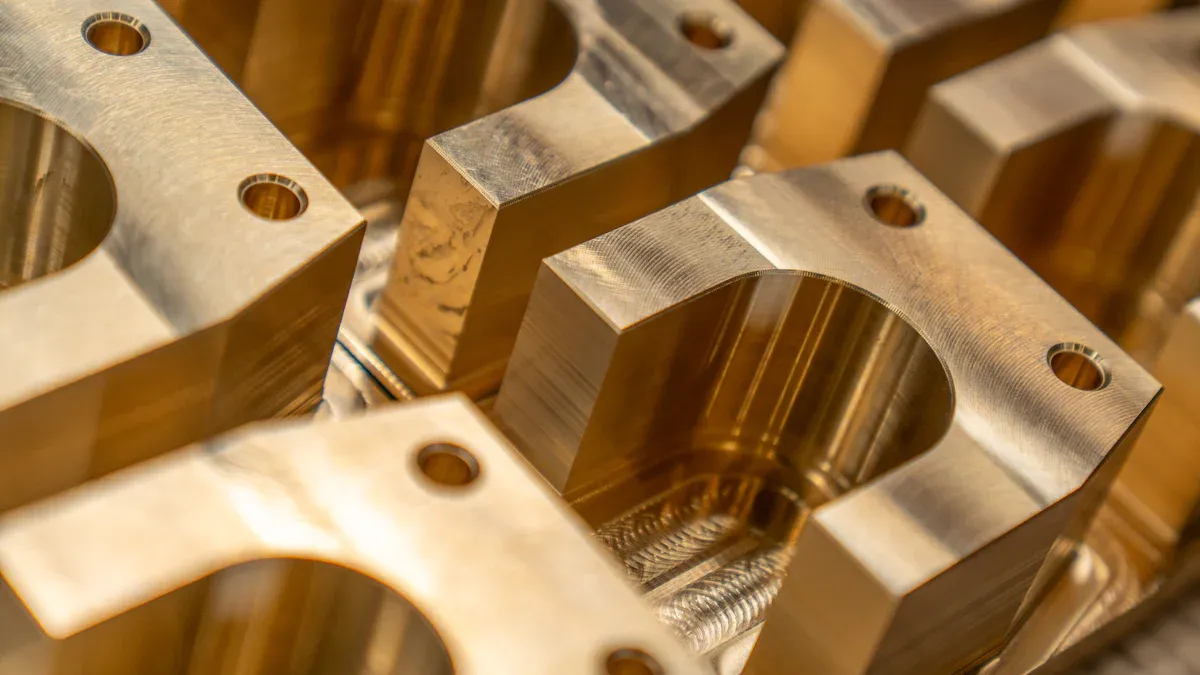

Xyuas kom zoo ntawmtuag casting CNC machining qhov chawyog qhov tseem ceeb rau kev ua tiav durability thiab precision hauv koj cov khoom kawg. Cov khoom siv tsis zoo tuaj yeem ua rau muaj teeb meem kev ua haujlwm, tus nqi siab dua, thiab txawm tias muaj kev nyab xeeb. Koj yuav tsum tau txais ib txoj hauv kev kom tswj tau cov qauv siab. Qhov no suav nrog kev tsom mus rau qhov raug tsim, xaiv cov khoom tsim nyog, thiab ua raws li cov txheej txheem tsim khoom. Piv txwv li, sivOEM txhuas tuag castingua kom cov txiaj ntsig zoo ib yam, tshwj xeeb tshaj yog rau cov khoom nyuaj xws li ib qhoaluminium tuag casting maus taus npog. Kev tswj kom zoo thiab cov kws tshaj lij kev sib koom tes ntxiv pab koj ua tiav qhov kev ntseeg siab thiab kav ntev.

Ntsiab Cai

- Xyuas kom tseeb tias covtsim muaj tseebyog li cov khoom haum zoo. Siv CAD cov cuab yeej kom tau txais kev ntsuas tseeb.

- Xaiv cov ntaub ntawv raws lilawv ua tau dab tsi. Aluminium yog lub teeb, thiab zinc muaj zog.

- Ua raws li cov txheej txheem tsim khoom zoo xws li ua kom qhov kub thiab txias tsis tu ncua. Siv tshuab kom tsis txhob ua yuam kev.

- Tshawb xyuas thiab sim cov khoom feem ntau kom pom cov teeb meem ntxov. Siv X-rays lossis suab nthwv dej los kuaj xyuas cov ntaub ntawv.

- Ua haujlwm nrog cov kws tsim khoom siv los siv lawv cov kev paub. Lawv tuaj yeem pab txhim kho cov qauv tsim thiab ua kom zoo dua qub.

Tsim kev txiav txim siab rau Tuag Casting CNC Machining Parts

Qhov tseem ceeb ntawm geometric raug

Geometric precision plays lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev ua haujlwm thiab kev ntseeg tau ntawmtuag casting CNC machining qhov chaw. Koj yuav tsum tau tsom mus rau qhov tseeb qhov ntev thiab kam rau ua thaum lub sij hawm tsim qauv. Txawm tias me me yuam kev tuaj yeem ua rau misalignment lossis tsis haum, uas cuam tshuam rau kev ua haujlwm ntawm cov khoom kawg. Siv cov software CAD siab heev pab koj tsim cov qauv tsim nrog cov kev ntsuas tseeb. Qhov no ua kom cov khoom ua tau raws li qhov xav tau tshwj xeeb thiab ua haujlwm seamlessly hauv lawv cov ntawv thov.

Tsim rau manufacturability

Tsim rau manufacturabilitysimplifies ntau lawm thiab txo cov nqi. Koj yuav tsum tsom los tsim cov qauv tsim uas yooj yim los tsim yam tsis muaj kev cuam tshuam zoo. Cov yam ntxwv zoo li cov phab ntsa tuab tuab thiab kev hloov pauv ntawm qhov chaw pab kom tsis txhob muaj teeb meem thaum lub sijhawm tuag casting txheej txheem. Tsis tas li ntawd, txo qis cov geometry nyuaj txo cov sijhawm ua haujlwm thiab cov khoom siv pov tseg. Kev koom tes nrog cov kws tsim khoom lossis cov tuam txhab tsim khoom ua kom koj cov qauv tsim ua raws li cov peev txheej ntawm cov cuab yeej siv rau kev tsim khoom.

Zam kev tsim qauv tsis zoo

Kev tsim qauv tsis zoo tuaj yeem ua rau muaj qhov tsis xws luag thiab tsis muaj txiaj ntsig hauv kev tuag casting CNC machining qhov chaw. Koj yuav tsum zam cov ces kaum ntse, vim lawv tuaj yeem ua rau muaj kev ntxhov siab thiab ua rau lub cev tsis muaj zog. Ib yam li ntawd, overcuts los yog intricate cov ntsiab lus yuav complicate txheej txheem casting thiab ua rau kom muaj kev pheej hmoo ntawm cov teeb meem. Kev tshuaj xyuas tag nrho ntawm koj tus qauv tsim pab koj txheeb xyuas cov teeb meem tshwm sim thaum ntxov. Siv cov cuab yeej simulation tso cai rau koj los ntsuas seb qhov kev tsim ua tau zoo li cas hauv lub ntiaj teb tiag tiag, kom ntseeg tau tias cov khoom siv zaum kawg.

Kev xaiv cov khoom siv rau cov khoom zoo

Xaiv qhov zoo alloys rau tuag casting

Xaiv cov hlau zoo yog qhov tseem ceeb rau kev tsim cov khoom zoo tuag casting qhov chaw. Koj yuav tsum tsom mus rau cov ntaub ntawv uas muaj castability zoo heev thiab durability. Aluminium alloys yog nrov vim lawv lub teeb yuag thiab corrosion kuj. Zinc alloys muab lub zog zoo tshaj plaws thiab zoo tagnrho rau kev tsim qauv zoo nkauj. Magnesium alloys ua haujlwm zoo rau cov ntawv thov uas xav tau lub zog-rau-qhov hnyav piv.

Tswv yim: Ib txwm phim cov alloy rau cov kev cai tshwj xeeb ntawm koj qhov project. Piv txwv li, aluminium alloys zoo meej rau cov khoom siv tsheb, thaum zinc alloys zoo tshaj plaws hauv cov khoom siv kho kom zoo nkauj.

Cov khoom siv thiab lawv qhov cuam tshuam rau qhov zoo

Khoom sivncaj qha cuam tshuam rau kev ua haujlwm thiab kev ua neej nyob ntawm koj qhov chaw. Koj yuav tsum xav txog yam xws li lub zog tensile, thermal conductivity, thiab hnav tsis kam. Lub zog tensile siab ua kom lub cev tuaj yeem tiv taus kev ntxhov siab. Thermal conductivity yog qhov tseem ceeb rau cov ntawv thov uas cuam tshuam nrog kev hloov hluav taws xob. Hnav tiv thaiv tiv thaiv kom tsis txhob ntxov ntxov hauv qhov chaw muaj kev sib txhuam siab.

- Cov khoom siv tseem ceeb los ntsuas:

- Lub zog thiab durability

- Corrosion kuj

- Machineability

Kev nkag siab txog cov khoom no pab koj xaiv cov ntaub ntawv uas ua tau raws li koj cov khoom siv thiab ib puag ncig xav tau.

Ntsuas tus nqi thiab kev ua haujlwm hauv kev xaiv cov khoom siv

Kev ntsuas tus nqi thiab kev ua tau zoo yog qhov tseem ceeb rau kev txhim kho koj cov txheej txheem tsim khoom. Koj yuav tsum tsom mus xaiv cov ntaub ntawv uas xa cov khoom tsim nyog yam tsis muaj ntau tshaj koj cov peev nyiaj.Aluminium alloysyog tus nqi-zoo rau kev siv lub teeb yuag, thaum zinc alloys muaj peev xwm them taus rau cov khoom muaj zog.

Nco tseg: Tsis txhob cuam tshuam rau qhov zoo kom txuag tau nqi. Kev xaiv cov khoom siv tsis zoo tuaj yeem ua rau muaj qhov tsis xws luag thiab kev siv nyiaj ntau dua tom qab.

Los ntawm ua tib zoo ntsuas koj qhov project qhov xav tau, koj tuaj yeem cuam tshuam qhov sib npaug ntawm tus nqi thiab kev ua haujlwm. Qhov no ua kom koj qhov tuag casting CNC machining qhov chaw ua tau raws li cov hom phiaj kev lag luam thiab nyiaj txiag.

Cov txheej txheem tsim khoom kom ntseeg tau qhov zoo

Cov kev coj ua zoo tshaj plaws hauv kev tuag casting

Koj tuaj yeem ua tiavhigh-quality tuag casting tshwm simlos ntawm kev ua raws li kev coj ua pov thawj. Pib los ntawm kev ua kom qhov tuag tsim yog optimized rau cov ntaub ntawv du. Qhov no txo qhov kev pheej hmoo ntawm huab cua hnab ris thiab qhov chaw tsis sib xws. Khaws qhov kub zoo ib yam thaum lub sij hawm casting txheej txheem los tiv thaiv qhov tsis xws luag xws li shrinkage los yog warping. Tsis tu ncua xyuas cov pwm rau hnav thiab tsim kua muag. Cov pwm puas tuaj yeem cuam tshuam qhov tseeb ntawm koj qhov chaw.

Tswv yim: Preheat cov pwm ua ntej casting. Qhov no minimizes thermal shock thiab txhim kho tag nrho saum npoo ntawm koj qhov chaw.

Siv cov tshuab automated los tswj kev txhaj tshuaj ceev thiab siab. Automation kom meej meej thiab txo cov neeg ua yuam kev. Tsis tas li ntawd, ntxuav cov pwm kom huv si tom qab txhua lub voj voog. Residue buildup tuaj yeem cuam tshuam qhov zoo ntawm cov nrum tom ntej.

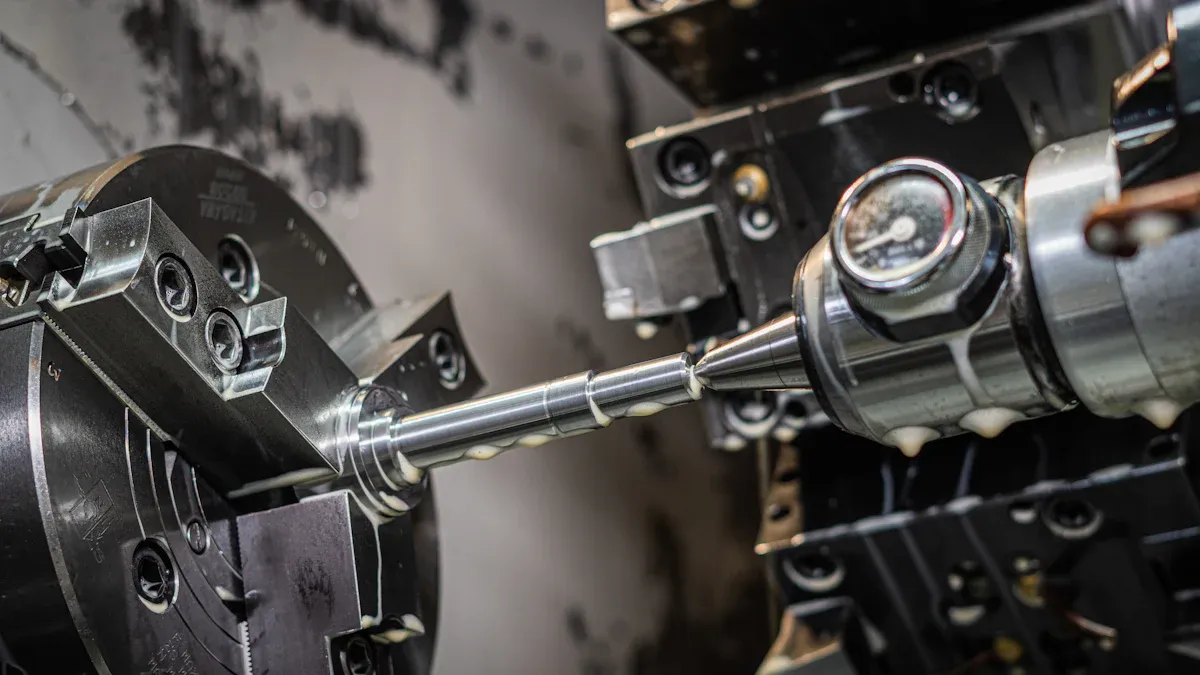

CNC machining cov txheej txheem rau precision

CNC machining plays ib qho tseem ceebLub luag haujlwm hauv kev ua kom zoo dua tuag casting CNC machining qhov chaw. Koj yuav tsum siv cov cuab yeej siv high-speed machining kom ua tiav cov tiav du thiab nruj kam rau ua. Multi-axis CNC tshuab tso cai rau koj los tsim cov geometry nyuaj nrog yooj yim. Cov tshuab no txhim kho qhov tseeb thiab txo qhov xav tau rau kev ua haujlwm theem nrab.

- Cov txheej txheem tseem ceeb los xav txog:

- Siv cov cuab yeej txiav carbide kom ruaj khov thiab raug.

- Txhim kho cov cuab yeej siv kom txo tau lub sijhawm machining.

- Siv cov tshuab coolant kom tsis txhob overheating thaum lub sij hawm machining.

Nco tseg: Tsis tu ncua calibrate koj cov tshuab CNC. Kev calibration kom zoo ua kom cov txiaj ntsig zoo ib yam thiab tiv thaiv qhov ua yuam kev.

Ua lag luam nyob rau hauv advanced software rau programming CNC tshuab. Cov software no pab koj simulate cov txheej txheem machining thiab txheeb xyuas cov teeb meem ua ntej pib tsim khoom.

Txo qhov tsis xws luag thaum tsim khoom

Qhov tsis xws luag tuaj yeem cuam tshuam qhov zoo ntawm koj qhov tuag casting CNC machining qhov chaw. Koj yuav tsum tsom rau kev txheeb xyuas thiab tshem tawm cov teeb meem xws li porosity, tawg, thiab qhov tsis zoo ntawm qhov chaw. Ua txhua yam kev soj ntsuam ntawm txhua theem ntawm kev tsim khoom. Kev tshawb pom ntxov tso cai rau koj los daws cov teeb meem ua ntej lawv nce ntxiv.

Siv cov kev tswj xyuas zoo xws li kev kuaj X-ray thiab tshuaj xyuas ultrasonic. Cov tswv yim no pab koj txheeb xyuas cov teeb meem sab hauv uas tsis pom ntawm qhov muag liab qab. Tswj nruj tswj hwm ib puag ncig yam xws li av noo thiab kub. Kev hloov pauv tuaj yeem cuam tshuam rau cov khoom siv thiab ua rau tsis sib xws.

Hu rau: Kev cob qhia koj pab neeg ntawm cov txheej txheem tiv thaiv tsis zoo yog qhov tseem ceeb. Cov neeg ua haujlwm txawj ntse tuaj yeem pom cov teeb meem sai sai thiab kho kom raug.

Siv cov txheej txheem txheeb cais (SPC) los saib xyuas cov ntaub ntawv tsim khoom. SPC pab koj txheeb xyuas cov xwm txheej thiab hloov kho kom muaj txiaj ntsig zoo. Thaum kawg, koom tes nrog koj cov neeg muag khoom kom ntseeg tau tias cov ntaub ntawv raw ua tau raws li koj cov kev qhia tshwj xeeb. Cov ntaub ntawv zoo heev txo qhov kev pheej hmoo ntawm qhov tsis xws luag thaum tsim khoom.

Lub luag haujlwm ntawm kev kho cua sov thiab cov txheej txheem tuag

Kev kho cua sov thiab cov txheej txheem tuag ua lub luag haujlwm tseem ceeb hauv kev txhim kho qhov zoo thiab ua haujlwm ntawm kev tuag casting CNC machining qhov chaw. Cov txheej txheem no txhim kho cov khoom siv, ua kom ntev lub neej ntawm cov cuab yeej, thiab ua kom muaj kev ua tau zoo ib yam hauv cov kev xav tau. Kev nkag siab txog lawv qhov tseem ceeb yuav pab koj txiav txim siab paub thaum lub sijhawm tsim khoom.

Cov txiaj ntsig ntawm kev kho cua sov

Kev kho cua sov hloov kho lub cev thiab cov khoom siv hluav taws xob ntawm cov hlau, ua rau lawv tsim nyog rau kev siv tshwj xeeb. Koj tuaj yeem siv cov txheej txheem no los txhim kho lub zog, hardness, thiab hnav tsis kam.

- Cov txiaj ntsig tseem ceeb ntawm kev kho cua sov:

- Ua kom muaj zog: Kev kho cua sov ua kom lub zog tensile ntawm qhov chaw, ua rau lawv tiv taus ntau dua.

- Txhim kho Hardness: Kho qhov chaw tiv thaiv deformation thiab hnav, ua kom lub neej ntev dua.

- Kev ntxhov siab: Cov txheej txheem txo cov kev ntxhov siab sab hauv los ntawm kev casting lossis machining, tiv thaiv cov kab nrib pleb thiab distortions.

Tswv yim: Xaiv txoj kev kho cua sov kom raug raws li koj cov khoom siv thiab daim ntawv thov. Cov txheej txheem muaj xws li annealing, quenching, thiab tempering.

Piv txwv li, quenching ua raws li tempering tuaj yeem tsim qhov sib npaug ntawm hardness thiab toughness, ua rau nws zoo tagnrho rau automotive lossis aerospace Cheebtsam.

Qhov tseem ceeb ntawm Die Coatings

Tuag txheej tiv thaiv pwm thiab txhim kho qhov zoo ntawm cov khoom cam khwb cia. Cov coatings no txo kev sib txhuam, tiv thaiv kev hnav, thiab txhim kho qhov chaw tiav ntawm koj cov khoom.

- Vim li cas koj yuav tsum siv cov txheej txheem tuag:

- Txo kev sib txhuam: Coatings txo qhov kev sib txhuam ntawm cov hlau molten thiab tuag nto, kom ntseeg tau tias cov khoom ntws zoo.

- Extended Tool Life: Cov khaubncaws sab nraud povtseg tiv thaiv cov tuag los ntawm thermal thiab mechanical puas, txo cov nqi kho.

- Txhim kho nto tiav: Coated dies tsim qhov chaw uas muaj qhov tsis xws luag, xws li qhov chaw ntxhib lossis porosity.

Hu rau: Tsis tu ncua tshuaj xyuas thiab rov ua cov txheej txheem tuag kom tswj tau lawv cov txiaj ntsig. Cov coatings hnav tuaj yeem ua rau cov txiaj ntsig tsis sib xws thiab ntau dua qhov tsis xws luag.

Kev sib xyaw ua ke ntawm kev kho cua sov thiab cov txheej txheem tuag

Thaum koj muab kev kho cua sov nrog cov txheej txheem tuag, koj ua tiav cov txiaj ntsig zoo. Thaum tshav kub kub-kho qhov chaw tau txais lub zog thiab ua haujlwm ntev uas xav tau rau cov ntawv thov, thaum coated tuag kom meej meej thiab sib xws thaum tsim khoom.

| Txheej txheem | Cov txiaj ntsig tseem ceeb | Piv txwv daim ntawv thov |

|---|---|---|

| Kev kho cua sov | Ua kom muaj zog thiab hardness | Automotive cav Cheebtsam |

| Tuag Coatings | Enhances nto finish thiab cuab yeej lub neej | High-precision electronic enclosures |

Los ntawm kev koom ua ke cov txheej txheem no rau hauv koj qhov kev tsim khoom, koj tuaj yeem tsim cov khoom zoo tuag casting CNC machining qhov chaw uas ua tau raws li cov qauv kev lag luam.

Nco tseg: Tham nrog cov kws tshaj lij los txiav txim siab qhov zoo tshaj plaws ntawm kev kho cua sov thiab cov txheej txheem tuag rau koj qhov project tshwj xeeb. Lawv cov kev taw qhia ua kom pom cov txiaj ntsig zoo thiab cov nqi siv tau.

Kev Tswj Xyuas Zoo hauv Kev Tuag Casting CNC Machining

Kev tshuaj xyuas cov txheej txheem rau qhov tseeb qhov tseeb

Dimensional raugxyuas kom cov khoom haum thiab ua haujlwm raws li qhov xav tau. Koj tuaj yeem siv ntau yam kev tshuaj xyuas los txheeb xyuas qhov ntev ntawm qhov tuag casting CNC machining qhov chaw. Ib txoj hauv kev zoo yog kev sib koom tes ntsuas tshuab (CMMs). Cov tshuab no ntsuas qhov ntev ntawm ib feem nrog siab precision. Lawv tuaj yeem pom txawm tias qhov sib txawv me tshaj plaws los ntawm cov qauv tsim.

Lwm cov cuab yeej siv tau yog kho qhov muag tshuaj xyuas tshuab. Cov tshuab no siv lub koob yees duab thiab lasers los luam theej duab ntawm ib feem. Lawv tsim cov qauv 3D uas koj tuaj yeem sib piv rau tus qauv tsim. Txoj kev no yog ceev ceev thiab ua haujlwm zoo rau cov geometry nyuaj.

Tswv yim: Ib txwm tshuaj xyuas qhov tseem ceeb ua ntej. Cov no yog cov kev ntsuas uas cuam tshuam ncaj qha rau kev ua haujlwm ntawm ntu.

Siv cov ntsuas ntsuas thiab calipers yog lwm txoj hauv kev. Cov cuab yeej no yooj yim siv thiab muab cov txiaj ntsig ceev. Txawm li cas los xij, lawv yog qhov zoo tshaj plaws rau kev ntsuas kev ntsuas. Rau ntau qhov chaw, cov tswv yim zoo li CMMs lossis cov tshuab kho qhov muag muaj kev ntseeg siab dua.

Cov kev sim rau kev ncaj ncees ntawm cov khoom

Khoom siv ncaj nceestxiav txim siab lub zog thiab durability ntawm koj qhov chaw. Koj tuaj yeem siv ntau txoj hauv kev los xyuas kom cov khoom ua tau raws li cov qauv zoo. Kev kuaj tsis yog kev puas tsuaj (NDT) yog ib txoj hauv kev zoo tshaj plaws. Nws tso cai rau koj los txheeb xyuas cov teeb meem sab hauv yam tsis muaj kev puas tsuaj. Cov txheej txheem NDT feem ntau suav nrog kev kuaj X-ray thiab kuaj ultrasonic.

- X-ray kuaj: Txoj kev no nthuav tawm sab hauv qhov tsis zoo xws li porosity lossis tawg. Nws yog tshwj xeeb tshaj yog pab tau rau qhov chaw nrog intricate designs.

- Kev kuaj ultrasonic: Cov txheej txheem no siv lub suab nthwv dej txhawm rau txheeb xyuas qhov tsis xws luag. Nws ua haujlwm zoo rau kev txheeb xyuas qhov khoob lossis qhov tsis sib xws hauv cov khoom.

Rau qhov tsis xws luag ntawm qhov chaw, koj tuaj yeem siv dye penetrant testing. Txoj kev no suav nrog kev siv tshuaj zas xim rau ntawm qhov chaw. Cov xim nkag mus rau hauv cov kab nrib pleb lossis qhov tsis zoo, ua rau lawv pom hauv UV teeb.

Hu rau: Kev ntsuam xyuas cov khoom tsis tu ncua pab koj tswj kom zoo ib yam. Nws kuj txo qhov kev pheej hmoo ntawm qhov tsis ua haujlwm hauv cov ntawv thov tseem ceeb.

Kev ntsuas tshuab yog lwm kauj ruam tseem ceeb. Kev ntsuam xyuas zoo li tensile lub zog thiab hardness kuaj ntsuas cov khoom muaj peev xwm tiv taus kev ntxhov siab. Cov kev ntsuam xyuas no ua kom cov khoom tuaj yeem ua tau zoo raws li lub ntiaj teb tiag tiag.

Ua raws li kev tshuaj ntsuam xyuas

Kev soj ntsuam hauv txheej txheem pab koj ntes cov teeb meem thaum ntxov ntawm cov txheej txheem tsim khoom. Txoj kev no txuag lub sijhawm thiab txo cov khoom pov tseg. Koj tuaj yeem siv cov tshuab automated los saib xyuas qhov tseem ceeb thaum lub sijhawm tsim khoom. Piv txwv li, sensors tuaj yeem taug qab qhov kub, siab, thiab cov khoom ntws thaum lub sij hawm tuag casting.

Kev kuaj pom pom kuj muaj txiaj ntsig. Qhia koj pab neeg kom txheeb xyuas qhov tsis xws luag xws li deg imperfections lossis misalignments. Kev ua cov tshev no nyob rau ib ntus kom paub meej tias cov teeb meem raug daws sai.

Nco tseg: Kev soj ntsuam hauv txheej txheem tsis yog ib qho kev hloov pauv rau qhov kev kuaj xyuas zaum kawg. Nws txhawb lawv los ntawm kev txheeb xyuas cov teeb meem ua ntej lawv nce ntxiv.

Statistical process control (SPC) yog lwm cov cuab yeej siv tau zoo. SPC suav nrog kev sau thiab tshuaj xyuas cov ntaub ntawv los ntawm cov txheej txheem tsim khoom. Nws pab koj txheeb xyuas cov xwm txheej thiab hloov kho kom muaj txiaj ntsig zoo.

Los ntawm kev sib txuas cov tshuab hluav taws xob, kev kuaj pom, thiab SPC, koj tuaj yeem tsim lub tswv yim zoo hauv kev soj ntsuam. Qhov no ua kom ntseeg tau tias koj qhov tuag casting CNC machining qhov chaw ua tau raws li cov qauv zoo tshaj plaws.

Qhov tseem ceeb ntawm lub tshuab calibration thiab kev tiv thaiv kev saib xyuas

Tshuab calibration thiab tiv thaiv kev saib xyuas yog qhov tseem ceeb rau kev tsim cov khoom zoo siab tuag casting CNC machining qhov chaw. Cov kev coj ua no ua kom ntseeg tau tias koj cov cuab yeej ua haujlwm ntawm qhov ua tau zoo tshaj plaws, txo qhov ua yuam kev thiab txuas ntxiv lub neej ntawm koj lub tshuab. Kev tsis saib xyuas lawv tuaj yeem ua rau muaj qhov tsis raug, ua rau lub sijhawm poob qis, thiab cov nqi tsim khoom ntau dua.

Vim li cas Machine Calibration Matters

Calibration xyuas kom meej tias koj cov cav tov tsim cov khoom nrog cov qhov ntev thiab qhov ntev. Nyob rau tib lub sijhawm, hnav thiab tsim kua muag tuaj yeem ua rau koj cov khoom siv los ntawm nws qhov chaw qub. Qhov kev cuam tshuam no cuam tshuam rau qhov tseeb ntawm koj qhov chaw, ua rau muaj qhov tsis xws luag thiab misalignments.

- Cov txiaj ntsig tseem ceeb ntawm kev calibration tsis tu ncua:

- Txhim kho qhov tseeb: Ua kom cov khoom ua tau raws li cov qauv tsim.

- Zoo ib yam: Txo kev hloov pauv hauv kev tsim khoom.

- Txo cov pov tseg: Txo cov khoom poob vim qhov yuam kev.

Tswv yim: Teem caij calibration checks ntawm ib ntus. Siv cov cuab yeej thiab cov qauv ntawv pov thawj los xyuas koj lub tshuab qhov tseeb.

Piv txwv li, lub tshuab CNC uas tsis ntsuas ntsuas yuav tsim cov khoom nrog qhov tsis sib xws lossis qhov tsis raug. Cov teeb meem no tuaj yeem cuam tshuam kev ua haujlwm ntawm koj cov khoom kawg.

Lub luag haujlwm ntawm Kev Tiv Thaiv Kev Tiv Thaiv

Kev tiv thaiv kev saib xyuas suav nrog kev kuaj xyuas niaj hnub thiab kev pabcuam kom koj lub tshuab ua haujlwm zoo. Txoj hauv kev zoo no yuav pab koj txheeb xyuas cov teeb meem muaj peev xwm ua ntej lawv nce mus rau cov teeb meem loj.

- Cov haujlwm tseem ceeb ntawm kev saib xyuas:

- Lubrication: Ua kom cov khoom txav mus tau zoo.

- Ntxuav: Tshem tawm cov khib nyiab uas tuaj yeem cuam tshuam kev ua haujlwm.

- Kev tshuaj xyuas: Txheeb xyuas qhov hnav thiab tsim kua muag ntawm cov khoom tseem ceeb.

- Hloov: Kom paub meej tias cov khoom puas tau hloov tam sim ntawd.

Hu rau: Lub tshuab ua haujlwm zoo ua haujlwm tau zoo dua, txo qis kev siv hluav taws xob thiab cov nqi tsim khoom.

Combining Calibration thiab Maintenance

Thaum koj ua ke calibration nrog kev tiv thaiv kev saib xyuas, koj tsim kom muaj kev ruaj ntseg rau kev ruaj ntseg zoo. Calibration ua kom raug, thaum kho kom koj cov tshuab txhim khu kev qha thiab ua haujlwm tau zoo.

| Xyaum | Cov txiaj ntsig tseem ceeb | Ntau zaus |

|---|---|---|

| Tshuab Calibration | Ua kom qhov tseeb qhov tseeb | Txhua 3-6 lub hlis |

| Kev Tiv Thaiv Kev Tiv Thaiv | Extens tshuab lifespan | Txhua lub lim tiam lossis txhua hli |

Nco tseg: Khaws cov ntaub ntawv ntxaws ntxaws ntawm kev ntsuas ntsuas thiab kev saib xyuas cov haujlwm. Cov ntaub ntawv no pab koj taug qab cov kev ua tau zoo thiab npaj kev pabcuam yav tom ntej.

Yuav ua li cas los siv cov kev coj ua no

Pib los ntawm kev tsim lub sijhawm saib xyuas kom haum rau koj cov khoom siv. suav nrog cov haujlwm tshwj xeeb thiab lawv cov zaus pom zoo. Qhia koj pab neeg kom ua haujlwm yooj yim thiab paub txog cov cim ntawm kev hnav. Rau calibration, nqis peev hauv cov cuab yeej ntsuas zoo thiab koom tes nrog cov kws tshaj lij.

Emoji Ceeb Toom:

Post lub sij hawm: Jun-06-2025