Uma ngisebenza ne-CNC machining, ngibona ukuthi amasistimu alawulwa ngekhompiyutha akuguqula kanjani ukukhiqizwa kweOEM aluminium die cast izingxenye.

- Imishini iyalandelaiziqondiso eziqondile, okususa ubungozi bamaphutha okwenziwa ngesandla.

- Ukuhlolwa kwekhwalithi okuzenzakalelayo nokulungiswa kwendlela yamathuluzi kugcina zonke izingxenye zingashintshi.

- I-OEM aluminium die casting ibhekiselaezingxenyeni ezidinga ukubekezelelana okuqinile, futhi i-CNC inikeza leziI-Aluminium Die Casting Amakhono.NgiyethembaI-OEM Aluminium Die Casting Part Manufacturer- i-essai ukuletha imiphumela ethembekile.

Okuthathwayo Okubalulekile

- CNC imishiniisebenzisa isilawuli sekhompiyutha ukuze ilandele iziqondiso eziqondile, ezisusa amaphutha omuntu futhi zikhiqize izingxenye ezinezilinganiso eziqinile nezingaguquguquki.

- Izinhlelo zesofthiwe ezithuthukisiwe futhi zilungiselela izindlela zamathuluzi ukwenza ukusika kusebenze kahle futhi kunembile, kuncishiswe amaphutha, ukonga isikhathi, nokwehlisa izindleko.

- Imishini ye-CNC enembayo ephezulu kanye nesistimu yempendulo yesikhathi sangempela iqinisekisa ukuthi zonke izingxenye zilingana kahle, zihlala isikhathi eside, futhi ziyahlangana.izindinganiso eziqinile zekhwalithi.

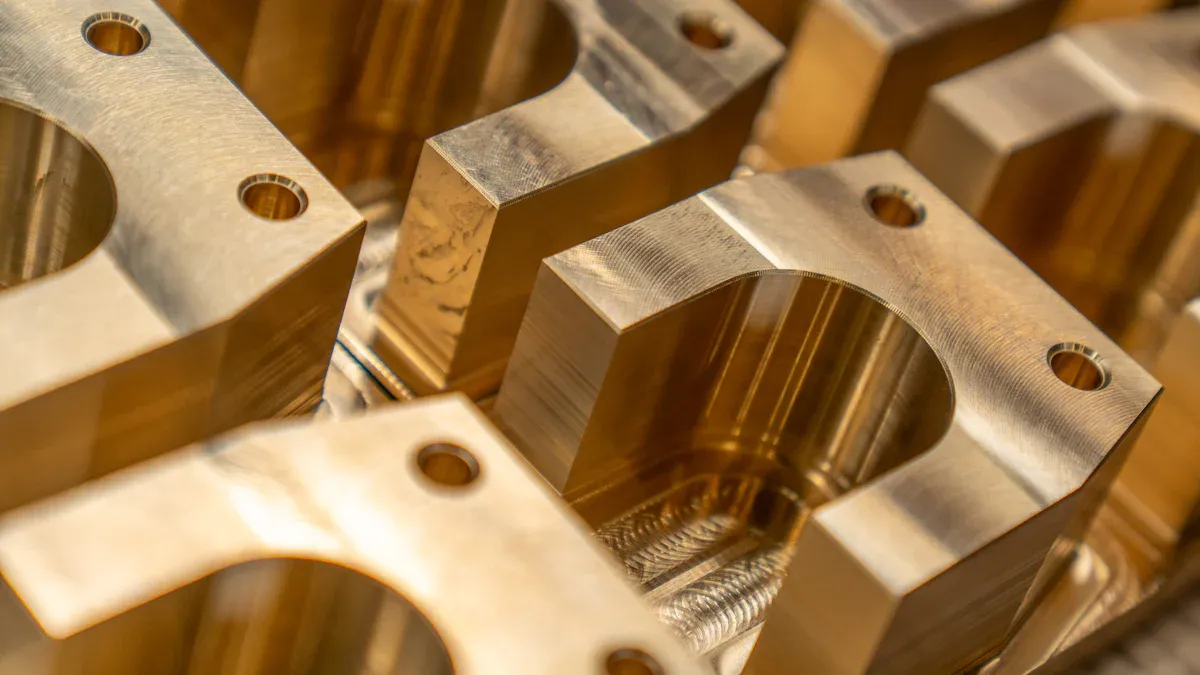

I-CNC Machining Iletha Kanjani Ukunemba Kwezingxenye Zokusakaza Ze-OEM Aluminium Die

Ukunyakaza Okulawulwa Ngekhompyutha

Lapho ngisebenza ngemishini ye-CNC, ngibona ukuthi imiklamo yedijithali iba kanjani izingxenye zangempela ngokunemba okumangalisayo. Inqubo iqala ngokuthi aImodeli ye-CAD. NgiyasebenzisaIsoftware ye-CAMukushintsha leyo modeli ibeIkhodi ye-G, etshela umshini ukuthi uhambe kanjani. Isilawuli se-CNC sifunda le miyalo futhi siqondise ithuluzi lokusika ngokuhambisana nezimbazo ezimbalwa, kwesinye isikhathi kufika kwemihlanu. Lokhu kungivumela ukuthi ngidale izimo eziyinkimbinkimbi namakhona aqinile angeke angenzeki ngesandla.

Umshini ugcina umkhondo wakho konke ukunyakaza. Ithumela amasiginali kumamotho, iqinisekisa ukuthi ithuluzi lilandela indlela ngokuphelele. Ngiyabuka njengoba umshini usika, ubhoboza, futhi ugaya i-aluminium, ihambisana njalo nomklamo. Lokhu kulawula kusho ukuthi ngiyakwazi ukwenzaOEM aluminium die cast izingxenyeezinobukhulu obuqondile, noma ngabe izimo ziba yinkimbinkimbi.

Ithiphu:Multi-axis CNC imishiningisize ngikhiqize izingxenye ngeukubekezelelana okuqinilekanye nemininingwane eyinkimbinkimbi, ebalulekile ezimbonini ezifana nezimoto nemishini yezokwelapha.

Ukuthuthukisa Indlela Yethuluzi Okuzenzakalelayo

Ngithembele ekuthuthukisweni kwendlela yamathuluzi ukuze ngiqinisekise ukuthi konke ukusika kusebenza kahle futhi kunembile. Isofthiwe ye-CAM ingisiza ukuthi ngihlele umzila ongcono kakhulu wethuluzi lokusika. Ihlola amaphutha okungenzeka, njengokushayisana noma izinguquko zamathuluzi ezingadingekile, ngaphambi kokuthi umshini uqale. Lokhu konga isikhathi futhi kunciphisa amaphutha.

Nali ithebula elibonisa ukuthi ukwenza ngcono kuwuthuthukisa kanjani umsebenzi wami:

| Isici Sokuthuthukisa | Incazelo Yokuthuthukisa | Umthelela Kumaphutha Emashini kanye Nempumelelo |

|---|---|---|

| Ukuthuthukisa Indlela Yethuluzi | Ithola ngokuzenzakalelayo indlela yamathuluzi emfushane, ephephe kakhulu | Ifinyeza izikhathi zomjikelezo futhi ikhuphule ukusebenza kahle cishe ngo-15% |

| Ukulandelana Kokushintsha Ithuluzi | Ikhetha i-oda elingcono kakhulu lezinguquko zamathuluzi | Inciphisa isikhathi sokushintsha ithuluzi ngo-20%, yehlisa ingozi yephutha |

| Ukutholwa Kwephutha Lomqondo | Ibeka izinkinga njengethuluzi elingalungile noma imiyalo epholile | Igwema ukungqubuzana nokunqamuka komoya ngaphezu kuka-80% |

| Ukuvimbela Ingozi | Ilungisa izinkinga ngaphambi kokuqala komshini | Yehlisa isikhathi sokuphumula kanye ne-scrap, ithuthukisa ukuzinza |

| Ukuzinza kanye Nokwehliswa Kwezindleko | Igcina inqubo ishelela futhi izinzile | Yehlisa izindleko zokulungisa nokulungisa |

| Ukusebenza Ezingxenyeni Eziyinkimbinkimbi | Ijwayela ama-multi-eksisi nokukhiqizwa kwenqwaba | Khulisa amandla omshini wokukhiqiza okusheshayo, okuzinzile |

Ngisebenzisa isofthiwe ye-CAM ethuthukisiwe engivumela ngilingise inqubo yokwenza imishini. Ngiyabona ukuthi ithuluzi lizoshaya noma yini noma uma indlela idinga ukushintsha. Ama-algorithms afanaukuhlanza okuguquguqukayo kanye nomshini wejubane eliphezulungisize ngigcine ithuluzi lihamba kahle futhi ngigweme ukuguga. Lokhu kusho ukuthi izingxenye zami ze-OEM aluminium die casting ziphuma okokuqala, zinemfucuza encane namaphutha ambalwa.

- Ngikhetha izindlela ezihlukene zamathuluzi kuye ngokuma kwengxenye.

- Ngezingxenye ezilula, ngisebenzisa izindlela ze-2D.

- Ezingxenyeni eziyinkimbinkimbi, ngisebenzisa izindlela ze-3D namasu we-multi-axis.

Amakhono Okubekezelela Okuphakeme

Ukunemba kubaluleke kakhulu lapho ngenza izingxenye ze-OEM aluminium die casting. CNC machining ingivumela ngifinyeleleukubekezelela okuqinile njengo-±0.01 mm, okuyinto engcono kakhulu kune-die casting yendabuko. Ngihlola zonke izingxenye ngamathuluzi okulinganisa afana nama-caliper nama-micrometer. Ngiphinde ngisebenzise amasistimu azenzakalelayo afana nemishini yokulinganisa yokuxhumanisa (CMM) ngokunemba okwengeziwe.

Nasi isiqhathaniso esisheshayo:

| Indlela Yokukhiqiza | Izinga Elijwayelekile Lokubekezelela | Amanothi |

|---|---|---|

| CNC Machining | ±0.025 mm (±0.001 in) noma okungcono | Ilungele izingxenye ezisebenza kahle kakhulu ezidinga ukulingana ncamashi |

| I-Die Casting | ±0.076 mm (±0.003 in) noma okungcono | Ilungele amaqoqo amakhulu, kodwa hhayi enembile njenge-CNC |

Ngilandela izindinganiso eziqinile zemboni, njengeISO 9001 kanye ne-IATF 16949, ukuqinisekisa ukuthi yonke ingxenye ihlangabezana nezidingo zekhwalithi. Ngisebenzisa imishini ye-CNC kuma-prototypes namaqoqo amancane lapho ngidinga ukunemba okuphezulu kakhulu. Ngokugijima okukhulu, ngihlanganisa i-die casting nemishini yesibili ye-CNC ukuze ngithuthukise izindawo ezibucayi.

- Ngihlala ngihlola izingxenye ngesikhathi nangemva kokukhiqiza.

- Ngisebenzisa izinzwa ezithuthukisiwe namasistimu okulawula ukugcina ukubekezelelana kuqinile.

- I-automation ingisiza ukuthi ngigweme amaphutha omuntu futhi igcina yonke ingxenye ingashintshi.

Uma ngiqeda inqwaba yezingxenye ze-OEM aluminium die casting, ngiyazi ngayinye izolingana futhi isebenze njengoba iklanywe. Lokhu ukwethembeka kunganiizimboni ezifana nezezimoto, ezamandla, nezokwelaphabathembe ukwenza imishini ye-CNC kumaphrojekthi abo adinga kakhulu.

Izici Eziyinhloko Nezinzuzo Ezisebenzayo Zokunemba Ezingxenyeni Zokusakaza Ze-OEM Aluminium Die

Ukuphindaphinda Okuvumelanayo

Uma ngisebenzisa imishini ye-CNC, ngiyaqaphela ukuthi zonke izingxenye ziphuma ngokufanayo, ngisho nasemaqenjini amakhulu. Inqubo iqala ngomklamo wedijithali. Ngilayisha lo mklamo emshinini, olandela imiyalelo ngokuqondile. Le ndlela isusa iphutha lomuntu futhi igcina ingxenye ngayinye ekubekezeleleni okuqinile. Ngiqinisa i-workpiece ngokucophelela, futhi umshini usika ungqimba ngongqimba. Ngemva komshini, ngibheka izingxenye ngamathuluzi afanaama-calipers nama-CMM. Lezi zinyathelo zingisiza ukuthi ngigcine ikhwalithi iphezulu nemiphumela ingaguquki.

- Imishini ye-CNC isebenzisa isilawuli sekhompyutha ngokunemba okuphezulu nokuphindaphinda.

- Ingxenye ngayinye ifana nomklamo wokuqala we-CAD.

- Ukuhlola okuzenzakalelayo kubamba noma yimaphi amaphutha ngokushesha.

- Ngingakhiqiza amakhulu noma izinkulungwaneOEM aluminium die cast izingxenyengokunemba okufanayo.

Izilinganiso Ezithuthukisiwe Nezinhlelo Zempendulo

Ngithembele kumathuluzi okulinganisa athuthukile ukuze ngihlole umsebenzi wami. Imishini ye-CNC manje isetshenziswaizinzwafuthiUbuchwepheshe be-IoTukubuka inqubo ngesikhathi sangempela. Lawa masistimu alandelela izinto ezifana nokuguga kwamathuluzi, izinga lokushisa, nokudlidliza. Uma kukhona okungahambi kahle, ngithola isexwayiso ngokushesha. NgiyasebenzisaAma-CMMukukala ubukhulu bengxenye ngayinye. Umshini ukwazi nokuzilungisa uma uthola inkinga. Le luphu yempendulo igcina izingxenye zami ngaphakathi kokubekezelelana okudingekayo.

Qaphela:Ukuqapha kwesikhathi sangempela kanye nempendulongisize ngehlise udoti futhi ngithuthukise ikhwalithi yayo yonke iqoqo lezingxenye zokuphonsa ze-OEM aluminium die.

Ukufaneleka Okuthuthukisiwe, Ukuqina, Nokwethembeka

Ngibona umehluko omkhulu kuukulingana namandlayezingxenye zomshini we-CNC. Ukubekezelelana okuqinile kusho ukuthi izingxenye zihlangana kahle, okwenza ukuhlanganisa kusheshe futhi kube lula. Ukuqedwa okubushelelezi okuvela kumishini ye-CNC nakho kusiza ngokubeka uphawu futhi kunciphisa ukuguga. Ngisebenzisa lezi zingxenye ezimbonini ezifanaizimoto kanye ne-aerospace, lapho ukwethembeka kubaluleke kakhulu. Imishini ye-CNC igcina impahla iqinile futhi ingenazo iziphambeko zokusakaza, ngakho izingxenye zihlala isikhathi eside futhi zisebenza kangcono.

| Isici | Izingxenye Zomshini ze-CNC | Izingxenye ze-Die Cast |

|---|---|---|

| Ukubekezelelana | ±0.01 mm | ±0.13 mm |

| I-Surface Finish (Ra) | 16-125 amasentimitha | 125-300 amasentimitha |

| Ukuqina | Phezulu | Kuphakathi kuya Ekuphakameni |

| Ukwethembeka | Kuhle kakhulu | Kuhle |

Ngiyethemba i-CNC machining ukuletha izingxenye ze-OEM aluminium die castingukunemba okuphezulu kanye nekhwalithi.

- Ngibona amaphutha ambalwa futhiukubekezelelana okuqinilekuwo wonke amaqoqo.

- Amakhasimende abikaukusebenza okungcono kanye nempilo yengxenye ende.

Imishini ye-CNC iyangisiza ukuthi ngihlanganeizindinganiso eziqinile zezimbonifuthi ugcine amakhasimende ami enelisekile.

FAQ

Iyiphi inzuzo enkulu ye-CNC machining yezingxenye ezisele?

NgiyabonaCNC imishiniletha izilinganiso eziqondile ngaso sonke isikhathi. Lokhu kunemba kungisiza ngigweme amaphutha futhi ngigcine izingxenye zami zithembekile.

Ngihlola kanjani ukunemba kwezingxenye zomshini we-CNC?

Ngisebenzisa ama-caliper, ama-micrometer, nama-CMM.

- I-Calipers ikala ubude.

- Ama-Micrometers hlola ukujiya.

- Ama-CMM aqinisekisa izimo eziyinkimbinkimbi.

Ingabe imishini ye-CNC ingaphatha imiklamo eyinkimbinkimbi?

| Uhlobo Lomklamo | CNC Amandla |

|---|---|

| Amajamo alula | Yebo |

| Amajika ayinkimbinkimbi | Yebo |

| Izingxenye ze-Multi-eksisi | Yebo |

Ngiyethemba imishini ye-CNC kuzo zonke izidingo zami zokuklama.

Ibhalwe ngu: Daphne

I-imeyili:daphne@haihongxintang.com

Ifoni: Ukuthengisa: 0086-134 8641 8015

Isikhathi sokuthumela: Aug-24-2025