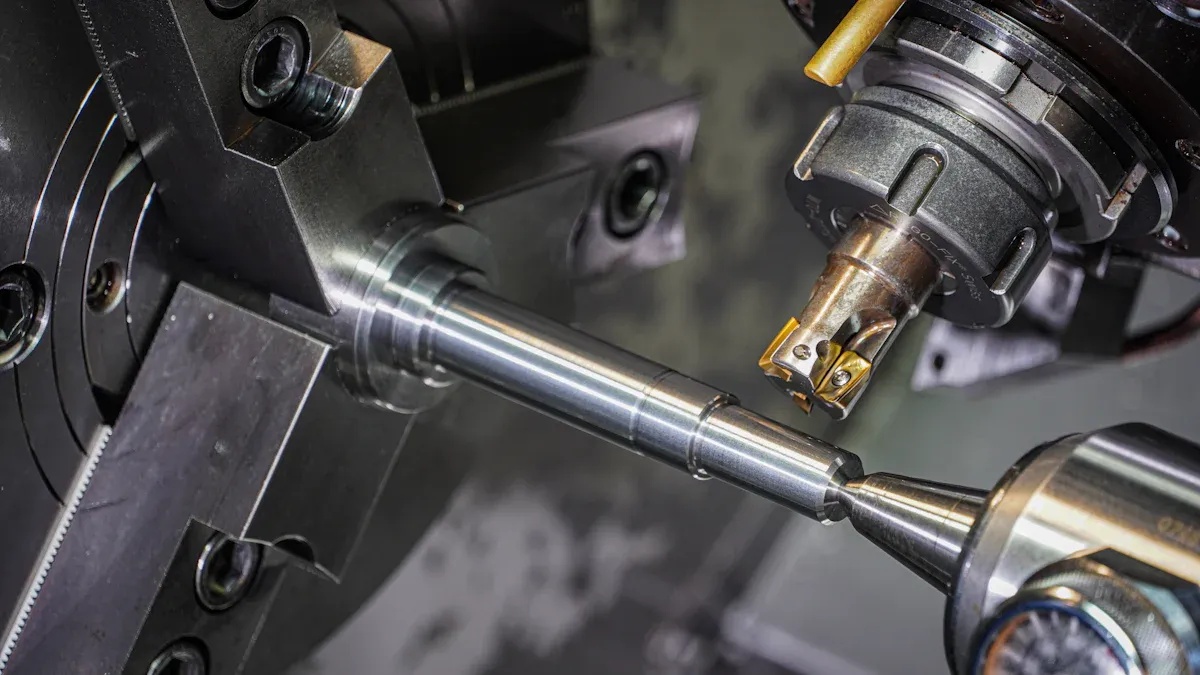

Uma ubheka izingxenye ze-aluminium ezenziwe ngensimbiimoto or ezokuxhumanaizimboni, ufuna isiphetho esibushelelezi, esingenasici. Imishini ye-CNC ikunikeza lolo mngcele. Kuthatha izindawo ezimahhadlahhadla, ezifana nokulingisa futhi kuzenze zibeshelele futhi ziqonde. Bheka nje umehluko:

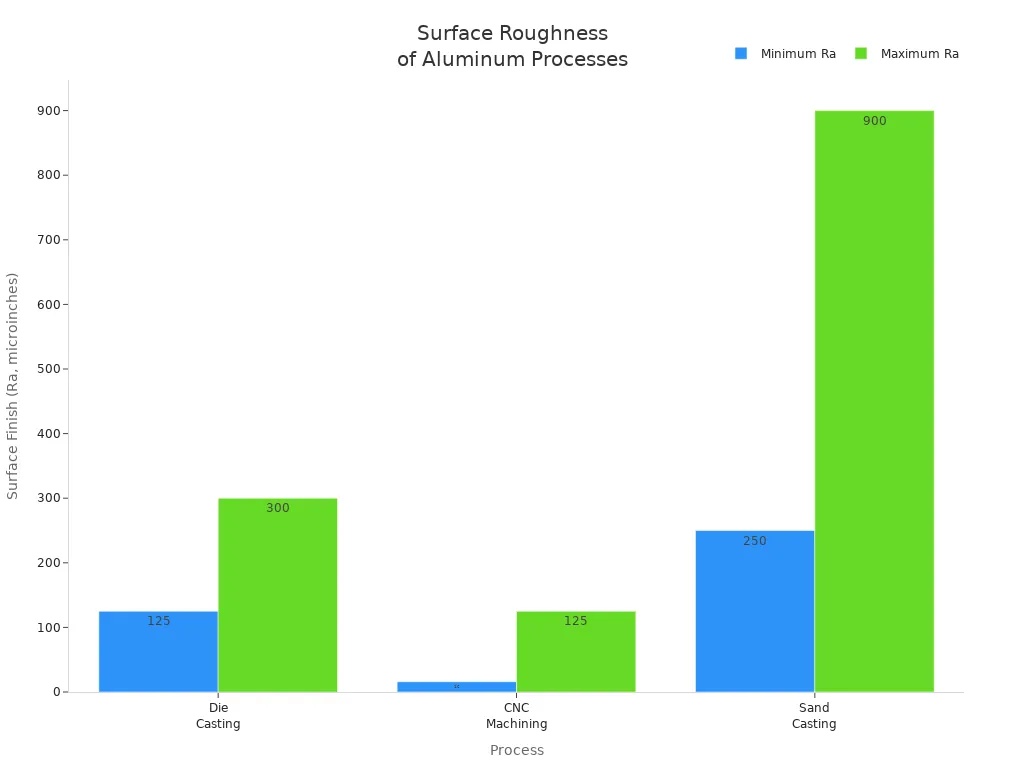

| Inqubo | I-Surface Finish Ejwayelekile (Ra) |

|---|---|

| I-Die Casting | 125-300 amasentimitha |

| CNC Machining | 16-125 amasentimitha |

| I-Sand Casting | 250-900 amasentimitha |

Ungabona ukuthi ukwenza imishini ye-CNC kukusiza kanjani ukuthi ufinyelele isiphetho esihle kakhulu, wenze zonke izingxenye zibukeke futhi zenze kangcono.

Okuthathwayo Okubalulekile

- CNC machining kakhuluithuthukisa isiphetho sangaphezuluwezingxenye ze-aluminium enziwe, ukufeza ukuqeda okushelelayo phakathi kuka-16 no-125 microinches Ra.

- Ukusebenzisa i-CNC milling kanye nezinqubo zokuguqulakuthuthukisa ukunembakanye nokuvumelana kwezingxenye, okuqinisekisa ukubekezelelana okuqinile nokusebenza okungcono.

- Amasu okuqedela athuthukile njengokupholisha kanye ne-anodizing awathuthukisi nje kuphela ukubukeka kodwa futhi andisa ukuqina nokumelana nokugqwala.

Imikhawulo Yokuqeda Ubuso Ekusakazeni Kwe-Cast Aluminium

Ukungapheleli Okujwayelekile ku-Cast Aluminium

Uma usebenza nge-aluminium ekhonjiwe, ungase ubone amaphutha endaweni. Lokhu kungapheleli kungathinta indlela izingxenye zakho ezibukeka futhi zisebenza ngayo. Nazi izinkinga ezimbalwa ongazibona:

- Ukuqedwa kwendawo kudlala indima enkuluukuthi ingxenye yakho ihlala isikhathi esingakanani.

- Uma isiphetho singalungile, ukumelana nokugqwala kuyehla.

- Kwesinye isikhathi, ingxenye ayibukeki kahle ngendlela ofisa ngayo.

Ungase futhi ubone izinhlobo ezimbili ze-porosity. Ukuqina kwegesi kwenzeka lapho umoya noma i-hydrogen ivaleleka ensimbi, ishiya izimbobo ezincane, eziyindilinga. I-shrinkage porosity ibonakala njengemigodi emikhulu, emise okwenqaba lapho insimbi iphola futhi incipha.

Izinselelo Zokubekezelelana Nokungaguquguquki

Ufuna izingxenye zakho zilingane kahle ngaso sonke isikhathi. I-aluminium die casting evamile ngokuvamile ikunikeza ukubekezelela phakathi kuka-±0.05 mm no-±0.10 mm. Ukuze uthole imisebenzi enemba ngempela, ungehlela ku-±0.01 mm. Amazinga omkhakha afana ne-ISO 8062-3 kanye ne-NADCA asiza ukuqondisa ukuthi yini engenzeka. Noma kunjalo,ukushaya lezo tolerances eziqinilekungaba nzima, ikakhulukazi uma udinga imiphumela efanayo kuzo zonke izingxenye.

Imikhawulo yeJiyomethri ku-Die Casting

I-Die casting isebenza kahle kakhulu emimoyeni ethile. Uma udinga amakhona acijile, izimbobo ezijulile, noma izindonga ezincane, ungase ungene enkingeni. Inqubo ikhawulela ukuthi ingxenye yakho ingaba yinkimbinkimbi kangakanani. Ngezinye izikhathi, kufanele ushintshe umklamo wakho noma wengeze izinyathelo ezengeziwe ukuze uthole izici ozifunayo.

Izinqubo Zomshini ze-CNC Zokuthuthukisa I-Aluminium Yabalingisi

I-Milling for Flatness kanye Nezindawo ezibushelelezi

Lapho ufuna eyakhoizingxenye ze-aluminiumukuze ubukeke futhi uzizwe ubushelelezi, ukugaya kwe-CNC kuwuhlelo lwakho lokuya kuyo. Imishini yokugaya isebenzisa amathuluzi abukhali, ukuphotha ukuze kuphuce izindawo ezimahhadlahhadla nokudala izindawo eziyisicaba, ezilinganayo. Ungathembela ku-CNC Milling ukulungisa izindawo ezingalingani futhi uqiniseke ukuthi izingxenye zakho zihlangana kahle. Le nqubo ingafinyelela ukubekezelelana okuqinile, ngezinye izikhathi okunembe njengo-±0.005 mm. Lokho kusho ukuthi izingxenye zakho zizoba nokujiya okungaguquki nokushelela, okubalulekile ezintweni ezifana namakhava enjini noma abakaki bemishini.

I-flatness yinto enkulu. Ikutshela ukuthi bushelelezi kangakanani ngisho nendawo engaphezulu. Uma udinga izingxenye ezimbili ukuze zilingane ngaphandle kwezikhala, ufuna zombili zibe flat ngangokunokwenzeka. Ukugaya kwe-CNC kukusiza ukuthi ufike lapho ngokususa amaqhubu namadiphu asele ekulingiseni. I-aluminium ye-MIC-6, isibonelo, inokwakheka okusanhlamvu okukhethekile okwenza kube lula nakakhulu ukufeza isiphetho esiyisicaba kakhulu uma uyimshini.

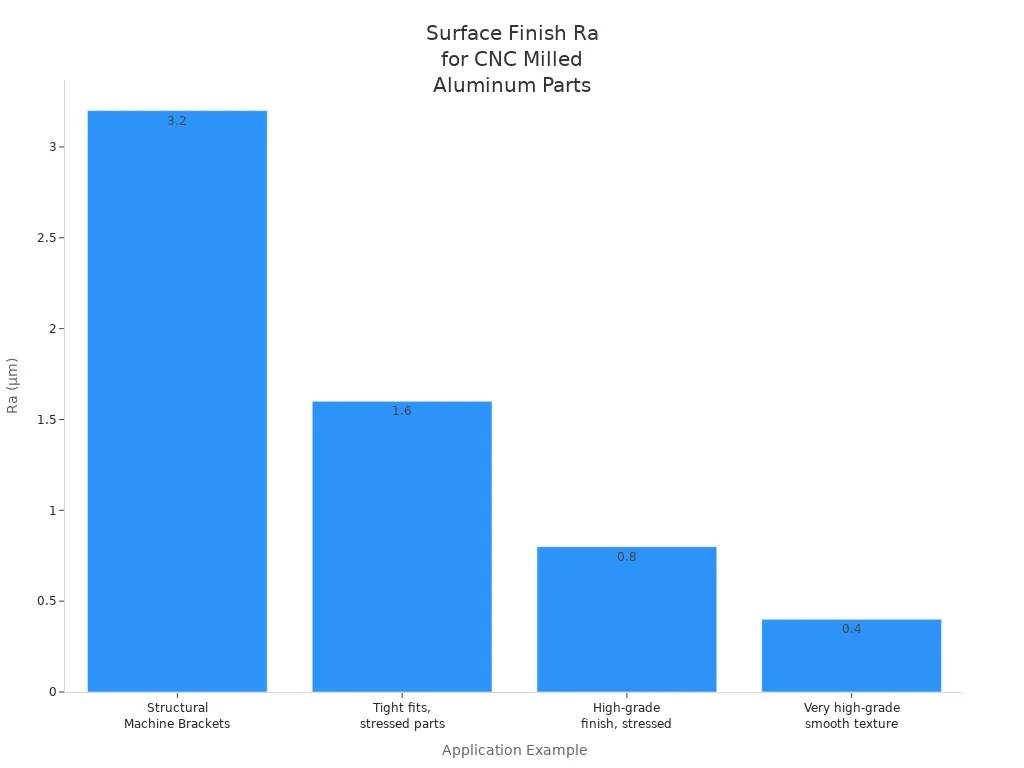

Ungakhetha amaleveli ahlukene okuphela kwendawo, kuye ngokuthi ingxenye yakho idinga ini. Nakhu ukubuka okusheshayo kokuthi yini engenzeka:

| I-Ra (µm) | Izibonelo Zohlelo Lokusebenza | Izimpawu Ezisemqoka |

|---|---|---|

| 3.2 | Abakaki Bomshini Wesakhiwo, Amakhava Enjini Yezimoto, Ukulungiswa Kwamathuluzi Okujwayelekile, I-Chassis Yomshini | Ukusetshenziswa okusebenzayo, ukucindezeleka okuphakathi |

| 1.6 | Ukulingana okuqinile, izingxenye ezingaphansi kwengcindezi | Amamaki okusika abonakala kancane, anyuse izindleko zokukhiqiza ngo-2.5% |

| 0.8 | Ukuqedwa kwebanga eliphezulu kwezingxenye ezigcizelelwe | Idinga amaphasi okuqeda, yengeza u-5% ezindlekweni zokukhiqiza |

| 0.4 | Ukuthungwa okubushelelezi kwezinga eliphezulu kakhulu | Awekho amamaki asikiwe aqaphelekayo, angeza kufika ku-15% ezindlekweni zokukhiqiza |

Uma udinga ingxenye ebukeka iyinhle futhi isebenza kahle, ukugaya kwe-CNC kukunikeza ukulawula ukuze uthole isiphetho osifunayo.

Ukuguqula Ukunemba Kwe-Cylindrical

Ukuphenduka kwe-CNC kuyindlela engcono kakhulu yokwenza izingxenye eziyindilinga noma eziyisilinda kusuka ku-aluminium ekhonjiwe. Umshini uzungeza ingxenye yakho ngenkathi ithuluzi lokusika liyilolonga. Le nqubo ilungele ukwenza izinto ezinjengama-shafts, bushings, nanoma iyiphi ingxenye edinga ukuba yindilinga ngokuphelele.

Uthola ukunemba okumangalisayo ngokujika kwe-CNC. Umshini ungabamba ukubekezelelana kuqine njengamayintshi angu-±0.0001 (ama-microns angu-2.54). Lokho kusho ukuthi yonke ingxenye oyenzayo izocishe ifane ncamashi. Awudingi ukukhathazeka ngamaphutha avela ezandleni zabantu, ngoba ikhompuyutha ilawula yonke into. Lokhu kuyinkinga enkulu ezimbonini ezifana nezezimoto kanye ne-aerospace, lapho ngisho namaphutha amancane angabangela izinkinga.

Nasi isiqhathaniso esisheshayo:

| Isici | Ukuphenduka kwe-CNC | Ukuphenduka Kwendabuko |

|---|---|---|

| Ukubekezelelana | ±0.0001 amayintshi (2.54 microns) | Ngokujwayelekile ukubekezelelana okuxekethile |

| Ukuphindaphinda | Ikhwalithi ephezulu, engaguquki | Iyaguquguquka, ijwayele ukuba nephutha lomuntu |

| I-Surface Qeda | Okuphezulu, ngokuvamile akukho okwesibili | Kungase kudinge ukuqedwa okwengeziwe |

| Iphutha Lomuntu | Yehlisiwe | Ingozi ephezulu yamaphutha |

Ngokuphenduka kwe-CNC, uthola imiphumela ebushelelezi, enembile, futhi ephindaphindwayo njalo.

Ukupholisha kanye Nezindlela Zokuqeda Ezithuthukile

Ngemva kokugaya noma ukujika, ungase ufune izingxenye zakho ze-aluminium ezisansimbi zibukeke kangcono nakakhulu. Yilapho ukupholishwa nokuqedwa okuthuthukisiwe kungena khona. Lezi zindlela zingenza izingxenye zakho zicwebezele, zibushelelezi, noma zizinikeze ukuthungwa okukhethekile.

Nazi ezinye izinketho ezidumile zokuqeda:

- Ukupholisha ngomshini:Imishini igaya futhi ipholishe indawo engaphezulu ukuze isuse amaqhuqhuva nama-burrs amancane.

- Ukupholisha ngamakhemikhali:Amakhemikhali ashelela phezulu ngokukhipha ungqimba lwe-oxide.

- Ukupholisha nge-Electrochemical:Isebenzisa ugesi namakhemikhali ukuqeda ubushelelezi.

- Ukupholisha ngomshini okunembayo:Izinyathelo eziningi ezinamathuluzi anemba okuphezulu okushelela okwengeziwe.

- Ukupholisha okunembe kakhulu:Ubuchwepheshe obuthuthukile njengamalaser noma ama-ion beams ukuze kuqedwe bushelelezi ngangokunokwenzeka.

- I-Surface passivation:Ibuyisela ukumelana nokugqwala ngemva kokupholisha, ngokuvamile isebenzisa i-anodizing.

Ungasebenzisa futhi izindlela ezinjengokuqedwa kokudlidliza nokuqhunyiswa kwesibhamu. Ukuqedwa kokudlidliza kubeka izingxenye zakho endishini enemidiya ekhethekile ezipholisha ngobumnene futhi izisuse. I-shot blasting isebenzisa izinhlayiya ezinesivinini esikhulu ukudala indawo efanayo, e-matte. Lezi zindlela zisiza ukulungisa izingxenye zakho zokumboza noma zivele zibukeke zizinhle.

Uma ufuna ukwengeza umbala noma ukuvikeleka okwengeziwe, ungazama:

- I-Anodizing:Yengeza isendlalelo esiqinile, esimibalabala esimelana nokuguga nokugqwala.

- I-Powder coating:Inikeza okuqinile, ngisho nokuqeda cishe kunoma yimuphi umbala.

- Ukuqhunyiswa kwesihlabathi:Idala ukubukeka kwe-matte bese ilungiselela indawo ukuze iqedele okwengeziwe.

Ukuqedwa kwemishini namakhemikhali ngakunye kunokubukeka kwayo kanye nezinzuzo. Nansi inkomba esheshayo:

| I-Mechanical Qeda | Ukubukeka Kobuso | Indlela Yokufaka Isicelo | Ukusetshenziswa Okuvamile |

|---|---|---|---|

| Ukuxubha | I-Directional, isiphetho se-satin | Amabhulashi/amaphedi abrasive | Imiklamo yezakhiwo |

| Ukupholisha | Okubushelelezi, okukhanyayo | Ama-abrasives aqhubekayo | Izicelo zokuhlobisa nezivikelayo |

| Ukuqedwa kokuqhuma | I-uniform matte | Izinhlayiya zejubane eliphezulu | Ukwelashwa kwangaphambili kwama-coatings |

Ukulungisa Ukukhubazeka Kokusakaza Nge-CNC Machining

Ngezinye izikhathi, izingxenye ze-aluminium ezenziwe ngensimbi ziphuma esikhunjini ezinamaphutha amancane.Imishini ye-CNC ingalungisaeziningi zalezi zindaba, ngakho-ke akudingeki ulahle ingxenye.

Izinkinga ezivame kakhulu ongazilungisa zihlanganisa:

- I-Porosity:Izimbobo ezincane noma amaphakethe abangelwa igesi evaleleke. Imishini ye-CNC ingasusa lokhu phezulu, yenze ingxenye ibe namandla futhi ingavuzi.

- Ukukhubazeka komumo:Izinkinga ezifana nezici ezingaqondani kahle noma imiphetho emangelengele. Imishini ye-CNC inganquma futhi imise kabusha lezi zindawo ukuze zilingane kahle.

| Isici Sokusakaza | Incazelo |

|---|---|

| I-Porosity | Kuvela lapho ukuvaleka kwegesi kudala amaphakethe noma imigodi, okuholela ekuvuzeni. |

| Ukukhubazeka Komumo | Ukuvela ekungaqondani kahle noma ukuhlanekezela, okuholela ezicini ezingaphelele. |

Ngokusebenzisa imishini ye-CNC, ungaguqula ingxenye ye-aluminium enamaphutha ibe ingxenye yekhwalithi ephezulu ehlangabezana nezidingo zakho ngqo.

Izinzuzo ze-CNC Machining for Cast Aluminium Parts

Ukubukeka Okuthuthukisiwe kanye Nekhwalithi Ebonakalayo

Ufuna izingxenye zakho zibukeke zibukhali futhi zobuchwepheshe. CNC machining ikusiza ukufeza lokho. Ngamasu okuqedela athuthukile, ungakhetha ukubukeka okunembile okufunayo kwezingxenye zakho ze-aluminium yokusakaza. Hlola ezinye izinketho ezidumile:

| Icebo | Incazelo | Izinzuzo |

|---|---|---|

| Ukuqhunyiswa kobuhlalu | Isebenzisa imidiya e-abrasive ukuze iqede i-matte | Isusa izimpawu zamathuluzi, ithuthukisa ukunamathela kopende, ukuzwa okubushelelezi |

| I-Powder Coating | Igcoba i-polymer powder futhi yelapha ngokushisa | Ukumelana nokugqwala okukhulu, ukunamathela okuqinile, ukuqedwa okuningi |

| Ukupholisha isibuko | Ukuqedela okunembayo kwendawo ecwebezelayo, ekhanyayo | Yehlisa ukungqubuzana, ikhuphula ukumelana nokugqwala, ukukhanya kwe-optical |

| Ukuqeda Ibhulashi | Idala iphethini yokusanhlamvu efanayo | Ukuthungwa okuyingqayizivele, kugcina ubukhulu buzinzile |

| I-anodizing | Yakha isendlalelo se-oxide ku-aluminium | Ukumelana nokugqwala okwengeziwe, indawo eqinile, izinketho zombala |

Lezi zindlela zenza izingxenye zakho zigqame futhi zihlale isikhathi eside.

Ukufaneleka Okuthuthukisiwe, Ukusebenza, kanye nokusebenza

Udinga izingxenye zakho ukuze uhlangane ngokuphelele. Imishini ye-CNC iletha ukubekezelelana okuqinile kanye nokulingana okunembile, okusho ukuthi izinkinga ezimbalwa zomhlangano nokusebenza okungcono. Nakhu ukuthi umshini we-CNC usiza kanjani:

| Umnikelo we-CNC Machining | Incazelo |

|---|---|

| Ukubekezelelana Okuqinile | Izingxenye zihlangabezana nezilinganiso eziqondile zokuhlanganisa ngokushelelayo |

| I-Precise Fits | Izingxenye zilingana kahle, zinciphisa amaphutha |

| I-High-Precision CAD Modelling | Iqinisekisa ukuthi umklamo wakho ufana nomkhiqizo wokugcina |

Uma izingxenye zakho zilingana kahle, imishini yakho isebenza kangcono futhi ihlala isikhathi eside.

Ukukhula Ukuqina kanye Nempilo Yesevisi

Ufuna izingxenye zakho ze-aluminium zabalingisi zibambe imisebenzi enzima futhi ziqhubeke nokusebenza. Imishini ye-CNC isiza ngokulawula ukushisa, ukuguga kwamathuluzi, namapharamitha womshini. Lokhu kugcina izingxenye zakho ziqinile futhi zithembekile. Nazi ezinye izindlela ze-CNC machining ezithuthukisa ukuqina:

- Isebenzisa uketshezi lokusika ukuphatha ukushisa nokuvikela izindawo ezingaphezulu

- Igcina isivinini sokusika ngokupholisa okufanele

- Ilungisa izilungiselelo zomshini ukuze kugwenywe ukungqubuzana noma ukuhlanekezela

Ithiphu: Uma usebenzisa imishini ye-CNC, uthola izingxenye ezihlala isikhathi eside futhi ezisebenza kangcono, ngisho nasezimweni ezinzima kakhulu.

Imishini ye-CNC ikunikeza izingxenye ze-aluminium ezibushelelezi, ezithembeke kakhulu. Uthola ukubukeka okungcono, ukulingana okuqinile, kanye nezingxenye ezihlala isikhathi eside. Izimboni eziningi zithembele kule nqubo:

| Imboni | Isizathu Sokusetshenziswa |

|---|---|

| Ezezimoto | Injini engasindi, eqinile nezingxenye ze-chassis |

| I-Aerospace | Isilinganiso esiphezulu samandla nesisindo sendiza |

| Ukwakha | Ukumelana nokugqwala kwezakhiwo |

| Osolwandle | Izingxenye ezingasindi, ezimelana nokugqwala |

| Ezogesi | Izingxenye zokunemba zamadivayisi |

| Izimpahla Zabathengi | Ukusetshenziswa okuhlukahlukene emikhiqizweni eminingi |

| Imishini Yezokwelapha | Amathuluzi angenabo ubuthi, okulula ukuwabulala amagciwane |

Ukutshala imali ekuqedeni i-CNC kukusiza ukuthi uhlangabezane namazinga aphezulu ngaso sonke isikhathi.

FAQ

Yikuphi ukuqedwa kwendawo ongayilindela ngemuva kwe-CNC machining cast aluminium?

Ngokuvamile uthola isiphetho esibushelelezi phakathi kuka-16 no-125 microinches Ra. Imishini ye-CNC isusa izindawo ezimahhadlahhadla futhi ishiye izingxenye zakho zibukeka zipholile.

Ithiphu: Ungakhetha ukuqedela okuhle kwamaphrojekthi akhethekile.

Ingabe imishini ye-CNC ithuthukisa amandla ezingxenye ze-aluminium eziphonswe?

Yebo, uthola izingxenye eziqinile. Imishini ye-CNC isusa izindawo ezibuthakathaka nezilimele, ukuze izingxenye zakho zihlale isikhathi eside futhi zenze kangcono.

Ungakwazi yini ukuhlanganisa imishini ye-CNC nezinye izindlela zokuqeda?

Nakanjani! Ungasebenzisa imishini ye-CNC kuqala, bese wengeza i-anodizing, i-powder coating, noma ukupholisha. Lokhu kukunikeza ukubukeka ngokwezifiso nokuvikelwa okwengeziwe.

| Indlela Yokuqeda | Zuza |

|---|---|

| I-anodizing | Ukumelana nokugqwala |

| I-Powder Coating | Izinketho zombala |

| Ukupholisha | Indawo ecwebezelayo |

Isikhathi sokuthumela: Sep-03-2025