Automakers now use advanced Aluminium die casting to produce lighter and stronger Aluminium die casting car chasis parts for electric vehicles. These techniques improve performance and safety. Manufacturers achieve lower Aluminium die casting price and better sustainability. The industry sees more integrated designs, helping electric cars become more efficient and reliable.

Key Takeaways

- Advanced die casting creates lighter, stronger electric car chassis parts that improve safety, performance, and efficiency.

- New methods like high-pressure, mega, and giga casting reduce parts and assembly time, lowering costs and boosting production speed.

- Automation, digital tools, and advanced alloys ensure high quality, customization, and better thermal management for longer-lasting electric vehicles.

Breakthroughs in Aluminium Die Casting Car Chasis Parts Technology

High-Pressure Die Casting for EV Chassis

High-pressure die casting has become a game-changer for electric vehicle chassis production. This process injects molten aluminum into steel molds at very high speeds and pressures. The result is a dense, strong part with precise dimensions. Manufacturers use this method to create complex shapes that traditional methods cannot achieve. High-pressure die casting also reduces the need for welding and assembly. This leads to fewer weak points in the chassis and improves safety.

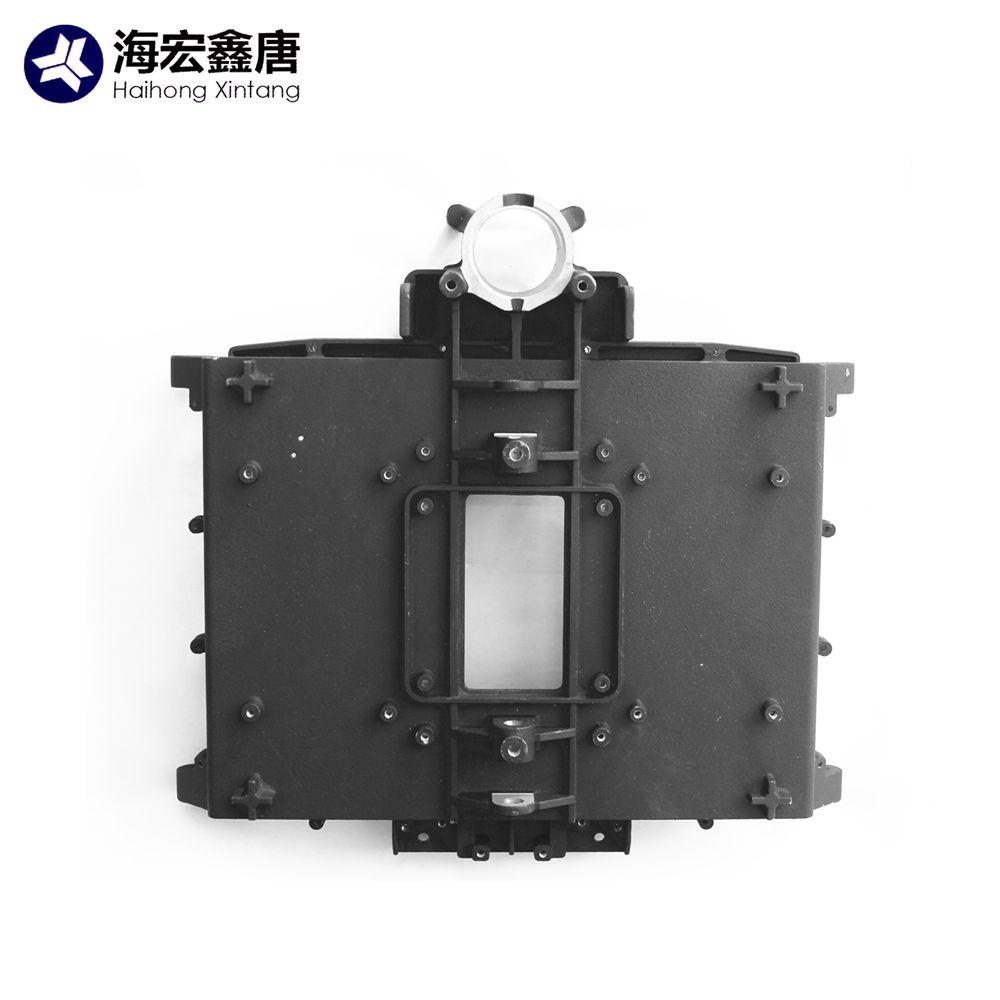

HHXT uses advanced high-pressure die casting to produce Aluminium die casting car chasis parts. Their process ensures each part meets strict quality standards. The use of premium aluminum alloys, such as ADC12 and A380, gives the parts excellent strength and corrosion resistance. These features are essential for electric vehicles, which require both lightweight and durable components.

Note: High-pressure die casting allows for rapid production cycles. This helps automakers meet growing demand for electric vehicles without sacrificing quality.

Mega and Giga Casting in Electric Vehicles

Mega casting and giga casting represent the next step in die casting technology. These methods use massive machines to produce very large, single-piece chassis components. Tesla pioneered this approach with its Giga Press, and other manufacturers now follow suit. By casting large sections of the chassis in one piece, automakers reduce the number of parts and joints. This makes the chassis lighter and stronger.

Mega and giga casting also streamline the manufacturing process. Fewer parts mean less assembly time and lower costs. The process supports the production of Aluminium die casting car chasis parts that are both robust and lightweight. This innovation helps electric vehicles achieve better range and performance.

A comparison of traditional vs. giga casting:

| Feature | Traditional Casting | Giga Casting |

|---|---|---|

| Number of Parts | Many | Few (often one) |

| Assembly Time | Long | Short |

| Structural Strength | Moderate | High |

| Weight | Higher | Lower |

Automation and Digitalization in Die Casting

Automation and digitalization now play a key role in modern die casting. Factories use robots and smart machines to handle tasks like mold filling, cooling, and part removal. This reduces human error and increases consistency. Digital tools monitor every step of the process. Sensors collect data on temperature, pressure, and cycle times. Engineers use this data to improve quality and efficiency.

HHXT has invested in advanced CNC machining centers and digital inspection systems. These technologies ensure that every Aluminium die casting car chasis part meets exact specifications. Automation also allows for quick changes in design. Manufacturers can respond faster to new trends and customer needs.

Tip: Digitalization helps identify problems early. This leads to fewer defects and higher customer satisfaction.

Design and Performance Benefits for Electric Vehicles

One-Piece Castings and Structural Integration

Automakers now use one-piece castings to create large sections of the electric vehicle chassis. This method combines multiple parts into a single, strong component. Engineers design these castings to fit perfectly with other parts of the car. The result is a chassis that has fewer joints and welds.

One-piece castings offer several key benefits:

- Increased strength: Fewer joints mean fewer weak spots. The chassis can handle more stress during driving.

- Improved safety: A solid structure protects passengers better in case of a crash.

- Simplified assembly: Workers spend less time putting parts together. This speeds up production and reduces errors.

Note: Structural integration allows designers to add features like mounting points and channels directly into the casting. This reduces the need for extra brackets or fasteners.

Weight Reduction and Efficiency Gains

Electric vehicles need to be as light as possible to maximize their range. Advanced die casting helps achieve this goal. Aluminum alloys, such as those used by HHXT, provide high strength while keeping weight low. Engineers can design thin walls and complex shapes that traditional methods cannot produce.

A lighter chassis brings many advantages:

- Longer driving range: The car uses less energy to move, so the battery lasts longer.

- Better acceleration: Less weight means the car can speed up faster.

- Lower energy costs: Drivers spend less money charging their vehicles.

| Benefit | Impact on EVs |

|---|---|

| Lower weight | Increased range |

| Stronger structure | Improved safety |

| Fewer parts | Faster production |

Manufacturers like HHXT use precise CNC machining to keep parts accurate and minimize waste. This process ensures every chassis part meets strict standards for weight and balance.

Enhanced Thermal Management

Electric vehicles generate heat in their batteries and motors. Proper thermal management keeps these parts cool and working well. Advanced die casting allows engineers to build cooling channels and heat sinks directly into the chassis parts.

Key features of enhanced thermal management include:

- Built-in cooling paths: Channels inside the casting help move heat away from sensitive areas.

- Improved reliability: Cooler batteries and motors last longer and perform better.

- Consistent performance: The car can drive longer distances without overheating.

Tip: Integrated thermal management reduces the need for extra cooling systems. This saves space and weight, making the vehicle even more efficient.

Automakers now rely on these design and performance benefits to create electric vehicles that are safer, lighter, and more reliable. Advanced die casting stands at the center of this transformation.

Leading Alloys and Materials in Aluminium Die Casting Car Chasis Parts

Advanced Aluminum Alloys for EV Chassis

Automakers rely on advanced aluminum alloys to create strong and lightweight chassis parts for electric vehicles. Alloys such as ADC1, ADC12, A380, and AlSi9Cu3 offer excellent mechanical properties. These materials resist corrosion and provide the strength needed for demanding automotive applications. Manufacturers like HHXT select these alloys because they help reduce vehicle weight while maintaining durability.

Note: Aluminum alloys allow for complex shapes and thin walls, which are important for modern electric vehicle designs.

Criteria for Alloy Selection in Electric Vehicles

Engineers choose alloys based on several important factors:

- Strength: The material must handle stress and impact during driving.

- Corrosion resistance: The chassis needs to last in different weather conditions.

- Machinability: The alloy should allow for precise cutting and shaping.

- Thermal conductivity: Good heat transfer helps with battery and motor cooling.

A table below shows key criteria for alloy selection:

| Criteria | Importance for EVs |

|---|---|

| Strength | Safety and durability |

| Corrosion Resistance | Long lifespan |

| Machinability | Accurate production |

| Thermal Conductivity | Efficient cooling |

Material Innovations for Strength and Durability

Material science continues to advance. New aluminum alloys now offer higher strength and better performance. Manufacturers use micro-alloying and improved casting techniques to make parts that last longer. These innovations help Aluminium die casting car chasis parts meet strict safety and quality standards. As a result, electric vehicles become safer and more reliable for drivers.

Manufacturing and Customization Trends

Streamlined Production and Quality Control

Manufacturers now use advanced technology to make production faster and more reliable. Automated machines handle many steps, such as die casting, CNC machining, and inspection. This reduces mistakes and keeps every part consistent. Companies like HHXT use digital inspection systems to check each chassis part at different stages. They follow strict quality rules and use certifications like ISO9001:2008 and IATF16949. These steps help deliver parts that meet high standards every time.

Tip: Automated quality checks catch problems early. This saves time and money for both manufacturers and customers.

Design Flexibility and Custom Solutions

Automakers want parts that fit their unique designs. Modern die casting supports custom shapes and sizes. Engineers can use 2D or 3D drawings to create new molds quickly. HHXT offers OEM and ODM services, which means they can make parts based on customer samples or drawings. Their CNC machining centers allow for precise changes, even for small batches. This flexibility helps car makers launch new models faster.

Key customization options:

- Custom dimensions and shapes

- Choice of aluminum alloys

- Special mounting points or features

Surface Treatments and Finishing Options

Surface treatments protect chassis parts and make them look better. HHXT offers many finishing options, such as shot blasting, sand blasting, powder coating, painting, and anodizing. These treatments improve corrosion resistance and durability. Customers can also choose colors like silver white, black, or custom shades.

| Surface Treatment | Benefit |

|---|---|

| Powder Coating | Strong, even finish |

| Anodizing | Extra corrosion protection |

| Polishing | Smooth, shiny surface |

A good finish helps parts last longer and perform better in tough conditions.

Cost, Sustainability, and Real-World Impact

Lower Production Costs and Efficiency

Automakers see significant cost savings with advanced die casting. High-pressure processes reduce the number of parts needed for each chassis. Fewer parts mean less assembly time and lower labor costs. Automated systems help factories produce more units in less time. Companies like HHXT use digital inspection and CNC machining to keep waste low and quality high. These steps help manufacturers offer competitive prices for Aluminium die casting car chasis parts.

Tip: Streamlined production helps automakers respond quickly to market changes and customer needs.

Environmental Benefits and Recycling Initiatives

Modern die casting supports sustainability goals. Aluminum is highly recyclable. Factories collect and reuse scrap metal from the production process. This reduces the need for new raw materials. Many manufacturers use eco-friendly surface treatments to lower their environmental impact. Recycling initiatives help keep waste out of landfills and save energy.

A quick look at environmental benefits:

| Benefit | Impact |

|---|---|

| Recyclable materials | Less waste |

| Energy-efficient steps | Lower carbon footprint |

| Eco-friendly finishes | Cleaner production |

Performance Improvements in Leading Automakers

Leading automakers use advanced die casting to improve vehicle performance. Stronger and lighter chassis parts help electric cars accelerate faster and travel farther on a single charge. Built-in cooling features keep batteries and motors at safe temperatures. Companies like HHXT deliver precision parts that meet strict industry standards. These improvements help electric vehicles earn higher safety ratings and customer trust.

Industry Examples in Aluminium Die Casting Car Chasis Parts

Tesla’s Giga Casting Approach

Tesla leads the industry with its Giga Casting technology. The company uses massive casting machines to create large sections of the car chassis in one piece. This process reduces the number of parts and welds. Engineers at Tesla design these castings to improve strength and lower vehicle weight. The Giga Press allows Tesla to speed up production and cut costs. Many automakers now study Tesla’s methods to improve their own manufacturing.

Tesla’s Giga Casting sets a new standard for efficiency and innovation in electric vehicle production.

Innovations from HHXT and Other Manufacturers

HHXT stands out as a trusted supplier of Aluminium die casting car chasis parts. The company uses advanced high-pressure die casting and CNC machining. Their process ensures each part meets strict quality standards. HHXT offers custom solutions for different electric vehicle models. Other manufacturers also invest in automation and digital inspection. These steps help deliver precise and reliable chassis parts for the growing electric vehicle market.

- HHXT uses premium aluminum alloys for strength and durability.

- The company provides a range of surface treatments for better protection.

- Customers can request custom dimensions and features.

Future Outlook for Electric Vehicle Chassis

The future of electric vehicle chassis looks promising. Automakers will continue to adopt advanced die casting methods. New materials and digital tools will help create even lighter and stronger chassis parts. Industry experts expect more one-piece castings and integrated cooling features. These trends will support safer, more efficient, and more affordable electric vehicles.

The next generation of electric cars will benefit from ongoing innovation in die casting technology.

Advanced die casting shapes the future of electric vehicles. Manufacturers now create lighter, stronger Aluminium die casting car chasis parts. These innovations help automakers lower costs and improve sustainability. The industry moves toward efficient, high-performance chassis manufacturing. Electric vehicles benefit from these advancements every day.

FAQ

What makes aluminum die casting ideal for electric vehicle chassis parts?

Aluminum die casting creates lightweight, strong, and precise parts. These qualities help electric vehicles achieve better efficiency, safety, and performance.

How does HHXT ensure quality in its die cast chassis parts?

HHXT uses advanced CNC machining, strict inspections, and certified processes. Each part meets high standards for strength, accuracy, and durability.

Can manufacturers customize aluminum die cast chassis parts for specific EV models?

Yes. Manufacturers like HHXT offer OEM and ODM services. They create custom shapes, sizes, and finishes to match unique electric vehicle requirements.

Post time: Jul-04-2025