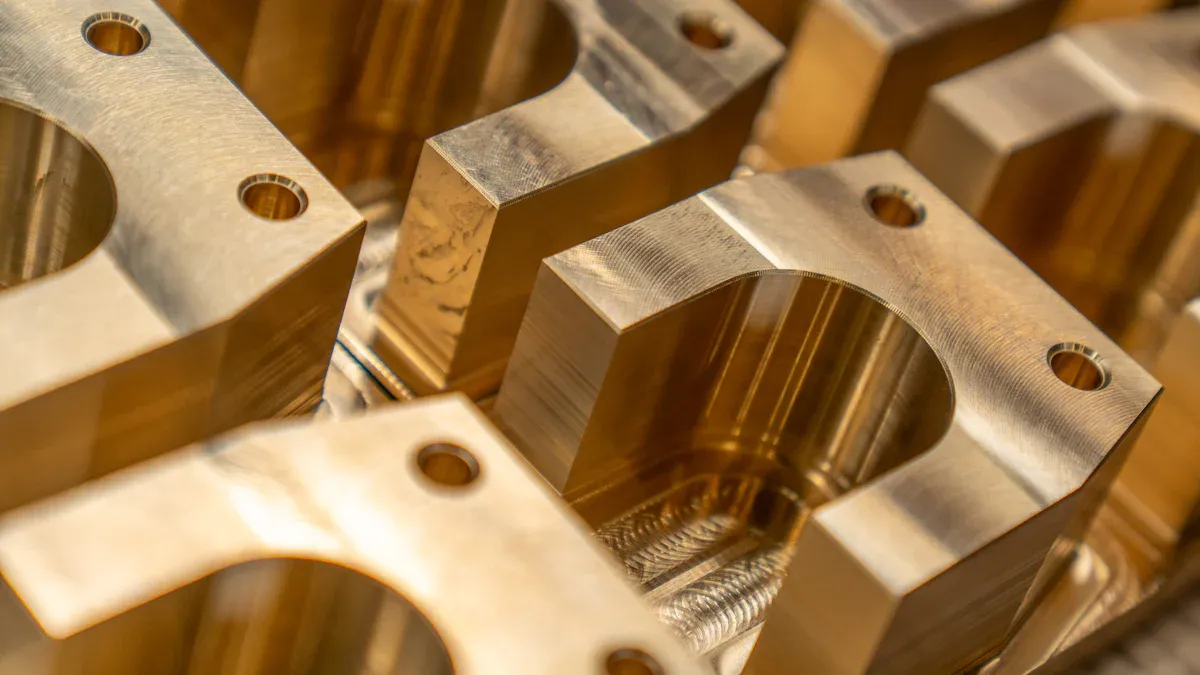

Lokacin da na yi aiki tare da CNC machining, na ga yadda kwamfuta sarrafa tsarin canza samar daOEM aluminum mutu simintin sassa.

- Injin na biyeainihin umarnin, wanda ke kawar da haɗarin kurakurai na hannu.

- Duban ingancin atomatik da gyare-gyaren hanyar kayan aiki suna kiyaye kowane sashi daidai.

- OEM aluminum mutu simintin gyare-gyare yana nufinzuwa sassan da ke buƙatar juriya mai ƙarfi, kuma CNC tana ba da waɗannanAluminum Die Casting Capabilities.Na aminceOEM Aluminum Die Casting Part Maƙeran- essai don isar da ingantaccen sakamako.

Key Takeaways

- Injin CNCyana amfani da sarrafa kwamfuta don bin ainihin umarnin, wanda ke kawar da kurakuran ɗan adam kuma yana samar da sassa tare da ma'auni masu ma'ana sosai.

- Babban software yana tsarawa da haɓaka hanyoyin kayan aiki don yin yanke ingantaccen kuma daidai, rage kurakurai, adana lokaci, da rage farashi.

- Madaidaicin injunan CNC da tsarin amsawa na lokaci-lokaci suna tabbatar da kowane bangare ya dace daidai, yana dadewa, kuma ya hadu.m ingancin matsayin.

Yadda CNC Machining ke Ba da Madaidaicin Sashin Kayan Aluminum Die na OEM

Motsi-Kwamfuta Mai Sarrafawa

Lokacin da nake aiki tare da injunan CNC, na ga yadda ƙirar dijital ta zama sassa na gaske tare da daidaito mai ban mamaki. Tsarin yana farawa da aCAD model. Ina amfaniCAM softwaredon juya wannan samfurin zuwaG-code, wanda ke gaya wa injin daidai yadda ake motsawa. Mai kula da CNC yana karanta waɗannan umarni kuma yana jagorantar kayan aikin yanke tare da gatari da yawa, wani lokacin har zuwa biyar. Wannan yana ba ni damar ƙirƙirar sifofi masu sarƙaƙƙiya da kusurwoyi masu tsauri waɗanda ba za su yi yuwuwa da hannu ba.

Injin yana lura da kowane motsi. Yana aika sigina zuwa injiniyoyi, tabbatar da cewa kayan aiki yana bin hanyar daidai. Ina kallo yayin da injin ya yanke, yana yin rawar jiki, yana niƙa aluminum, koyaushe yana daidai da ƙira. Wannan iko yana nufin zan iya yinOEM aluminum mutu simintin sassatare da ma'auni daidai, ko da lokacin da siffofi suka yi rikitarwa.

Tukwici:Multi-axis CNC injitaimake ni samar da sassa dam haƙurida cikakkun bayanai masu rikitarwa, waɗanda ke da mahimmanci ga masana'antu kamar na'urorin mota da na likitanci.

Inganta Hanyar Kayan aiki Mai sarrafa kansa

Na dogara da ingantaccen hanyar kayan aiki mai sarrafa kansa don tabbatar da cewa kowane yanke yana da inganci kuma daidai. Software na CAM yana taimaka min tsara hanya mafi kyau don kayan aikin yanke. Yana bincika yiwuwar kurakurai, kamar karo ko canje-canjen kayan aikin da ba dole ba, kafin injin ya fara. Wannan yana adana lokaci kuma yana rage kurakurai.

Anan ga tebur yana nuna yadda ingantawa ke inganta aikina:

| Bangaren ingantawa | Bayanin Ingantawa | Tasiri kan Kurakurai na Machining da Inganci |

|---|---|---|

| Inganta Hanyar Kayan aiki | Nemo mafi gajarta, hanya mafi aminci ta kayan aiki ta atomatik | Yana rage lokutan zagayowar kuma yana haɓaka aiki da kusan 15% |

| Jerin Canjin Kayan aiki | Yana zaɓar mafi kyawun tsari don canjin kayan aiki | Yanke lokacin canjin kayan aiki da kashi 20%, yana rage haɗarin kuskure |

| Gano Kuskuren Hankali | Matsalolin tabo kamar kayan aiki mara kyau ko umarnin sanyaya | Yana hana haɗuwa da yanke iska da sama da 80% |

| Rigakafin Hadari | Yana gyara al'amura kafin fara mashin ɗin | Rage raguwa da raguwa, inganta kwanciyar hankali |

| Kwanciyar hankali da Rage Kuɗi | Yana kiyaye tsarin santsi da kwanciyar hankali | Rage farashin gyarawa da gyarawa |

| Aiwatar da Rukunin Rukunoni | Daidaita don Multi-axis da samar da tsari | Yana haɓaka yuwuwar injin don samar da sauri, karko |

Ina amfani da software na CAM na ci gaba wanda ke ba ni damar kwaikwayi tsarin injina. Zan iya ganin ko kayan aikin zai bugi wani abu ko kuma idan hanyar tana buƙatar canzawa. Algorithms kamardaidaitacce sharewa da kuma high-gudun machiningtaimake ni in ci gaba da tafiya da kayan aiki lafiya da kuma hana lalacewa. Wannan yana nufin sassan simintin ƙarfe na OEM aluminum sun fito daidai da farko, tare da ƙarancin sharar gida da ƙarancin kurakurai.

- Na zaɓi hanyoyin kayan aiki daban-daban dangane da siffar ɓangaren.

- Don sassa masu sauƙi, Ina amfani da hanyoyin 2D.

- Don hadaddun sassa, Ina amfani da hanyoyin 3D da dabarun axis masu yawa.

Babban Hakurin Hakuri

Matsakaicin mahimmanci mafi mahimmanci lokacin da na yi OEM aluminum mutu simintin sassa. CNC machining yana ba ni damar isaHaƙuri kamar ± 0.01 mm, wanda ya fi yin simintin mutuwa na gargajiya. Ina duba kowane bangare tare da kayan aikin aunawa kamar calipers da micrometers. Hakanan ina amfani da tsarin sarrafa kansa kamar injunan aunawa (CMM) don ƙarin daidaito.

Ga kwatance mai sauri:

| Hanyar sarrafawa | Matsayin Haƙuri Na Musamman | Bayanan kula |

|---|---|---|

| Farashin CNC | ± 0.025 mm (± 0.001 in) ko mafi kyau | Cikakkun ɓangarorin ayyuka masu girma waɗanda ke buƙatar dacewa daidai |

| Mutuwar Casting | ± 0.076 mm (± 0.003 in) ko mafi kyau | Yana da kyau ga manyan batches, amma ba daidai ba kamar CNC |

Ina bin tsauraran matakan masana'antu, kamarISO 9001 da IATF 16949, don tabbatar da kowane bangare ya cika buƙatun inganci. Ina amfani da injina na CNC don samfura da ƙananan batches lokacin da nake buƙatar daidaito mafi girma. Don manyan gudu, na haɗa simintin kashewa tare da injinan CNC na biyu don inganta wurare masu mahimmanci.

- A koyaushe ina duba sassan lokacin samarwa da bayan samarwa.

- Ina amfani da na'urori masu auna firikwensin ci gaba da tsarin sarrafawa don kiyaye haƙuri.

- Yin aiki da kai yana taimaka mini nisantar kurakuran ɗan adam kuma yana kiyaye kowane sashi daidai.

Lokacin da na gama batch na OEM aluminum mutu simintin sassa, Na san kowannensu zai dace da aiki kamar yadda aka tsara. Wannan dogara shine dalilin da ya samasana'antu kamar motoci, makamashi, da likitanciamince CNC machining domin su mafi m ayyukan.

Maɓalli Maɓalli da Fa'idodin Aiki na Madaidaici a cikin sassan OEM Aluminum Die Casting Parts

Matsakaicin Maimaituwa

Lokacin da nake amfani da mashin ɗin CNC, na lura cewa kowane sashi yana fitowa iri ɗaya, har ma a cikin manyan batches. Tsarin yana farawa da ƙirar dijital. Ina ɗora wannan ƙirar a cikin injin, wanda ke bin umarnin daidai. Wannan hanyar tana kawar da kuskuren ɗan adam kuma tana kiyaye kowane sashe cikin tsananin juriya. Ina manne kayan aikin a hankali, kuma injin yana yanke Layer ta Layer. Bayan machining, na duba sassan da kayan aiki kamarcalipers da CMMs. Waɗannan matakan suna taimaka mini in kiyaye ingancin inganci da daidaiton sakamako.

- CNC machining yana amfani da sarrafa kwamfuta don babban daidaito da maimaitawa.

- Kowane bangare ya dace da ainihin ƙirar CAD.

- Binciken atomatik yana kama kowane kuskure nan da nan.

- Zan iya samar da daruruwan ko dubbanOEM aluminum mutu simintin sassatare da daidaito iri ɗaya.

Babban Ma'auni da Tsarukan Sake Maimaitawa

Na dogara da kayan aikin auna na ci gaba don duba aikina. Ana amfani da injin CNC yanzuna'urori masu auna firikwensinkumaFasahar IoTdon kallon tsarin a ainihin lokacin. Waɗannan tsarin suna bin abubuwa kamar lalacewa na kayan aiki, zazzabi, da rawar jiki. Idan wani abu ba daidai ba, Ina samun faɗakarwa nan da nan. Ina amfaniCMMsdon auna girman kowane bangare. Na'urar ma tana iya daidaita kanta idan ta sami matsala. Wannan madauki na martani yana kiyaye sassana cikin juriyar da ake buƙata.

Lura:Sa ido na ainihin lokaci da amsawataimake ni rage sharar gida da inganta inganci ga kowane tsari na OEM aluminum mutu simintin sassa.

Ingantattun Fitsari, Dorewa, da Dogara

Ina ganin babban bambanci a cikindacewa da ƙarfina sassan injinan CNC. Matsakaicin haƙuri yana nufin cewa sassa sun dace da juna daidai, wanda ke sa haɗuwa cikin sauri da sauƙi. Ƙarƙashin ƙasa mai santsi daga mashin ɗin CNC shima yana taimakawa tare da rufewa da rage lalacewa. Ina amfani da waɗannan sassa a cikin masana'antu kamarmotoci da sararin samaniya, inda dogara ya fi muhimmanci. CNC machining yana kiyaye kayan da ƙarfi kuma ba su da lahani, don haka sassan suna daɗe da yin aiki mafi kyau.

| Siffar | CNC Machined Parts | Rasu Cast Parts |

|---|---|---|

| Hakuri | ± 0.01 mm | ± 0.13 mm |

| Ƙarshen Surface (Ra) | 16-125 microinches | 125-300 microinches |

| Dorewa | Babban | Matsakaici zuwa Babban |

| Abin dogaro | Madalla | Yayi kyau |

Na amince CNC machining don sadar da OEM aluminum mutu simintin sassa tare dasaman daidaito da inganci.

- Ina ganin ƙananan kurakurai kumam haƙuria cikin kowane rukuni.

- Abokan ciniki sun ba da rahotomafi kyawun aiki da tsawon rayuwa.

CNC machining taimaka mini saduwam masana'antu matsayinkuma ku gamsar da abokan cinikina.

FAQ

Mene ne babban fa'idar CNC machining don kayayyakin gyara?

Na ganiInjin CNCisar da ma'auni daidai kowane lokaci. Wannan daidaito yana taimaka mini in guje wa kurakurai kuma yana kiyaye sassana abin dogaro.

Ta yaya zan bincika madaidaicin sassan injinan CNC?

Ina amfani da calipers, micrometers, da CMMs.

- Calipers suna auna tsayi.

- Micrometers duba kauri.

- CMMs suna tabbatar da hadaddun siffofi.

Shin CNC machining na iya ɗaukar hadaddun ƙira?

| Nau'in Zane | CNC iyawa |

|---|---|

| Siffai masu sauƙi | Ee |

| Matsaloli masu rikitarwa | Ee |

| Multi-axis sassa | Ee |

Na amince da injinan CNC don duk buƙatun ƙira na.

By: Daphne

Imel:daphne@haihongxintang.com

Waya: Siyarwa: 0086-134 8641 8015

Lokacin aikawa: Agusta-24-2025