Ii-automakers ngoku zisebenzisa i-advancedI-Aluminiyam yokuphosa ukufaukuvelisa ukukhanya kunye namandlaI-Aluminiyam yokufa iphosa iinxalenye ze-chasis yemotokwizithuthi zombane. Ezi ndlela ziphucula ukusebenza kunye nokhuseleko. Abavelisi bazuza ngaphantsiIxabiso lokuphosa iAluminiyamkunye nokuzinza okungcono. Ishishini libona ukuyila okudibeneyo, ukunceda iimoto zombane zisebenze ngakumbi kwaye zithembeke.

Izinto eziphambili zokuThatha

- Advanced die castingyenza izinto ezikhaphukhaphu, ezomeleleyo ze-chassis yemoto yombane eziphucula ukhuseleko, ukusebenza kunye nokusebenza kakuhle.

- Iindlela ezintsha ezifana noxinzelelo oluphezulu, i-mega, kunye ne-giga casting zinciphisa iinxalenye kunye nexesha lokuhlanganisa, ukunciphisa iindleko kunye nokunyusa isantya sokuvelisa.

- Ukuzenzekelayo, izixhobo zedijithali, kunyeialloys eziphambiliqinisekisa umgangatho ophezulu, ukwenza ngokwezifiso, kunye nolawulo olungcono lwe-thermal kwiimoto zombane ezihlala ixesha elide.

Ukuphumelela kwiAluminiyam Die Casting Car Chasis Parts Technology

Uxinzelelo oluphezulu Die Casting for EV Chassis

Ukuphoswa koxinzelelo oluphezulu kuye kwaba yinto etshintshayo kwimveliso ye-chassis yesithuthi sombane. Le nkqubo ifaka i-aluminiyam etyhidiweyo kwizibungu zentsimbi ngesantya esiphezulu kunye noxinzelelo. Isiphumo sixinene, inxalenye eyomeleleyo enemilinganiselo echanekileyo. Abavelisi basebenzisa le ndlela ukwenza iimilo ezintsonkothileyo iindlela zemveli ezingenakufikelela kuzo. High-uxinzelelo die casting kwakhona kunciphisa imfuno welding kunye nendibano. Oku kukhokelela kumanqaku ambalwa abuthathaka kwi-chassis kwaye kuphuculwe ukhuseleko.

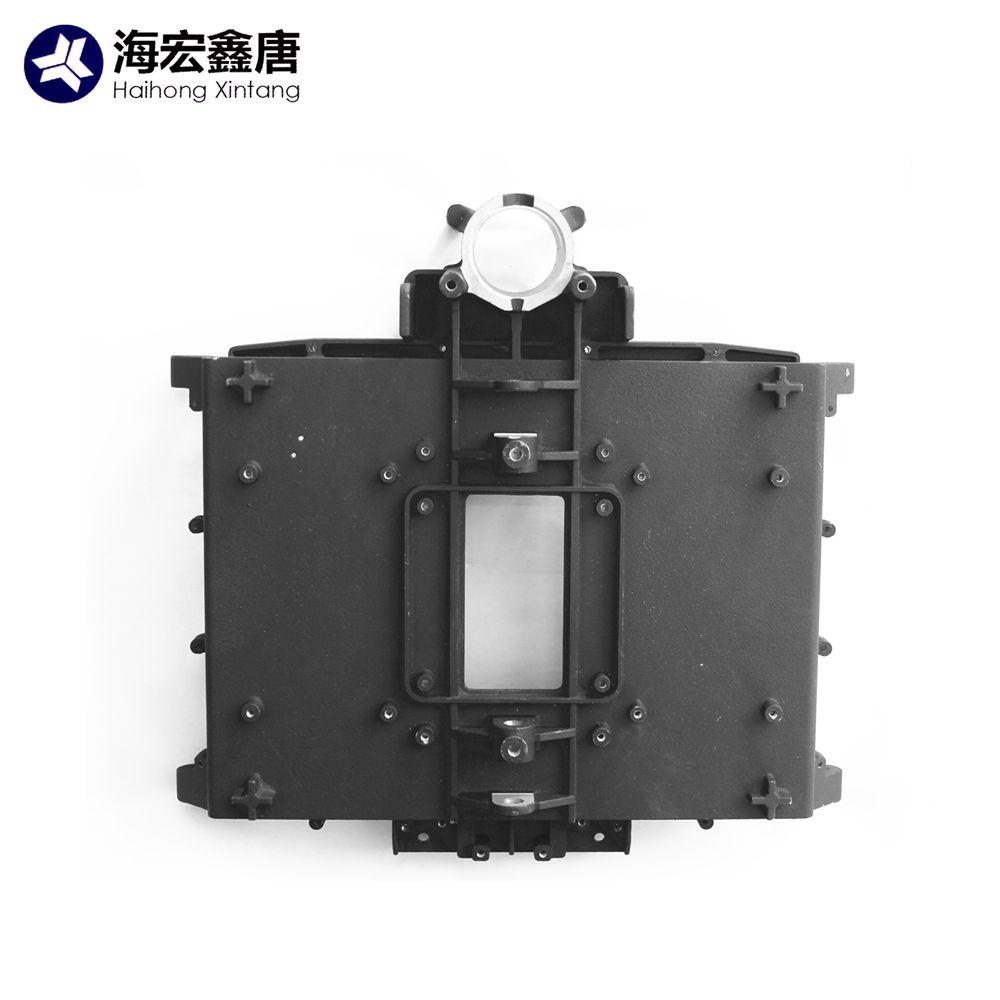

I-HHXT isebenzisa i-high-high-pressure die casting ukuvelisa iinxalenye ze-Aluminiyam yokufa yokuphosa imoto. Inkqubo yabo iqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho engqongqo yomgangatho. Ukusetyenziswa kwe-premium aluminium alloys, njenge-ADC12 kunye ne-A380, inika amalungu amandla abalaseleyo kunye nokumelana nokubola. Ezi mpawu ziyimfuneko kwizithuthi zombane, ezifuna zombini izinto ezilula kunye nezizinzileyo.

Phawula:Ukuphoswa koxinzelelo oluphezulu kuvumela imijikelo yemveliso ekhawulezileyo. Oku kunceda ii-automakers ukuhlangabezana nemfuno ekhulayo yeemoto zombane ngaphandle kokuncama umgangatho.

I-Mega kunye ne-Giga Casting kwiiThuthi zoMbane

I-Mega casting kunye ne-giga casting imele inyathelo elilandelayo kwitekhnoloji yokuphosa. Ezi ndlela zisebenzisa oomatshini abakhulu ukuvelisa izinto ezinkulu kakhulu, isiqwenga esinye se-chassis. UTesla unguvulindlela ngale ndlela kunye neGiga Press, kunye nabanye abavelisi ngoku balandela. Ngokuphosa amacandelo amakhulu e-chassis kwisiqwenga esinye, ii-automakers zinciphisa inani lamalungu kunye namalungu. Oku kwenza i-chassis ibe khaphukhaphu kwaye yomelele.

I-Mega kunye ne-giga casting kwakhona kulungelelanisa inkqubo yokuvelisa. Amalungu ambalwa athetha ixesha elincinci lokuhlanganisa kunye neendleko eziphantsi. Inkqubo ixhasa ukuveliswa kweAluminiyam yokufa yokuphosa iinxalenye ze-chasis zemoto zombini ezomeleleyo kwaye zikhaphukhaphu. Olu lutsha lunceda izithuthi zombane zifezekise uluhlu olungcono kunye nokusebenza.

Uthelekiso lwemveli vs. giga casting:

| Uphawu | Ukuphosa kweNdabuko | Giga Casting |

|---|---|---|

| Inani lezahlulo | Abaninzi | Bambalwa (kaninzi ibe nye) |

| Ixesha leNdibano | Inde | Mfutshane |

| Ukomelela Kwesakhiwo | Phakathi | Phezulu |

| Ubunzima | Phezulu | Ngasezantsi |

Ukuzenzekela kunye neDigitalization kwiDie Casting

I-automation kunye nedijithali ngoku idlala indima ephambili kumdlalo wokufa wangoku. Iifektri zisebenzisa iirobhothi kunye noomatshini abakrelekrele ukuphatha imisebenzi efana nokuzaliswa komngundo, ukupholisa, kunye nokususwa kwenxalenye. Oku kunciphisa impazamo yomntu kwaye kwandisa ukuhambelana. Izixhobo zedijithali zibeke iliso kwinyathelo ngalinye lenkqubo. Iinzwa ziqokelela idatha malunga nobushushu, uxinzelelo, kunye namaxesha okujikeleza. Iinjineli zisebenzisa le datha ukuphucula umgangatho kunye nokusebenza kakuhle.

I-HHXT ityale imali kuyoamaziko Machining CNC eziphambilikunye neenkqubo zokuhlola idijithali. Ezi teknoloji ziqinisekisa ukuba yonke i-Aluminiyam yokufa yokuphosa i-chasis yemoto idibana neenkcukacha ezichanekileyo. Ukuzenzekelayo kwakhona kuvumela utshintsho olukhawulezayo kuyilo. Abavelisi banokuphendula ngokukhawuleza kwiindlela ezintsha kunye neemfuno zabathengi.

Ingcebiso:I-digitalization inceda ukuchonga iingxaki kwangethuba. Oku kukhokelela kwiziphene ezimbalwa kunye nokwaneliseka okuphezulu kwabathengi.

Uyilo kunye neNzuzo zokuSebenza kwiZithuthi zoMbane

I-One-Piece Castings kunye nokuhlanganiswa kwesakhiwo

Abenzi beemoto ngoku basebenzisa isiqwenga esinye ukwenza amacandelo amakhulu e-chassis yesithuthi sombane. Le ndlela idibanisa iindawo ezininzi zibe yinto enye, eyomeleleyo. Iinjineli ziyila ezi castings ukuze zilingane ngokugqibeleleyo nezinye iindawo zemoto. Isiphumo yi-chassis enamalungu ambalwa kunye ne-welds.

I-casting yesiqwenga esinye ibonelela ngeenzuzo ezininzi eziphambili:

- Ukonyuka kwamandla:Amalungu ambalwa athetha iindawo ezibuthathaka ezimbalwa. I-chassis inokusingatha uxinzelelo ngakumbi ngexesha lokuqhuba.

- Ukhuseleko oluphuculweyo:Isakhiwo esiluqilima sikhusela abakhweli ngcono xa kukho ingozi.

- Indibano eyenziwe lula:Abasebenzi bachitha ixesha elincinane behlanganisa iinxalenye. Oku kukhawulezisa imveliso kwaye kunciphisa iimpazamo.

Phawula:Ukudityaniswa kolwakhiwo kuvumela abaqulunqi ukuba bongeze iimpawu ezinje ngeendawo zokukhwela kunye neetshaneli ngokuthe ngqo kwi-casting. Oku kunciphisa imfuno yezibiyeli ezongezelelweyo okanye iziqhoboshi.

UkuNcitshiswa kobunzima kunye nokuzuza ngokuSebenzayo

Izithuthi zombane kufuneka zibe lula kangangoko ukuze zandise uluhlu lwazo. Ukuphosa ukufa okuphambili kunceda ukufezekisa le njongo. I-alloys ye-aluminiyam, njengaleyo isetyenziswa yiHHXT, unikeze amandla aphezulu ngelixa ugcina ubunzima obuphantsi. Iinjineli zinokwenza iindonga ezicekethekileyo nezintsonkothileyo ezingenakukwazi ukuvelisa iindlela zamandulo.

I-chassis elula izisa izinto ezininzi ezintle:

- Uluhlu olude lokuqhuba:Imoto isebenzisa amandla amancinci ukuhamba, ngoko ibhetri ihlala ixesha elide.

- Isantya esingcono:Ubunzima obungaphantsi buthetha ukuba imoto inokukhawuleza ngokukhawuleza.

- Amaxabiso aphantsi amandla:Abaqhubi bachitha imali encinci bebiza izithuthi zabo.

| Inzuzo | Impembelelo kwii-EVs |

|---|---|

| Ubunzima obuphantsi | Uluhlu olwandisiweyo |

| Isakhiwo esomeleleyo | Ukuphuculwa kokhuseleko |

| Amalungu ambalwa | Ukuveliswa ngokukhawuleza |

Abavelisi abafana ne-HHXT basebenzisa ubuchwephesha be-CNC obuchanekileyo ukugcina iindawo zichanekile kwaye banciphise inkunkuma. Le nkqubo iqinisekisa ukuba yonke inxalenye ye-chassis ihlangabezana nemigangatho engqongqo yobunzima kunye nokulinganisela.

Ulawulo lwe-Thermal olongezelelweyo

Izithuthi zombane zivelisa ubushushu kwiibhetri kunye neenjini zazo. Ulawulo olufanelekileyo lwe-thermal lugcina ezi ndawo zipholile kwaye zisebenza kakuhle. Ukuphosa ukufa okukwinqanaba eliphezulu kuvumela iinjineli ukuba zakhe amajelo okupholisa kunye neentsini zobushushu ngokuthe ngqo kwiindawo ze-chassis.

Iimpawu eziphambili zolawulo oluphuculweyo lwe-thermal ziquka:

- Iindlela zokupholisa ezakhelwe ngaphakathi:Imijelo engaphakathi kwi-casting inceda ukususa ubushushu kwiindawo ezibuthathaka.

- Ukuthembeka okuphuculweyo:Iibhetri ezipholileyo kunye neenjini zihlala ixesha elide kwaye zisebenza ngcono.

- Ukusebenza okufanayo:Imoto ingaqhuba imigama emide ngaphandle kokutshisa.

Ingcebiso:Ulawulo oludibeneyo lwe-thermal lunciphisa imfuno yeenkqubo zokupholisa ezongezelelweyo. Oku konga indawo kunye nobunzima, okwenza isithuthi sisebenze ngakumbi.

Abenzi be-Automaker ngoku baxhomekeke kolu yilo kunye neenzuzo zokusebenza ukwenza iimoto zombane ezikhuselekileyo, ezikhaphukhaphu, nezithembekileyo. Ukuphosa okukwinqanaba eliphezulu kume embindini wolu tshintsho.

I-alloys ehamba phambili kunye neMathiriyeli kwiAluminiyam Die Casting Car Chasis Parts

Advanced Aluminiyam Alloys for EV Chassis

Abavelisi be-automaker baxhomekeke kwi-alloys ye-aluminiyam ephezulu ukwenza iindawo ezomeleleyo nezikhaphukhaphu ze-chassis kwizithuthi zombane. I-alloys ezifana ne-ADC1, i-ADC12, i-A380, kunye ne-AlSi9Cu3 zibonelela ngeempawu ezibalaseleyo zoomatshini. Ezi zixhobo zixhathisa ukubola kwaye zinika amandla afunekayo ekufuneni izicelo zemoto. Abavelisi abafana ne-HHXT bakhetha ezi alloys kuba zinceda ukunciphisa ubunzima besithuthi ngelixa zigcina ukuqina.

Phawula:I-aluminium alloys ivumela iimilo eziyinkimbinkimbi kunye neendonga ezincinci, ezibalulekileyo kuyilo lwezithuthi zombane zanamhlanje.

Iikhrayitheriya zokuKhetha i-alloy kwiZithuthi zoMbane

Iinjineli zikhetha i-alloys ngokusekelwe kwizinto ezininzi ezibalulekileyo:

- Amandla:Izinto eziphathekayo kufuneka zijongane noxinzelelo kunye nefuthe ngexesha lokuqhuba.

- Ukuchasa umhlwa:I-chassis kufuneka ihlale kwiimeko ezahlukeneyo zemozulu.

- Ubuchule:I-alloy kufuneka ivumelekeukusika kunye nokubunjwa okuchanekileyo.

- I-Thermal conductivity:Ukugqithiswa kakuhle kobushushu kunceda ngebhetri kunye nokupholisa imoto.

Itheyibhile engezantsi ibonisa iindlela eziphambili zokukhetha i-alloy:

| Iikhrayitheriya | Ukubaluleka kwee-EVs |

|---|---|

| Amandla | Ukhuseleko kunye nokuqina |

| Ukunyangwa kokuMhlwa | Ubomi obude |

| Ubuchule | Imveliso echanekileyo |

| I-Thermal Conductivity | Ukupholisa okusebenzayo |

Izinto ezintsha ezintsha zokomelela kunye nokuzinza

Inzululwazi yezinto eziphathekayo iyaqhubeka ihambela phambili. Iialloyi ezintsha ze-aluminium ngoku zinika amandla aphezulu kunye nokusebenza okungcono. Abavelisi basebenzisa i-micro-alloying kunye neendlela zokuphosa eziphuculweyo ukwenza iindawo ezihlala ixesha elide. Olu tshintsho lunceda iAluminiyam yokufa yokuphosa iinxalenye ze-chasis yemoto ukuhlangabezana nokhuseleko olungqongqo kunye nemigangatho yomgangatho. Ngenxa yoko, izithuthi zombane ziba zikhuselekile kwaye zithembeke ngakumbi kubaqhubi.

Uveliso kunye neeNdlela zokuLungisa

IMveliso eLungelweyo kunye noLawulo loMgangatho

Abavelisi ngoku basebenzisa itekhnoloji ephezulu ukwenza imveliso ikhawuleze kwaye ithembeke ngakumbi. Oomatshini abazenzekelayo baphatha amanyathelo amaninzi, njengayeukuphosa ukufa, CNC machining, kunye nokuhlolwa. Oku kunciphisa iimpazamo kwaye kugcina yonke inxalenye ihambelana. Iinkampani ezifana ne-HHXT zisebenzisa iinkqubo zokuhlola idijithali ukujonga indawo nganye ye-chassis kumanqanaba ahlukeneyo. Balandela imithetho engqongqo esemgangathweni kwaye basebenzise izatifikethi ezifana ne-ISO9001: 2008 kunye ne-IATF16949. La manyathelo anceda ukuhambisa iindawo ezihlangabezana nemigangatho ephezulu ngalo lonke ixesha.

Ingcebiso:Umgangatho ozenzekelayo ujonga iingxaki zokubamba kwangoko. Oku konga ixesha kunye nemali kubo bobabini abavelisi kunye nabathengi.

Uyilo lokuguquguquka kunye nezisombululo zesiko

Abavelisi beemoto bafuna iindawo ezihambelana noyilo lwabo olulodwa. Ukuphoswa kwedie yanamhlanje kuxhasa iimilo kunye nobukhulu besiko. Iinjineli zinokusebenzisa i-2D okanye imizobo ye-3D ukwenza iimolds ezintsha ngokukhawuleza.I-HHXT ibonelela nge-OEMkunye neenkonzo ze-ODM, oku kuthetha ukuba banokwenza iinxalenye ezisekelwe kwiisampuli zabathengi okanye imizobo. Amaziko abo omatshini e-CNC avumela utshintsho oluchanekileyo, nakwiibhetshi ezincinci. Oku bhetyebhetye kunceda abenzi beemoto baqalise iimodeli ezintsha ngokukhawuleza.

Iinketho eziphambili zokwenza ngokwezifiso:

- Imilinganiselo emiselweyo kunye neemilo

- Ukukhethwa kwee-alloys ze-aluminium

- Iindawo ezikhethekileyo zokuxhoma okanye iimpawu

Unyango loMphezulu kunye noKhetho lokuQeda

Unyango oluphezulu lukhusela iindawo ze-chassis kwaye zibenze zibukeke ngcono. I-HHXT ibonelela ngeendlela ezininzi zokugqiba, ezinje ngokudubula, ukuqhushumba kwesanti, ukugquma umgubo, ukupeyinta, kunye ne-anodizing. Olu nyango luphucula ukuxhathisa umhlwa kunye nokuqina. Abathengi banokukhetha imibala efana nesilivere emhlophe, emnyama, okanye imithunzi yesiko.

| Unyango loMphezulu | Inzuzo |

|---|---|

| Powder Coating | Yomelele, ide igqibe |

| Anodizing | Ukhuseleko olongezelelweyo lomhlwa |

| Ukugudisa | Umphezulu ogudileyo, umenyezelayo |

Ukugqiba okulungileyo kunceda ukuba iindawo zihlale ixesha elide kwaye zisebenze ngcono kwiimeko ezinzima.

Iindleko, uZinzo, kunye neMpembelelo yeHlabathi yokwenyani

Iindleko zeMveliso ePhantsi kunye nokusebenza ngokuSebenzayo

Abavelisi beemoto babona ugcino lweendleko ezibalulekileyo ngokusasaza okuphambili. Iinkqubo zoxinzelelo oluphezulu zinciphisa inani lamalungu afunekayo kwi-chassis nganye. Amalungu ambalwa athetha ixesha elincinci lokuhlanganisa kunye neendleko eziphantsi zabasebenzi. Iinkqubo ezizenzekelayo zinceda iifektri zivelise iiyunithi ezininzi ngexesha elincinci. Iinkampani ezifana ne-HHXT zisebenzisa ukuhlolwa kwedijithali kunye nomatshini we-CNC ukugcina inkunkuma iphantsi kunye nomgangatho ophezulu. La manyathelo anceda abavelisi babonelele ngamaxabiso akhuphisanayoI-Aluminiyam yokufa iphosa iinxalenye ze-chasis yemoto.

Ingcebiso:Imveliso ephuculweyo inceda abenzi beemoto baphendule ngokukhawuleza kwiinguqu zemarike kunye neemfuno zabathengi.

Okuzuzwayo kokusiNgqongileyo kunye namaNyathelo oKurisayikilisha

Ukuphoswa kweefa kwanamhlanje kuxhasa iinjongo zozinzo. I-Aluminiyam inokuphinda isetyenziswe. Iifektri ziqokelela kwaye ziphinde zisebenzise isinyithi esilahliweyo kwinkqubo yokuvelisa. Oku kunciphisa isidingo semathiriyeli entsha ekrwada. Abavelisi abaninzi basebenzisa unyango lwe-eco-friendly surface ukuthoba ifuthe labo lokusingqongileyo. Amanyathelo okuhlaziya anceda ukugcina inkunkuma kwindawo yokulahla inkunkuma kwaye onge amandla.

Ujongo olukhawulezileyo kwiinzuzo zokusingqongileyo:

| Inzuzo | Impembelelo |

|---|---|

| Izinto ezinokuphinda zisetyenziswe | Inkcitho encinci |

| Amanyathelo awonga amandla | Unyawo lwekhabhoni esezantsi |

| Eco-friendly finishes | Imveliso yokucoca |

Uphuculo lokuSebenza kuBanzi abaKhokelayo

Ii-automakers eziphambili zisebenzisa i-die casting ephezulu ukuphucula ukusebenza kwesithuthi. Amalungu e-chassis eyomelele kwaye ekhaphukhaphu anceda iimoto zombane ukuba zikhawuleze kwaye zihambe umgama omde ngentlawulo enye. Iimpawu zokupholisa ezakhelwe ngaphakathi zigcina iibhetri kunye neenjini kumaqondo obushushu akhuselekileyo. Iinkampani ezifana ne-HHXT zihambisa iindawo ezichanekileyo ezihlangabezana nemigangatho engqongqo yoshishino. Olu phuculo lunceda izithuthi zombane ukuba zifumane amanqaku aphezulu okhuseleko kunye nokuthembela kwabathengi.

Imizekelo yoShishino kwiAluminiyam Die Casting Car Chasis Parts

Indlela kaTesla yeGiga Casting

UTesla ukhokela ishishini ngetekhnoloji yeGiga Casting. Inkampani isebenzisa oomatshini abakhulu bokuphosa ukwenza amacandelo amakhulu e-chassis yemoto kwisiqwenga esinye. Le nkqubo inciphisa inani leenxalenye kunye ne-welds. Iinjineli kwaTesla ziyila ezi zixhobo ukuphucula amandla kunye nobunzima besithuthi esisezantsi. I-Giga Press ivumela iTesla ukuba ikhawuleze imveliso kunye nokunciphisa iindleko. Uninzi lwee-automakers ngoku lufunda iindlela zikaTesla zokuphucula ukwenziwa kwazo.

I-Giga Casting kaTesla ibeka umgangatho omtsha wokusebenza kakuhle kunye nokutsha kwimveliso yemoto yombane.

Izinto ezintsha ezivela kwi-HHXT kunye nabanye abavelisi

I-HHXT ibalasele njengomthengisi othembekileyoyeAluminiyam kufa ukuphosa iindawo chasis imoto. Inkampani isebenzisa i-high-pressure die casting kunye nomatshini we-CNC. Inkqubo yabo iqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho engqongqo yomgangatho. I-HHXT inikezela ngezisombululo zesiko kwiimodeli ezahlukeneyo zezithuthi zombane. Abanye abavelisi batyala imali kwi-automation kunye nokuhlolwa kwedijithali. La manyathelo anceda ukuhambisa iindawo ezichanekileyo nezithembekileyo ze-chassis kwimakethi ekhulayo yemoto yombane.

- I-HHXT isebenzisa iialloyi ze-aluminiyam zeprimiyamu ukomelela kunye nokuqina.

- Inkampani ibonelela ngoluhlu lwezonyango ezingaphezulu zokhuseleko olungcono.

- Abathengi banokucela imilinganiselo yesiko kunye neempawu.

Ikamva leChassis yesiThuthi soMbane

Ikamva le-chassis yesithuthi sombane libukeka lithembisa. Abavelisi bee-Automakers baya kuqhubeka besebenzisa iindlela eziphambili zokufa. Izixhobo ezitsha kunye nezixhobo zedijithali ziya kunceda ekudaleni iindawo ze-chassis ezikhaphukhaphu nezinamandla. Iingcali zemizi-mveliso zilindele ukuphoswa kwesiqwenga esinye kunye neempawu zokupholisa ezidibeneyo. Ezi ndlela ziza kuxhasa iimoto zombane ezikhuselekileyo, ezisebenza kakuhle, nezifikelelekayo.

Isizukulwana esilandelayo seemoto zombane siya kuxhamla kwizinto ezintsha eziqhubekayo kwi-die casting technology.

Advanced die casting iimilo ikamva izithuthi zombane. Abavelisi ngoku benza iAluminiyam ekhaphukhaphu, eyomeleleyo yokuphosa iinxalenye ze-chasis yemoto. Olu lutsha lunceda abenzi beemoto banciphise iindleko kunye nokuphucula ukuzinza. Ishishini liqhubela phambili ekuveliseni i-chassis esebenzayo, esebenza kakhulu. Izithuthi zombane ziyaxhamla kwezi nkqubela phambili yonke imihla.

FAQ

Yintoni eyenza i-aluminiyam yokufa ilungile kwiindawo ze-chassis yesithuthi sombane?

I-Aluminiyam yokuphosa ukufayenza iindawo ezikhaphukhaphu, ezomeleleyo, nezichanekileyo. Ezi mpawu zinceda izithuthi zombane ukuba zifezekise ukusebenza kakuhle, ukhuseleko, kunye nokusebenza.

I-HHXT iqinisekisa njani umgangatho kwiindawo zayo ze-chassis ezifayo?

I-HHXT isebenzisa umatshini we-CNC ophezulu, uhlolo olungqongqo, kunye neenkqubo eziqinisekisiweyo. Ilungu ngalinye lihlangabezana nemigangatho ephezulu yokomelela, ukuchaneka, kunye nokuqina.

Ngaba abavelisi banokwenza ngokwezifiso iinxalenye ze-aluminiyam yokufa ye-chassis kwiimodeli ezithile ze-EV?

Ewe. Abavelisi abafana nonikezelo lwe-HHXTIinkonzo ze-OEM kunye ne-ODM. Benza iimilo eziqhelekileyo, ubungakanani, kunye nokugqiba ukuhambelana neemfuno ezizodwa zesithuthi sombane.

Ixesha lokuposa: Jul-04-2025