When I work with CNC machining, I see how computer-controlled systems transform the production of OEM aluminum die casting parts.

- The machines follow exact instructions, which removes the risk of manual errors.

- Automated quality checks and tool path adjustments keep every part consistent.

- OEM aluminum die casting refers to parts needing tight tolerances, and CNC offers these Aluminum Die Casting Capabilities.I trust OEM Aluminum Die Casting Part Manufacturer - essai to deliver reliable results.

Key Takeaways

- CNC machining uses computer control to follow exact instructions, which removes human errors and produces parts with very tight and consistent measurements.

- Advanced software plans and optimizes tool paths to make cutting efficient and accurate, reducing mistakes, saving time, and lowering costs.

- High-precision CNC machines and real-time feedback systems ensure every part fits perfectly, lasts longer, and meets strict quality standards.

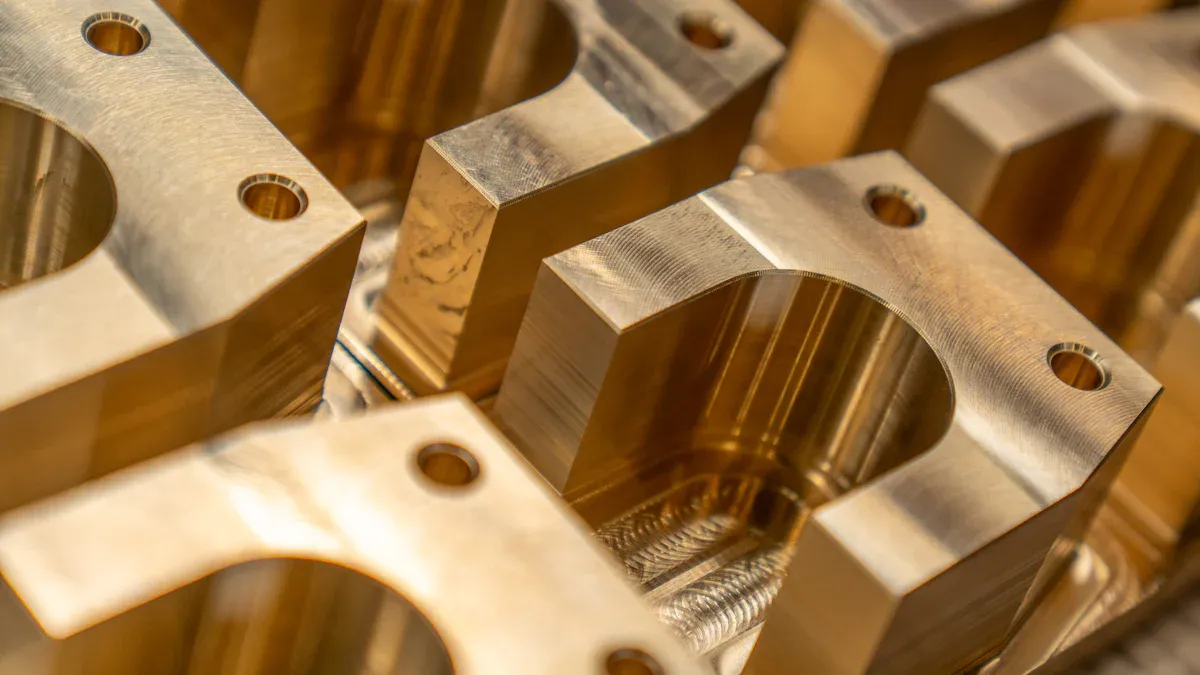

How CNC Machining Delivers Precision for OEM Aluminum Die Casting Parts

Computer-Controlled Movements

When I work with CNC machines, I see how digital designs become real parts with incredible accuracy. The process starts with a CAD model. I use CAM software to turn that model into G-code, which tells the machine exactly how to move. The CNC controller reads these instructions and guides the cutting tool along several axes, sometimes up to five. This lets me create complex shapes and tight corners that would be impossible by hand.

The machine keeps track of every movement. It sends signals to motors, making sure the tool follows the path perfectly. I watch as the machine cuts, drills, and mills the aluminum, always matching the design. This control means I can make OEM aluminum die casting parts with exact dimensions, even when the shapes get complicated.

Tip: Multi-axis CNC machines help me produce parts with tight tolerances and intricate details, which is essential for industries like automotive and medical devices.

Automated Tool Path Optimization

I rely on automated tool path optimization to make sure every cut is efficient and accurate. The CAM software helps me plan the best route for the cutting tool. It checks for possible errors, like collisions or unnecessary tool changes, before the machine starts. This saves time and reduces mistakes.

Here’s a table showing how optimization improves my work:

| Optimization Aspect | Description of Optimization | Impact on Machining Errors and Efficiency |

|---|---|---|

| Tool Path Optimization | Automatically finds the shortest, safest tool path | Shortens cycle times and boosts efficiency by about 15% |

| Tool Change Sequence | Picks the best order for tool changes | Cuts tool change time by 20%, lowers error risk |

| Logic Error Detection | Spots problems like wrong tool or coolant commands | Prevents collisions and air cuts by over 80% |

| Risk Prevention | Fixes issues before machining starts | Reduces downtime and scrap, improves stability |

| Stability and Cost Reduction | Keeps the process smooth and steady | Lowers maintenance and repair costs |

| Applicability to Complex Parts | Adapts for multi-axis and batch production | Maximizes machine potential for fast, stable production |

I use advanced CAM software that lets me simulate the machining process. I can see if the tool will hit anything or if the path needs to change. Algorithms like adaptive clearing and high-speed machining help me keep the tool moving smoothly and prevent wear. This means my OEM aluminum die casting parts come out right the first time, with less waste and fewer errors.

- I choose different tool paths depending on the part’s shape.

- For simple parts, I use 2D paths.

- For complex parts, I use 3D paths and multi-axis strategies.

High Tolerance Capabilities

Precision matters most when I make OEM aluminum die casting parts. CNC machining lets me reach tolerances as tight as ±0.01 mm, which is much better than traditional die casting. I check every part with measuring tools like calipers and micrometers. I also use automated systems like coordinate measuring machines (CMM) for extra accuracy.

Here’s a quick comparison:

| Manufacturing Method | Typical Tolerance Level | Notes |

|---|---|---|

| CNC Machining | ±0.025 mm (±0.001 in) or better | Perfect for high-performance parts needing exact fit |

| Die Casting | ±0.076 mm (±0.003 in) or better | Good for large batches, but not as precise as CNC |

I follow strict industry standards, such as ISO 9001 and IATF 16949, to make sure every part meets quality requirements. I use CNC machining for prototypes and small batches when I need the highest precision. For large runs, I combine die casting with secondary CNC machining to improve critical areas.

- I always inspect parts during and after production.

- I use advanced sensors and control systems to keep tolerances tight.

- Automation helps me avoid human errors and keeps every part consistent.

When I finish a batch of OEM aluminum die casting parts, I know each one will fit and function as designed. This reliability is why industries like automotive, energy, and medical trust CNC machining for their most demanding projects.

Key Features and Practical Benefits of Precision in OEM Aluminum Die Casting Parts

Consistent Repeatability

When I use CNC machining, I notice that every part comes out the same, even in large batches. The process starts with a digital design. I load this design into the machine, which follows the instructions exactly. This method removes human error and keeps each part within tight tolerances. I clamp the workpiece carefully, and the machine cuts layer by layer. After machining, I check the parts with tools like calipers and CMMs. These steps help me keep the quality high and the results consistent.

- CNC machining uses computer control for high precision and repeatability.

- Each part matches the original CAD design.

- Automated inspections catch any mistakes right away.

- I can produce hundreds or thousands of OEM aluminum die casting parts with the same accuracy.

Advanced Measurement and Feedback Systems

I rely on advanced measurement tools to check my work. CNC machines now use sensors and IoT technology to watch the process in real time. These systems track things like tool wear, temperature, and vibration. If something goes wrong, I get an alert right away. I use CMMs to measure each part’s dimensions. The machine can even adjust itself if it finds a problem. This feedback loop keeps my parts within the required tolerances.

Note: Real-time monitoring and feedback help me reduce waste and improve quality for every batch of OEM aluminum die casting parts.

Improved Fit, Durability, and Reliability

I see a big difference in the fit and strength of CNC-machined parts. The tight tolerances mean that parts fit together perfectly, which makes assembly faster and easier. The smooth surface finish from CNC machining also helps with sealing and reduces wear. I use these parts in industries like automotive and aerospace, where reliability matters most. CNC machining keeps the material strong and free from casting defects, so the parts last longer and perform better.

| Feature | CNC Machined Parts | Die Cast Parts |

|---|---|---|

| Tolerance | ±0.01 mm | ±0.13 mm |

| Surface Finish (Ra) | 16-125 microinches | 125-300 microinches |

| Durability | High | Moderate to High |

| Reliability | Excellent | Good |

I trust CNC machining to deliver OEM aluminum die casting parts with top precision and quality.

- I see fewer errors and tighter tolerances in every batch.

- Customers report better performance and longer part life.

CNC machining helps me meet strict industry standards and keep my clients satisfied.

FAQ

What is the main advantage of CNC machining for spare parts?

I see CNC machining deliver exact dimensions every time. This accuracy helps me avoid mistakes and keeps my parts reliable.

How do I check the precision of CNC-machined parts?

I use calipers, micrometers, and CMMs.

- Calipers measure length.

- Micrometers check thickness.

- CMMs confirm complex shapes.

Can CNC machining handle complex designs?

| Design Type | CNC Capability |

|---|---|

| Simple shapes | Yes |

| Complex curves | Yes |

| Multi-axis parts | Yes |

I trust CNC machines for all my design needs.

By:Daphne

Email:daphne@haihongxintang.com

Phone:Sales: 0086-134 8641 8015

Post time: Aug-24-2025