Izingxenye zokuphonswa kwezinsimbi zochwepheshezibalulekile ekukhiqizeni izingxenye zekhwalithi ephezulu ngokunemba okungenakuqhathaniswa. Izimboni ezahlukene zincikemetal die castinqubo yezixazululo ezihlala isikhathi eside, ezingaka, nezingabizi kakhulu. Amasistimu azenzakalelayo adlala indima ebalulekile ekuthuthukiseni ikhwalithi ngokuqapha okuguquguqukayo okufana nesivinini sensimbi nomfutho we-hydraulic. Lobu buchwepheshe obuthuthukisiwe buqinisekisa imiphumela engaguquki, okwenza imetal die casting izingxenye foundryingxenye ebalulekile yokukhiqiza yesimanje.

Okuthathwayo Okubalulekile

- I-Metal die castingyenza izingxenye eziqinile ngokuphusha insimbi eshisayo ibe yisikhunta.

- Ukukhaizinto ezinhle, njenge-aluminium noma i-magnesium, yenza izingxenye zisebenze kangcono futhi zihlale isikhathi eside.

- Ukusebenzisa imishini ku-die casting konga isikhathi nemali, okusiza izimboni ezinkulu njengabakhi bezimoto nezindiza.

Ukuqonda Izingxenye Zokusakaza Ze-Metal Die

Iyini i-Metal Die Casting?

I-Metal die casting iyinqubo yokukhiqiza eyakha izingxenye zensimbi ezinembayo nezihlala isikhathi eside. Kuhilela ukujova insimbi encibilikisiwe esikhunjeni, noma ukufa, ngaphansi kwengcindezi ephezulu. Le ndlela ivumela abakhiqizi ukuthi bakhiqize izingxenye ezinemininingwane eyinkimbinkimbi kanye nekhwalithi engaguquki.

I-Die casting inika amandla ukukhiqizwa kwezingxenye zensimbi ngokunemba okuphezulu nemininingwane emihle, njengezindawo ezithungwe, ngaphandle kokudinga ukucutshungulwa okwengeziwe.

Le nqubo isetshenziswa kakhulu ezimbonini ezifana nezezimoto, i-aerospace, nezimpahla zabathengi. Isekela ukwakhiwa kwezingxenye ezingasindi, eziqinile, futhi ezimelana nokugqwala, okuyenza ibaluleke ekukhiqizeni kwesimanje.

Izinto Ezisetshenziswa Enqubweni

Ukukhethwa kwezinto ezibonakalayo kuba nomthelela omkhulu ekusebenzeni kanye nekhwalithi yezingxenye zokuphonswa kwezinsimbi eziwuchwepheshe. Abakhiqizi basebenzisa izinsimbi ezihlukahlukene nama-alloys, ngamunye unikeza izakhiwo ezihlukile ezifanele izinhlelo zokusebenza ezithile.

| Uhlobo Lwezinto | Izakhiwo | Izinhlelo zokusebenza |

|---|---|---|

| I-Aluminium Alloy 380 | I-castability enhle kakhulu, i-lightweight, ukumelana nokugqwala | Abakaki benjini, ifenisha, izibaya zikagesi |

| I-Aluminium Alloy B390 | Ukudlidliza okukhethekile nokumelana nokugqoka | Izindlu zamaphampu, imizimba yama-valve, ama-impeller |

| I-Magnesium AZ91D | Isilinganiso esiphezulu samandla nesisindo, ukumelana nokugqwala | Izingxenye ze-Powertrain, izingxenye zemishini |

| Zinc Zamak 3 | Ukuzinza kwe-Dimensional, ukusakaza kalula | Izingxenye zamapayipi, abalandeli be-ceiling |

I-Aluminium iyisinqumo esithandwayongenxa yesilinganiso samandla nesisindo kanye nokumelana nokugqwala. Ama-alloys e-Magnesium akhethwa ekusetshenzisweni okungasindi, kuyilapho ama-zinc alloys ehamba phambili ngokunemba nokuqedwa okubushelelezi.

Izinyathelo Ezibalulekile Kunqubo Yokusakaza Ifa

Inqubo yokulingisa ifa ihlanganisa izinyathelo ezimbalwa ezibalulekile, ngasinye sinikela kwikhwalithi yomkhiqizo wokugcina.

- Ukulungiselela: Izindawo zesikhunta ziyagcotshwa ukuze kuqinisekiswe ukukhishwa kalula kokusakazwa. Lesi sinyathelo sinciphisa amaphutha futhi siqinisekise ukususwa okubushelelezi.

- Ukugcwalisa: Insimbi encibilikisiwe ijova esikhunjeni ngaphansi kwengcindezi ephezulu. Lesi sinyathelo sivimbela ukuncipha kanye ne-porosity ngokuqinisekisa ukugcwaliswa okuphelele.

- Ukukhishwa: Izikhonkwane ze-ejector zisusa ama-castings esikhunjini. Lokhu kuvumela imijikelezo yokukhiqiza esheshayo futhi kunciphisa umonakalo ezingxenyeni.

- Shakeout: Izingxenye ze-Scrap ziyasuswa ekubunjweni okuqediwe. Lesi sinyathelo siqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zekhwalithi.

Ukunemba kwalezi zinyathelo kuqinisekisa ukuthi izingxenye zokuphonswa kwezinsimbi zensimbi zihlangabezana nezicaciso ezidingekayo zokuqina nokusebenza.

Izinzuzo Zezingxenye Zokusakaza Ze-Metal Die Professional

Ukunemba nokuvumelana

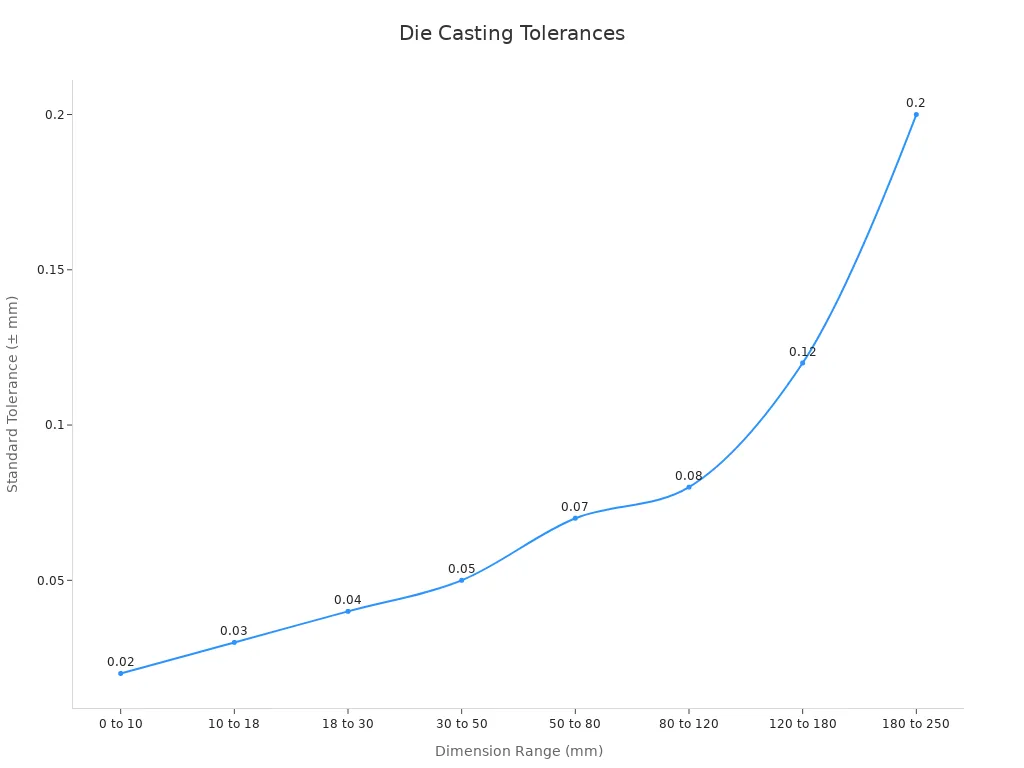

Insimbi yochwephesheizingxenye zokufazaziwa ngokunemba kwazo okukhethekile nokuvumelana kobukhulu. Indlela yomjovo wengcindezi ephezulu esetshenziswa kule nqubo iqinisekisa ukuthi yonke ingxenye ihlangabezana nokubekezelelana okuqinile, iyenze ibe ilungele izimboni ezidinga imiklamo eyinkimbinkimbi. Isibonelo, izixazululo ze-CastMold's die-casting zikhiqiza izingxenye ezinokunemba okuphezulu kobukhulu, zinciphisa isidingo somshini wesibili.

Ikhono lokuthola ukubekezelelana okuqinile kuwuphawu lokufa. Lokhu kunemba kubalulekile ezinhlelweni zokusebenza lapho ngisho nokuchezuka okuncane kungonakalisa ukusebenza.

| Ububanzi Bobukhulu obuyisisekelo (mm) | Ukubekezelela Okujwayelekile (± mm) |

|---|---|

| 0 ku10 | 0.02 |

| 10 ku-18 | 0.03 |

| 18 ku30 | 0.04 |

| 30 kuya ku-50 | 0.05 |

| 50 ku80 | 0.07 |

| 80 kuya ku-120 | 0.08 |

| 120 kuya ku-180 | 0.12 |

| 180 kuya ku-250 | 0.2 |

Ukuqedwa okubushelelezi okutholakala ngokufaka i-die casting kuthuthukisa ikhwalithi yomkhiqizo wokugcina. Lokhu kuqeda isidingo esikhulu sokucutshungulwa kwangemuva, ukonga isikhathi kanye nezindleko ngenkathi kuqinisekiswa umphumela obukeka kahle.

Ukusebenza Kwezindleko Zokukhiqiza Okukhulu

I-Die casting inikeza aisixazululo esingabizi kakhuluukukhiqiza imiqulu emikhulu yezingxenye zensimbi. Inqubo isebenzisa izinto ezizenzakalelayo kanye nezinto ezigaywa kabusha ukuze kwehliswe izindleko zokukhiqiza. Ukutshalwa kwezimali kokuqala ku-automation kungase kubonakale kuphakeme, kodwa kuholela ekongeni okubalulekile emsebenzini kanye nokusebenza kahle okwandisiwe ngokuhamba kwesikhathi.

| Isici | Incazelo |

|---|---|

| I-Material Recyclability | Izinto ezisetshenziswayo zinciphisa izindleko futhi zihambisane nezinhloso zokusimama. |

| Ukusetshenziswa kwamandla | Ukusetshenziswa kwamandla okuthuthukisiwe emishinini kwehlisa izindleko zokusebenza. |

| Automation Investments | I-automation inciphisa izindleko zabasebenzi futhi ithuthukisa isivinini sokukhiqiza. |

| Ukulawulwa kwe-Scrap and Waste | Ukulawulwa kwemfucuza okusebenzayo kunciphisa ukulahleka kwempahla kanye nezindleko. |

| Izinyathelo Zokulawula Ikhwalithi | Ukuhlolwa kwekhwalithi okuqinile kunciphisa amaphutha, konga isikhathi nezinsiza. |

Ukukhula kwe-die casting kukwenza kube nenzuzo ikakhulukazi ezimbonini ezifana nezezimoto nezogesi, lapho ukukhiqizwa kwevolumu ephezulu kubalulekile. Ngokunciphisa ukungcola nokwandisa ukusetshenziswa kwamandla, abakhiqizi bangazuza kokubili izinzuzo zezomnotho nezemvelo.

Ukuqina Nokuqina Kwezingxenye

Izingxenye zokuphonswa kwezinsimbi eziwuchwepheshe zibungazwa ukuqina kwazo namandla emishini. Inqubo ikhiqiza izingxenye ezinobunzima obuhle kakhulu kanye nezakhiwo eziqinile, ezizenza zifanelekele izicelo ezifunayo. Isibonelo, ukuhlolwa kwemishini, okuhlanganisa ubulukhuni kanye nokuhlolwa komthelela we-Charpy, kuqinisekisa amandla nokuthembeka kwezingxenye ze-die-cast.

Izimboni ezifana ne-aerospace kanye nezimoto zithembele ezingxenyeni ze-die-cast ukuze zikwazi ukumelana nezimo ezibucayi ngaphandle kokubeka engcupheni ukusebenza.

Amandla okukhathala ezinsimbi ze-die-cast aphinde athuthukise ukuqina kwazo, aqinisekise ukusebenza okuhlala isikhathi eside ngisho nangaphansi kwengcindezi eqhubekayo. Lokhu kubenza babe yinketho ekhethwayo yezinhlelo zokusebenza ezibucayi njengezingxenye zenjini nezingxenye zesakhiwo.

Ngokuhlanganisa amandla, ukuqina, nokunemba, i-die casting iletha izingxenye ezihlangabezana nezidingo ezinzima zezimboni zesimanje.

Izicelo ze-Professional Metal Die Casting Parts

Imboni Yezimoto

Umkhakha wezimoto uthembele kakhulu ezingxenyeni zokusakaza zensimbi ezichwepheshile ngokunemba nokuqina kwazo. Njengoba ukukhiqizwa kwezimoto emhlabeni wonke kufinyelela cishe kumayunithi ayizigidi ezingama-85 ngo-2022, isidingo sezingxenye ze-die-cast sihlala siqinile. Abakhiqizi basebenzisa ubuchwepheshe obuthuthukisiwe obufana ne-automation kanye nedijithali ukuze bahlangabezane nezidingo eziguqukayo zemboni, ikakhulukazi ezimotweni zikagesi namadizayini angasindi. Ukwakhiwa okusha okufana “nokusakaza kwe-giga” ka-Ryobi kwezingxenye zomzimba ezinkulu ze-EV kanye nemishini emikhulu yokusakaza ye-UBE Corporation igqamisa ukugxila komkhakha ekusebenzeni kahle nasekunciphiseni izindleko. Le ntuthuko iqinisekisa ukuthi izingxenye ze-die-cast zihlangabezana nezidingo eziqinile zezimoto zesimanje, okuhlanganisa amandla, ukunciphisa isisindo, nokumelana nokugqwala.

I-Aerospace kanye Nezokuvikela

Emkhathini nasekuvikeleni, i-die casting idlala indima ebalulekile ekukhiqizeni izingxenye ezingasindi kodwa eziqinile. Ama-alloys athuthukile nezindlela zokukhipha i-vacuum die zinciphisa isisindo sezingxenye, zithuthukise ukusebenza kahle kukaphethiloli kufika ku-20%. Inqubo iqinisekisa ukuthi izingxenye zingakwazi ukumelana nokucindezeleka okukhulu kokundiza ngenkathi ihlangabezana nezindinganiso eziqinile zokuphepha.

| Zuza | Incazelo | Umthelela ku-Aerospace kanye Nokuvikela |

|---|---|---|

| Izingxenye Ezingasindi | Ama-alloys athuthukile kanye ne-vacuum die casting kunciphisa isisindo sengxenye. | Ithuthukisa ukusebenza kahle kukaphethiloli ngokufika ku-20%. |

| Amandla Nokuqina | Iqinisekisa ukuthi izingxenye zingakwazi ukumelana nengcindezi yendiza namazinga okuphepha. | Ihlangabezana nezimfuneko zokuphepha eziphezulu. |

| Ukuphumelela Kwamafutha | Ukunciphisa isisindo kuholela ekusebenziseni uphethiloli okungcono. | Ibalulekile ekongeni izindleko zokusebenza. |

Lezi zinzuzo zenza i-die casting ibaluleke kakhulu ekukhiqizeni i-aerospace ebalulekile kanye nezingxenye zokuzivikela.

Izinto zikagesi kanye nezabathengi

I-Die casting nayo ihamba phambiliembonini ye-electronics kanye nempahla yabathengi. Ihlinzeka ngezingxenye eziqinile, ezinokwethenjelwa zamasistimu kagesi, izingxenye eziqinile zemishini yasendlini, kanye nezingxenyekazi zehadiwe ezisebenzayo kodwa ezihlobisa ifenisha.

| Imboni | Izinzuzo Zezingxenye Zokusakaza ze-Die |

|---|---|

| Imboni kagesi | Izingxenye zikagesi ezinamandla zezinhlelo ezithembekile |

| Imboni kagesi | Izingxenye ezihlala isikhathi eside zemishini yasendlini zithuthukisa ukusebenza kahle |

| Imboni Yefenisha | I-hardware esebenzayo neyokuhlobisa yokukhanga kobuhle |

Ngokuhlanganisa ukunemba, ukuqina, kanye nokuguquguquka, izingxenye zensimbi eziwuchwepheshe zihlangabezana nezidingo ezihlukahlukene zalezi zimboni.

Ukukhetha Isixazululo Esilungile Sokusakaza Kwe-Metal Die Casting

Ukuhlola Ubungcweti Nesipiliyoni

Ukukhetha umkhiqizi ofanele kuqala ngokuhlola ubuchwepheshe kanye nolwazi lwabo. Izinkampani ezinamashumi eminyaka olwazi lwemboni zivame ukuletha imiphumela ephezulu. I-Dynacast, ngokwesibonelo, inesipiliyoni seminyaka engaphezu kwengama-80 ikhiqiza izingxenye zensimbi ezinembile zemikhakha eyahlukene. Ngokufanayo, i-A&B isebenzisa onjiniyela abanekhono abakwazi ukuphatha imiklamo eyinkimbinkimbi, baqinisekise imiphumela yekhwalithi ephezulu. Abakhiqizi abafana ne-Castingod ne-Golden Pond Metal Die Casting Co., Ltd. babonisa ukwethembeka nekhono ngokuphatha amaphrojekthi ayinkimbinkimbi nokusebenzisa izinyathelo eziqinile zokulawula ikhwalithi.

Uchwepheshe buqinisekisa ukuthi abakhiqizi bangakwazi ukubhekana nezinselele ezihlukile, kuyilapho ulwazi luqinisekisa ukusebenza okungaguquki kuwo wonke amaphrojekthi.

Lapho uhlola umphakeli, cabangela irekhodi lakhe lokulandela kanye nezinkomba. Umlando oqinile wokuletha izingxenye zekhwalithi ubonisa ukuzibophezela kwazo ekwenzeni okuhle.

Ukuhlola Ubuchwepheshe Nezisetshenziswa

Ubuchwepheshe besimanje budlala indima ebalulekile ekukhiqizeni izinga eliphezuluizingxenye ze-die-cast. Amasistimu azenzakalelayo athuthukisa ukusebenza kahle nokunemba, ehlisa izindleko zabasebenzi futhi anciphise amaphutha abantu. Amarobhothi enza lula umjovo kanye nezinqubo zokukhipha, aqinisekisa ikhwalithi engashintshi kukho konke ukukhiqizwa. Isofthiwe yokulingisa ethuthukisiwe ibikezela ukukhubazeka futhi ithuthukise inqubo yokulingisa, inike amandla i-virtual prototyping ngaphambi kokukhiqiza ngokomzimba.

Abakhiqizi abasebenzisa i-AI kanye nokufunda komshini bangaqapha futhi bathuthukise ukusebenza ngesikhathi sangempela. Lokhu kuthuthuka kuthuthukisa ukuphepha, isivinini, kanye nokunemba, kukwenze kudingekile ezingxenyeni zokuphonswa kwensimbi eziwuchwepheshe.

Ukubaluleka Kokuqinisekisa Ikhwalithi Nezitifiketi

Izitifiketi ziqinisekisa okomkhiqiziukuzibophezela kwikhwalithikanye nokuhambisana namazinga embonini. Izitifiketi ze-ISO ziqinisekisa ukubambelela kumabhentshimakhi wamazwe ngamazwe, kuyilapho amazinga aseMelika afana ne-NADCA kanye ne-ASTM eqinisekisa ukwethembeka. Ukuhlolwa kwe-Metallurgical kuqinisekisa izakhiwo zemishini, kuyilapho ukuhlaziywa kwamakhemikhali kuqinisekisa ikhwalithi yezinto ezibonakalayo.

Izindlela zokuhlola eziqinile, ezifana namandla aqinile nokuhlola ubulukhuni, ziqinisekisa ukuqina kwezingxenye ze-die-cast.

Izitifiketi ezifana ne-ISO 9001 ne-AS9100 zibaluleke kakhulu ezimbonini ezidinga izingxenye ezizwelayo zokuphepha, njenge-aerospace nokuvikela. Lawa mabhentshimakhi ahlinzeka ngokuqiniseka emandleni omkhiqizi wokuletha imikhiqizo engaguquki, yekhwalithi ephezulu.

Izingxenye zokuphonswa kwezinsimbi zochwepheshe zidlala indima ebalulekile ekukhiqizeni kwanamuhla. Isilinganiso samandla nesisindo sazo sithuthukisa ukusebenza kwezimboni ezifana nezezimoto, kuyilapho uketshezi lwazo lusekela imiklamo eyinkimbinkimbi futhi kunciphisa izindleko zezinto ezibonakalayo. Ukusakazwa kwengcindezi ephezulu kuqinisekisa amaphutha ambalwa, okwenza imikhiqizo ithembeke futhi isebenze kahle. Ukukhetha umkhiqizi owethembekile kuqinisekisa ikhwalithi nezixazululo ezihambisanayo zezidingo ezithile. Ukubonisana nochwepheshe kusiza amabhizinisi athole imiphumela emihle.

FAQ

Yiziphi izimboni ezizuza kakhulu ngokufaka ukufa kwensimbi?

Izimboni zezimoto, i-aerospace, ne-electronics zizuza kakhulu. Bathembela ku-die casting ukuze bathole ukunemba, ukuqina, nokukhiqizwa okungabizi kakhulu kwezingxenye zekhwalithi ephezulu.

I-die casting iqinisekisa kanjani ukunemba kobukhulu?

Umjovo wengcindezi ephezulu ubumba insimbi ibe yizimo ezinembile. Le nqubo inciphisa ukuchezuka, iqinisekise ukuthi izingxenye zihlangabezana nokubekezelelana okuqinile ngaphandle kokudinga ukucutshungulwa okubanzi kwangemuva.

Ingabe i-die casting ingasebenzisa izinto ezigaywe kabusha?

Yebo, abakhiqizi bavame ukusebenzisa izinsimbi ezigaywa kabusha njenge-aluminium ne-zinc. Lo mkhuba wehlisa imfucuza, wehlisa izindleko, futhi usekela imigomo yokusimama.

By: haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Ucingo:

Ukuthengisa: 0086-134 8641 8015

Ukusekela: 0086-574 8669 1714

Isikhathi sokuthumela: Apr-22-2025