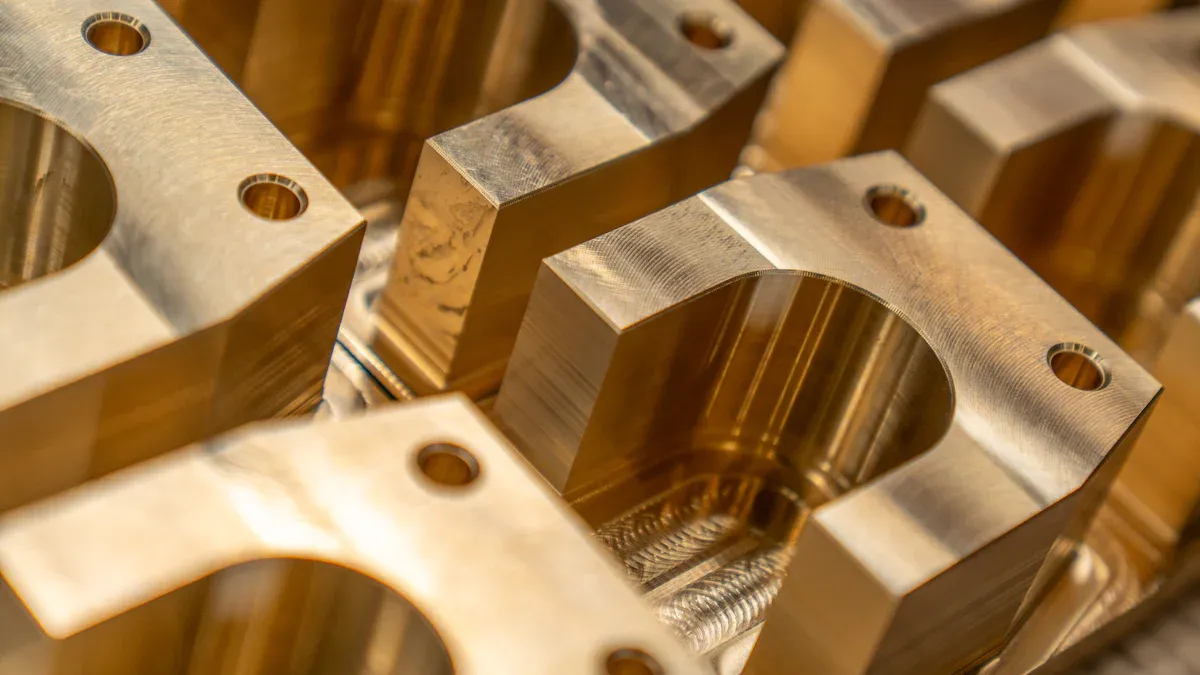

Ensuring the quality of die casting CNC machining parts is essential for achieving durability and precision in your final products. Poorly made components can lead to performance issues, higher costs, and even safety risks. You must adopt a systematic approach to maintain high standards. This includes focusing on design accuracy, selecting the right materials, and following precise manufacturing processes. For example, using OEM aluminum die casting ensures consistent results, especially for complex items like an aluminum die casting motorcycle cover. Quality control and expert collaboration further help you achieve reliable and long-lasting parts.

Key Takeaways

- Make sure the design is accurate so parts fit well. Use CAD tools to get exact measurements.

- Pick materials based on what they can do. Aluminum is light, and zinc is strong.

- Follow good manufacturing steps like keeping temperatures steady. Use machines to avoid mistakes.

- Check and test parts often to find problems early. Use X-rays or sound waves to check materials.

- Work with skilled manufacturers to use their knowledge. They can help improve designs and make better parts.

Design Considerations for Die Casting CNC Machining Parts

Importance of geometric accuracy

Geometric accuracy plays a vital role in ensuring the functionality and reliability of die casting CNC machining parts. You need to focus on precise dimensions and tolerances during the design phase. Even small errors can lead to misalignment or improper fit, which affects the performance of the final product. Using advanced CAD software helps you create detailed designs with exact measurements. This ensures that the parts meet the required specifications and work seamlessly in their intended applications.

Designing for manufacturability

Designing for manufacturability simplifies production and reduces costs. You should aim to create designs that are easy to produce without compromising quality. Features like uniform wall thickness and smooth transitions between surfaces help avoid complications during the die casting process. Additionally, minimizing complex geometries reduces machining time and material waste. Collaborating with engineers or manufacturers ensures your designs align with the capabilities of the equipment used for production.

Avoiding common design flaws

Common design flaws can lead to defects and inefficiencies in die casting CNC machining parts. You should avoid sharp corners, as they can cause stress concentrations and weaken the part. Similarly, excessive undercuts or intricate details may complicate the casting process and increase the risk of defects. Conducting a thorough review of your design helps you identify potential issues early. Using simulation tools allows you to test how the design performs under real-world conditions, ensuring a robust final product.

Material Selection for High-Quality Parts

Choosing the right alloys for die casting

Selecting the right alloy is crucial for producing high-quality die casting parts. You should focus on materials that offer excellent castability and durability. Aluminum alloys are popular due to their lightweight nature and corrosion resistance. Zinc alloys provide superior strength and are ideal for intricate designs. Magnesium alloys work well for applications requiring high strength-to-weight ratios.

Tip: Always match the alloy to the specific requirements of your project. For example, aluminum alloys are perfect for automotive components, while zinc alloys excel in decorative parts.

Material properties and their impact on quality

Material properties directly affect the performance and lifespan of your parts. You need to consider factors like tensile strength, thermal conductivity, and wear resistance. High tensile strength ensures the part can withstand mechanical stress. Thermal conductivity is essential for applications involving heat transfer. Wear resistance prevents premature degradation in high-friction environments.

- Key material properties to evaluate:

- Strength and durability

- Corrosion resistance

- Machinability

Understanding these properties helps you choose materials that meet your product’s functional and environmental demands.

Balancing cost and performance in material selection

Balancing cost and performance is essential for optimizing your production process. You should aim to select materials that deliver the required quality without exceeding your budget. Aluminum alloys are cost-effective for lightweight applications, while zinc alloys offer affordability for high-strength parts.

Note: Avoid compromising on quality to save costs. Poor material choices can lead to defects and higher maintenance expenses later.

By carefully evaluating your project’s needs, you can strike the right balance between cost and performance. This ensures your die casting CNC machining parts meet both technical and financial goals.

Manufacturing Processes to Ensure Quality

Best practices in die casting

You can achieve high-quality die casting results by following proven practices. Start by ensuring the die design is optimized for smooth material flow. This reduces the risk of air pockets and uneven surfaces. Maintain consistent temperatures during the casting process to prevent defects like shrinkage or warping. Regularly inspect the molds for wear and tear. Damaged molds can compromise the accuracy of your parts.

Tip: Preheat the molds before casting. This minimizes thermal shock and improves the overall surface finish of your parts.

Use automated systems to control injection speed and pressure. Automation ensures precision and reduces human error. Additionally, clean the molds thoroughly after each cycle. Residue buildup can affect the quality of subsequent casts.

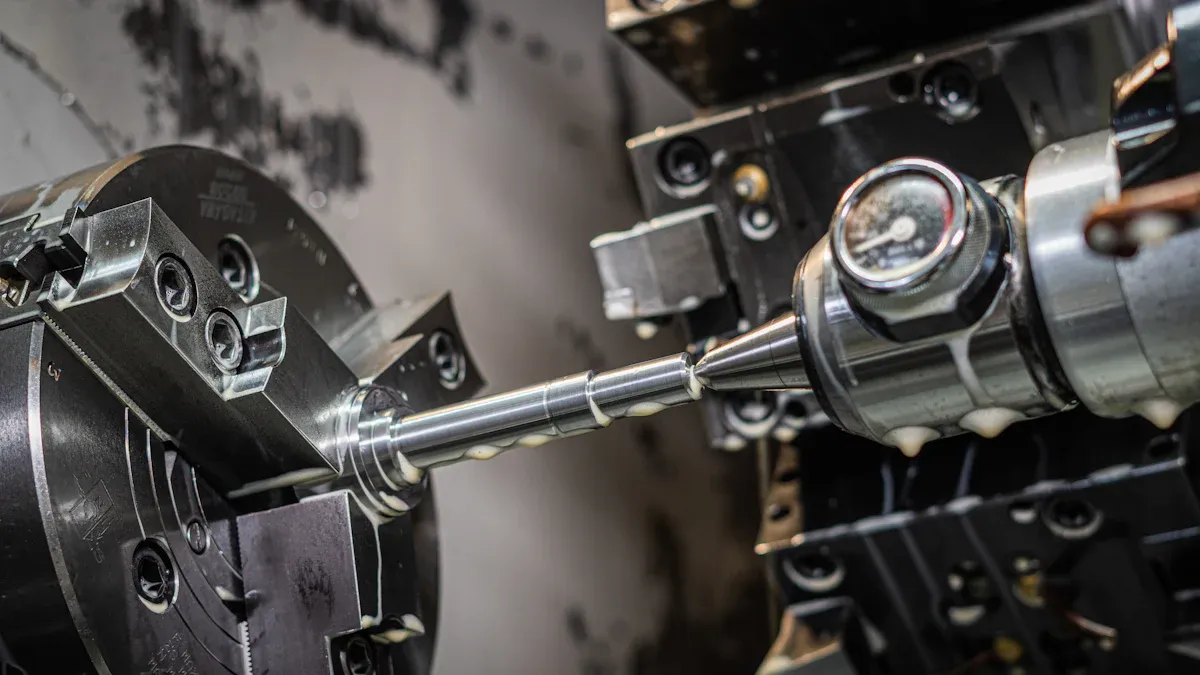

CNC machining techniques for precision

CNC machining plays a critical role in refining die casting CNC machining parts. You should use high-speed machining tools to achieve smooth finishes and tight tolerances. Multi-axis CNC machines allow you to create complex geometries with ease. These machines enhance precision and reduce the need for secondary operations.

- Key techniques to consider:

- Use carbide cutting tools for durability and accuracy.

- Optimize tool paths to minimize machining time.

- Implement coolant systems to prevent overheating during machining.

Note: Regularly calibrate your CNC machines. Proper calibration ensures consistent results and prevents dimensional errors.

Invest in advanced software for programming CNC machines. This software helps you simulate the machining process and identify potential issues before production begins.

Minimizing defects during production

Defects can undermine the quality of your die casting CNC machining parts. You should focus on identifying and eliminating common issues like porosity, cracks, and surface imperfections. Conduct thorough inspections at every stage of production. Early detection allows you to address problems before they escalate.

Implement quality control measures such as X-ray testing and ultrasonic inspection. These techniques help you detect internal defects that are not visible to the naked eye. Maintain strict control over environmental factors like humidity and temperature. Fluctuations can affect material properties and lead to inconsistencies.

Callout: Training your team on defect prevention techniques is essential. Skilled operators can spot issues quickly and take corrective action.

Use statistical process control (SPC) to monitor production data. SPC helps you identify trends and make adjustments to maintain quality. Finally, collaborate with your suppliers to ensure the raw materials meet your specifications. High-quality materials reduce the likelihood of defects during production.

Role of heat treatment and die coatings

Heat treatment and die coatings play a critical role in enhancing the quality and durability of die casting CNC machining parts. These processes improve material properties, extend tool life, and ensure consistent performance in demanding applications. Understanding their importance helps you make informed decisions during production.

Benefits of Heat Treatment

Heat treatment alters the physical and mechanical properties of metals, making them more suitable for specific applications. You can use this process to improve strength, hardness, and wear resistance.

- Key advantages of heat treatment:

- Enhanced Strength: Heat treatment increases the tensile strength of parts, allowing them to withstand higher loads.

- Improved Hardness: Treated parts resist deformation and wear, ensuring a longer lifespan.

- Stress Relief: The process reduces internal stresses caused by casting or machining, preventing cracks and distortions.

Tip: Choose the right heat treatment method based on your material and application. Common methods include annealing, quenching, and tempering.

For example, quenching followed by tempering can create a balance between hardness and toughness, making it ideal for automotive or aerospace components.

Importance of Die Coatings

Die coatings protect molds and improve the quality of cast parts. These coatings reduce friction, prevent wear, and enhance the surface finish of your products.

- Why you should use die coatings:

- Reduced Friction: Coatings minimize friction between the molten metal and the die surface, ensuring smooth material flow.

- Extended Tool Life: Protective layers shield the die from thermal and mechanical damage, reducing maintenance costs.

- Improved Surface Finish: Coated dies produce parts with fewer defects, such as rough surfaces or porosity.

Callout: Regularly inspect and reapply die coatings to maintain their effectiveness. Worn coatings can lead to inconsistent results and higher defect rates.

Combining Heat Treatment and Die Coatings

When you combine heat treatment with die coatings, you achieve superior results. Heat-treated parts gain the strength and durability needed for demanding applications, while coated dies ensure precision and consistency during production.

| Process | Primary Benefit | Application Example |

|---|---|---|

| Heat Treatment | Increases strength and hardness | Automotive engine components |

| Die Coatings | Enhances surface finish and tool life | High-precision electronic enclosures |

By integrating these processes into your manufacturing workflow, you can produce high-quality die casting CNC machining parts that meet industry standards.

Note: Consult with experts to determine the best combination of heat treatment and die coatings for your specific project. Their guidance ensures optimal results and cost efficiency.

Quality Control Measures in Die Casting CNC Machining

Inspection techniques for dimensional accuracy

Dimensional accuracy ensures that parts fit and function as intended. You can use several inspection techniques to verify the dimensions of die casting CNC machining parts. One effective method is coordinate measuring machines (CMMs). These machines measure the dimensions of a part with high precision. They can detect even the smallest deviations from the design specifications.

Another useful tool is optical inspection systems. These systems use cameras and lasers to scan the surface of a part. They create a 3D model that you can compare to the original design. This method is fast and works well for complex geometries.

Tip: Always inspect critical dimensions first. These are the measurements that directly affect the performance of the part.

Using gauges and calipers is another practical approach. These tools are simple to use and provide quick results. However, they are best suited for basic measurements. For more complex parts, advanced techniques like CMMs or optical systems are more reliable.

Testing methods for material integrity

Material integrity determines the strength and durability of your parts. You can use several testing methods to ensure the materials meet quality standards. Non-destructive testing (NDT) is one of the most effective approaches. It allows you to check for internal defects without damaging the part. Common NDT methods include X-ray inspection and ultrasonic testing.

- X-ray inspection: This method reveals internal flaws like porosity or cracks. It is especially useful for parts with intricate designs.

- Ultrasonic testing: This technique uses sound waves to detect defects. It works well for identifying voids or inconsistencies in the material.

For surface-level defects, you can use dye penetrant testing. This method involves applying a dye to the surface of the part. The dye seeps into cracks or imperfections, making them visible under UV light.

Callout: Regular material testing helps you maintain consistent quality. It also reduces the risk of part failure in critical applications.

Mechanical testing is another important step. Tests like tensile strength and hardness testing evaluate the material’s ability to withstand stress. These tests ensure the parts can perform reliably under real-world conditions.

Implementing in-process inspection

In-process inspection helps you catch defects early in the production process. This approach saves time and reduces waste. You can use automated systems to monitor key parameters during manufacturing. For example, sensors can track temperature, pressure, and material flow during die casting.

Visual inspections are also valuable. Train your team to identify common defects like surface imperfections or misalignments. Conducting these checks at regular intervals ensures that issues are addressed promptly.

Note: In-process inspection is not a replacement for final quality checks. It complements them by identifying problems before they escalate.

Statistical process control (SPC) is another effective tool. SPC involves collecting and analyzing data from the production process. It helps you identify trends and make adjustments to maintain quality.

By combining automated systems, visual checks, and SPC, you can create a robust in-process inspection strategy. This approach ensures that your die casting CNC machining parts meet the highest standards of quality.

Importance of machine calibration and preventive maintenance

Machine calibration and preventive maintenance are critical for producing high-quality die casting CNC machining parts. These practices ensure that your equipment operates at peak performance, reducing errors and extending the lifespan of your machinery. Neglecting them can lead to dimensional inaccuracies, increased downtime, and higher production costs.

Why Machine Calibration Matters

Calibration ensures that your machines produce parts with precise dimensions and tolerances. Over time, wear and tear can cause your equipment to drift from its original settings. This drift affects the accuracy of your parts, leading to defects and misalignments.

- Key benefits of regular calibration:

- Improved Accuracy: Ensures parts meet design specifications.

- Consistent Quality: Reduces variability in production.

- Reduced Waste: Minimizes material loss due to errors.

Tip: Schedule calibration checks at regular intervals. Use certified tools and standards to verify your machine’s accuracy.

For example, a CNC machine that is not calibrated may produce parts with uneven surfaces or incorrect dimensions. These issues can compromise the functionality of your final product.

The Role of Preventive Maintenance

Preventive maintenance involves routine checks and servicing to keep your machines in optimal condition. This proactive approach helps you identify potential issues before they escalate into major problems.

- Essential maintenance tasks:

- Lubrication: Keeps moving parts running smoothly.

- Cleaning: Removes debris that can affect performance.

- Inspection: Identifies wear and tear on critical components.

- Replacement: Ensures worn-out parts are replaced promptly.

Callout: A well-maintained machine operates more efficiently, reducing energy consumption and production costs.

Combining Calibration and Maintenance

When you combine calibration with preventive maintenance, you create a robust system for quality assurance. Calibration ensures accuracy, while maintenance keeps your machines reliable and efficient.

| Practice | Primary Benefit | Frequency |

|---|---|---|

| Machine Calibration | Ensures dimensional accuracy | Every 3-6 months |

| Preventive Maintenance | Extends machine lifespan | Weekly or monthly |

Note: Keep detailed records of calibration and maintenance activities. These records help you track performance trends and plan future servicing.

How to Implement These Practices

Start by creating a maintenance schedule tailored to your equipment. Include specific tasks and their recommended frequencies. Train your team to perform basic maintenance and recognize signs of wear. For calibration, invest in high-quality measuring tools and partner with certified technicians.

Emoji Reminder:

Post time: Jun-06-2025