo.

Ukujikela ukuChaneka kweCylindrical

Ukujika kwe-CNC yeyona ndlela ilungileyo yokwenza iinxalenye ezijikelezileyo okanye zecylindrical ukusuka kwi-aluminium ephosiweyo. Umatshini ujikelezisa inxalenye yakho ngelixa isixhobo sokusika siyibumba. Le nkqubo ifanelekile ukwenza izinto ezifana neeshafts, bushings, okanye nayiphi na inxalenye efuna ukuba ijikeleze ngokugqibeleleyo.

Ufumana ukuchaneka okumangalisayo ngokujika kwe-CNC. Umatshini unokubamba ukunyamezelwa okuqinileyo njenge-± 0.0001 intshi (i-2.54 microns). Oko kuthetha ukuba yonke indawo oyenzayo iya kuba phantse ifana ncam. Awunakukhathazeka malunga neempazamo ezivela ezandleni zabantu, kuba ikhompyutha ilawula yonke into. Le yingxaki enkulu kumashishini afana neemoto kunye ne-aerospace, apho neempazamo ezincinci zinokubangela iingxaki.

Nalu uthelekiso olukhawulezayo:

| Uphawu | Ukujika kwe-CNC | Ukuguquka ngokweMveli |

|---|---|---|

| Ukunyamezelana | ±0.0001 intshizi (2.54 microns) | Ngokuqhelekileyo ukunyamezelana okukhululekile |

| Ukuphindaphinda | Umgangatho ophezulu, ongaguqukiyo | Iyaguquguquka, ithanda impazamo yomntu |

| Umphezulu Gqiba | Kuphezulu, kaninzi akukho yesibini | Isenokufuna ukugqiba okongeziweyo |

| Impazamo yomntu | Nciphisiwe | Umngcipheko ophezulu weempazamo |

Ngokujika kwe-CNC, ufumana iziphumo ezigudileyo, ezichanekileyo, neziphindaphindwayo ngalo lonke ixesha.

Iindlela zokuNgcwelisa kunye nokuQeda okuPhezulu

Emva kokugaya okanye ukujika, unokufuna ukuba iindawo zakho ze-aluminium zibukeke ngcono. Kulapho ukupolisha kunye nokugqibezela okuphambili kungena khona. Ezi ndlela zinokwenza iindawo zakho zibengezele, zigudileyo, okanye zibanike ukuthungwa okukhethekileyo.

Nazi ezinye iindlela zokugqiba ezidumileyo:

- Ukugulisa oomatshini:Oomatshini baguba baze bapolishe umphezulu ukuze basuse amaqhuma amancinane namaqhuqhuva.

- Ukugulisa imichiza:Iikhemikhali zigudisa umphezulu ngokususa umaleko weoksidi.

- Ukupholisha kwe-Electrochemical:Isebenzisa umbane kunye neekhemikhali ukugqibezela okugudileyo.

- Ukuchaneka komatshini wokugulisa:Amanyathelo amaninzi anezixhobo ezichanekileyo zokuguda okungaphezulu.

- Ukuchaneka okuphezulu:Itekhnoloji ephucukileyo efana nelaser okanye imiqadi yeion kweyona siphelo sigudileyo sinokwenzeka.

- Intshukumo yomphezulu:Ibuyisela ukuxhathisa umhlwa emva kokupolisha, ihlala isebenzisa i-anodizing.

Unokusebenzisa iindlela ezifana nokugqiba ukungcangcazela kunye nokudutyulwa kokudubula. Ukugqityezelwa kweVibratory kubeka iinxalenye zakho kwisitya esineendaba ezikhethekileyo ezizipolisha ngobunono kwaye ziziphose. Ukudubula kwe-shot kusebenzisa amasuntswana anesantya esiphezulu ukwenza iyunifomu, umphezulu we-matte. Ezi ndlela zobuchule zinceda ukulungiselela iindawo zakho zokugquma okanye uzenze zibukeke kakuhle.

Ukuba ufuna ukongeza umbala okanye ukhuseleko olongezelelweyo, ungazama:

- Anodizing:Yongeza umaleko oqinileyo, onemibala omelana nokuguga kunye nokubola.

- Ukwaleka umgubo:Inika ukuqina, nokuba kugqitywe phantse kuwo nawuphi na umbala.

- Ukuqhunyiswa kwesanti:Yenza inkangeleko ye-matte kwaye ilungise umphezulu wokugqiba ngakumbi.

Ukugqitywa komatshini kunye neekhemikhali nganye inenkangeleko yayo kunye neenzuzo. Nasi isikhokelo esikhawulezayo:

| Ukugqitywa koomatshini | Imbonakalo yoMphezulu | Indlela yokusetyenziswa | Ukusetyenziswa okuqhelekileyo |

|---|---|---|---|

| Ukubrasha | Umkhombandlela, ukugqiba kwe-satin | Iibhrashi ezirhabaxa/iiphedi | Uyilo lwezakhiwo |

| Ukugudisa | Igudile, ibonakalisa | Abrasives Progressive | Ukuhlobisa kunye nezicelo zokukhusela |

| Ukugqiba uqhushululu | Iyunifomu matte | Amasuntswana esantya esiphezulu | Unyango lwangaphambili lweengubo |

Ukulungisa iziphene zokuCasa nge-CNC Machining

Ngamanye amaxesha, iinxalenye ze-aluminiyam ziphuma kwi-mold zineziphene ezincinci.Umatshini we-CNC unokulungisaemininzi yale miba, ngoko akuyomfuneko ukuba ulahle inxalenye.

Ezona ziphene zixhaphakileyo onokuzilungisa ziquka:

- I-Porosity:Imingxuma emincinci okanye iipokotho ezibangelwa yirhasi evalelekileyo. Umatshini we-CNC unokususa oku kumphezulu, wenze inxalenye yomelele kwaye ivuze-ingqinisiso.

- Iziphene kwimilo:Iingxaki ezifana neempawu ezingalungelelaniswanga kakuhle okanye imiphetho erhabaxa. Oomatshini be-CNC banokunciphisa kwaye bahlaziye ezi ndawo ukuze zilungele ngokugqibeleleyo.

| Ukuphosa isiphene | Inkcazo |

|---|---|

| I-Porosity | Kwenzeka xa ukuvalelwa kwerhasi kudala iipokotho okanye imingxuma, ekhokelela ekuvuzeni. |

| Iziphene zeMilo | Ukuvela kwimpazamo okanye ukugqwetheka, okukhokelela kwiimpawu ezingaphelelanga. |

Ngokusebenzisa i-CNC machining, unokuguqula inxalenye ye-aluminium eneziphene ibe yinto ekumgangatho ophezulu ehlangabezana neemfuno zakho kanye.

Izibonelelo ze-CNC zokuLungisa iiNdawo zeAluminiyam yeCast

Imbonakalo eyongeziweyo kunye noMgangatho obonakalayo

Ufuna ukuba amalungu akho abonakale ebukhali kwaye enobuchule. CNC machining kukunceda ukuba ufezekise oko. Ngeendlela zokugqiba eziphambili, unokukhetha inkangeleko oyifunayo kumacandelo akho e-aluminium. Jonga ezinye iinketho ezidumileyo:

| Ubuchwephesha | Inkcazo | Iingenelo |

|---|---|---|

| Ukuqhushumba kwamaso | Isebenzisa i-media e-abrasive ukugqitywa kwe-matte | Isusa iimpawu zesixhobo, iphucula ukunamathela kwepeyinti, ivakale kakuhle |

| Powder Coating | Isebenzisa umgubo wepolymer kwaye unyange ngobushushu | Ukuxhathisa okukhulu kwe-corrosion, ukunamathela okuqinileyo, ukugqitywa okuninzi |

| Ukuhombisa isipili | Ukugqitywa ngokuchanekileyo kwendawo ekhanyayo, ekhanyayo | Yehlisa ukukhuhlana, yongeza ukuxhathisa ukubola, ukucaca kwe-optical |

| Brushed Ukugqiba | Yenza ipateni efanayo yeenkozo | Ubume obubodwa, bugcina imilinganiselo izinzile |

| Anodizing | Yakha umaleko we-oxide kwi-aluminiyam | Ukuxhathisa ngakumbi kwi-corrosion, umphezulu onzima, ukhetho lombala |

Ezi ndlela zenza ukuba amalungu akho abonakale kwaye ahlale ixesha elide.

Ukuphuculwa kokufaneleka, ukusebenza kunye nokuSebenza

Kufuneka amalungu akho adibane ngokugqibeleleyo. Umatshini we-CNC unikezela ukunyamezelana okuqinileyo kunye nokulingana okuchanekileyo, okuthetha iingxaki ezimbalwa zendibano kunye nokusebenza okungcono. Nantsi indlela okunceda ngayo oomatshini beCNC:

| Igalelo le-CNC Machining | Inkcazo |

|---|---|

| Ukunyamezelana okuqinileyo | Amacandelo adibana nemilinganiselo echanekileyo yokudibanisa okugudileyo |

| IiFinethi ezichanekileyo | Amacandelo angenamthungo, anciphisa iimpazamo |

| IModeli yeCAD echanekileyo | Iqinisekisa ukuba uyilo lwakho luhambelana nemveliso yokugqibela |

Xa amalungu akho elingana ngokufanelekileyo, oomatshini bakho basebenza ngcono kwaye bahlala ixesha elide.

Ukonyuka kokuZinza kunye noBomi beNkonzo

Ufuna iinxalenye zakho ze-aluminium ukuze uphathe imisebenzi enzima kwaye uqhubeke usebenza. CNC machining inceda ngokulawula ubushushu, isixhobo ukunxiba, kunye neparameters machining. Oku kugcina amalungu akho omelele kwaye athembekile. Nazi ezinye iindlela ze-CNC zokwandisa ukuqina:

- Isebenzisa ulwelo lokusika ukulawula ubushushu kunye nokukhusela umphezulu

- Igcina isantya esiphezulu sokusika kunye nokupholisa okufanelekileyo

- Lungisa useto lomatshini ukunqanda ukulwa okanye ukugqwetheka

Ingcebiso: Xa usebenzisa i-CNC machining, ufumana iindawo ezihlala ixesha elide kwaye zisebenze ngcono, nakwiindawo ezifuna ngamandla.

CNC machining ikunika agudileyo, iinxalenye aluminiyam ethembekileyo ngakumbi. Ufumana inkangeleko engcono, ukuqina, kunye nezinto ezihlala ixesha elide. Amashishini amaninzi axhomekeke kule nkqubo:

| Ishishini | Isizathu Sokusetyenziswa |

|---|---|

| Iimoto | I-injini ekhaphukhaphu, eyomeleleyo kunye namalungu e-chassis |

| I-Aerospace | Umlinganiselo ophezulu wobunzima bobunzima benqwelomoya |

| Ukwakhiwa | Ukumelana nokubola kwezakhiwo |

| Owaselwandle | Ikhaphukhaphu, i-corrosion-resistant components |

| Electronics | Iindawo ezichanekileyo zezixhobo |

| Impahla zomthengi | Ukusetyenziswa okuguquguqukayo kwiimveliso ezininzi |

| Izixhobo zonyango | Izixhobo ezingenayo ityhefu, kulula ukuzibulala iintsholongwane |

Ukutyala imali ekugqityweni kwe-CNC kukunceda ukuba uhlangabezane nemigangatho ephezulu ngalo lonke ixesha.

FAQ

Yeyiphi isiphelo somphezulu onokusilindela emva komatshini we-CNC wokuphosa i-aluminium?

Ngokuqhelekileyo ufumana ukugqiba okugudileyo phakathi kwe-16 kunye ne-125 microinches Ra. Umatshini we-CNC ususa amabala arhabaxa kwaye ushiye iindawo zakho zijongeka zikhazimlisiwe.

Ingcebiso: Unokukhetha ukugqiba kakuhle kwiiprojekthi ezizodwa.

Ngaba umatshini we-CNC uphucula amandla eenxalenye ze-aluminium?

Ewe, ufumana iindawo ezomeleleyo. Umatshini we-CNC ususa iindawo ezibuthathaka kunye neziphene, ukuze izinto zakho zihlale ixesha elide kwaye zisebenze ngcono.

Ngaba unokudibanisa i-CNC machining kunye nezinye iindlela zokugqiba?

Ngokuqinisekileyo! Ungasebenzisa i-CNC machining kuqala, emva koko wongeze i-anodizing, i-powder coating, okanye ukupolisha. Oku kukunika inkangeleko yesiko kunye nokhuseleko olongezelelweyo.

| Indlela yokugqiba | Inzuzo |

|---|---|

| Anodizing | Ukumelana nokubola |

| Powder Coating | Ukhetho lombala |

| Ukugudisa | Umphezulu ocwebezelayo |

Ixesha lokuposa: Sep-03-2025