Iinxalenye zokuphosa iintsimbi zobuchwepheshazibalulekile ekuveliseni amacandelo akumgangatho ophezulu ngokuchaneka okungahambelaniyo. Amashishini ahlukeneyo axhomekeke kwimetal die castinkqubo yezisombululo ezihlala ixesha elide, ezikhawulezayo, nezingabizi kakhulu. Iinkqubo ezizenzekelayo zidlala indima ebalulekileyo ekwandiseni umgangatho ngokubeka iliso kwizinto eziguquguqukayo ezifana nesantya sentsimbi kunye noxinzelelo lwehydraulic. Ezi teknoloji ziphezulu ziqinisekisa iziphumo ezihambelanayo, okwenza imetal die ekujuleni iindawo foundryinkalo ebalulekileyo yemveliso yanamhlanje.

Izinto eziphambili zokuThatha

- Metal die castingyenza iindawo ezomeleleyo ngokutyhala intsimbi eshushu ibe ngumngundo.

- Ukucholaizixhobo ezilungileyo, njenge-aluminium okanye i-magnesium, yenza iinxalenye zisebenze ngcono kwaye zihlala ixesha elide.

- Ukusebenzisa oomatshini kwi-die casting konga ixesha kunye nemali, enceda amashishini amakhulu afana nabenzi beemoto kunye neenqwelomoya.

Ukuqonda iiNdawo zokugalela iMetal Die

Yintoni i-Metal Die Casting?

Ukuphoswa kwesinyithi yinkqubo yokuvelisa eyenza amacandelo esinyithi achanekileyo kwaye ahlala ixesha elide. Kubandakanya ukutofa isinyithi esinyibilikisiweyo kwisingundo, okanye sife, phantsi koxinzelelo oluphezulu. Le ndlela ivumela abavelisi ukuba bavelise iinxalenye ezineenkcukacha eziyinkimbinkimbi kunye nomgangatho ohambelanayo.

I-Die casting yenza ukuveliswa kweendawo zetsimbi ngokuchaneka okuphezulu kunye neenkcukacha ezintle, ezinje ngemigangatho ye-textured, ngaphandle kokufuna ukuqhutyelwa phambili.

Inkqubo isetyenziswa kakhulu kumashishini afana neemoto, i-aerospace, kunye nempahla yabathengi. Ixhasa ukuyilwa kwezinto ezinobunzima obukhaphukhaphu, ezomeleleyo, kunye ne-corrosion, iyenza ibaluleke kakhulu kwimveliso yanamhlanje.

Izinto ezisetyenziswa kwiNkqubo

Ukukhethwa kwezinto eziphathekayo kuchaphazela kakhulu ukusebenza kunye nomgangatho wentsimbi yobuchwephesha bentsimbi yokuphosa. Abavelisi basebenzisa isinyithi ezahlukahlukeneyo kunye ne-alloys, nganye inika iipropati ezikhethekileyo ezifanelekileyo kwizicelo ezithile.

| Uhlobo lwezinto eziphathekayo | Iipropati | Usetyenziso |

|---|---|---|

| Ingxubevange yeAluminiyam 380 | I-castability egqwesileyo, ilula, ukumelana nokugqwala | Izibiyeli ze-injini, ifenitshala, iindawo ezivaliweyo zombane |

| Ingxubevange yeAluminiyam B390 | Ukungcangcazela okungaqhelekanga kunye nokumelana nokunxiba | Izindlu zempompo, imizimba yevalvu, izifudumezi |

| I-Magnesium AZ91D | Umlinganiselo ophakamileyo wobunzima bobunzima, ukuxhathisa ukubola | Amacandelo e-Powertrain, amacandelo oomatshini |

| Zinc Zamak 3 | Uzinzo lweDimensional, ukukhululeka kokuphosa | Iinxalenye zemibhobho, iifeni zesilingi |

I-Aluminiyam lukhetho oludumileyongenxa yomlinganiselo wayo wobunzima bobunzima kunye nokuxhathisa umhlwa. I-Magnesium alloys ikhethwa kwizicelo ezilula, ngelixa i-zinc alloys igqwesa ngokuchaneka kunye nokugqitywa okugudileyo.

Amanyathelo aPhambili kwiNkqubo yeDie Casting

Inkqubo yokuphosa ifa ibandakanya amanyathelo abalulekileyo aliqela, ngalinye linegalelo kumgangatho wemveliso yokugqibela.

- Ukulungiselela: Imiphezulu yokungunda iyathanjiswa ukuze kuqinisekiswe ukukhutshelwa lula kweecastings. Eli nyathelo linciphisa iziphene kwaye liqinisekisa ukususwa okugudileyo.

- Ukuzalisa: Intsimbi etyhidiweyo ifakwe kwi-mold phantsi koxinzelelo oluphezulu. Eli nyathelo lithintela ukuncipha kunye ne-porosity ngokuqinisekisa ukuzaliswa okupheleleyo.

- Ukukhutshwa: Izikhonkwane ze-Ejector zisusa ii-castings kwi-mold. Oku kuvumela imijikelezo yokuvelisa ngokukhawuleza kunye nokunciphisa umonakalo kwiindawo.

- Shakeout: Amacandelo e-Scrap asusiwe kwi-castings egqityiweyo. Eli nyathelo liqinisekisa ukuba imveliso yokugqibela idibana nemigangatho yomgangatho.

Ukuchaneka kwala manyathelo kuqinisekisa ukuba intsimbi yobuchwephesha yokuphosa iinxalenye zokuphosa ziyahlangabezana nemigaqo efunekayo yokuqina nokusebenza.

Izibonelelo zeProfessional Metal Die Casting Parts

Ukuchaneka kunye nokungqinelana

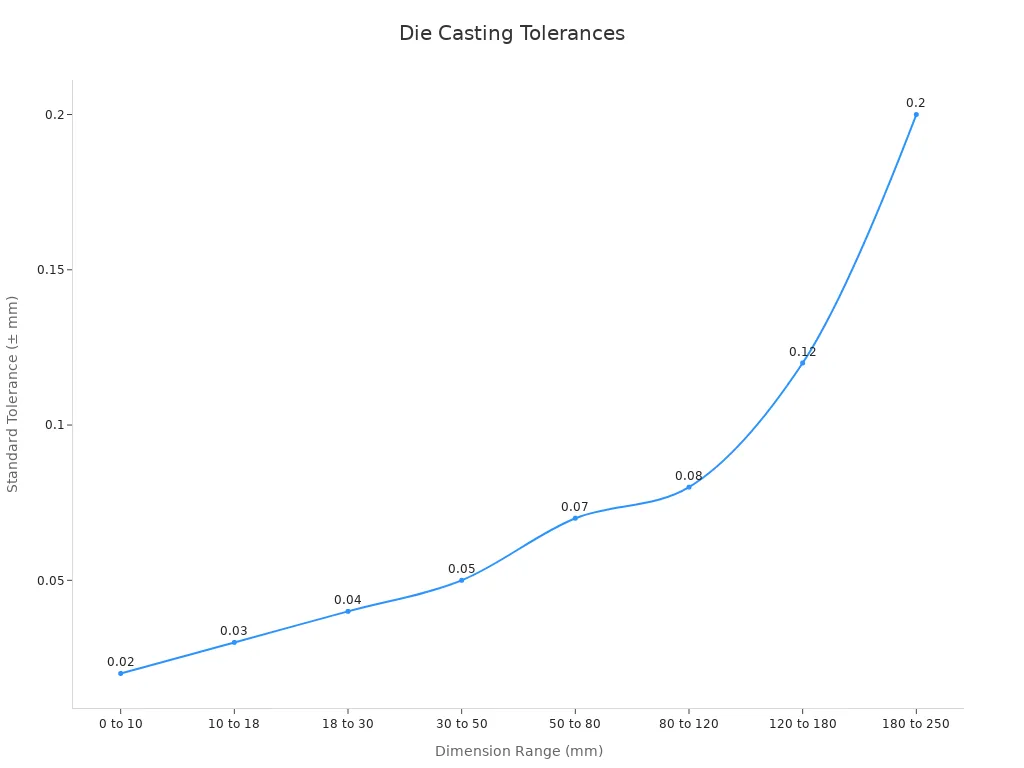

Intsimbi yobuchwepheshaiinxalenye zokuphosazaziwa ngokuchaneka kwazo okungaqhelekanga kunye nokuhambelana kobukhulu. Indlela yokutofa yoxinzelelo oluphezulu esetyenziswa kwinkqubo iqinisekisa ukuba icandelo ngalinye lidibana nokunyamezelana okuqinileyo, oko kuyenza ilunge kumashishini afuna uyilo oluntsonkothileyo. Umzekelo, izisombululo ze-CastMold's die-casting zivelisa iindawo ezichaneke kakhulu, zinciphisa imfuno yomatshini wesibini.

Ukukwazi ukufezekisa ukunyamezelana okuqinileyo luphawu lokufa. Oku kuchaneka kubalulekile kwizicelo apho nonxano olungephi lunokubeka esichengeni ukusebenza.

| Uluhlu loMdaniso oSisiseko (mm) | Unyamezelo olusemgangathweni (± mm) |

|---|---|

| 0 ukuya kwi-10 | 0.02 |

| 10 ukuya kwi-18 | 0.03 |

| 18 ukuya ku-30 | 0.04 |

| 30 ukuya ku-50 | 0.05 |

| 50 ukuya kuma-80 | 0.07 |

| 80 ukuya kwi-120 | 0.08 |

| 120 ukuya 180 | 0.12 |

| 180 ukuya 250 | 0.2 |

Ukugqitywa komphezulu ogudileyo okuphunyezwe ngokuphosa ukufa konyusa ngakumbi umgangatho wemveliso yokugqibela. Oku kuphelisa imfuno ebanzi emva kokucubungula, ukugcina ixesha kunye neendleko ngelixa uqinisekisa umphumo obonakalayo.

Iindleko-zokusebenza kwiMveliso eNkulu

Die casting inikeza aisisombululo esingabizi kakhuluukuvelisa umthamo omkhulu wamacandelo esinyithi. Inkqubo iphakamisa i-automation kunye nezixhobo ezinokuphinda zisetyenziswe ukunciphisa iindleko zemveliso. Utyalo-mali lokuqala kwi-automation lunokubonakala luphezulu, kodwa lukhokelela kulondolozo olubalulekileyo emsebenzini kunye nokwandisa ukusebenza kakuhle ekuhambeni kwexesha.

| Umba | Inkcazo |

|---|---|

| IMaterial Recyclability | Izinto ezinokuphinda zisetyenziswe zinciphisa iindleko kwaye zihambelane neenjongo zokuzinza. |

| Ukusetyenziswa kwamandla | Ukusetyenziswa kakuhle kwamandla koomatshini kwehlisa iindleko zokusebenza. |

| Utyalo-mali oluzenzekelayo | Ukuzenzekela kunciphisa iindleko zabasebenzi kunye nokwandisa isantya semveliso. |

| Ulawulo lweNkunkuma kunye neNkunkuma | Ulawulo lwenkunkuma olusebenzayo lunciphisa ilahleko yempahla kunye neendleko. |

| Imilinganiselo yoLawulo loMgangatho | Ukuhlolwa komgangatho ongqongqo kunciphisa iziphene, ukonga ixesha kunye nezixhobo. |

Ubunzima bokuphosa ukufa kwenza ukuba kube luncedo ngakumbi kumashishini afana neemoto kunye ne-elektroniki, apho imveliso yomthamo ophezulu iyimfuneko. Ngokunciphisa inkunkuma kunye nokwandisa ukusetyenziswa kwamandla, abavelisi banokufikelela zombini izibonelelo zoqoqosho kunye nokusingqongileyo.

Ukuqina kunye nokomelela kwaMacandelo

Amalungu okujula ngentsimbi yobuchwephesha abhiyozelwa ngokuhlala kwawo kunye nokomelela kwawo koomatshini. Inkqubo ivelisa amacandelo anobulukhuni obugqwesileyo kunye neempawu zokuqina, ezenza zilungele izicelo ezifunayo. Umzekelo, ukuvavanywa koomatshini, kubandakanya ubulukhuni kunye novavanyo lwempembelelo yeCharpy, kuqinisekisa amandla kunye nokuthembeka kwamacandelo e-die-cast.

Imizi-mveliso efana ne-aerospace kunye neemoto zixhomekeke kwiindawo ezifayo ukuze zibe nako ukumelana neemeko ezigqithisileyo ngaphandle kokubeka esichengeni ukusebenza.

Amandla okudinwa kweentsimbi ze-die-cast kwandisa ngakumbi ukuqina kwazo, ukuqinisekisa ukusebenza okuhlala ixesha elide naphantsi koxinzelelo oluqhubekayo. Oku kubenza babe lolona khetho lukhethwayo kwizicelo ezibalulekileyo ezifana nezixhobo ze-injini kunye neendawo zesakhiwo.

Ngokudibanisa amandla, ukuqina, kunye nokuchaneka, ukuphosa ukufa kuzisa izinto ezihlangabezana neemfuno eziqatha zamashishini anamhlanje.

Usetyenziso lwezahlulo zeMetal Die Casting

Ushishino lweemoto

Icandelo leemoto lixhomekeke kakhulu kwintsimbi yobuchwephesha yokuphosa iinxalenye zokuchaneka kwazo kunye nokuqina. Ngemveliso yezithuthi zehlabathi efikelela malunga ne-85 yezigidi zeeyunithi ngo-2022, imfuno yamacandelo e-die-cast ihlala yomelele. Abavelisi basebenzisa itekhnoloji ephucukileyo efana ne-automation kunye nedijithali ukuhlangabezana neemfuno eziguqukayo zeshishini, ngakumbi kwizithuthi zombane kunye noyilo olukhaphukhaphu. Izinto ezintsha ezifana ne-Ryobi's "giga casting" yamalungu omzimba we-EV amakhulu kunye noomatshini abakhulu be-UBE Corporation be-ultra-large babonisa ukugxila kwecandelo ekusebenzeni kakuhle kunye nokunciphisa iindleko. Olu phuculo luqinisekisa ukuba iinxalenye ze-die-cast zihlangabezana neemfuno ezingqongqo zezithuthi zala maxesha, kubandakanywa amandla, ukunciphisa ubunzima, kunye nokumelana nomhlwa.

I-Aerospace kunye noKhuseleko

Kwi-aerospace kunye nokhuselo, ukuphosa ukufa kudlala indima ebalulekileyo ekuveliseni izinto ezinobunzima kodwa omelele. Ii-alloys eziphucukileyo kunye neendlela zokulahla i-vacuum die zinciphisa ubunzima bamalungu, ziphucula ukusebenza kakuhle kwamafutha ukuya kuthi ga kwi-20%. Inkqubo iqinisekisa ukuba amacandelo anokumelana noxinzelelo olugqithisileyo lokubhabha ngelixa ehlangabezana nemigangatho engqongqo yokhuseleko.

| Inzuzo | Inkcazo | Impembelelo kwi-Aerospace kunye noKhuselo |

|---|---|---|

| Izixhobo eziKhala | I-alloys ephezulu kunye ne-vacuum die casting ukunciphisa ubunzima becandelo. | Ukuphucula ukusebenza kakuhle kwamafutha ukuya kuthi ga kwi-20%. |

| Ukomelela kunye noKuhlala ixesha elide | Iqinisekisa ukuba iinxalenye ziyakwazi ukumelana noxinzelelo lwenqwelomoya kunye nemigangatho yokhuseleko. | Ihlangabezana neemfuno zokhuseleko eziphezulu. |

| UFanelo lwamafutha | Ukunciphisa ubunzima kukhokelela ekusetyenzisweni okungcono kwamafutha. | Okubalulekileyo kugcino lweendleko zokusebenza. |

Ezi zibonelelo zenza ukuba ukuphosa ukufa kubaluleke kakhulu ekwenzeni i-aerospace ebalulekileyo kunye nezinto zokukhusela.

I-Electronics kunye neeMpahla zabaThengi

I-Die casting nayo iyagqwesakumashishini ombane kunye nempahla yabathengi. Ibonelela ngezixhobo ezomeleleyo, ezithembekileyo kwiinkqubo zombane, iindawo ezomeleleyo zezixhobo zasekhaya, kunye nehardware esebenzayo kodwa yokuhombisa yefenitshala.

| Ishishini | Izinto eziluncedo kwiDie Casting Parts |

|---|---|

| Ishishini loMbane | Amacandelo ombane anamandla kwiinkqubo ezithembekileyo |

| Ishishini lezixhobo | Amalungu ahlala ixesha elide kwizixhobo zasekhaya aphucula ukusebenza kakuhle |

| Ishishini leFenitshala | I-hardware esebenzayo kunye neyokuhlobisa isibheno sobuhle |

Ngokudibanisa ukuchaneka, ukuqina, kunye nokuguquguquka, iindawo zokuphosa iintsimbi ezichwepheshile zihlangabezana neemfuno ezahlukeneyo zala mashishini.

Ukukhetha eLungileyo Professional Metal Die Casting Solution

Ukuvavanya ubuNgcali kunye namava

Ukukhetha umenzi ofanelekileyo kuqala ngokuvavanya ubuchule kunye namava abo. Iinkampani ezinamashumi eminyaka yolwazi lweshishini zihlala zibonelela ngeziphumo eziphezulu. I-Dynacast, umzekelo, ineminyaka engaphezulu kwe-80 yamava ivelisa iindawo zentsimbi ezichanekileyo kumacandelo ahlukeneyo. Ngokufanayo, i-A&B iqesha iinjineli ezinezakhono ezikwaziyo ukuphatha uyilo oluntsonkothileyo, ziqinisekisa iziphumo ezikumgangatho ophezulu. Abavelisi abafana neCastingod kunye neGolden Pond Metal Die Casting Co., Ltd. babonisa ukuthembeka kunye nobuchule ngokulawula iiprojekthi ezinzima kunye nokuphumeza imilinganiselo yokulawula umgangatho ongqongqo.

Ubuchwephesha buqinisekisa ukuba abavelisi banokujongana nemingeni ekhethekileyo, ngelixa amava eqinisekisa ukusebenza okufanayo kuzo zonke iiprojekthi.

Xa uvavanya umthengisi, qwalasela irekhodi labo kunye nezalathiso. Imbali eyomeleleyo yokunikezela ngamacandelo asemgangathweni ibonisa ukuzinikela kwabo ekugqweseni.

UVavanyo lweTekhnoloji kunye neZixhobo

Itekhnoloji yale mihla idlala indima ebalulekileyo ekuveliseni umgangatho ophezuluamacandelo die-cast. Iinkqubo ezizenzekelayo ziphucula ukusebenza kakuhle kunye nokuchaneka, ukunciphisa iindleko zabasebenzi kunye nokunciphisa impazamo yabantu. Iirobhothi zilungelelanisa inaliti kunye neenkqubo zokukhupha, ziqinisekisa umgangatho ongaguqukiyo kuyo yonke imveliso. Isoftware yokulinganisa ekwinqanaba eliphambili iqikelela iziphene kwaye yandise inkqubo yokuphosa, ivumela iprototyping yenyani phambi kokwenziwa komzimba.

Abavelisi abasebenzisa i-AI kunye nokufunda koomatshini banokubeka iliso kunye nokwandisa ukusebenza ngexesha lokwenyani. Olu phuculo luphucula ukhuseleko, isantya, kunye nokuchaneka, luzenza zibe yimfuneko kwiindawo zokuphosa iintsimbi zobuchwephesha.

Ukubaluleka koQinisekiso loMgangatho kunye neziQinisekiso

Iziqinisekiso ziqinisekisa umvelisiukuzibophelela kumgangathokunye nokuthotyelwa kwemigangatho yoshishino. Iziqinisekiso ze-ISO ziqinisekisa ukuthotyelwa kwemigangatho yamazwe ngamazwe, ngelixa imigangatho yaseMelika efana ne-NADCA kunye ne-ASTM iqinisekisa ukuthembeka. Uvavanyo lwe-Metallurgical luqinisekisa iimpawu zoomatshini, ngelixa uhlalutyo lokubunjwa kweekhemikhali luqinisekisa umgangatho wezinto eziphathekayo.

Iindlela zovavanyo ezingqongqo, ezinje ngokuqina kokuqina kunye novavanyo lokuqina, ziqinisekisa ukuqina kwezixhobo zokuphosa.

Izatifikethi ezifana ne-ISO 9001 kunye ne-AS9100 zibaluleke kakhulu kumashishini afuna iindawo ezibuthathaka kukhuseleko, ezifana ne-aerospace kunye nokhuselo. Ezi mpawu zibonelela ngentembeko kubuchule bomenzi bokuhambisa iimveliso ezingaguqukiyo, ezikumgangatho ophezulu.

Amalungu okujula ngentsimbi yobuchwephesha adlala indima ebalulekileyo kwimveliso yanamhlanje. Umlinganiselo wabo wokomelela ukuya kubunzima wonyusa ukusebenza kumashishini afana neemoto, ngelixa ulwelo lwabo luxhasa uyilo oluntsonkothileyo kwaye lunciphisa iindleko zemathiriyeli. Ukuphoswa koxinzelelo oluphezulu kuqinisekisa iziphene ezimbalwa, okwenza iimveliso zithembeke kwaye zisebenze kakuhle. Ukukhetha umenzi othembekileyo kuqinisekisa umgangatho kunye nezisombululo ezilungiselelwe iimfuno ezithile. Iingcali zokubonisana zinceda amashishini ukuba afumane iziphumo ezilungileyo.

FAQ

Ngawaphi amashishini azuza kakhulu kwi-metal die casting?

Imizi-mveliso yeemoto, i-aerospace, kunye neye-elektroniki ixhamla kakhulu. Baxhomekeke kwi-die casting ngokuchaneka, ukuqina, kunye nemveliso enexabiso eliphantsi lamacandelo aphezulu.

Ukuphosa ukufa kuqinisekisa njani ukuchaneka komda?

Inaliti yoxinzelelo oluphezulu ibumba isinyithi kwiimilo ezichanekileyo. Le nkqubo inciphisa ukutenxa, iqinisekisa ukuba amacandelo ahlangabezana nokunyamezelwa okungqongqo ngaphandle kokufuna ukusetyenzwa okubanzi kwasemva.

Ngaba i-die casting ingasebenzisa imathiriyeli ehlaziyiweyo?

Ewe, abavelisi bahlala besebenzisa iintsimbi ezinokuphinda zisetyenziswe njengealuminiyam kunye nezinc. Esi senzo sinciphisa inkcitho, sehlisa iindleko, kwaye sixhasa iinjongo zozinzo.

Ngu:haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Ifowuni:

Iintengiso: 0086-134 8641 8015

Inkxaso: 0086-574 8669 1714

Ixesha lokuposa: Apr-22-2025