Baetsi ba li-automaker joale ba sebelisa e tsoetseng peleAluminium die castingho hlahisa bobebe le matlaAluminium die casting car chasis likarolobakeng sa likoloi tsa motlakase. Mekhoa ena e ntlafatsa ts'ebetso le polokeho. Baetsi ba fumana tlaseTheko ea ho lahla Aluminiumle botsitso bo betere. Indasteri e bona meralo e mengata e kopantsoeng, e thusang likoloi tsa motlakase hore li sebetse hantle le tse tšepahalang.

Lintlha tsa bohlokoa

- Ts'ebetso e tsoetseng pele ea lefue theha likarolo tse bobebe, tse matla tsa koloi ea motlakase tse ntlafatsang polokeho, ts'ebetso le katleho.

- Mekhoa e mecha e kang khatello e phahameng, mega, le giga casting e fokotsa likarolo le nako ea kopano, e fokotsa litšenyehelo le ho eketsa lebelo la tlhahiso.

- Automation, lisebelisoa tsa digital, leli-alloys tse tsoetseng pelenetefatsa boleng ba boleng bo holimo, ho itlhophisa, le tsamaiso e ntle ea mocheso bakeng sa likoloi tsa motlakase tse tšoarellang nako e telele.

Katlehohle e Hlahang Aluminium Die Casting Car Chasis Parts Technology

High-Pressure Die Casting bakeng sa EV Chassis

High-press die casting e fetohile phetoho ea papali bakeng sa tlhahiso ea chassis ea koloi ea motlakase. Mokhoa ona o kenya aluminium e qhibilihisitsoeng ka har'a liforomo tsa tšepe ka lebelo le phahameng haholo le likhatello. Sephetho ke karolo e teteaneng, e matla e nang le litekanyo tse nepahetseng. Baetsi ba sebelisa mokhoa ona ho etsa libopeho tse rarahaneng tseo mekhoa ea setso e ke keng ea e finyella. High-pressure die casting e boetse e fokotsa tlhoko ea ho cheselletsa le ho kopanya. Sena se lebisa libakeng tse fokolang tse fokolang ka har'a chassis le ho ntlafatsa polokeho.

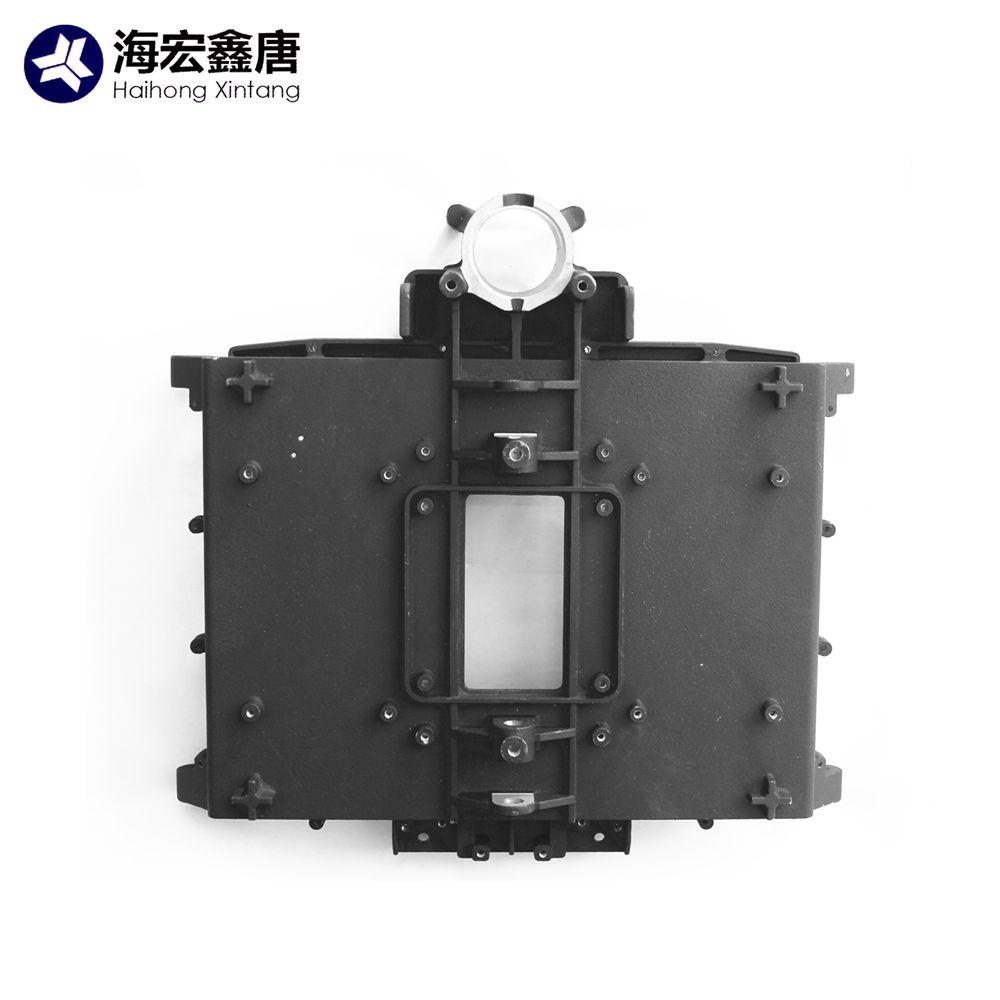

HHXT e sebelisa mochini o tsoetseng pele oa khatello e phahameng ho hlahisa likarolo tsa chasis ea koloi ea Aluminium die casting. Ts'ebetso ea bona e netefatsa hore karolo e 'ngoe le e' ngoe e kopana le litekanyetso tse tiileng tsa boleng. Tšebeliso ea li-alloys tsa aluminium tsa premium, tse kang ADC12 le A380, li fa likarolo tse matla haholo le ho hanyetsa kutu. Likarolo tsena li bohlokoa bakeng sa likoloi tsa motlakase, tse hlokang likarolo tse bobebe le tse tšoarellang.

Hlokomela:High-press die casting e lumella hore ho be le lipotoloho tse potlakileng tsa tlhahiso. Sena se thusa baetsi ba likoloi ho fihlela tlhoko e ntseng e hola ea likoloi tsa motlakase ntle le ho tela boleng.

Mega le Giga Casting ka Likoloi tsa Motlakase

Mega casting le giga casting li emela mohato o latelang ho thekenoloji ea die casting. Mekhoa ena e sebelisa mechini e meholohali ho hlahisa likarolo tsa chassis tse kholo haholo tse nang le karolo e le 'ngoe. Tesla e ile ea bula mokhoa ona ka Giga Press ea eona, 'me baetsi ba bang ba latela mohlala ona. Ka ho lahla likarolo tse kholo tsa chassis karolong e le 'ngoe, baetsi ba likoloi ba fokotsa palo ea likarolo le manonyeletso. Sena se etsa hore chassis e be bobebe hape e be matla.

Mega le giga casting e boetse e tsamaisa mokhoa oa ho etsa lihlahisoa. Likarolo tse fokolang li bolela nako e fokolang ea kopano le litšenyehelo tse tlaase. Ts'ebetso e ts'ehetsa tlhahiso ea likarolo tsa chasis ea koloi ea Aluminium die casting tse matla le tse bobebe. Tlhahiso ena e thusa likoloi tsa motlakase ho fumana mefuta e metle le ts'ebetso e ntle.

Papiso ea setso vs. Giga casting:

| Sebopeho | Traditional Casting | Giga Casting |

|---|---|---|

| Palo ea Likarolo | Tse ngata | Tse 'maloa (hangata e le' ngoe) |

| Nako ea Kopano | Nako e telele | Khutšoane |

| Matla a Sebopeho | E itekanetseng | Phahameng |

| Boima ba 'mele | E phahameng | Tlase |

Automation le Digitalization in Die Casting

Automation le digitalization hona joale li bapala karolo ea bohlokoa ho fetiseng lefu la sejoale-joale. Lifeme li sebelisa liroboto le mechini e bohlale ho sebetsana le mesebetsi e kang ho tlatsa hlobo, ho pholisa le ho tlosa likarolo. Sena se fokotsa phoso ea motho mme se eketsa botsitso. Lisebelisoa tsa dijithale li lekola mohato o mong le o mong oa ts'ebetso. Li-sensor li bokella lintlha ka mocheso, khatello le linako tsa potoloho. Baenjiniere ba sebelisa lintlha tsena ho ntlafatsa boleng le katleho.

HHXT e tsetetse holitsi tse tsoetseng pele tsa mochini oa CNCle litsamaiso tsa tlhahlobo tsa dijithale. Theknoloji ena e netefatsa hore karolo e 'ngoe le e' ngoe ea Aluminium die cast chasis ea koloi e kopana le litlhaloso tse hlakileng. Automation e boetse e lumella liphetoho tse potlakileng tsa moralo. Baetsi ba ka arabela ka potlako ho mekhoa e mecha le litlhoko tsa bareki.

Keletso:Digitalization e thusa ho tseba mathata esale pele. Sena se etsa hore ho be le mefokolo e fokolang le khotsofalo e phahameng ea bareki.

Melemo ea Moralo le Ts'ebetso ea Likoloi tsa Motlakase

Lits'oants'o tsa Karolo e le 'ngoe le Kopanyo ea Sebopeho

Hona joale baetsi ba likoloi ba sebelisa lisebelisoa tsa karolo e le 'ngoe ho etsa likarolo tse kholo tsa mochine oa koloi oa motlakase. Mokhoa ona o kopanya likarolo tse ngata ho ba karolo e le 'ngoe, e matla. Lienjineri li rala li-casts tsena hore li lumellane hantle le likarolo tse ling tsa koloi. Sephetho ke chassis e nang le manonyeletso a fokolang le li-welds.

Sekhahla se le seng se fana ka melemo e mengata ea bohlokoa:

- Matla a eketsehileng:Manonyeletso a fokolang a bolela matheba a fokolang a fokolang. Chassis e ka sebetsana le khatello ea maikutlo e eketsehileng nakong ea ho khanna.

- Tšireletseho e ntlafetseng:Sebopeho se tiileng se sireletsa bapalami hamolemo ha ho ka ba le kotsi.

- Kopano e nolofalitsoeng:Basebetsi ba qeta nako e nyane ba kopanya likarolo. Sena se potlakisa tlhahiso le ho fokotsa liphoso.

Hlokomela:Khokahano ea sebopeho e lumella baqapi ho eketsa likarolo tse kang lintlha tse ntseng li hola le likanale ka kotloloho ho sebatli. Sena se fokotsa tlhoko ea li-brackets kapa li-fasteners tse eketsehileng.

Phokotso ea Boima le ho Fumana Katleho

Likoloi tsa motlakase li hloka ho ba bobebe ka hohle kamoo ho ka khonehang ho eketsa lebelo la tsona. Mokhoa o tsoetseng pele oa lefu o thusa ho fihlela sepheo sena. Lisebelisoa tsa aluminium, tse kang tse sebelisoang keHHXT, fana ka matla a phahameng ha u ntse u boloka boima bo le tlase. Baenjiniere ba ka qapa mabota a masesaane le libōpeho tse rarahaneng tseo mekhoa ea khale e ke keng ea li hlahisa.

Chassis e bobebe e tlisa melemo e mengata:

- Sebaka se selelele sa ho khanna:Koloi e sebelisa matla a fokolang ho tsamaea, kahoo betri e tšoarella nako e telele.

- Ho potlakisa ho betere:Boima bo fokolang bo bolela hore koloi e ka potlaka ka potlako.

- Litšenyehelo tse tlase tsa matla:Bakhanni ba sebelisa chelete e nyane ho lefisa likoloi tsa bona.

| Molemo | Tšusumetso ho li-EV |

|---|---|

| Boima bo tlase | Bophahamo bo eketsehileng |

| Sebopeho se matla | Tšireletseho e ntlafetseng |

| Likarolo tse fokolang | Tlhahiso e potlakileng |

Baetsi ba kang HHXT ba sebelisa mochini o nepahetseng oa CNC ho boloka likarolo li nepahetse le ho fokotsa litšila. Ts'ebetso ena e netefatsa hore karolo e 'ngoe le e' ngoe ea chassis e kopana le litekanyetso tse thata tsa boima le ho leka-lekana.

Taolo e Ntlafetseng ea Thermal

Likoloi tsa motlakase li hlahisa mocheso ka har'a libeteri le li-motor. Tsamaiso e nepahetseng ea mocheso e boloka likarolo tsena li pholile ebile li sebetsa hantle. Advanced die casting e lumella baenjiniere ho haha liteishene tse pholileng le licheso tsa mocheso ka kotloloho likarolong tsa chassis.

Likarolo tsa bohlokoa tsa taolo e ntlafalitsoeng ea mocheso li kenyelletsa:

- Litsela tsa ho pholisa tse hahelletsoeng ka hare:Likanale tse ka hare ho casting li thusa ho tlosa mocheso hole le libaka tse bobebe.

- Botšepehi bo ntlafetseng:Libetri tse pholileng le li-motor li nka nako e telele 'me li sebetsa hantle.

- Tshebetso e tsitsitseng:Koloi e khona ho khanna sebaka se selelele ntle le mocheso o feteletseng.

Keletso:Taolo e kopaneng ea mocheso e fokotsa tlhoko ea litsamaiso tse eketsehileng tsa ho pholisa. Sena se boloka sebaka le boima ba 'mele, ho etsa hore koloi e sebetse hantle le ho feta.

Hona joale baetsi ba likoloi ba itšetlehile ka melemo ena ea moralo le ts'ebetso ho etsa likoloi tsa motlakase tse sireletsehileng haholoanyane, tse bobebe, le tse tšepahalang haholoanyane. Advanced die casting e eme bohareng ba phetoho ena.

Li-alloys tse etellang pele le lisebelisoa ka likarolo tsa Aluminium Die Casting Car Chasis

Lisebelisoa tse tsoetseng pele tsa Aluminium bakeng sa EV Chassis

Baetsi ba likoloi ba itšetleha ka lisebelisoa tse tsoetseng pele tsa aluminium ho theha likarolo tse matla le tse bobebe tsa chassis bakeng sa likoloi tsa motlakase. Li-alloys tse kang ADC1, ADC12, A380, le AlSi9Cu3 li fana ka thepa e ntle ea mochini. Lisebelisoa tsena li hanela kutu 'me li fana ka matla a hlokahalang bakeng sa lisebelisoa tse hlokang likoloi. Baetsi ba kang HHXT ba khetha li-alloys tsena hobane li thusa ho fokotsa boima ba koloi ha li ntse li boloka nako e telele.

Hlokomela:Lisebelisoa tsa aluminium li lumella libopeho tse rarahaneng le marako a mosesaane, a bohlokoa bakeng sa meralo ea mehleng ea kajeno ea likoloi tsa motlakase.

Mekhoa ea ho Khetha Alloy ka Likoloi tsa Motlakase

Baenjiniere ba khetha li-alloys ho latela lintlha tse 'maloa tsa bohlokoa:

- Matla:Thepa e tlameha ho sebetsana le khatello ea maikutlo le tšusumetso nakong ea ho khanna.

- Corrosion resistance:Chassis e hloka ho tšoarella maemong a leholimo a fapaneng.

- Boikemisetso:Alloy e lokela ho lumellaho seha le ho bōptjoa hantle.

- Thermal conductivity:Phetisetso e ntle ea mocheso e thusa ka betri le mohatsela oa motlakase.

Tafole e ka tlase e bonts'a lintlha tsa bohlokoa tsa khetho ea alloy:

| Litekanyetso | Bohlokoa bakeng sa li-EVs |

|---|---|

| Matla | Tšireletseho le ho tšoarella |

| Khanyetso ea Corrosion | Nako e telele ea bophelo |

| Boikemisetso | Tlhahiso e nepahetseng |

| Thermal Conductivity | Pholiso e sebetsang hantle |

Lintlafatso tsa Lintho tse Matla bakeng sa Matla le Tšireletseho

Material science e ntse e tsoela pele. Lisebelisoa tse ncha tsa aluminium joale li fana ka matla a holimo le ts'ebetso e ntle. Baetsi ba sebelisa micro-alloying le mekhoa e ntlafalitsoeng ea ho lahla ho etsa likarolo tse tšoarellang nako e telele. Litlhahiso tsena li thusa likarolo tsa chasis ea Aluminium die casting ho fihlela litekanyetso tse tiileng tsa polokeho le boleng. Ka lebaka leo, likoloi tsa motlakase li fetoha tse sireletsehileng le tse ka tšeptjoang ho bakhanni.

Mekhoa ea Tlhahiso le ho Itloaetsa

Tlhahiso e Nolofalitsoeng le Taolo ea Boleng

Hona joale bahlahisi ba sebelisa theknoloji e tsoetseng pele ho etsa hore tlhahiso e potlake le ho tšepahala haholoanyane. Mechini e ikemetseng e sebetsana le mehato e mengata, joalo kaho lahla, CNC machining, le tlhahlobo. Sena se fokotsa liphoso mme se boloka karolo e 'ngoe le e' ngoe e tsitsitse. Likhamphani tse kang HHXT li sebelisa lisebelisoa tsa tlhahlobo ea dijithale ho lekola karolo ka 'ngoe ea chassis ka mekhahlelo e fapaneng. Ba latela melao e thata ea boleng mme ba sebelisa litifikeiti tse kang ISO9001:2008 le IATF16949. Mehato ena e thusa ho fana ka likarolo tse fihlelang maemo a holimo nako le nako.

Keletso:Boleng ba othomathike bo lekola mathata pele ho nako. Sena se boloka nako le chelete bakeng sa bahlahisi le bareki.

Moqapi oa Fetola le Litharollo tsa Tloaelo

Baetsi ba likoloi ba batla likarolo tse lumellanang le meralo ea bona e ikhethang. Moralo oa morao-rao oa die casting o tšehetsa libopeho le boholo ba tloaelo. Baenjiniere ba ka sebelisa litšoantšo tsa 2D kapa 3D ho etsa liforomo tse ncha kapele.HHXT e fana ka OEMle lits'ebeletso tsa ODM, ho bolelang hore ba ka etsa likarolo ho latela lisampole tsa bareki kapa litšoantšo. Litsi tsa bona tsa machining tsa CNC li lumella liphetoho tse nepahetseng, esita le bakeng sa lihlopha tse nyane. Ho tenyetseha hona ho thusa baetsi ba likoloi ho hlahisa mefuta e mecha kapele.

Likhetho tsa bohlokoa tsa ho khetha:

- Litekanyo le libopeho tse ikhethileng

- Khetho ea lisebelisoa tsa aluminium

- Lintlha tse khethehileng kapa likarolo

Liphekolo tsa Bokaholimo le Likhetho tsa ho Qetella

Litlhare tse holim'a metsi li sireletsa likarolo tsa chassis le ho li etsa hore li shebahale hantle. HHXT e fana ka likhetho tse ngata tsa ho qetela, joalo ka ho phatloha ka sethunya, ho phatloha lehlabathe, ho penta ka phofo, ho penta le ho tlotsa linotsi. Liphekolo tsena li ntlafatsa ho hanyetsa kutu le ho tšoarella. Bareki ba ka boela ba khetha mebala e kang silevera e tšoeu, e ntšo, kapa meriti e tloaelehileng.

| Phekolo ea Bokaholimo | Molemo |

|---|---|

| Ho roala ka phofo | E matla, esita le ho qetela |

| Anodizing | Tšireletso e eketsehileng ea kutu |

| Ho benya | Sebaka se boreleli, se benyang |

Qetello e ntle e thusa likarolo ho tšoarella nako e telele le ho sebetsa hantle maemong a thata.

Litšenyehelo, Moshoelella, le Tšusumetso ea Sebele ea Lefatše

Litšenyehelo tse Tlase tsa Tlhahiso le Sebetsa se Molemo

Baetsi ba li-automaker ba bona chelete e ngata ea ho boloka litšenyehelo ka mokhoa o tsoetseng pele oa lefu. Mekhoa ea khatello e phahameng e fokotsa palo ea likarolo tse hlokahalang bakeng sa chassis ka 'ngoe. Likarolo tse fokolang li bolela nako e fokolang ea kopano le litšenyehelo tse tlaase tsa basebetsi. Litsamaiso tse ikemetseng li thusa lifeme ho hlahisa likarolo tse ngata ka nako e nyane. Likhamphani tse kang HHXT li sebelisa tlhahlobo ea dijithale le mochini oa CNC ho boloka litšila li le tlase le boleng bo holimo. Mehato ena e thusa bahlahisi ho fana ka litheko tsa tlholisano bakeng saAluminium die casting car chasis likarolo.

Keletso:Tlhahiso e hlophisitsoeng e thusa baetsi ba likoloi ho arabela ka potlako liphetohong tsa 'maraka le litlhoko tsa bareki.

Melemo ea Tikoloho le Mekhoa ea ho Recycle

Moralo oa morao-rao oa lefu o tšehetsa lipakane tsa ts'ebetso. Aluminium e sebelisoa haholo hape. Lifeme li bokella le ho sebelisa litšepe tse lahliloeng bocha tšebetsong ea tlhahiso. Sena se fokotsa tlhoko ea lisebelisoa tse ncha. Baetsi ba bangata ba sebelisa mekhoa ea phekolo ea eco-friendly ho fokotsa tšusumetso ea bona ea tikoloho. Mehato ea ho tsosolosa e thusa ho boloka litšila libakeng tsa ho lahlela lithōle le ho boloka matla.

Ho sheba ka potlako melemo ea tikoloho:

| Molemo | Tšusumetso |

|---|---|

| Lisebelisoa tse ka sebelisoang hape | Ho fokotseha ho fokolang |

| Mehato e baballang matla | Boemo bo tlase ba khabone |

| Eco-friendly finishes | Tlhahiso e hloekileng |

Lintlafatso tsa Ts'ebetso ho Baetsi ba Li-automaker ba ka Sehloohong

Baetsi ba likoloi ba etelletseng pele ba sebelisa lisebelisoa tse tsoetseng pele tsa lefu ho ntlafatsa ts'ebetso ea koloi. Likarolo tse matla le tse bobebe tsa chassis li thusa likoloi tsa motlakase ho potlaka le ho tsamaea hole ka tefiso e le 'ngoe. Lisebelisoa tse hahelletsoeng ka har'a pholileng li boloka libeteri le lienjene li le mochesong o sireletsehileng. Likhamphani tse kang HHXT li fana ka likarolo tse nepahetseng tse fihlelang maemo a thata a indasteri. Lintlafatso tsena li thusa likoloi tsa motlakase ho fumana litekanyetso tse phahameng tsa polokeho le ts'epo ea bareki.

Mehlala ea indasteri ea Aluminium Die Casting Car Chasis Parts

Mokhoa oa Tesla oa Giga Casting

Tesla e etella pele indasteri ka theknoloji ea eona ea Giga Casting. Khamphani e sebelisa mechini e meholo ea ho lahla ho etsa likarolo tse kholo tsa chassis ea koloi sekotong se le seng. Mokhoa ona o fokotsa palo ea likarolo le li-welds. Baenjineri ba Tesla ba rala li-casts tsena ho ntlafatsa matla le ho theola boima ba koloi. Giga Press e lumella Tesla ho potlakisa tlhahiso le ho fokotsa litšenyehelo. Baetsi ba likoloi ba bangata joale ba ithuta mekhoa ea Tesla ea ho ntlafatsa tlhahiso ea bona.

Giga Casting ea Tesla e beha maemo a macha a ho sebetsa hantle le ho nchafatsa tlhahiso ea likoloi tsa motlakase.

Lintho tse ncha tse tsoang ho HHXT le Baetsi ba Bang

HHXT e hlahella e le morekisi ea tšepahalangea Aluminium die casting car chasis likarolo. Khamphani e sebelisa mochini o tsoetseng pele oa khatello e phahameng le mochini oa CNC. Ts'ebetso ea bona e netefatsa hore karolo e 'ngoe le e' ngoe e kopana le litekanyetso tse tiileng tsa boleng. HHXT e fana ka tharollo ea tloaelo bakeng sa mefuta e fapaneng ea likoloi tsa motlakase. Baetsi ba bang le bona ba tsetela ho automation le tlhahlobo ea dijithale. Mehato ena e thusa ho fana ka likarolo tsa chassis tse nepahetseng le tse tšepahalang bakeng sa mmaraka o ntseng o hola oa likoloi tsa motlakase.

- HHXT e sebelisa lialloi tsa premium tsa aluminium bakeng sa matla le ho tšoarella.

- Khampani e fana ka mefuta e mengata ea phekolo ea holim'a metsi bakeng sa tšireletso e molemo.

- Bareki ba ka kopa boholo le likarolo tsa tloaelo.

Pono ea Bokamoso bakeng sa Chassis ea Likoloi tsa Motlakase

Bokamoso ba chassis ea koloi ea motlakase bo shebahala bo ts'episa. Baetsi ba likoloi ba tla tsoela pele ho sebelisa mekhoa e tsoetseng pele ea ho lahla lefu. Lisebelisoa tse ncha le lisebelisoa tsa dijithale li tla thusa ho theha likarolo tse bobebe le tse matla tsa chassis. Litsebi tsa indasteri li lebelletse ho bapala karolo e le 'ngoe le likarolo tse kopaneng tsa ho pholisa. Mekhoa ena e tla tšehetsa likoloi tsa motlakase tse sireletsehileng, tse sebetsang hantle le tse theko e tlaase.

Moloko o latelang oa likoloi tsa motlakase o tla rua molemo ho tsoa boqapi bo tsoelang pele ho theknoloji ea die casting.

Advanced die casting shapes bokamoso ba likoloi tsa motlakase. Hona joale bahlahisi ba theha likarolo tsa chasis ea koloi ea Aluminium e bobebe, e matla haholoanyane. Litlhahiso tsena li thusa baetsi ba likoloi ho theola litšenyehelo le ho ntlafatsa ts'ebetso. Indasteri e tsoela pele ho etsa tlhahiso ea chassis e sebetsang hantle, e sebetsang hantle haholo. Likoloi tsa motlakase li rua molemo ho nts'etsopele ena letsatsi le leng le le leng.

LBH

Ke eng e etsang hore aluminium die casting e be e loketseng likarolo tsa chassis ea koloi ea motlakase?

Aluminium die castinge etsa likarolo tse bobebe, tse matla le tse nepahetseng. Litšobotsi tsena li thusa likoloi tsa motlakase ho fumana ts'ebetso e ntle, polokeho le ts'ebetso.

HHXT e netefatsa boleng ba likarolo tsa chassis ea eona joang?

HHXT e sebelisa mochini o tsoetseng pele oa CNC, tlhahlobo e tiileng, le lits'ebetso tse netefalitsoeng. Karolo ka 'ngoe e finyella litekanyetso tse phahameng tsa matla, ho nepahala le ho tšoarella.

Na bahlahisi ba ka etsa likarolo tsa chassis tsa aluminium die cast bakeng sa mefuta e ikhethang ea EV?

Ee. Baetsi ba joalo ka tlhahiso ea HHXTOEM le ODM ditshebeletso. Ba theha libopeho tse tloahelehileng, boholo, le liphetho ho lumellana le litlhoko tse ikhethang tsa koloi ea motlakase.

Nako ea poso: Jul-04-2025