Ukuqinisekisa umgangatho webafe bephosa iindawo machining CNCKubalulekile ukufezekisa ukuqina kunye nokuchaneka kwiimveliso zakho zokugqibela. Amacandelo enziwe kakubi angakhokelela kwimiba yokusebenza, iindleko eziphezulu, kunye nemingcipheko yokhuseleko. Kufuneka usebenzise indlela ecwangcisiweyo yokugcina imigangatho ephezulu. Oku kubandakanya ukugxila ekuchanekeni koyilo, ukukhetha izinto ezifanelekileyo, kunye nokulandela iinkqubo ezichanekileyo zokuvelisa. Umzekelo, ukusebenzisaOEM aluminiyam die castingiqinisekisa iziphumo ezingaguqukiyo, ngakumbi kwizinto ezinzima njengealuminiyam die bephosa isigqubuthelo isithuthuthu. Ulawulo lomgangatho kunye nentsebenziswano yeengcali ngakumbi kukunceda ufezekise iindawo ezithembekileyo nezihlala ixesha elide.

Izinto eziphambili zokuThatha

- Qinisekisa iuyilo luchanekilengoko amalungu angena kakuhle. Sebenzisa izixhobo zeCAD ukufumana imilinganiselo echanekileyo.

- Khetha imathiriyeli ngokusekelwe kwiinto abanokuyenza. I-aluminiyam ilula, kwaye i-zinc yomelele.

- Landela amanyathelo okuvelisa afanelekileyo njengokugcina amaqondo obushushu engatshintshi. Sebenzisa oomatshini ukunqanda iimpazamo.

- Jonga kwaye uvavanye iindawo rhoqo ukufumana iingxaki kwangoko. Sebenzisa iiX-reyi okanye amaza esandi ukujonga imathiriyeli.

- Sebenza nabavelisi abanezakhono ukusebenzisa ulwazi lwabo. Banokunceda ukuphucula uyilo kunye nokwenza iindawo ezingcono.

Iingqwalasela zoYilo lweDie Casting CNC Machining Parts

Ukubaluleka kokuchaneka kwejometri

Ukuchaneka kwejometri kudlala indima ebalulekileyo ekuqinisekiseni ukusebenza kunye nokuthembeka kwebafe bephosa iindawo machining CNC. Kufuneka ugxininise kwimilinganiselo echanekileyo kunye nokunyamezela ngexesha lesigaba soyilo. Nokuba iimpazamo ezincinci zingakhokelela ekungalungelelaniseni okanye ukulungelelana okungafanelekanga, okuchaphazela ukusebenza kwemveliso yokugqibela. Ukusebenzisa isoftware yeCAD ekwinqanaba eliphezulu kukunceda wenze uyilo oluneenkcukacha ngemilinganiselo echanekileyo. Oku kuqinisekisa ukuba iinxalenye ziyahlangabezana neenkcukacha ezifunekayo kwaye zisebenze ngokungenamthungo kwizicelo ezijoliswe kuzo.

Ukuyila ukwenziwa

Ukuyila ukwenziwayenza lula imveliso kwaye inciphisa iindleko. Kuya kufuneka ujolise ekudaleni uyilo olulula ukuvelisa ngaphandle kokuthomalalisa umgangatho. Iimpawu ezifana nobukhulu bodonga obufanayo kunye nokutshintsha okugudileyo phakathi komphezulu kunceda ukuphepha iingxaki ngexesha lenkqubo yokufa. Ukongeza, ukunciphisa iijiyometri ezintsonkothileyo kunciphisa ixesha lomatshini kunye nenkcitho yezinto eziphathekayo. Ukusebenzisana neenjineli okanye abavelisi kuqinisekisa ukuba uyilo lwakho luhambelana nesakhono sezixhobo ezisetyenziselwa imveliso.

Ukuphepha iziphene zoyilo eziqhelekileyo

Iziphene zoyilo eziqhelekileyo zinokukhokelela kwiziphene kunye nokungaphumeleli kwiindawo zomatshini ze-CNC zokufa. Kufuneka ugweme iikona ezibukhali, njengoko zinokubangela uxinzelelo kunye nokunciphisa inxalenye. Ngokufanayo, ii-undercuts ezigqithisileyo okanye iinkcukacha ezintsonkothileyo zinokwenza nzima inkqubo yokuphosa kwaye yonyuse umngcipheko weziphene. Ukuqhuba uphononongo olucokisekileyo loyilo lwakho kukunceda uchonge imiba enokubakho kwangethuba. Ukusebenzisa izixhobo zokulinganisa kukuvumela ukuba uvavanye ukuba uyilo lusebenza njani phantsi kweemeko zehlabathi lokwenyani, ukuqinisekisa imveliso eyomeleleyo yokugqibela.

Ukukhethwa kwezinto ezikuMgangatho oPhezulu

Ukukhetha i-alloys efanelekileyo yokuphosa ukufa

Ukukhetha i-alloy efanelekileyo kubalulekile ekuveliseni iindawo zokuphosa ezikumgangatho ophezulu. Kuya kufuneka ugxininise kwizinto ezibonelela ngokugqwesa ukuqina kunye nokuqina. I-alloys ye-aluminiyam iyathandwa ngenxa yendalo yabo elula kunye nokuxhathisa ukubola. I-alloys ye-Zinc inika amandla aphezulu kwaye ifanelekile kuyilo oluntsonkothileyo. I-Magnesium alloys isebenza kakuhle kwizicelo ezifuna umlinganiselo ophezulu wamandla ukuya kubunzima.

Ingcebiso: Soloko udibanisa ialloyi kwiimfuno ezithile zeprojekthi yakho. Ngokomzekelo, ii-alloys ze-aluminium zifanelekile kumacandelo eemoto, ngelixa i-zinc alloys igqwesa kwiindawo zokuhlobisa.

Iimpawu zezinto eziphathekayo kunye nefuthe labo kumgangatho

Iimpawu zezinto eziphathekayokuchaphazela ngokuthe ngqo ukusebenza kunye nokuphila kwamalungu akho. Kuya kufuneka uqwalasele izinto ezifana namandla okuqina, ukuhanjiswa kwe-thermal, kunye nokumelana nokunxiba. Amandla aphezulu okuqina aqinisekisa ukuba inxalenye inokumelana noxinzelelo lomatshini. I-Thermal conductivity ibalulekile kwizicelo ezibandakanya ukutshintshwa kobushushu. Ukumelana nokunxiba kuthintela ukuthotywa kwangaphambi kwexesha kwiindawo ezinoxinzelelo oluphezulu.

- Iimpawu zezinto eziphambili zokuvavanya:

- Amandla kunye nokuqina

- Ukumelana nokubola

- Ubuchule

Ukuqonda ezi mpawu kukunceda ukhethe imathiriyeli ehlangabezana neemfuno zemveliso yakho kunye nokusingqongileyo.

Ukulinganisa iindleko kunye nokusebenza ekukhetheni izinto eziphathekayo

Ukulinganisa ixabiso kunye nokusebenza kubalulekile ekuphuculeni inkqubo yakho yemveliso. Kufuneka ujolise ekukhetheni imathiriyeli ehambisa umgangatho ofunekayo ngaphandle kokugqithisa uhlahlo lwabiwo-mali lwakho.Iingxube zeAluminiyamzingabizi kakhulu kwizicelo ezikhaphukhaphu, ngelixa i-zinc alloys inikezela ukufikeleleka kwiindawo eziphezulu zamandla.

Phawula: Kuphephe ukuthotyelwa kumgangatho wokonga iindleko. Ukukhetha izinto ezingafanelekanga kunokukhokelela kwiziphene kunye neendleko eziphezulu zokulondolozwa kamva.

Ngokuphonononga ngononophelo iimfuno zeprojekthi yakho, unokwenza ibhalansi elungileyo phakathi kweendleko kunye nokusebenza. Oku kuqinisekisa ukuba iindawo zakho zomatshini ze-CNC ziyahlangabezana neenjongo zobugcisa nezemali.

Iinkqubo zokwenziwa koMveliso zokuqinisekisa uMgangatho

Iinkqubo ezigqwesileyo zokuphosa ukufa

Unako ukufezekisaiziphumo zokuphosa ezikumgangatho ophezulungokulandela izenzo eziqinisekisiweyo. Qala ngokuqinisekisa uyilo lokufa lulungiselelwe ukuhamba kakuhle kwezinto. Oku kunciphisa umngcipheko weepokotho zomoya kunye neendawo ezingalinganiyo. Gcina amaqondo obushushu angaguqukiyo ngexesha lenkqubo yokuphosa ukuthintela iziphene ezifana nokushwabana okanye ukulwa. Gcoba rhoqo iimolds ukuba zigugile kwaye zikrazukile. Ukungunda okonakalisiweyo kunokuphazamisa ukuchaneka kwamalungu akho.

Ingcebiso: Shisisa izibumba phambi kokuba ugalele. Oku kunciphisa ukothuka kwe-thermal kwaye kuphucula ukugqitywa komphezulu wamalungu akho.

Sebenzisa iinkqubo ezizenzekelayo ukulawula isantya sokutofa kunye noxinzelelo. Ukuzenzekelayo kuqinisekisa ukuchaneka kunye nokunciphisa impazamo yomntu. Ukongezelela, hlambulula iimbumba ngokucokisekileyo emva komjikelo ngamnye. Ukwakhiwa kwentsalela kunokuchaphazela umgangatho weesanti ezilandelayo.

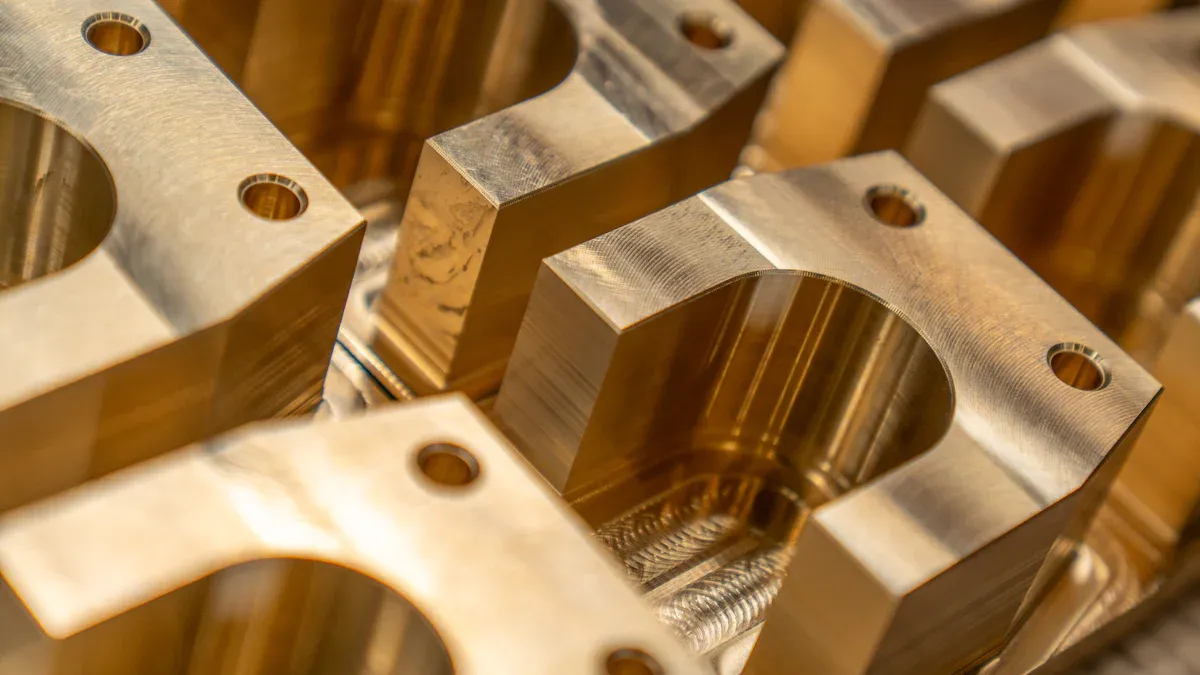

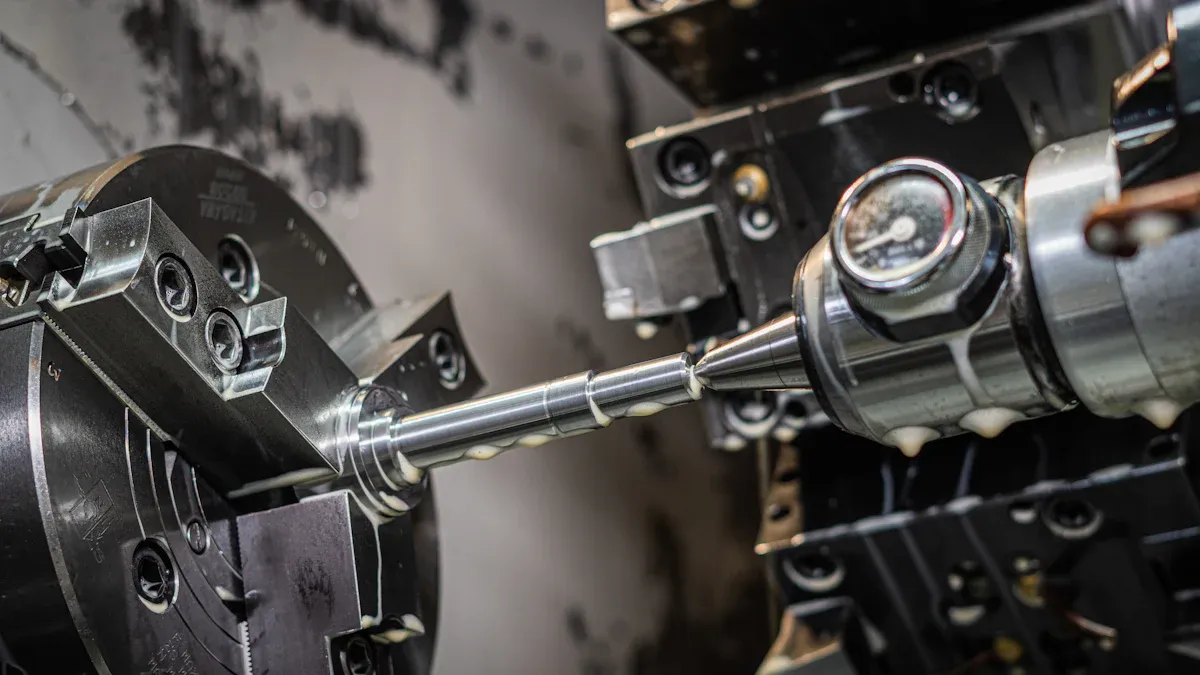

CNC machining ubuchule ngokuchanekileyo

Umatshini we-CNC udlala indima ebalulekileyoindima ekusulungekiseni kufa ukuphosa iindawo machining CNC. Kuya kufuneka usebenzise izixhobo zomatshini ezikhawulezayo ukufezekisa ukugqiba okugudileyo kunye nokunyamezelana okuqinileyo. Oomatshini be-CNC be-Multi-axis bakuvumela ukuba wenze iijiyometri ezinzima ngokulula. Aba matshini baphucula ukuchaneka kunye nokunciphisa imfuno yemisebenzi yesibini.

- Iindlela eziphambili zokuqwalasela:

- Sebenzisa izixhobo zokusika i-carbide ukwenzela ukuhlala kunye nokuchaneka.

- Lungiselela iindlela zesixhobo ukunciphisa ixesha lomatshini.

- Sebenzisa iinkqubo zokupholisa ukuthintela ukutshisa kakhulu ngexesha lomatshini.

Phawula: Rhoqo ulungelelanisa oomatshini bakho be-CNC. Ulungelelwaniso olufanelekileyo luqinisekisa iziphumo ezingaguqukiyo kwaye lunqanda iimpazamo ezinobungakanani.

Tyala kwisoftware ephucukileyo yokucwangcisa oomatshini beCNC. Le software ikunceda ukulinganisa inkqubo yomatshini kwaye uchonge imiba enokubakho ngaphambi kokuba imveliso iqale.

Ukunciphisa iziphene ngexesha lemveliso

Iziphene zinokujongela phantsi umgangatho weendawo zomatshini ze-CNC zokufa. Kuya kufuneka ugxile ekuchongeni nasekususeni imiba eqhelekileyo efana ne-porosity, iintanda, kunye nokungafezeki komphezulu. Yenza uhlolo olucokisekileyo kwinqanaba ngalinye lemveliso. Ukufunyanwa kwangoko kukuvumela ukuba ulungise iingxaki ngaphambi kokuba zinyuke.

Sebenzisa amanyathelo okulawula umgangatho afana novavanyo lwe-X-ray kunye nokuhlolwa kwe-ultrasonic. Ezi ndlela zikunceda ukuba ubone iziphene zangaphakathi ezingabonakali ngeso lenyama. Gcina ulawulo olungqongqo kwimiba yokusingqongileyo efana nokufuma kunye nobushushu. Ukuguquguquka kunokuchaphazela izinto eziphathekayo kwaye kukhokelela ekungahambelani.

Biza ngaphandle: Ukuqeqesha iqela lakho kubuchule bokuthintela iziphene kubalulekile. Abasebenzi abanezakhono banokubona imiba ngokukhawuleza kwaye bathathe amanyathelo okulungisa.

Sebenzisa ulawulo lwenkqubo yezibalo (SPC) ukujonga idatha yemveliso. I-SPC ikunceda ukuba uchonge iintsingiselo kwaye wenze uhlengahlengiso ukugcina umgangatho. Okokugqibela, sebenzisana nababoneleli bakho ukuqinisekisa ukuba imathiriyeli ekrwada iyahlangabezana neenkcukacha zakho. Izinto ezikumgangatho ophezulu zinciphisa amathuba okuba neziphene ngexesha lemveliso.

Indima yonyango lobushushu kunye neengubo zokufa

Unyango lobushushu kunye neengubo zokufa zidlala indima ebalulekileyo ekwandiseni umgangatho kunye nokuqina kweendawo zomatshini ze-CNC zokufa. Ezi nkqubo ziphucula iipropati zezinto eziphathekayo, zandisa ubomi besixhobo, kwaye ziqinisekisa ukusebenza okungaguqukiyo kwizicelo ezifunwayo. Ukuqonda ukubaluleka kwazo kukunceda wenze izigqibo ezizizo ngexesha lemveliso.

Izibonelelo zoNyango loBubushushu

Ukunyangwa kobushushu kuguqula iipropathi ezibonakalayo kunye nomatshini wesinyithi, okwenza ukuba zifaneleke ngakumbi kwizicelo ezithile. Ungasebenzisa le nkqubo ukuphucula amandla, ubulukhuni, kunye nokumelana nokunxiba.

- Iinzuzo eziphambili zonyango lobushushu:

- Amandla Ongeziweyo: Ukunyangwa kobushushu kwandisa amandla okuqina kwamalungu, okubavumela ukuba bamelane nemithwalo ephezulu.

- Ubulukhuni obuphuculweyo: Amalungu anyangwayo axhathise inguquko kunye nokuguga, eqinisekisa ubomi obude.

- Ukuphelisa Uxinzelelo: Inkqubo inciphisa uxinzelelo lwangaphakathi olubangelwa ukuphosa okanye umatshini, ukuthintela ukuqhekeka kunye nokuphazamiseka.

Ingcebiso: Khetha indlela efanelekileyo yonyango lokushisa ngokusekelwe kwizinto zakho kunye nesicelo. Iindlela eziqhelekileyo zibandakanya ukucima, ukucima, kunye nokuthoba.

Umzekelo, ukucima okulandelwa kukuthoba kunokudala ulungelelwaniso phakathi kobulukhuni kunye nokuqina, kuyenze ilungele izithuthi okanye izixhobo ze-aerospace.

Ukubaluleka kweDie Coatings

Iingubo zokufa zikhusela isikhunta kwaye ziphucule umgangatho weendawo ezityhidiweyo. Ezi zogquma zinciphisa ingxabano, zithintele ukuguga, kwaye ziphucule ukugqitywa komphezulu weemveliso zakho.

- Kutheni kufuneka usebenzise iingubo zokufa:

- I-Friction eNcitshisiweyo: Iingubo zokwaleka zinciphisa ingxabano phakathi kwesinyithi esityhidiweyo kunye nomphezulu wokufa, uqinisekisa ukuhamba kwezinto ezigudileyo.

- Ubomi besixhobo esandisiweyo: Iileya ezikhuselayo zikhusela ukufa kumonakalo obushushu kunye noomatshini, ukunciphisa iindleko zokugcinwa.

- UkuGqiba komphezulu ophuculweyo: Iifa ezigqunyiweyo zivelisa iindawo ezineziphene ezimbalwa, ezinje ngemigangatho erhabaxa okanye iporosity.

Biza ngaphandle: Hlola rhoqo kwaye usebenzise kwakhona iicolethi zokufa ukugcina ukusebenza kwazo. Iingubo ezigugileyo zingakhokelela kwiziphumo ezingahambelaniyo kunye namazinga aphezulu esiphako.

Ukudibanisa unyango lobushushu kunye Die Coatings

Xa udibanisa unyango lokushisa kunye neengubo zokufa, ufezekisa iziphumo eziphezulu. Amalungu aphethwe ngubushushu afumana amandla kunye nokuqina okufunekayo kwizicelo ezifunayo, ngelixa i-coated dies iqinisekisa ukuchaneka kunye nokuhambelana ngexesha lemveliso.

| Inkqubo | INzuzo yokuqala | Umzekelo weSicelo |

|---|---|---|

| Unyango lobushushu | Yandisa amandla kunye nobunzima | Amacandelo enjini yeemoto |

| Die Coatings | Yongeza umphezulu wokugqiba kunye nobomi besixhobo | Izivalo ze-elektroniki ezichaneke kakhulu |

Ngokudibanisa ezi nkqubo kwi-workflow yakho yokuvelisa, unokuvelisa iindawo zomatshini ze-CNC ezikumgangatho ophezulu ezihlangabezana nemigangatho yoshishino.

Phawula: Dibana neengcaphephe ukufumanisa eyona ndibaniselwano yonyango lobushushu kunye neengubo zokufa zeprojekthi yakho ethile. Isikhokelo sabo siqinisekisa iziphumo ezilungileyo kunye nokusebenza kakuhle kweendleko.

Amanyathelo oLawulo loMgangatho kwiDie Casting CNC Machining

Iindlela zokuhlola ukuchaneka kwe-dimensional

Ukuchaneka komgangathoiqinisekisa ukuba amalungu ayalingana kwaye asebenza njengoko kucetyiwe. Ungasebenzisa iindlela ezininzi zokuhlola ukuze uqinisekise imilinganiselo yeendawo zomatshini ze-CNC zokufa. Enye indlela esebenzayo kukulungelelanisa oomatshini bokulinganisa (i-CMMs). Aba matshini balinganisa imilinganiselo yenxalenye ngokuchaneka okuphezulu. Bayakwazi ukubona nokona kunxaxhile kuncinci kwiinkcukacha zoyilo.

Esinye isixhobo esiluncedo ziinkqubo zokuhlola amehlo. Ezi nkqubo zisebenzisa iikhamera kunye nelaser ukuskena umphezulu wenxalenye. Benza imodeli ye-3D onokuyithelekisa noyilo lwangaphambili. Le ndlela iyakhawuleza kwaye isebenza kakuhle kwiijometri ezintsonkothileyo.

Ingcebiso: Soloko ujonga imilinganiselo ebalulekileyo kuqala. Le yimilinganiselo echaphazela ngokuthe ngqo ukusebenza kwenxalenye.

Ukusebenzisa iigeyiji neecaliper yenye indlela esebenzayo. Ezi zixhobo zilula ukusebenzisa kwaye zibonelela ngeziphumo ezikhawulezayo. Nangona kunjalo, zifaneleke kakhulu kwimilinganiselo esisiseko. Kwiindawo ezinzima ngakumbi, ubuchule obuphambili njenge-CMM okanye iinkqubo zamehlo zithembeke ngakumbi.

Iindlela zokuvavanya imfezeko yezinto eziphathekayo

Ingqibelelo yezinto eziphathekayoimisela ukomelela kunye nokuqina kwamalungu akho. Ungasebenzisa iindlela ezininzi zokuvavanya ukuqinisekisa ukuba izixhobo ziyahlangabezana nemigangatho yomgangatho. Uvavanyo olungonakalisi (NDT) yenye yezona ndlela zisebenzayo. Ikuvumela ukuba ukhangele iziphene zangaphakathi ngaphandle kokonakalisa inxalenye. Iindlela eziqhelekileyo ze-NDT ziquka ukuhlolwa kwe-X-ray kunye novavanyo lwe-ultrasonic.

- Ukuhlolwa kweX-reyi: Le ndlela ibonisa iimpazamo zangaphakathi ezifana ne-porosity okanye iintanda. Iluncedo ngakumbi kwiindawo ezinoyilo oluntsonkothileyo.

- Uvavanyo lwe-ultrasonic: Obu buchule busebenzisa amaza esandi ukubona iziphene. Isebenza kakuhle ekuchongeni i-voids okanye ukungahambelani kwezinto.

Kwiziphene zomgangatho ophezulu, ungasebenzisa uvavanyo lokungena kwedayi. Le ndlela ibandakanya ukusebenzisa idayi kumphezulu wenxalenye. Idayi ingena kwiintanda okanye ukungafezeki, ibenze babonakale phantsi kokukhanya kwe-UV.

Biza ngaphandle: Uvavanyo lwemathiriyeli rhoqo lukunceda ugcine umgangatho ongaguqukiyo. Kwakhona kunciphisa umngcipheko wokungaphumeleli kwenxalenye kwizicelo ezibalulekileyo.

Uvavanyo lomatshini lelinye inyathelo elibalulekileyo. Uvavanyo olunjengokuqina kokuqina kunye novavanyo lokuqina luvavanya amandla esixhobo sokumelana noxinzelelo. Olu vavanyo luqinisekisa ukuba iinxalenye zinokusebenza ngokuthembekileyo phantsi kweemeko zehlabathi lokwenyani.

Ukuphumeza uhlolo lwenkqubo

Ukuhlolwa kwenkqubo kukunceda ukuba ubambe iziphene ekuqaleni kwenkqubo yemveliso. Le ndlela yonga ixesha kwaye inciphisa inkcitho. Ungasebenzisa iinkqubo ezizenzekelayo ukujonga iiparamitha eziphambili ngexesha lokuvelisa. Umzekelo, abenzi boluvo banokulandelela ubushushu, uxinzelelo, kunye nokuhamba kwezinto ngexesha lokufa.

Ukuhlola okubonwayo nako kuxabisekile. Qeqesha iqela lakho ukuba lichonge iziphene eziqhelekileyo ezifana nokungafezeki komphezulu okanye ukungahambi kakuhle. Ukuqhuba olu vavanyo rhoqo ngamathuba athile kuqinisekisa ukuba imiba isonjululwa ngokukhawuleza.

Phawula: Ukuhlolwa kwenkqubo akuyiyo indawo yokuhlolwa komgangatho wokugqibela. Iyazixhasa ngokuchonga iingxaki ngaphambi kokuba zande.

Ulawulo lwenkqubo yeStatistical (SPC) sesinye isixhobo esisebenzayo. I-SPC ibandakanya ukuqokelela kunye nokuhlalutya idatha evela kwinkqubo yokuvelisa. Ikunceda ukuba uchonge iintsingiselo kwaye wenze uhlengahlengiso ukugcina umgangatho.

Ngokudibanisa iinkqubo ezizenzekelayo, iitshekhi ezibonakalayo, kunye ne-SPC, unokwenza isicwangciso esiqinileyo sokuhlola kwinkqubo. Le ndlela iqinisekisa ukuba iinxalenye zakho zomatshini ze-CNC ziyahlangabezana neyona migangatho iphezulu yomgangatho.

Ukubaluleka kokulinganisa umatshini kunye nokugcinwa kokuthintela

Ulungelelwaniso lomatshini kunye nokugcinwa kothintelo kubalulekile ekuveliseni iindawo zomatshini ze-CNC ezikumgangatho ophezulu. Olu qheliselo luqinisekisa ukuba isixhobo sakho sisebenza ngokucokisekileyo, sinciphisa iimpazamo kwaye sandise ubomi boomatshini bakho. Ukungazihoyi kunokukhokelela ekungachaneni kwemilinganiselo, ukunyuka kwexesha lokunciphisa, kunye neendleko eziphezulu zemveliso.

Kutheni kubalulekile ukulinganisa umatshini

Ulungelelwaniso luqinisekisa ukuba oomatshini bakho bavelisa iindawo ezinobungakanani obuchanekileyo kunye nokunyamezelana. Ngokuhamba kwexesha, ukunxiba kunye nokukrazula kunokubangela ukuba izixhobo zakho zikhukuliseke kwiisetingi zayo zangaphambili. Oku kukhukuliseka kuchaphazela ukuchaneka kwamalungu akho, okukhokelela kwiziphene kunye nokungahambi kakuhle.

- Iinzuzo eziphambili zokulinganisa rhoqo:

- Ukuchaneka okuphuculweyo: Iqinisekisa ukuba iindawo ziyahlangabezana nemigaqo yoyilo.

- Umgangatho ohambelanayo: Ukunciphisa ukuhluka kwimveliso.

- Inkunkuma eNcitshisiweyo: Yehlisa ilahleko yezinto eziphathekayo ngenxa yeempazamo.

Ingcebiso: Cwangcisa iitshekhi zolungelelwaniso ngamaxesha aqhelekileyo. Sebenzisa izixhobo eziqinisekisiweyo kunye nemigangatho yokuqinisekisa ukuchaneka komatshini wakho.

Umzekelo, umatshini we-CNC ongalungiswanga unokuvelisa iindawo ezinomgangatho ongalinganiyo okanye imilinganiselo engalunganga. Le miba inokuphazamisa ukusebenza kwemveliso yakho yokugqibela.

Indima yoLondolozo loThintelo

Ulondolozo lothintelo lubandakanya ukuhlolwa okuqhelekileyo kunye nokusevisa ukugcina oomatshini bakho bekwimeko efanelekileyo. Le ndlela isebenzayo ikunceda ukuba uchonge imiba enokubakho ngaphambi kokuba inyuke ibe yingxaki enkulu.

- Imisebenzi yolondolozo ebalulekileyo:

- Ukuthambisa: Igcina iindawo ezihambayo zihamba kakuhle.

- Ukucoca: Isusa inkunkuma enokuchaphazela ukusebenza.

- Ukuhlolwa: Uchonga ukuguga kumalungu abalulekileyo.

- Ukutshintshwa: Iqinisekisa ukuba iindawo ezigugileyo zitshintshwa ngokukhawuleza.

Biza ngaphandle: Umatshini ogcinwe kakuhle usebenza ngokufanelekileyo, ukunciphisa ukusetyenziswa kwamandla kunye neendleko zokuvelisa.

Ukudibanisa uCalibration kunye noLondolozo

Xa udibanisa ukulinganisa kunye nokugcinwa kokukhusela, udala inkqubo eyomeleleyo yokuqinisekisa umgangatho. Ukulinganisa kuqinisekisa ukuchaneka, ngelixa ukulungiswa kugcina oomatshini bakho bethembekile kwaye besebenza kakuhle.

| Ziqhelise | INzuzo yokuqala | Ukuphindaphinda |

|---|---|---|

| Ulungelelwaniso lomatshini | Iqinisekisa ukuchaneka komda | Rhoqo kwiinyanga ezi-3-6 |

| ULondolozo oluThintelayo | Yandisa ubomi bomatshini | Ngeveki okanye ngenyanga |

Phawula: Gcina iirekhodi ezineenkcukacha zolungelelwaniso kunye nokugcinwa kwemisebenzi. Ezi rekhodi zikunceda ukulandelela iintsingiselo zentsebenzo kwaye ucwangcise inkonzo yexesha elizayo.

Indlela Yokuzenza Ezi Ziqheliselo

Qala ngokwenza ishedyuli yogcino elungiselelwe izixhobo zakho. Bandakanya imisebenzi ethile kunye neefrikhwensi ezicetyiswayo. Qeqesha iqela lakho ukuba lenze ulondolozo olusisiseko kwaye liqaphele iimpawu zokunxila. Ukulungelelaniswa, tyala imali kwizixhobo zokulinganisa ezikumgangatho ophezulu kunye neqabane namagcisa aqinisekisiweyo.

Isikhumbuzo se-Emoji:

Ixesha lokuposa: Jun-06-2025