Kev cob qha hlau tuag casting qhov chawyog qhov tseem ceeb rau kev tsim cov khoom zoo nrog qhov tsis sib xws. Ntau yam kev lag luam nyob ntawm qhovhlau tuag castingtxheej txheem kom ruaj, scalable, thiab raug nqi daws teeb meem. Cov tshuab ua haujlwm tsis siv neeg ua lub luag haujlwm tseem ceeb hauv kev txhim kho qhov zoo los ntawm kev saib xyuas qhov sib txawv xws li hlau tshaj tawm thiab hydraulic siab. Cov thev naus laus zis no tau lees paub cov txiaj ntsig zoo ib yam, ua rauhlau tuag casting qhov chaw foundryib qho tseem ceeb ntawm kev tsim khoom niaj hnub.

Ntsiab Cai

- Hlau tuag castingua kom muaj zog qhov chaw los ntawm kev thawb cov hlau kub rau hauv pwm.

- Xaivcov ntaub ntawv zoo, zoo li txhuas lossis magnesium, ua rau cov khoom ua haujlwm zoo dua thiab kav ntev dua.

- Siv cov tshuab hauv kev tuag casting txuag lub sijhawm thiab nyiaj txiag, uas pab cov lag luam loj xws li tsheb thiab dav hlau tsim.

Nkag siab txog Kev Lag Luam Hlau Tuag Casting Qhov Chaw

Hlau Tuag Casting yog dab tsi?

Hlau tuag casting yog cov txheej txheem tsim khoom uas tsim cov khoom zoo thiab ruaj khov hlau. Nws koom nrog kev txhaj tshuaj molten hlau rau hauv pwm, lossis tuag, nyob rau hauv siab. Txoj kev no tso cai rau cov tuam txhab tsim cov khoom nrog cov ntsiab lus sib txawv thiab zoo ib yam.

Tuag casting enables zus tau tej cov hlau qhov chaw nrog siab raug thiab zoo cov ntsiab lus, xws li textured nto, tsis tas yuav tsum tau ntxiv ua.

Cov txheej txheem yog dav siv hauv kev lag luam xws li tsheb, aerospace, thiab cov khoom siv. Nws txhawb kev tsim cov khoom hnyav, muaj zog, thiab corrosion-resistant Cheebtsam, ua rau nws tseem ceeb rau kev tsim khoom niaj hnub.

Cov ntaub ntawv siv hauv cov txheej txheem

Qhov kev xaiv ntawm cov khoom muaj feem cuam tshuam rau kev ua tau zoo thiab zoo ntawm cov hlau tuag casting qhov chaw. Cov neeg tsim khoom siv ntau yam hlau thiab alloys, txhua qhov muab cov khoom tshwj xeeb haum rau cov kev siv tshwj xeeb.

| Hom khoom | Cov khoom | Daim ntawv thov |

|---|---|---|

| Aluminium alloy 380 | Zoo castability, hnav, corrosion kuj | Cav brackets, rooj tog zaum, electronics enclosures |

| Aluminium alloy B390 | Exceptional vibration thiab hnav tsis kam | Cov twj tso kua mis, lub cev valve, impellers |

| Magnesium AZ91D | Siab zog-rau-qhov hnyav piv, corrosion kuj | Powertrain Cheebtsam, mechanical parts |

| Zinc Zinc 3 | Dimensional stability, yooj yim ntawm casting | Cov kav dej, cov kiv cua qab nthab |

Aluminium yog qhov kev xaiv nrovvim nws lub zog-rau-qhov hnyav piv thiab corrosion kuj. Magnesium alloys yog qhov zoo dua rau kev siv lub teeb yuag, thaum zinc alloys ua tau zoo nyob rau hauv precision thiab du tiav.

Cov kauj ruam tseem ceeb hauv Kev Tuag Casting

Cov txheej txheem tuag casting muaj ob peb kauj ruam tseem ceeb, txhua qhov ua rau qhov zoo ntawm cov khoom kawg.

- Kev npaj: Pwm nto yog lubricated kom yooj yim ejection ntawm castings. Cov kauj ruam no txo qhov tsis xws luag thiab xyuas kom meej tshem tawm.

- Sau: Molten hlau yog txhaj rau hauv pwm nyob rau hauv siab. Cov kauj ruam no tiv thaiv shrinkage thiab porosity los ntawm kev ua kom tiav filling.

- Tshem tawm: Ejector pins tshem tawm cov castings ntawm pwm. Qhov no tso cai rau lub voj voog ntau lawm thiab txo qis kev puas tsuaj rau cov khoom.

- Caw tawm: Cov seem seem raug tshem tawm ntawm qhov ua tiav castings. Cov kauj ruam no ua kom cov khoom kawg ua tau raws li cov qauv zoo.

Lub precision ntawm cov kauj ruam no xyuas kom meej tias cov hlau tuag casting qhov chaw ua tau raws li qhov yuav tsum tau specifications rau durability thiab kev ua tau zoo.

Cov txiaj ntsig ntawm Professional Hlau Tuag Casting Parts

Precision thiab sib npaug

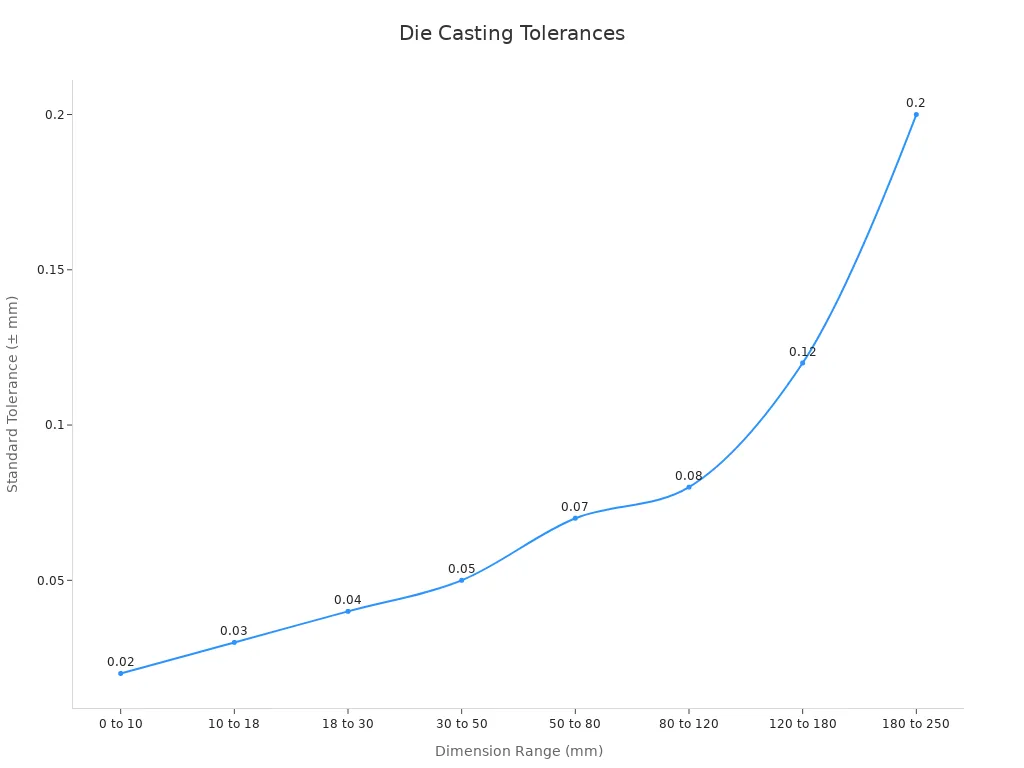

Kev cob qha hlautuag casting qhov chawpaub txog lawv qhov tshwj xeeb precision thiab qhov sib xws. Txoj kev txhaj tshuaj tiv thaiv siab siv hauv cov txheej txheem ua kom ntseeg tau tias txhua qhov kev tiv thaiv ua tau raws li kev ua haujlwm nruj, ua rau nws zoo tagnrho rau kev lag luam uas xav tau cov qauv tsim sib txawv. Piv txwv li, CastMold's die-casting solutions tsim qhov chaw nrog qhov tseeb qhov tseeb, txo qis qhov xav tau rau kev ua haujlwm thib ob.

Lub peev xwm ua tau kom nruj tolerances yog lub cim ntawm kev tuag casting. Qhov kev txiav txim siab no yog qhov tseem ceeb rau cov ntawv thov uas txawm tias me me sib txawv tuaj yeem cuam tshuam kev ua haujlwm.

| Basic Dimension Range (hli) | Standard kam rau ua (± mm) |

|---|---|

| 0 rau 10 | 0.02 ib |

| 10 rau 18 | 0.03 ib |

| 18 rau 30 | 0.04 ib |

| 30 rau 50 | 0.05 Nws |

| 50 rau 80 | 0.07 ib |

| 80 rau 120 | 0.08 ib |

| 120-180 Nws | 0.12 |

| 180-250 Nws | 0.2 |

Qhov nto du tiav tiav los ntawm kev tuag casting ntxiv txhim kho qhov zoo ntawm cov khoom kawg. Qhov no tshem tawm qhov kev xav tau ntawm kev ua tiav tom qab kev ua tiav, txuag lub sijhawm thiab cov nqi thaum ua kom pom qhov pom tau zoo.

Nqi-Effectiveness rau Loj-Scale Production

Tuag casting muab ibkev daws teeb meem raug nqirau kev tsim khoom loj ntawm cov khoom siv hlau. Cov txheej txheem leverages automation thiab recyclable cov ntaub ntawv los txo cov nqi ntau lawm. Kev nqis peev pib hauv automation yuav zoo li siab, tab sis lawv ua rau muaj kev txuag nyiaj ntau hauv kev ua haujlwm thiab nce kev ua haujlwm tau zoo nyob rau lub sijhawm.

| Qhov xwm txheej | Kev piav qhia |

|---|---|

| Cov khoom siv rov ua dua tshiab | Cov khoom siv rov ua dua tshiab txo cov nqi thiab ua raws li cov hom phiaj sustainability. |

| Kev siv hluav taws xob | Optimized zog siv nyob rau hauv cov cav tov txo cov nqi khiav hauj lwm. |

| Automation Kev nqis peev | Automation txo cov nqi zog thiab txhim kho kev tsim khoom ceev. |

| Kev tswj cov khib nyiab thiab khib nyiab | Kev tswj cov khoom pov tseg zoo txo qis cov khoom poob thiab cov nqi. |

| Kev Tswj Xyuas Zoo | Kev kuaj xyuas zoo kom txo tau qhov tsis xws luag, txuag lub sijhawm thiab cov peev txheej. |

Lub scalability ntawm tuag casting ua rau nws tshwj xeeb tshaj yog zoo rau kev lag luam xws li automotive thiab electronics, qhov twg high-volume ntau lawm yog qhov tseem ceeb. Los ntawm kev txo cov khoom pov tseg thiab kev ua kom zoo dua qub, cov tuam txhab lag luam tuaj yeem ua tiav cov txiaj ntsig kev lag luam thiab ib puag ncig.

Durability thiab lub zog ntawm cov Cheebtsam

Kev cob qha hlau tuag casting qhov chaw yog ua kev zoo siab rau lawv cov durability thiab mechanical zog. Cov txheej txheem tsim cov khoom nrog zoo heev hardness thiab tensile zog, ua rau lawv tsim nyog rau kev thov. Piv txwv li, kev ntsuam xyuas tshuab, suav nrog hardness thiab Charpy cuam tshuam cov kev ntsuam xyuas, lees paub lub zog thiab kev ntseeg siab ntawm cov khoom siv tuag.

Kev lag luam xws li aerospace thiab automotive cia siab rau qhov tuag-cam khwb cia rau lawv lub peev xwm tiv taus huab cua yam tsis muaj kev cuam tshuam kev ua haujlwm.

Lub zog qaug zog ntawm cov hlau tuag-cam khwb cia ntxiv txhim kho lawv cov kav ntev, ua kom muaj kev ua haujlwm ntev ntev txawm tias muaj kev ntxhov siab tas mus li. Qhov no ua rau lawv xaiv rau cov kev siv tseem ceeb xws li cov khoom siv cav thiab cov khoom siv.

Los ntawm kev sib txuas lub zog, durability, thiab precision, tuag casting muab cov khoom uas ua tau raws li qhov xav tau ntawm cov kev lag luam niaj hnub no.

Daim ntawv thov ntawm Professional Hlau Tuag Casting Parts

Automotive Kev Lag Luam

Automotive sector cia siab rau ntau yam hlau tuag casting qhov chaw rau lawv cov precision thiab durability. Nrog rau kev tsim tsheb thoob ntiaj teb tau nce mus txog kwv yees li 85 lab units hauv 2022, qhov kev thov rau cov khoom siv tuag-casting tseem muaj zog. Cov neeg tsim khoom siv cov thev naus laus zis zoo li automation thiab digitalization kom ua tau raws li kev lag luam kev xav tau, tshwj xeeb tshaj yog rau cov tsheb hluav taws xob thiab cov qauv tsim. Kev tsim kho tshiab xws li Ryobi's "giga casting" rau loj EV lub cev qhov chaw thiab UBE Corporation's ultra-loj tuag-casting tshuab qhia txog kev ua haujlwm tsom mus rau kev ua tau zoo thiab txo nqi. Cov kev nce qib no ua kom ntseeg tau tias cov khoom siv tuag ua tau raws li cov kev cai nruj ntawm cov tsheb niaj hnub, suav nrog lub zog, qhov hnyav, thiab kev tiv thaiv corrosion.

Aerospace thiab Defense

Hauv aerospace thiab kev tiv thaiv, tuag casting plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom hnyav tsis tau ruaj khov. Advanced alloys thiab lub tshuab nqus tsev tuag casting cov txheej txheem txo qhov hnyav ntawm qhov chaw, txhim kho roj efficiency txog li 20%. Cov txheej txheem ua kom ntseeg tau tias cov khoom tuaj yeem tiv taus qhov kev ntxhov siab ntawm kev ya davhlau thaum ua tau raws li cov qauv kev nyab xeeb nruj.

| Cov txiaj ntsig | Kev piav qhia | Kev cuam tshuam rau Aerospace thiab Defense |

|---|---|---|

| Cov Khoom Siv Hluav Taws Xob | Advanced alloys thiab lub tshuab nqus tsev tuag casting txo cov khoom hnyav. | Txhim kho roj efficiency txog li 20%. |

| Lub zog thiab Durability | Ua kom cov khoom tuaj yeem tiv taus kev ntxhov siab ntawm kev ya davhlau thiab cov qauv kev nyab xeeb. | Ua tau raws li kev ruaj ntseg siab. |

| Roj Efficiency | Kev txo qhov hnyav ua rau kev siv roj zoo dua. | Qhov tseem ceeb rau kev txuag nyiaj ua haujlwm. |

Cov txiaj ntsig no ua rau tuag casting qhov tseem ceeb rau kev tsim cov khoom siv dav hlau tseem ceeb thiab kev tiv thaiv.

Electronics thiab Consumer Goods

Tuag casting kuj excelnyob rau hauv electronics thiab cov khoom siv industries. Nws muab cov khoom muaj zog, txhim khu kev qha rau cov tshuab hluav taws xob, qhov chaw ruaj khov rau cov khoom siv hauv tsev, thiab kev ua haujlwm tsis tau zoo nkauj rau cov rooj tog zaum.

| Kev lag luam | Qhov zoo ntawm Die Casting Parts |

|---|---|

| Kev lag luam hluav taws xob | Cov khoom siv hluav taws xob muaj zog rau cov tshuab txhim khu kev qha |

| Kev lag luam khoom siv | Cov khoom siv ruaj khov rau cov khoom siv hauv tsev ua kom muaj txiaj ntsig zoo |

| Kev lag luam rooj tog | Functional thiab cov khoom siv kho kom zoo nkauj rau kev zoo nkauj |

Los ntawm kev sib txuas cov precision, durability, thiab versatility, kev hlau tuag casting qhov chaw ua tau raws li ntau yam kev xav tau ntawm cov kev lag luam no.

Xaiv txoj cai Hlau Tuag Casting Solution

Kev ntsuas kev txawj ntse thiab kev paub

Xaiv cov chaw tsim khoom tsim nyog pib nrog kev ntsuas lawv cov kev txawj ntse thiab kev paub dhau los. Cov tuam txhab uas muaj ntau xyoo ntawm kev lag luam kev paub feem ntau xa cov txiaj ntsig zoo dua. Piv txwv li, Dynacast muaj ntau dua 80 xyoo ntawm kev tsim cov khoom hlau zoo rau ntau qhov chaw. Ib yam li ntawd, A&B ntiav cov kws tshaj lij engineers uas muaj peev xwm tuav cov qauv tsim, kom ntseeg tau cov txiaj ntsig zoo. Cov neeg tsim khoom xws li Castingod thiab Golden Pond Metal Die Casting Co., Ltd. qhia kev ntseeg tau thiab kev paub zoo los ntawm kev tswj xyuas cov haujlwm nyuaj thiab siv cov kev tswj xyuas nruj.

Cov kws tshaj lij ua kom cov tuam txhab lag luam tuaj yeem daws cov teeb meem tshwj xeeb, thaum muaj kev lees paub ua tau zoo ib yam ntawm cov haujlwm.

Thaum ntsuas tus neeg muag khoom, xav txog lawv cov ntaub ntawv teev tseg thiab cov ntaub ntawv siv. Cov keeb kwm muaj zog ntawm kev xa cov khoom zoo qhia txog lawv txoj kev mob siab rau kev ua tau zoo.

Kev soj ntsuam Technology thiab khoom siv

Niaj hnub nimno technology plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom zootuag-cast Cheebtsam. Automated systems txhim kho efficiency thiab precision, txo cov nqi zog thiab txo tib neeg kev ua yuam kev. Robots streamline txhaj tshuaj thiab ejection txheej txheem, kom ntseeg tau zoo ib yam thoob plaws hauv ntau lawm. Advanced simulation software kwv yees qhov tsis xws luag thiab optimizes cov txheej txheem casting, enabling virtual prototyping ua ntej lub cev raug tsim.

Cov neeg tsim khoom siv AI thiab kev kawm tshuab tuaj yeem saib xyuas thiab txhim kho kev ua haujlwm hauv lub sijhawm. Cov kev nce qib no txhim kho kev nyab xeeb, ceev, thiab raug, ua rau lawv tseem ceeb rau cov hlau tuag casting qhov chaw.

Qhov tseem ceeb ntawm Kev Pov Hwm Zoo thiab Ntawv Pov Thawj

Cov ntawv pov thawj validate ib lub chaw tsim khoomkev cog lus rau qhov zoothiab ua raws li cov qauv kev lag luam. Cov ntawv pov thawj ISO ua kom ua raws li cov qauv ntsuas thoob ntiaj teb, thaum Asmeskas cov qauv zoo li NADCA thiab ASTM lav kev ntseeg tau. Metallurgical kuaj xyuas cov khoom siv kho tshuab, thaum tshuaj lom neeg muaj pes tsawg leeg tsom xam xyuas cov khoom zoo.

Kev soj ntsuam nruj, xws li lub zog tensile thiab hardness ntsuam xyuas, paub meej tias lub durability ntawm die-cast Cheebtsam.

Cov ntawv pov thawj zoo li ISO 9001 thiab AS9100 yog qhov tseem ceeb tshwj xeeb rau kev lag luam uas xav tau kev nyab xeeb-rhiab qhov chaw, xws li aerospace thiab tiv thaiv. Cov qauv ntsuas no muab kev ntseeg siab rau cov chaw tsim khoom muaj peev xwm xa cov khoom zoo ib yam, zoo.

Kev cob qha hlau tuag casting qhov chaw ua lub luag haujlwm tseem ceeb hauv kev tsim khoom niaj hnub. Lawv lub zog-rau-qhov hnyav piv txhawb kev ua haujlwm hauv kev lag luam xws li automotive, thaum lawv cov fluidity txhawb cov qauv tsim thiab txo cov nqi khoom. High-pressure casting ua kom muaj qhov tsis xws luag, ua rau cov khoom txhim khu kev qha thiab ua haujlwm zoo. Xaiv ib lub chaw tsim khoom ntseeg tau ua kom muaj txiaj ntsig zoo thiab kho kom haum rau cov kev xav tau tshwj xeeb. Kev sab laj kws tshaj lij pab cov lag luam ua tiav cov txiaj ntsig zoo.

FAQ

Cov kev lag luam twg tau txais txiaj ntsig zoo tshaj plaws los ntawm cov hlau tuag casting?

Automotive, aerospace, thiab electronics industries tau txais txiaj ntsig zoo. Lawv cia siab rau tuag casting rau precision, durability, thiab raug nqi tsim khoom ntawm cov khoom zoo.

Yuav ua li cas tuag casting kom paub meej qhov tseeb?

High-pressure txhaj moulds hlau rau hauv cov duab meej. Cov txheej txheem no txo qis qhov sib txawv, ua kom cov khoom ua tau raws li kev ua haujlwm nruj yam tsis tas yuav tsum tau ua tom qab ua tiav.

Puas tuaj yeem tuag casting siv cov khoom siv rov ua dua tshiab?

Yog lawm, cov tuam ntxhab feem ntau siv cov khoom siv rov ua dua tshiab xws li txhuas thiab zinc. Qhov kev xyaum no txo cov khoom pov tseg, txo cov nqi, thiab txhawb nqa cov hom phiaj kev ruaj ntseg.

By: haij

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Xov tooj:

Muag: 0086-134 8641 8015

Kev them nyiaj yug: 0086-574 8669 1714

Post lub sij hawm: Apr-22-2025