Abenzi bezimoto manje basebenzisa okuthuthukileI-aluminium die castingukukhiqiza ukukhanya nokunamandlaIzingxenye ze-Aluminium die cast chasis yemotoezimotweni zikagesi. Lezi zindlela zokwenza ngcono ukusebenza nokuphepha. Abakhiqizi bazuza kancaneIntengo ye-aluminium die castkanye nokusimama okungcono. Imboni ibona imiklamo eminingi edidiyelwe, esiza izimoto zikagesi ukuthi zisebenze kahle futhi zithembeke.

Okuthathwayo Okubalulekile

- Ukusakaza kwefa okuthuthukisiweidala izingxenye ze-chassis yemoto kagesi ezilula, eziqinile ezithuthukisa ukuphepha, ukusebenza, nokusebenza kahle.

- Izindlela ezintsha ezifana ne-high-pressure, mega, kanye ne-giga casting zinciphisa izingxenye nesikhathi sokuhlanganisa, zehlise izindleko kanye nokuthuthukisa isivinini sokukhiqiza.

- Okuzenzakalelayo, amathuluzi edijithali, kanyeama-alloys athuthukileqinisekisa ikhwalithi ephezulu, ukwenza ngokwezifiso, kanye nokuphathwa okungcono kokushisa kwezimoto zikagesi ezihlala isikhathi eside.

Ukuthuthukiswa kwe-Aluminium Die Casting Car Chasis Parts Technology

I-High-Pressure Die Casting ye-EV Chassis

I-High-pressure die casting isiphenduke into eshintsha umdlalo ekukhiqizeni i-chassis yemoto kagesi. Le nqubo ijova i-aluminium encibilikisiwe ezibunjeni zensimbi ngesivinini esikhulu kakhulu kanye nezingcindezi. Umphumela uba ingxenye eminyene, eqinile enobukhulu obunembile. Abakhiqizi basebenzisa le ndlela ukuze bakhe izimo eziyinkimbinkimbi izindlela zendabuko ezingakwazi ukuzifinyelela. I-high-pressure die casting nayo inciphisa isidingo sokushisela nokuhlanganisa. Lokhu kuholela kumaphuzu abuthakathaka ambalwa ku-chassis futhi kuthuthukisa ukuphepha.

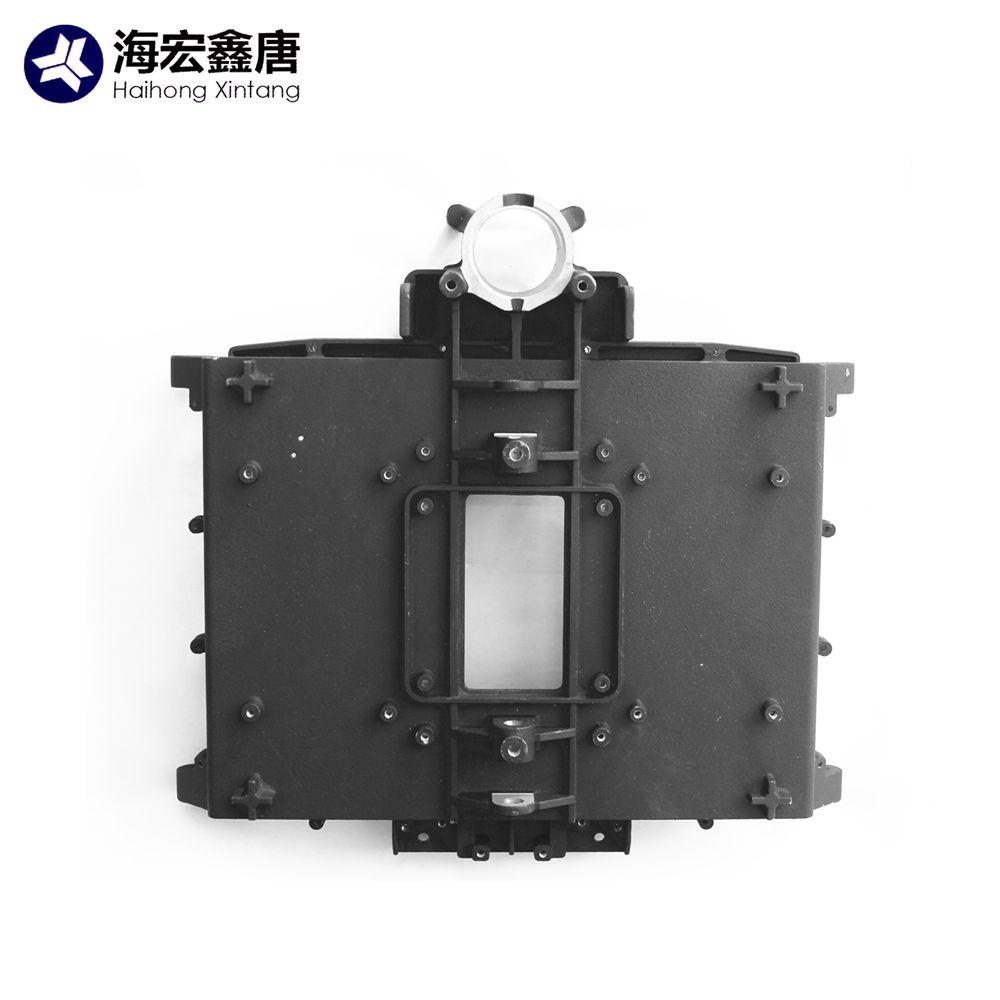

I-HHXT isebenzisa i-high-pressure die casting ethuthukisiwe ukukhiqiza izingxenye ze-Aluminium die cast chasis yemoto. Inqubo yabo iqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziqinile zekhwalithi. Ukusetshenziswa kwama-alloys e-premium aluminium, njenge-ADC12 ne-A380, kunikeza izingxenye amandla amahle kakhulu nokumelana nokugqwala. Lezi zici zibalulekile ezimotweni zikagesi, ezidinga izingxenye ezingasindi neziqinile.

Qaphela:I-High-press die casting ivumela imijikelezo yokukhiqiza esheshayo. Lokhu kusiza abakhiqizi bezimoto ukuthi bahlangabezane nesidingo esikhulayo sezimoto zikagesi ngaphandle kokudela ikhwalithi.

I-Mega ne-Giga Casting ezimotweni zikagesi

I-Mega Casting kanye ne-giga Casting kumelela isinyathelo esilandelayo kubuchwepheshe bokusakaza ngefa. Lezi zindlela zisebenzisa imishini emikhulu ukukhiqiza izingxenye ze-chassis ezinkulu kakhulu, ezinocezu olulodwa. I-Tesla iphayona le ndlela nge-Giga Press yayo, futhi abanye abakhiqizi manje balandela okufanayo. Ngokuphonsa izingxenye ezinkulu ze-chassis esiqeshini esisodwa, abakhiqizi bezimoto banciphisa inani lezingxenye namalunga. Lokhu kwenza i-chassis ibe lula futhi ibe namandla.

I-Mega kanye ne-giga casting futhi kuthuthukisa inqubo yokukhiqiza. Izingxenye ezimbalwa zisho isikhathi esincane sokuhlanganisa nezindleko eziphansi. Inqubo isekela ukukhiqizwa kwezingxenye ze-Aluminium die cast chasis yemoto eziqinile futhi ezingasindi. Lokhu okusha kusiza izimoto zikagesi zithole ibanga elingcono nokusebenza.

Ukuqhathaniswa kokulingisa kwendabuko kuqhathaniswa ne-giga:

| Isici | Ukulingisa Kwendabuko | Giga Casting |

|---|---|---|

| Inombolo Yezingxenye | Abaningi | Abambalwa (imvamisa eyodwa) |

| Isikhathi Somhlangano | Yinde | Kufushane |

| Amandla Esakhiwo | Kuphakathi | Phezulu |

| Isisindo | Phezulu | Phansi |

Ukuzenzakalela kanye nokwenza idijithali ku-Die Casting

Ukuzenzakalela kanye nokwenza idijithali manje kudlala indima ebalulekile ekulingiseni kwesimanjemanje. Izimboni zisebenzisa amarobhothi nemishini ehlakaniphile ukuphatha imisebenzi efana nokugcwalisa isikhunta, ukupholisa, nokususwa kwengxenye. Lokhu kunciphisa iphutha lomuntu futhi kwandisa ukungaguquguquki. Amathuluzi edijithali aqapha zonke izinyathelo zenqubo. Izinzwa ziqoqa idatha ngezinga lokushisa, ingcindezi, nezikhathi zomjikelezo. Onjiniyela basebenzisa le datha ukuze bathuthukise ikhwalithi nokusebenza kahle.

I-HHXT itshale imali kuyoeziphambili CNC machining izikhungokanye nezinhlelo zokuhlola idijithali. Lobu buchwepheshe buqinisekisa ukuthi yonke ingxenye ye-Aluminium die casting chasis yemoto ihlangabezana nokucaciswa okuqondile. I-Automation iphinde ivumele izinguquko ezisheshayo ekwakhiweni. Abakhiqizi bangaphendula ngokushesha kumathrendi amasha nezidingo zamakhasimende.

Ithiphu:Ukusebenzisa idijithali kusiza ukukhomba izinkinga kusenesikhathi. Lokhu kuholela emaphutheni ambalwa kanye nokwaneliseka okuphezulu kwamakhasimende.

Izinzuzo Zokuklama Nokusebenza Kwezimoto zikagesi

Ukulingisa Kwengxenye Eyodwa kanye Nokuhlanganiswa Kwesakhiwo

Abakhiqizi bezimoto manje basebenzisa ukulingisa okuyingxenye eyodwa ukuze bakhe izingxenye ezinkulu ze-chassis yemoto kagesi. Le ndlela ihlanganisa izingxenye eziningi zibe ingxenye eyodwa, eqinile. Onjiniyela baklama lezi zithombe ukuze zilingane kahle nezinye izingxenye zemoto. Umphumela uba i-chassis enamalunga ambalwa nama-welds.

Ukulingisa kwesiqephu esisodwa kunikeza izinzuzo ezimbalwa ezibalulekile:

- Amandla angeziwe:Amalunga ambalwa asho izindawo ezibuthakathaka ezimbalwa. I-chassis ingakwazi ukubhekana nokucindezeleka okwengeziwe ngesikhathi sokushayela.

- Ukuphepha okuthuthukisiwe:Isakhiwo esiqinile sivikela abagibeli kangcono uma kwenzeka ingozi.

- Ukuhlanganiswa okwenziwe lula:Abasebenzi bachitha isikhathi esincane behlanganisa izingxenye. Lokhu kusheshisa ukukhiqiza futhi kunciphisa amaphutha.

Qaphela:Ukuhlanganiswa kwesakhiwo kuvumela abaklami ukuthi bengeze izici ezifana namaphoyinti okukhweza namashaneli ngokuqondile ekulingiseni. Lokhu kunciphisa isidingo sabakaki abengeziwe noma izixhumi.

Ukwehliswa Kwesisindo Nokuzuza Ngokusebenza Kahle

Izimoto zikagesi zidinga ukukhanya ngangokunokwenzeka ukuze zandise ububanzi bazo. Ukulingisa okuthuthukisiwe kusiza ukufeza lo mgomo. Ama-alloys e-aluminium, njengalawo asetshenziswa yiI-HHXT, nikeza amandla aphezulu ngenkathi ugcina isisindo siphansi. Onjiniyela bangaklama izindonga ezincane nezimo eziyinkimbinkimbi ezingenakukwazi ukukhiqiza izindlela zendabuko.

I-chassis elula iletha izinzuzo eziningi:

- Ibanga lokushayela elide:Imoto isebenzisa amandla amancane ukuze ihambe, ngakho ibhethri lihlala isikhathi eside.

- Ukusheshisa okungcono:Isisindo esincane sisho ukuthi imoto ingasheshisa ngokushesha.

- Izindleko zamandla aphansi:Abashayeli bachitha imali encane bekhokhisa izimoto zabo.

| Zuza | Umthelela kuma-EVs |

|---|---|

| Isisindo esiphansi | Ububanzi obukhulisiwe |

| Isakhiwo esinamandla | Ukuphepha okuthuthukisiwe |

| Izingxenye ezimbalwa | Ukukhiqiza okusheshayo |

Abakhiqizi abafana ne-HHXT basebenzisa imishini ye-CNC enembile ukuze bagcine izingxenye zinembile futhi banciphise imfucuza. Le nqubo iqinisekisa ukuthi yonke ingxenye ye-chassis ihlangabezana nezindinganiso eziqinile zesisindo nebhalansi.

Ukuphatha Okushisayo Okuthuthukisiwe

Izimoto zikagesi zikhiqiza ukushisa kumabhethri namamotho azo. Ukuphatha okushisayo okufanelekile kugcina lezi zingxenye zipholile futhi zisebenza kahle. I-Advanced die Casting ivumela onjiniyela ukuthi bakhe iziteshi zokupholisa kanye namasinki okushisa ngqo ezingxenyeni ze-chassis.

Izici ezibalulekile zokuphathwa kwe-thermal okuthuthukisiwe zifaka:

- Izindlela zokupholisa ezakhelwe ngaphakathi:Iziteshi ezingaphakathi kokusakaza zisiza ukususa ukushisa ezindaweni ezibucayi.

- Ukuthembeka okuthuthukisiwe:Amabhethri apholile namamotho ahlala isikhathi eside futhi asebenza kangcono.

- Ukusebenza okungaguquki:Imoto ingahamba amabanga amade ngaphandle kokushisisa ngokweqile.

Ithiphu:Ukuphathwa kwe-thermal okudidiyelwe kunciphisa isidingo samasistimu okupholisa engeziwe. Lokhu konga isikhala nesisindo, okwenza imoto isebenze kahle nakakhulu.

Abenzi bezimoto manje bathembele kulezi zinzuzo zedizayini nokusebenza ukuze bakhe izimoto zikagesi eziphephe kakhudlwana, ezilula, nezithembekile. I-Advanced die Casting iphakathi nendawo yalolu shintsho.

Ama-alloys ahamba phambili nezinto zokwakha ezingxenyeni ze-Aluminium Die Casting Car Chasis

I-Aluminium Alloys Ethuthukisiwe ye-EV Chassis

Abakhiqizi bezimoto bathembele kuma-alloys e-aluminium ethuthukisiwe ukuze bakhe izingxenye ze-chassis eziqinile nezingasindi zezimoto zikagesi. Ama-alloys afana ne-ADC1, ADC12, A380, kanye ne-AlSi9Cu3 anikela ngezakhiwo ezinhle kakhulu zokusebenzisa imishini. Lezi zinto ezisetshenziswayo zimelana nokugqwala futhi zinikeza amandla adingekayo ekufuneni izicelo zezimoto. Abakhiqizi abafana ne-HHXT bakhetha lezi zingxubevange ngoba zisiza ukwehlisa isisindo semoto ngenkathi zigcina ukuqina.

Qaphela:Ama-alloys e-aluminium avumela ukubunjwa okuyinkimbinkimbi nezindonga ezincane, ezibalulekile emiklamo yesimanje yemoto kagesi.

Imibandela Yokukhetha Ingxubevange Ezimotweni zikagesi

Onjiniyela bakhetha ama-alloys ngokusekelwe ezintweni ezimbalwa ezibalulekile:

- Amandla:Okubalulekile kufanele kuphathe ingcindezi nomthelela ngesikhathi sokushayela.

- Ukumelana nokugqwala:I-chassis idinga ukuhlala ezimweni zezulu ezahlukene.

- Ukusebenziseka:I-alloy kufanele ivumeleukusika nokubumba okunembile.

- I-Thermal conductivity:Ukudlulisa ukushisa okuhle kusiza ngokupholisa ibhethri nemoto.

Ithebula elingezansi libonisa imibandela ebalulekile yokukhetha ingxubevange:

| Imibandela | Ukubaluleka kwama-EVs |

|---|---|

| Amandla | Ukuphepha nokuqina |

| Ukumelana Nokugqwala | Impilo ende |

| Ukusebenziseka kalula | Ukukhiqizwa okunembile |

| I-Thermal Conductivity | Ukupholisa okuphumelelayo |

Okusungulwe Kwezinto Ezibalulekile Zamandla Nokuqina

Isayensi yezinto ezibonakalayo iyaqhubeka nokuthuthuka. Ama-alloys amasha e-aluminium manje anikeza amandla aphezulu nokusebenza okungcono. Abakhiqizi basebenzisa i-micro-alloying kanye namasu okulingisa athuthukisiwe ukuze benze izingxenye ezihlala isikhathi eside. Lezi zinto ezintsha zisiza izingxenye ze-Aluminium die casting chasis ukuhlangabezana nezindinganiso eziqinile zokuphepha nekhwalithi. Ngenxa yalokho, izimoto zikagesi ziba ziphephile futhi zithembeke kakhulu kubashayeli.

Amathrendi Okukhiqiza Nokwenza Ngokwezifiso

Ukukhiqiza Okulula kanye Nokulawulwa Kwekhwalithi

Abakhiqizi manje basebenzisa ubuchwepheshe obuthuthukisiwe ukwenza ukukhiqiza kusheshe futhi kuthembeke kakhulu. Imishini ezenzakalelayo iphatha izinyathelo eziningi, njengeukufa kokusakaza, CNC machining, kanye nokuhlolwa. Lokhu kunciphisa amaphutha futhi kugcina yonke ingxenye ingashintshi. Izinkampani ezifana ne-HHXT zisebenzisa amasistimu okuhlola edijithali ukuhlola ingxenye ngayinye ye-chassis ezigabeni ezihlukene. Balandela imithetho eqinile yekhwalithi futhi basebenzise izitifiketi ezifana ne-ISO9001:2008 ne-IATF16949. Lezi zinyathelo zisiza ukuletha izingxenye ezihlangabezana nezindinganiso eziphakeme ngaso sonke isikhathi.

Ithiphu:Ikhwalithi ezenzakalelayo ihlola izinkinga zokubamba kusenesikhathi. Lokhu konga isikhathi nemali kubo bobabili abakhiqizi namakhasimende.

Ukuguquguquka Kwedizayini kanye Nezixazululo Zezifiso

Abakhiqizi bezimoto bafuna izingxenye ezilingana nemiklamo yabo ehlukile. I-die casting yesimanje isekela umumo nosayizi wangokwezifiso. Onjiniyela bangasebenzisa imidwebo engu-2D noma ye-3D ukuze bakhe isikhunta esisha ngokushesha.I-HHXT inikeza i-OEMkanye nezinsizakalo ze-ODM, okusho ukuthi zingenza izingxenye ngokusekelwe kumasampuli noma imidwebo yamakhasimende. Izikhungo zabo zemishini ye-CNC zivumela izinguquko eziqondile, ngisho namaqoqo amancane. Lokhu kuvumelana nezimo kusiza abenzi bezimoto baqalise amamodeli amasha ngokushesha.

Izinketho eziyinhloko zokwenza ngokwezifiso:

- Ubukhulu ngokwezifiso kanye nomumo

- Ukukhetha ama-alloys e-aluminium

- Amaphoyinti okukhweza akhethekile noma izici

Ukwelapha Okuphezulu Nezinketho Zokuqeda

Ukwelapha okungaphezulu kuvikela izingxenye ze-chassis futhi kuzenze zibukeke kangcono. I-HHXT inikezela ngezinketho eziningi zokuqeda, njengokuqhunyiswa kwesibhamu, ukuqhunyiswa kwesihlabathi, ukumbozwa kwempushana, ukupenda, nokugcotshwa kwe-anodizing. Lezi zindlela zokwelapha zithuthukisa ukumelana nokugqwala nokuqina. Amakhasimende angaphinda akhethe imibala efana nesiliva emhlophe, emnyama, noma imithunzi yangokwezifiso.

| Ukwelashwa Okungaphezulu | Zuza |

|---|---|

| I-Powder Coating | Eqinile, ngisho nokuqeda |

| I-anodizing | Ukuvikela ukugqwala okwengeziwe |

| Ukupholisha | Indawo ebushelelezi, ecwebezelayo |

Ukuqeda okuhle kusiza izingxenye ukuthi zihlale isikhathi eside futhi zenze kangcono ezimeni ezinzima.

Izindleko, Ukusimama, kanye Nomphumela Wangempela Womhlaba

Izindleko Zokukhiqiza Eziphansi kanye Nempumelelo

Abakhiqizi bezimoto babona ukonga kwezindleko okubalulekile ngokusakazwa kwefa okuthuthukisiwe. Izinqubo zokucindezela okuphezulu zinciphisa inani lezingxenye ezidingekayo ku-chassis ngayinye. Izingxenye ezimbalwa zisho isikhathi esincane sokuhlanganisa kanye nezindleko eziphansi zabasebenzi. Amasistimu azenzakalelayo asiza amafekthri ukuthi akhiqize amayunithi amaningi ngesikhathi esincane. Izinkampani ezifana ne-HHXT zisebenzisa ukuhlola kwedijithali kanye nemishini ye-CNC ukuze zigcine imfucuza iphansi nekhwalithi iphezulu. Lezi zinyathelo zisiza abakhiqizi ukunikeza amanani ancintisanayo weIzingxenye ze-Aluminium die cast chasis yemoto.

Ithiphu:Ukukhiqiza okuhlelekile kusiza abenzi bezimoto ukuthi baphendule ngokushesha ezinguqukweni zemakethe nezidingo zamakhasimende.

Izinzuzo Zemvelo kanye Nezinhlelo Zokugaywa kabusha

I-die casting yesimanje isekela imigomo yokusimama. I-Aluminium igaywa kabusha kakhulu. Izimboni ziqoqa futhi zisebenzise kabusha izinsimbi ezilahliwe kusukela kunqubo yokukhiqiza. Lokhu kunciphisa isidingo sezinto ezintsha zokusetshenziswa. Abakhiqizi abaningi basebenzisa ukwelashwa kwendawo eco-friendly ukuze behlise umthelela wabo kwezemvelo. Izinyathelo zokugaywa kabusha zisiza ukugcina imfucuza ezindaweni zokulahla futhi yonge amandla.

Ukubheka ngokushesha izinzuzo zemvelo:

| Zuza | Umthelela |

|---|---|

| Izinto ezingasetshenziswa kabusha | Imfucuza encane |

| Izinyathelo ezonga amandla | I-low carbon footprint |

| Ukuqedwa kwe-Eco-friendly | Ukukhiqizwa kokuhlanza |

Ukuthuthukiswa Kokusebenza Kubakhiqizi Bezimoto Abahamba Phambili

Abakhiqizi bezimoto abahamba phambili basebenzisa i-die casting ethuthukisiwe ukuthuthukisa ukusebenza kwemoto. Izingxenye ze-chassis eziqinile nezilula zisiza izimoto zikagesi ukuthi zisheshise futhi zihambe ziye kude ngeshaji eyodwa. Izici zokupholisa ezakhelwe ngaphakathi zigcina amabhethri namamotho kumazinga okushisa aphephile. Izinkampani ezifana ne-HHXT ziletha izingxenye ezinembayo ezihlangabezana namazinga aqinile embonini. Lokhu kuthuthukiswa kusiza izimoto zikagesi zithole izilinganiso zokuphepha eziphezulu kanye nokwethenjwa kwamakhasimende.

Izibonelo Zemboni Ezingxenyeni Ze-Aluminium Die Casting Chasis Yemoto

Indlela kaTesla's Giga Casting

I-Tesla ihola imboni ngobuchwepheshe bayo be-Giga Casting. Le nkampani isebenzisa imishini emikhulu yokuphonsa ukuze yakhe izingxenye ezinkulu ze-chassis yemoto ngesiqeshana esisodwa. Le nqubo inciphisa inani lezingxenye kanye nama-welds. Onjiniyela bakwaTesla baklama lezi zithombe ukuze bathuthukise amandla nesisindo semoto esiphansi. I-Giga Press ivumela uTesla ukuthi asheshise ukukhiqiza futhi anciphise izindleko. Abakhiqizi bezimoto abaningi manje sebefunda izindlela zikaTesla zokuthuthukisa ukukhiqiza kwabo.

I-Giga Casting kaTesla isetha indinganiso entsha yokusebenza kahle kanye nokuqanjwa okusha ekukhiqizeni izimoto zikagesi.

Okuqanjwe kabusha okuvela ku-HHXT Nakwabanye Abakhiqizi

I-HHXT igqama njengomhlinzeki othembekileizingxenye ze-Aluminium die cast chasis car. Inkampani isebenzisa i-high-pressure die casting kanye nemishini ye-CNC. Inqubo yabo iqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziqinile zekhwalithi. I-HHXT inikeza izixazululo zangokwezifiso zamamodeli ezimoto zikagesi ezihlukene. Abanye abakhiqizi baphinde batshale imali ekuzithengeleni nasekuhloleni idijithali. Lezi zinyathelo zisiza ukuletha izingxenye ze-chassis ezinembile nezithembekile zemakethe ekhulayo yezimoto zikagesi.

- I-HHXT isebenzisa ama-alloy e-aluminium e-premium ukuze ibe namandla nokuqina.

- Inkampani ihlinzeka ngemithi ehlukahlukene engaphezulu ukuze ivikeleke kangcono.

- Amakhasimende angacela ubukhulu ngokwezifiso nezici.

Ikusasa Outlook for Electric Vehicle Chassis

Ikusasa le-chassis yemoto kagesi libukeka lithembisa. Abakhiqizi bezimoto bazoqhubeka nokusebenzisa izindlela ezithuthukisiwe zokulingisa. Izinto ezintsha namathuluzi edijithali azosiza ekudaleni izingxenye ze-chassis ezilula neziqinile. Ochwepheshe bemboni balindele ukulingisa kwesiqephu esisodwa nezici zokupholisa ezididiyelwe. Lawa mathrendi azosekela izimoto zikagesi eziphephile, ezisebenza kahle kakhulu futhi ezithengekayo.

Isizukulwane esilandelayo sezimoto zikagesi sizozuza emisha eqhubekayo kubuchwepheshe be-die casting.

I-die casting ethuthukisiwe ibumba ikusasa lezimoto zikagesi. Abakhiqizi manje bakha izingxenye ze-chasis yemoto ezilula, eziqinile ze-Aluminium die casting. Lezi zindlela ezintsha zisiza abenzi bezimoto behlise izindleko futhi bathuthukise ukusimama. Imboni iqhubekela phambili ekukhiqizeni i-chassis ephumelelayo, esebenza kahle kakhulu. Izimoto zikagesi ziyazuza kulokhu kuthuthukiswa nsuku zonke.

FAQ

Yini eyenza i-aluminium die casting ilungele izingxenye ze-chassis yemoto kagesi?

I-aluminium die castingidala izingxenye ezingasindi, eziqinile, nezinembayo. Lezi zimfanelo zisiza izimoto zikagesi ukuba zithole ukusebenza kahle, ukuphepha, nokusebenza okungcono.

I-HHXT iqinisekisa kanjani ikhwalithi ezingxenyeni zayo ze-die cast chassis?

I-HHXT isebenzisa imishini ye-CNC ethuthukisiwe, ukuhlolwa okuqinile, nezinqubo eziqinisekisiwe. Ingxenye ngayinye ihlangabezana nezindinganiso eziphakeme zamandla, ukunemba, nokuqina.

Ingabe abakhiqizi bangakwazi ukwenza ngokwezifiso izingxenye ze-chassis ye-aluminium die cast kumamodeli athile e-EV?

Yebo. Abakhiqizi bathanda umnikelo we-HHXTIzinsizakalo ze-OEM ne-ODM. Bakha ubujamo obungokwezifiso, osayizi, kanye nokuqedwa ukuze kufaniswe nezidingo ezihlukile zemoto kagesi.

Isikhathi sokuthumela: Jul-04-2025