Professional metal die casting parts are essential for producing high-quality components with unmatched precision. Various industries depend on the metal die cast process for durable, scalable, and cost-effective solutions. Automated systems play a crucial role in enhancing quality by monitoring variables such as metal velocity and hydraulic pressure. These advanced technologies guarantee consistent results, making the metal die casting parts foundry an integral aspect of modern manufacturing.

Key Takeaways

- Metal die casting makes strong parts by pushing hot metal into molds.

- Picking good materials, like aluminum or magnesium, makes parts work better and last longer.

- Using machines in die casting saves time and money, which helps big industries like car and airplane makers.

Understanding Professional Metal Die Casting Parts

What is Metal Die Casting?

Metal die casting is a manufacturing process that creates precise and durable metal components. It involves injecting molten metal into a mold, or die, under high pressure. This method allows manufacturers to produce parts with intricate details and consistent quality.

Die casting enables the production of metal parts with high accuracy and fine details, such as textured surfaces, without requiring additional processing.

The process is widely used in industries like automotive, aerospace, and consumer goods. It supports the creation of lightweight, strong, and corrosion-resistant components, making it essential for modern manufacturing.

Materials Used in the Process

The choice of material significantly impacts the performance and quality of professional metal die casting parts. Manufacturers use various metals and alloys, each offering unique properties suited for specific applications.

| Material Type | Properties | Applications |

|---|---|---|

| Aluminum Alloy 380 | Excellent castability, lightweight, corrosion resistance | Engine brackets, furniture, electronic enclosures |

| Aluminum Alloy B390 | Exceptional vibration and wear resistance | Pump housings, valve bodies, impellers |

| Magnesium AZ91D | High strength-to-weight ratio, corrosion resistance | Powertrain components, mechanical parts |

| Zinc Zamak 3 | Dimensional stability, ease of casting | Plumbing parts, ceiling fans |

Aluminum is a popular choice due to its strength-to-weight ratio and corrosion resistance. Magnesium alloys are preferred for lightweight applications, while zinc alloys excel in precision and smooth finishes.

Key Steps in the Die Casting Process

The die casting process involves several critical steps, each contributing to the quality of the final product.

- Preparation: Mold surfaces are lubricated to ensure easy ejection of castings. This step reduces defects and ensures smooth removal.

- Filling: Molten metal is injected into the mold under high pressure. This step prevents shrinkage and porosity by ensuring complete filling.

- Ejection: Ejector pins remove the castings from the mold. This allows for quick production cycles and minimizes damage to the parts.

- Shakeout: Scrap sections are removed from the finished castings. This step ensures the final product meets quality standards.

The precision of these steps ensures that professional metal die casting parts meet the required specifications for durability and performance.

Benefits of Professional Metal Die Casting Parts

Precision and Consistency

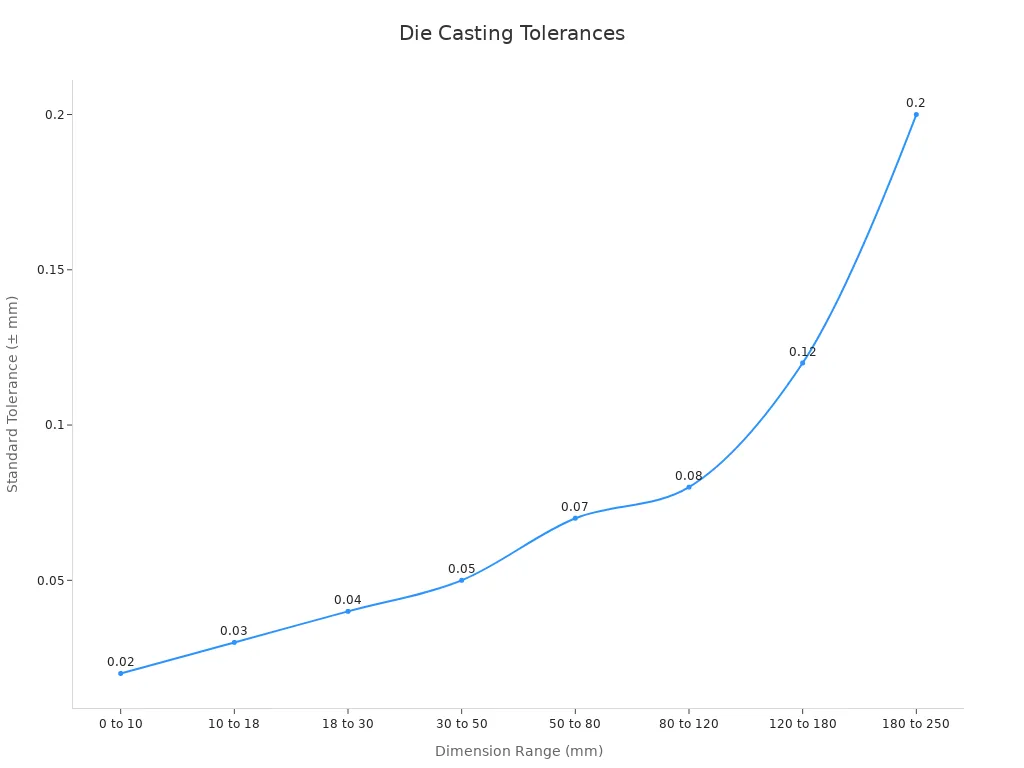

Professional metal die casting parts are known for their exceptional precision and dimensional consistency. The high-pressure injection method used in the process ensures that every component meets tight tolerances, making it ideal for industries requiring intricate designs. For example, CastMold’s die-casting solutions produce parts with superior dimensional accuracy, minimizing the need for secondary machining.

The ability to achieve tight tolerances is a hallmark of die casting. This precision is critical for applications where even minor deviations can compromise functionality.

| Basic Dimension Range (mm) | Standard Tolerance (± mm) |

|---|---|

| 0 to 10 | 0.02 |

| 10 to 18 | 0.03 |

| 18 to 30 | 0.04 |

| 30 to 50 | 0.05 |

| 50 to 80 | 0.07 |

| 80 to 120 | 0.08 |

| 120 to 180 | 0.12 |

| 180 to 250 | 0.2 |

The smooth surface finish achieved through die casting further enhances the quality of the final product. This eliminates the need for extensive post-processing, saving time and costs while ensuring a visually appealing result.

Cost-Effectiveness for Large-Scale Production

Die casting offers a cost-effective solution for producing large volumes of metal components. The process leverages automation and recyclable materials to reduce production costs. Initial investments in automation may seem high, but they lead to significant savings in labor and increased efficiency over time.

| Factor | Description |

|---|---|

| Material Recyclability | Recyclable materials reduce costs and align with sustainability goals. |

| Energy Consumption | Optimized energy usage in machines lowers operational expenses. |

| Automation Investments | Automation reduces labor costs and enhances production speed. |

| Scrap and Waste Management | Effective waste management minimizes material loss and costs. |

| Quality Control Measures | Rigorous quality checks reduce defects, saving time and resources. |

The scalability of die casting makes it particularly advantageous for industries like automotive and electronics, where high-volume production is essential. By reducing waste and optimizing energy consumption, manufacturers can achieve both economic and environmental benefits.

Durability and Strength of Components

Professional metal die casting parts are celebrated for their durability and mechanical strength. The process produces components with excellent hardness and tensile properties, making them suitable for demanding applications. For instance, mechanical testing, including hardness and Charpy impact tests, confirms the strength and reliability of die-cast components.

Industries like aerospace and automotive rely on die-cast parts for their ability to withstand extreme conditions without compromising performance.

The fatigue strength of die-cast metals further enhances their durability, ensuring long-lasting performance even under continuous stress. This makes them a preferred choice for critical applications such as engine components and structural parts.

By combining strength, durability, and precision, die casting delivers components that meet the rigorous demands of modern industries.

Applications of Professional Metal Die Casting Parts

Automotive Industry

The automotive sector relies heavily on professional metal die casting parts for their precision and durability. With global vehicle production reaching approximately 85 million units in 2022, the demand for die-cast components remains strong. Manufacturers use advanced technologies like automation and digitalization to meet the industry’s evolving needs, particularly for electric vehicles and lightweight designs. Innovations such as Ryobi’s “giga casting” for large EV body parts and UBE Corporation’s ultra-large die-casting machines highlight the sector’s focus on efficiency and cost reduction. These advancements ensure that die-cast parts meet the stringent requirements of modern vehicles, including strength, weight reduction, and corrosion resistance.

Aerospace and Defense

In aerospace and defense, die casting plays a critical role in producing lightweight yet durable components. Advanced alloys and vacuum die casting techniques reduce the weight of parts, improving fuel efficiency by up to 20%. The process ensures that components can withstand the extreme stresses of flight while meeting rigorous safety standards.

| Benefit | Description | Impact on Aerospace and Defense |

|---|---|---|

| Lightweight Components | Advanced alloys and vacuum die casting reduce component weight. | Improves fuel efficiency by up to 20%. |

| Strength and Durability | Ensures parts can withstand flight stress and safety standards. | Meets high safety requirements. |

| Fuel Efficiency | Reduction in weight leads to better fuel consumption. | Critical for operational cost savings. |

These benefits make die casting indispensable for manufacturing critical aerospace and defense components.

Electronics and Consumer Goods

Die casting also excels in the electronics and consumer goods industries. It provides strong, reliable components for electrical systems, durable parts for home appliances, and functional yet decorative hardware for furniture.

| Industry | Advantages of Die Casting Parts |

|---|---|

| Electrical Industry | Strong electrical components for reliable systems |

| Appliance Industry | Durable parts for home appliances enhancing effectiveness |

| Furniture Industry | Functional and decorative hardware for aesthetic appeal |

By combining precision, durability, and versatility, professional metal die casting parts meet the diverse demands of these industries.

Choosing the Right Professional Metal Die Casting Solution

Evaluating Expertise and Experience

Selecting the right manufacturer begins with assessing their expertise and experience. Companies with decades of industry knowledge often deliver superior results. Dynacast, for instance, has over 80 years of experience producing precise metal parts for diverse sectors. Similarly, A&B employs skilled engineers capable of handling intricate designs, ensuring high-quality outcomes. Manufacturers like Castingod and Golden Pond Metal Die Casting Co., Ltd. demonstrate reliability and proficiency by managing complex projects and implementing strict quality control measures.

Expertise ensures manufacturers can address unique challenges, while experience guarantees consistent performance across projects.

When evaluating a supplier, consider their track record and references. A strong history of delivering quality parts reflects their commitment to excellence.

Assessing Technology and Equipment

Modern technology plays a pivotal role in producing high-quality die-cast components. Automated systems enhance efficiency and precision, reducing labor costs and minimizing human error. Robots streamline injection and ejection processes, ensuring consistent quality throughout production. Advanced simulation software predicts defects and optimizes the casting process, enabling virtual prototyping before physical manufacturing.

Manufacturers leveraging AI and machine learning can monitor and optimize operations in real time. These advancements improve safety, speed, and accuracy, making them indispensable for professional metal die casting parts.

Importance of Quality Assurance and Certifications

Certifications validate a manufacturer’s commitment to quality and compliance with industry standards. ISO certifications ensure adherence to international benchmarks, while American standards like NADCA and ASTM guarantee reliability. Metallurgical testing verifies mechanical properties, while chemical composition analysis ensures material quality.

Rigorous testing methods, such as tensile strength and hardness evaluations, confirm the durability of die-cast components.

Certifications like ISO 9001 and AS9100 are particularly crucial for industries requiring safety-sensitive parts, such as aerospace and defense. These benchmarks provide confidence in the manufacturer’s ability to deliver consistent, high-quality products.

Professional metal die casting parts play a vital role in modern manufacturing. Their strength-to-weight ratio enhances performance in industries like automotive, while their fluidity supports intricate designs and reduces material costs. High-pressure casting ensures fewer defects, making products reliable and efficient. Selecting a trusted manufacturer ensures quality and tailored solutions for specific needs. Consulting experts helps businesses achieve optimal results.

FAQ

What industries benefit the most from metal die casting?

Automotive, aerospace, and electronics industries benefit significantly. They rely on die casting for precision, durability, and cost-effective production of high-quality components.

How does die casting ensure dimensional accuracy?

High-pressure injection molds metal into precise shapes. This process minimizes deviations, ensuring components meet strict tolerances without requiring extensive post-processing.

Can die casting use recycled materials?

Yes, manufacturers often use recyclable metals like aluminum and zinc. This practice reduces waste, lowers costs, and supports sustainability goals.

By:haihong

email:daphne@haihongxintang.com

email:haihong@haihongxintang.com

Phone:

Sales: 0086-134 8641 8015

Support: 0086-574 8669 1714

Post time: Apr-22-2025