Automaker ikozvino inoshandisa advancedAluminium die castingkugadzira zvakareruka uye zvakasimbaAluminium inofa ichikanda mota chasis zvikamuzvemotokari dzemagetsi. Aya maitiro anovandudza kushanda uye kuchengeteka. Vagadziri vanowana zvakadereraAluminium inofa yekukanda mutengouye kugarika kuri nani. Indasitiri inoona mamwe magadzirirwo akabatanidzwa, kubatsira motokari dzemagetsi kuti dzive dzakasimba uye dzakavimbika.

Key Takeaways

- Advanced die castinginogadzira yakareruka, yakasimba yemagetsi mota chassis zvikamu zvinovandudza kuchengeteka, kuita, uye kushanda nesimba.

- Nzira nyowani senge high-pressure, mega, uye giga casting inoderedza zvikamu uye nguva yegungano, kudzikisa mitengo uye kuwedzera kukurumidza kwekugadzira.

- Automation, maturusi edhijitari, uyeadvanced alloyschengetedza mhando yepamusoro, gadziriso, uye zvirinani kupisa manejimendi kune anogara-anogara emagetsi mota.

Mhedzisiro Mukati Aluminium Die Casting Car Chasis Parts Technology

High-Pressure Die Casting yeEV Chassis

High-pressure die casting yave shanduko yemitambo yemagetsi mota chassis kugadzirwa. Iyi nzira inopinza aruminiyamu yakanyungudutswa muzviumbwa zvesimbi nekumhanya kwakanyanya uye nekumanikidza. Mhedzisiro yacho chikamu chakakora, chakasimba chine zviyero chaizvo. Vagadziri vanoshandisa nzira iyi kugadzira zvimiro zvakaoma izvo nzira dzechinyakare dzisingakwanisi kuwana. High-pressure die casting zvakare inoderedza kudiwa kwewelding uye kusangana. Izvi zvinotungamira kune mashoma asina kusimba mapoinzi mune chassis uye inovandudza chengetedzo.

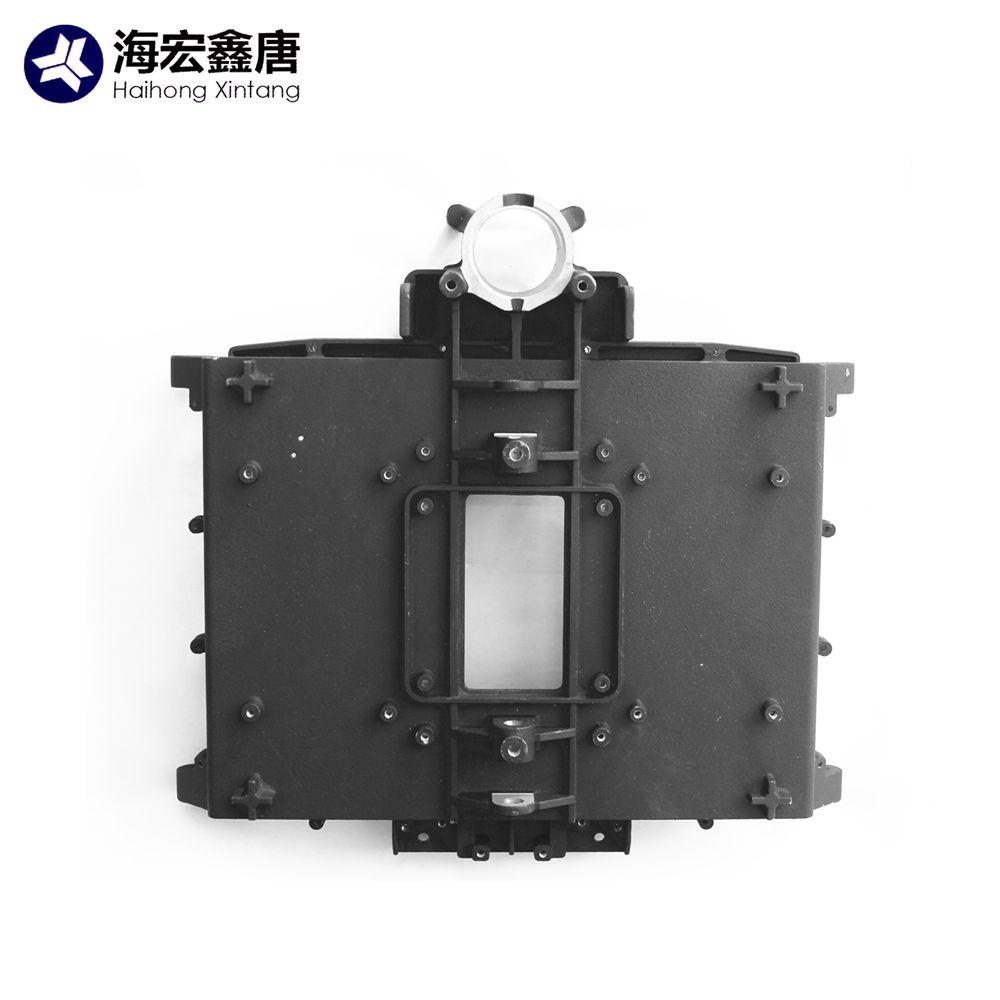

HHXT inoshandisa advanced high-pressure die casting kugadzira Aluminium die casting car chasis parts. Maitiro avo anovimbisa kuti chikamu chimwe nechimwe chinosangana neakaomesesa emhando zviyero. Iko kushandiswa kwearuminiyamu ekutanga alloys, senge ADC12 neA380, inopa zvikamu simba rakanakisa uye kusakara. Aya maficha akakosha kumotokari dzemagetsi, izvo zvinoda zvese zviri nyore uye zvinogara kwenguva refu.

Cherechedza:High-pressure die casting inobvumira kukurumidza kugadzira kutenderera. Izvi zvinobatsira ma automaker kusangana nekukura kuri kuda kwemotokari dzemagetsi pasina kupa mhando.

Mega uye Giga Casting muMagetsi Mota

Mega casting uye giga casting inomiririra nhanho inotevera mu die casting tekinoroji. Idzi nzira dzinoshandisa michina mikuru kugadzira yakakura kwazvo, imwe-chimedu chassis zvikamu. Tesla akapayona nzira iyi neGiga Press yake, uye vamwe vagadziri vava kutevedzera. Nekukanda zvikamu zvakakura zvechasi muchidimbu chimwe, vagadziri vanodzikisa huwandu hwezvikamu nemajoini. Izvi zvinoita kuti chassis ireruke uye yakasimba.

Mega uye giga casting zvakare inogadzirisa maitiro ekugadzira. Zvikamu zvishoma zvinoreva nguva shoma yegungano uye mutengo wakaderera. Maitiro acho anotsigira kugadzirwa kweAluminium die casting car chasis zvikamu izvo zvese zvakasimba uye zvisingaremi. Iyi innovation inobatsira mota dzemagetsi kuwana zvirinani huwandu uye kuita.

Kuenzanisa kwechinyakare vs. giga casting:

| Feature | Traditional Casting | Giga Casting |

|---|---|---|

| Nhamba yeZvikamu | Vazhinji | Vashoma (kazhinji imwe) |

| Nguva Yegungano | Kureba | Pfupi |

| Structural Strength | Pakati nepakati | High |

| Kurema | Higher | Lower |

Automation uye Digitalization muDie Casting

Automation uye digitalization ikozvino inoita basa rakakosha mukukanda kufa kwemazuva ano. Mafekitori anoshandisa marobhoti nemichina yakangwara kubata mabasa sekuzadza mold, kutonhora, uye kubvisa chikamu. Izvi zvinoderedza kukanganisa kwevanhu uye zvinowedzera kuwirirana. Zvishandiso zvedhijitari zvinotarisisa nhanho yega yega maitiro. Masensa anounganidza data pane tembiricha, kudzvanywa, uye kutenderera nguva. Mainjiniya anoshandisa iyi data kuvandudza kunaka uye kugona.

HHXT yakaisa mari mukatiadvanced CNC Machining nzvimbouye madhijitari ekuongorora masisitimu. Aya matekinoroji anovimbisa kuti yega yega Aluminium inofa ichikanda mota chasis chikamu inosangana chaizvo nezvinodiwa. Automation inobvumirawo kukurumidza kuchinja mukugadzira. Vagadziri vanogona kupindura nekukurumidza kune maitiro matsva uye zvinodiwa nevatengi.

Zano:Digitalization inobatsira kuona matambudziko nekukurumidza. Izvi zvinotungamirira kuhurema hushoma uye kugutsikana kwepamusoro kwevatengi.

Dhizaini uye Kuita Mabhenefiti eMagetsi Mota

One-Piece Castings uye Structural Integration

Vagadziri vemotokari ikozvino vanoshandisa-chimedu chekukanda kugadzira zvikamu zvakakura zvemotokari yemagetsi chassis. Iyi nzira inobatanidza zvikamu zvakawanda kuva chinhu chimwe, chakasimba. Mainjiniya vanogadzira aya ma castings kuti akwane zvakakwana nezvimwe zvikamu zvemota. Mhedzisiro yacho chassis ine majoini mashoma uye welds.

Imwe-chimedu castings inopa akati wandei mabhenefiti akakosha:

- Kuwedzera simba:Majoini mashoma anoreva mashoma makwapa asina simba. Iyo chassis inogona kubata zvakanyanya kushushikana panguva yekutyaira.

- Kuchengetedzeka kwakavandudzwa:Chimiro chakasimba chinodzivirira vafambi zviri nani kana pakaitika tsaona.

- Gungano rakarerutswa:Vashandi vanopedza nguva shoma vachiisa zvikamu pamwechete. Izvi zvinomhanyisa kugadzira uye zvinoderedza zvikanganiso.

Cherechedza:Kubatanidzwa kwemaitiro kunobvumira vagadziri kuti vawedzere maficha senge ekukwirisa mapoinzi uye chiteshi zvakananga mukukanda. Izvi zvinoderedza kudiwa kwemamwe mabhuraketi kana fasteners.

Kuderedza uremu uye Kubudirira Kuwana

Mota dzemagetsi dzinofanirwa kuve dzakareruka sezvinobvira kuti dziwedzere huwandu hwadzo. Advanced die casting inobatsira kuzadzisa ichi chinangwa. Aluminium alloys, akadai seaya anoshandiswa neHHXT, kupa simba rakakwirira uchichengeta uremu hwakaderera. Mainjiniya anogona kugadzira madziro matete uye maumbirwo akaomarara ayo asingakwanisi kugadzirwa nenzira dzechinyakare.

Chassis yakareruka inounza akawanda mabhenefiti:

- Kurebesa kutyaira:Motokari inoshandisa simba shoma kufamba, saka bhatiri rinogara kwenguva refu.

- Kuwedzera kurinani:Huremu hushoma zvinoreva kuti mota inogona kukurumidza kukurumidza.

- Mari yemagetsi yakaderera:Vatyairi vanopedza mari shoma vachichaja mota dzavo.

| Benefit | Impact paEVs |

|---|---|

| Uremu hwakaderera | Kuwedzera huwandu |

| Chimiro chakasimba | Kuchengetedzeka kwakavandudzwa |

| Zvikamu zvishoma | Kukurumidza kugadzira |

Vagadziri vakaita seHHXT vanoshandisa chaiyo CNC machining kuchengetedza zvikamu zvakarurama uye kuderedza marara. Iyi nzira inovimbisa kuti chikamu chese chassis chinosangana nemiyero yakasimba yehuremu uye chiyero.

Enhanced Thermal Management

Mota dzemagetsi dzinogadzira kupisa mumabhatiri nemamotor avo. Kutarisira kwakaringana kwekupisa kunoita kuti zvikamu izvi zvitonhore uye zvishande nemazvo. Yepamberi yekukanda kufa inobvumira mainjiniya kuvaka nzira dzekutonhora uye kupisa kunonyura zvakananga muzvikamu zvechassis.

Mamiriro akakosha ekunatsiridza thermal manejimendi anosanganisira:

- Nzira dzekutonhodza dzakavakwa-mukati:Machani ari mukati mekukanda anobatsira kubvisa kupisa kure nenzvimbo dzakaoma.

- Kuvimbika kwakavandudzwa:Mabhatiri anotonhorera uye mota dzinogara kwenguva refu uye dzinoita zvirinani.

- Kushanda kwakafanana:Motokari inogona kutyaira madaro marefu pasina kupisa.

Zano:Integrated thermal management inoderedza kudiwa kwekuwedzera kutonhora masisitimu. Izvi zvinochengetedza nzvimbo uye uremu, zvichiita kuti mota iwedzere kushanda.

Vagadziri vemotokari ikozvino vanovimba neaya magadzirirwo uye mabhenefiti ekuita kugadzira mota dzemagetsi dzakachengetedzeka, dzakareruka, uye dzakavimbika. Advanced die casting inomira pakati peshanduko iyi.

Inotungamira Alloys uye Zvishandiso muAluminium Die Kukanda Mota Chasis Zvikamu

Yepamberi Aluminium Alloys yeEV Chassis

Vagadziri vemotokari vanovimba nearuminiyamu alloys epamberi kugadzira akasimba uye akareruka chassis zvikamu zvemotokari dzemagetsi. Alloys akadai seADC1, ADC12, A380, uye AlSi9Cu3 inopa yakanakisa mechanic zvivakwa. Zvishandiso izvi zvinoramba corrosion uye zvinopa simba rinodiwa pakuda maapplication emotokari. Vagadziri vakaita seHHXT vanosarudza aya alloys nekuti anobatsira kudzikisa huremu hwemotokari uchichengetedza kusimba.

Cherechedza:Aluminium alloys inobvumira maumbirwo akaoma uye madziro akaonda, ayo akakosha kune emazuva ano emagetsi magadzirirwo emotokari.

Maitiro ekusarudzwa kweAlloy muMotokari dzeMagetsi

Mainjiniya vanosarudza ma alloys zvichienderana nezvakati wandei zvakakosha zvinhu:

- Simba:Izvo zvinhu zvinofanirwa kubata kushushikana uye kukanganisa panguva yekutyaira.

- Corrosion resistance:Iyo chassis inoda kugara mumamiriro ekunze akasiyana.

- Machinability:Iyo alloy inofanira kubvumirakunyatsocheka uye kuumba.

- Thermal conductivity:Kutamisa kupisa kwakanaka kunobatsira nebhatiri uye mota kutonhora.

Tafura iri pazasi inoratidza maitiro akakosha ekusarudza alloy:

| Criteria | Kukosha kweEVs |

|---|---|

| Simba | Kuchengetedza uye kusimba |

| Corrosion Resistance | Upenyu hurefu |

| Machinability | Kugadzirwa kwakarurama |

| Thermal Conductivity | Kutonhorera kunoshanda |

Material Innovations for Simba and Durability

Material science inoramba ichifambira mberi. New aluminium alloys ikozvino inopa simba repamusoro uye kuita zvirinani. Vagadziri vanoshandisa micro-alloying uye yakagadziridzwa maitiro ekukanda kugadzira zvikamu zvinogara kwenguva refu. Aya magadzirirwo anobatsira Aluminium kufa achikanda mota chasis zvikamu kusangana nekuchengetedzeka kwakasimba uye mhando zviyero. Somugumisiro, motokari dzemagetsi dzinova dzakachengeteka uye dzakavimbika kune vatyairi.

Manufacturing and Customization Trends

Yakakwenenzverwa Kugadzirwa uye Kudzora Kwemhando

Vagadziri ikozvino vanoshandisa tekinoroji yepamusoro kuita kuti kugadzira nekukurumidza uye kwakavimbika. Michina yemagetsi inobata matanho akawanda, akadaikufa kukandira, CNC machining, uye kuongorora. Izvi zvinoderedza zvikanganiso uye zvinochengeta chikamu chimwe nechimwe chakafanana. Makambani akaita seHHXT anoshandisa madhijitari ekuongorora masisitimu kutarisa chimwe nechimwe chassis chikamu pamatanho akasiyana. Vanotevera mitemo yakasimba yemhando uye kushandisa zvitupa se ISO9001:2008 uye IATF16949. Matanho aya anobatsira kuendesa zvikamu zvinosangana nemhando yepamusoro nguva dzese.

Zano:Automated quality inotarisa matambudziko ekubata kare. Izvi zvinochengetedza nguva nemari kune vese vagadziri uye vatengi.

Dhizaini Flexibility uye Tsika Solutions

Vagadziri vemotokari vanoda zvikamu zvinokwana magadzirirwo avo akasiyana. Mazuva ano kufa kukandira kunotsigira maumbirwo echinyakare uye saizi. Mainjiniya anogona kushandisa 2D kana 3D kudhirowa kugadzira mold nyowani nekukurumidza.HHXT inopa OEMuye ODM masevhisi, zvinoreva kuti vanogona kugadzira zvikamu zvinoenderana nevatengi samples kana kudhirowa. Yavo CNC machining nzvimbo inobvumira shanduko chaidzo, kunyangwe mabhechi madiki. Uku kuchinjika kunobatsira vagadziri vemotokari kuvhura mhando nyowani nekukurumidza.

Key customization sarudzo:

- Custom dimensions uye maumbirwo

- Sarudzo yealuminium alloys

- Special mounting points kana maficha

Surface Kurapa uye Kupedzisa Sarudzo

Kurapa kwepamusoro kunodzivirira chassis zvikamu uye kuita kuti zvitaridzike zviri nani. HHXT inopa akawanda ekupedzisa sarudzo, senge kuputika kwepfuti, kuputika kwejecha, poda coating, pendi, uye anodizing. Mishonga iyi inovandudza corrosion resistance uye kugara kwenguva refu. Vatengi vanogona zvakare kusarudza mavara senge sirivheri chena, dema, kana tsika shades.

| Surface Treatment | Benefit |

|---|---|

| Powder Coating | Simba, kunyange kupedza |

| Anodizing | Extra corrosion protection |

| Kupukuta | Yakapfava, inopenya |

Kupedzisa kwakanaka kunobatsira zvikamu kugara kwenguva refu uye kuita zvirinani mumamiriro akaoma.

Mutengo, Sustainability, uye Chaiyo-Nyika Impact

Mari Yekugadzira Yakaderera uye Nekubudirira

Vagadziri vemotokari vanoona kukosha kwekuchengetedza mari nekufambisa kwepamusoro kufa. High-pressure maitiro anoderedza huwandu hwezvikamu zvinodiwa kune yega chassis. Zvikamu zvishoma zvinoreva nguva shoma yekuunganidza uye kuderera kwemitengo yebasa. Automated system inobatsira mafekitori kuburitsa mamwe mayunitsi munguva shoma. Makambani akaita seHHXT anoshandisa kuongorora kwedhijitari uye CNC machining kuchengetedza tsvina yakaderera uye mhando yepamusoro. Aya matanho anobatsira vagadziri kupa mitengo yemakwikwi yeAluminium inofa ichikanda mota chasis zvikamu.

Zano:Kugadzirwa kwakakwenenzverwa kunobatsira vagadziri vemotokari kupindura nekukurumidza kune shanduko yemusika uye zvinodiwa nevatengi.

Mabhenefiti ezvakatipoteredza uye Matanho ekudzokorodzazve

Mazuva ano kufa kukandira kunotsigira zvinangwa zvekusimudzira. Aluminium inonyanya kushandiswa zvakare. Mafekitari anounganidza uye anoshandisa zvakare zvimedu zvesimbi kubva mukugadzira. Izvi zvinoderedza kudiwa kwezvinhu zvitsva. Vazhinji vagadziri vanoshandisa eco-inoshamwaridzika pamusoro pekurapa kudzikisa yavo nharaunda. Matanho ekudzokorodza anobatsira kuchengetedza tsvina kubva pamarara uye kuchengetedza simba.

Kutarisa nekukurumidza kune zvakatipoteredza zvinobatsira:

| Benefit | Impact |

|---|---|

| Zvinhu zvinogadziriswazve | Kurasa kushoma |

| Matanho anoshandisa simba | Lower carbon footprint |

| Eco-hushamwari inopedza | Cleaner production |

Kuita Kuvandudzwa muKutungamira Vagadziri

Vanotungamira automaker vanoshandisa advanced die casting kuvandudza mashandiro emotokari. Yakasimba uye yakareruka chassis zvikamu zvinobatsira mota dzemagetsi kuti ikurumidze kukurumidza uye kufamba kuenda kure nechaji imwe. Akavakirwa-mukati maficha ekutonhodza anochengeta mabhatiri nemamotor patembiricha yakachengeteka. Makambani akaita seHHXT anounza chaiwo zvikamu zvinosangana neyakaomarara indasitiri zviyero. Aya magadzirirwo anobatsira mota dzemagetsi kuwana mareti ekuchengetedza epamusoro uye kuvimba nevatengi.

Maindasitiri Mienzaniso muAluminium Die Kukanda Mota Chasis Zvikamu

Tesla's Giga Casting Nzira

Tesla inotungamira indasitiri neiyo Giga Casting tekinoroji. Iyo kambani inoshandisa mahombe ekukanda muchina kugadzira zvikamu zvakakura zvemotokari chassis muchidimbu chimwe. Iyi nzira inoderedza nhamba yezvikamu uye welds. Mainjiniya kuTesla vanogadzira aya ma castings kuvandudza simba uye kudzikisa huremu hwemotokari. Iyo Giga Press inobvumira Tesla kuti ikurumidze kugadzira uye kuderedza mitengo. Vazhinji vanogadzira mota izvozvi vanodzidza nzira dzaTesla dzekuvandudza yavo kugadzira.

Tesla's Giga Casting inoisa chiyero chitsva chekubudirira uye hunyanzvi mukugadzirwa kwemotokari yemagetsi.

Zvitsva kubva kuHHXT uye Vamwe Vagadziri

HHXT inomira pachena semutengesi akavimbikayeAluminium inofa ichikanda mota chasis zvikamu. Iyo kambani inoshandisa yepamusoro-kumanikidza kufa kukanda uye CNC machining. Maitiro avo anovimbisa kuti chikamu chimwe nechimwe chinosangana neakaomesesa emhando zviyero. HHXT inopa mhinduro dzetsika dzemhando dzakasiyana dzemotokari dzemagetsi. Vamwe vagadziri vanoisawo mari mune otomatiki uye kuongorora kwedhijitari. Aya matanho anobatsira kuendesa chaiyo uye yakavimbika chassis zvikamu zvemusika uri kukura wemotokari yemagetsi.

- HHXT inoshandisa premium aruminiyamu alloys kune simba uye kusimba.

- Iyo kambani inopa huwandu hwekurapa kwepamusoro kudzivirira zvirinani.

- Vatengi vanogona kukumbira hukuru hwetsika uye maficha.

Ramangwana Maonero eMagetsi Vehicle Chassis

Ramangwana remotokari yemagetsi chassis rinotaridzika kuvimbisa. Vagadziri vemotokari vanoenderera mberi nekutora nzira dzepamusoro dzekukanda kufa. Zvishandiso zvitsva uye maturusi edhijitari zvichabatsira kugadzira zvakareruka uye zvakasimba chassis zvikamu. Nyanzvi dzeindasitiri dzinotarisira zvimwe-chimwe-chidimbu castings uye zvakasanganiswa kutonhora maficha. Aya maitiro achatsigira akachengeteka, anoshanda zvakanyanya, uye anotengeka mota dzemagetsi.

Chizvarwa chinotevera chemotokari dzemagetsi chichabatsirwa kubva mukuenderera mberi hunyanzvi mu die casting tekinoroji.

Yepamberi yekukanda kufa inoumba ramangwana remotokari dzemagetsi. Vagadziri ikozvino vanogadzira yakareruka, yakasimba Aluminium inofa ichikanda mota chasis zvikamu. Aya magadzirirwo anobatsira automaker kudzikisira mitengo uye kuvandudza kusimudzira. Iyo indasitiri inoenda kune inoshanda, yepamusoro-inoshanda chassis kugadzira. Mota dzemagetsi dzinobatsirwa kubva kubudiriro idzi mazuva ese.

FAQ

Chii chinoita kuti aluminium kufa kukanda kwakanakira yemagetsi mota chassis zvikamu?

Aluminium die castinginogadzira zvikamu zvisingaremi, zvakasimba, uye chaizvo. Aya hunhu anobatsira mota dzemagetsi kuita zvirinani, kuchengeteka, uye kuita.

HHXT inova sei nechokwadi chemhando muzvikamu zvayo zvinofa zvakakandwa chassis?

HHXT inoshandisa advanced CNC machining, kuongorora kwakasimba, uye maitiro akasimbiswa. Chikamu chega chega chinosangana nemiyero yepamusoro yekusimba, kurongeka, uye kusimba.

Vagadziri vanogona kugadzirisa aluminium die cast chassis zvikamu zvemhando dzeEV chaiyo?

Ehe. Vagadziri vakaita seHHXT inopaOEM uye ODM masevhisi. Ivo vanogadzira maumbirwo echinyakare, saizi, uye anopedzisa kuti aenderane neakasarudzika mota yemagetsi zvinodiwa.

Nguva yekutumira: Jul-04-2025