Ukuqinisekisa izingabafe bephonsa CNC machining izingxenyekubalulekile ukuze uthole ukuqina nokunemba emikhiqizweni yakho yokugcina. Izingxenye ezenziwe kabi zingaholela ezinkingeni zokusebenza, izindleko eziphezulu, ngisho nezingozi zokuphepha. Kufanele usebenzise indlela ehlelekile yokugcina amazinga aphezulu. Lokhu kuhlanganisa ukugxila ekunembeni komklamo, ukukhetha izinto ezifanele, nokulandela izinqubo zokukhiqiza ezinembayo. Ngokwesibonelo, ngokusebenzisaOEM aluminium die Castingiqinisekisa imiphumela engaguquki, ikakhulukazi ezintweni eziyinkimbinkimbi njenge-aluminium die casting isithuthuthu ikhava. Ukulawulwa kwekhwalithi nokusebenzisana kochwepheshe kuphinde kukusize uzuze izingxenye ezithembekile nezihlala isikhathi eside.

Okuthathwayo Okubalulekile

- Qiniseka ukuthiumklamo unembilengakho izingxenye zilingana kahle. Sebenzisa amathuluzi e-CAD ukuze uthole izilinganiso eziqondile.

- Khetha izinto ezisekelwe kukhoabangakwenza. I-Aluminium ilula, futhi i-zinc inamandla.

- Landela izinyathelo ezinhle zokukhiqiza ezifana nokugcina amazinga okushisa engashintshi. Sebenzisa imishini ukugwema amaphutha.

- Hlola futhi uhlole izingxenye ngokuvamile ukuze uthole izinkinga kusenesikhathi. Sebenzisa ama-X-ray noma amaza omsindo ukuhlola izinto.

- Sebenzisana nabakhiqizi abanekhono ukusebenzisa ulwazi lwabo. Bangasiza ukuthuthukisa imiklamo nokwenza izingxenye ezingcono.

Ukucatshangelwa kwedizayini yezingxenye ze-Die Casting CNC Machining

Ukubaluleka kokunemba kwejometri

Ukunemba kweJiyomethri kudlala indima ebalulekile ekuqinisekiseni ukusebenza nokuthembeka kwebafe bephonsa CNC machining izingxenye. Udinga ukugxila kubukhulu obunembile nokubekezelelana phakathi nesigaba sokuklama. Ngisho namaphutha amancane angaholela ekuqondeni ngendlela engafanele noma ukulingana okungafanele, okuthinta ukusebenza komkhiqizo wokugcina. Ukusebenzisa isofthiwe ye-CAD ethuthukisiwe kukusiza ukuthi udale imiklamo enemininingwane enezilinganiso eziqondile. Lokhu kuqinisekisa ukuthi izingxenye zihlangabezana nokucaciswa okudingekayo futhi zisebenze ngaphandle komthungo ezinhlelweni ezihlosiwe.

Idizayinelwe ukwenziwa

Idizayinelwe ukwenziwayenza ukukhiqiza kube lula futhi kunciphisa izindleko. Kufanele uhlose ukudala imiklamo okulula ukuyikhiqiza ngaphandle kokubeka engcupheni ikhwalithi. Izici ezifana nokujiya kodonga olulinganayo kanye noshintsho olubushelelezi phakathi kwezindawo zisiza ukugwema izinkinga phakathi nenqubo yokufaka ukufa. Ukwengeza, ukunciphisa amajiyometri ayinkimbinkimbi kunciphisa isikhathi sokusebenza kanye nokuchithwa kwezinto ezibonakalayo. Ukusebenzisana nonjiniyela noma abakhiqizi kuqinisekisa ukuthi imiklamo yakho ihambisana namakhono ezinto ezisetshenziswayo ezisetshenziselwa ukukhiqiza.

Ukugwema amaphutha edizayini ajwayelekile

Amaphutha omklamo ojwayelekile angaholela ekushiyekeni nasekungasebenzi kahle ezingxenyeni zemishini ye-CNC yokufa. Kufanele ugweme amakhona abukhali, njengoba angabangela ukugxila kwengcindezi futhi enze buthaka ingxenye. Ngokufanayo, ama-undercuts ngokweqile noma imininingwane eyinkimbinkimbi ingase ixake inqubo yokulingisa futhi yandise ubungozi bokulimala. Ukwenza isibuyekezo esiphelele somklamo wakho kukusiza ukuthi ubone izinkinga ezingaba khona kusenesikhathi. Ukusebenzisa amathuluzi okulingisa kukuvumela ukuthi uhlole ukuthi umklamo usebenza kanjani ngaphansi kwezimo zomhlaba wangempela, uqinisekise umkhiqizo wokugcina oqinile.

Ukukhetha Okubalulekile Kwezingxenye Ezisezingeni Eliphezulu

Ukukhetha ama-alloys afanele wokusakaza okufa

Ukukhetha ingxubevange efanele kubalulekile ekukhiqizeni izingxenye zokusakaza ezifayo zekhwalithi ephezulu. Kufanele ugxile ezintweni ezinikeza ukuqina okuhle kakhulu nokuqina. Ama-alloys e-aluminium adumile ngenxa yemvelo yawo engasindi kanye nokumelana nokugqwala. Ama-zinc alloys anikeza amandla aphakeme futhi alungele imiklamo eyinkimbinkimbi. Ama-alloys e-Magnesium asebenza kahle ezinhlelweni ezidinga izilinganiso eziphezulu zamandla nesisindo.

Ithiphu: Hlala uqondanisa ingxubevange nezimfuneko ezithile zephrojekthi yakho. Isibonelo, ama-alloys e-aluminium aphelele ezingxenyeni zezimoto, kuyilapho ama-zinc alloys ehamba phambili ezingxenyeni zokuhlobisa.

Izinto ezibonakalayo kanye nomthelela wazo kukhwalithi

Izinto ezibonakalayokuthinta ngqo ukusebenza nempilo yezingxenye zakho. Udinga ukucabangela izici ezinjengamandla aqinile, ukuqhutshwa kwe-thermal, nokumelana nokugqoka. Amandla aqinile aphezulu aqinisekisa ukuthi ingxenye ingakwazi ukumelana nokucindezeleka komshini. I-Thermal conductivity ibalulekile ezinhlelweni ezibandakanya ukudluliswa kokushisa. Ukumelana nokugqoka kuvimbela ukuwohloka ngaphambi kwesikhathi ezindaweni ezingqubuzana kakhulu.

- Izinto ezibonakalayo ezibalulekile okufanele zihlolwe:

- Amandla nokuqina

- Ukumelana nokugqwala

- Ukusebenziseka kalula

Ukuqonda lezi zakhiwo kukusiza ukuthi ukhethe izinto ezihlangabezana nezidingo zomkhiqizo wakho zokusebenza nezemvelo.

Ukulinganisa izindleko nokusebenza ekukhetheni okubalulekile

Ukulinganisa izindleko nokusebenza kubalulekile ukuze uthuthukise inqubo yakho yokukhiqiza. Kufanele uhlose ukukhetha izinto eziletha ikhwalithi edingekayo ngaphandle kokudlula isabelomali sakho.Ama-alloys e-aluminiumayabiza kakhulu ekusetshenzisweni okungasindi, kuyilapho ama-zinc alloys anikeza ukufinyeleleka kwezingxenye eziqine kakhulu.

Qaphela: Gwema ukuyekethisa ikhwalithi ukuze wonge izindleko. Ukukhetha okungalungile kwempahla kungaholela ekulimaleni nasezindlekweni zokunakekela eziphezulu kamuva.

Ngokuhlola ngokucophelela izidingo zephrojekthi yakho, ungafinyelela ibhalansi efanele phakathi kwezindleko nokusebenza. Lokhu kuqinisekisa ukuthi izingxenye zakho zemishini ye-CNC ziyahlangabezana nezinjongo zobuchwepheshe nezezezimali.

Izinqubo Zokukhiqiza Zokuqinisekisa Ikhwalithi

Imikhuba emihle kakhulu ekulingiseni ukufa

Ungakwazi ukufezaimiphumela yekhwalithi ephezulu yokulingisangokulandela imikhuba efakazelwe. Qala ngokuqinisekisa ukuthi idizayini ye-die ilungiselelwe ukugeleza kwezinto ezibushelelezi. Lokhu kunciphisa ingozi yamaphakethe omoya kanye nezindawo ezingalingani. Gcina amazinga okushisa angaguquguquki phakathi nenqubo yokulingisa ukuze uvimbele amaphutha afana nokuncipha noma ukulwa. Njalo hlola isikhunta ukuthi sigugile futhi sidabukile. Izibungu ezilimele zingafaka engcupheni ukunemba kwezingxenye zakho.

Ithiphu: Shisisa isikhunta ngaphambi kokubunjwa. Lokhu kunciphisa ukushaqeka okushisayo futhi kuthuthukisa isiphetho esiphezulu sezingxenye zakho.

Sebenzisa amasistimu azenzakalelayo ukulawula isivinini somjovo nokucindezela. I-Automation iqinisekisa ukunemba futhi inciphisa amaphutha abantu. Ukwengeza, hlanza isikhunta kahle ngemva komjikelezo ngamunye. Ukunqwabelana kwezinsalela kungathinta ikhwalithi yabalingiswa abalandelayo.

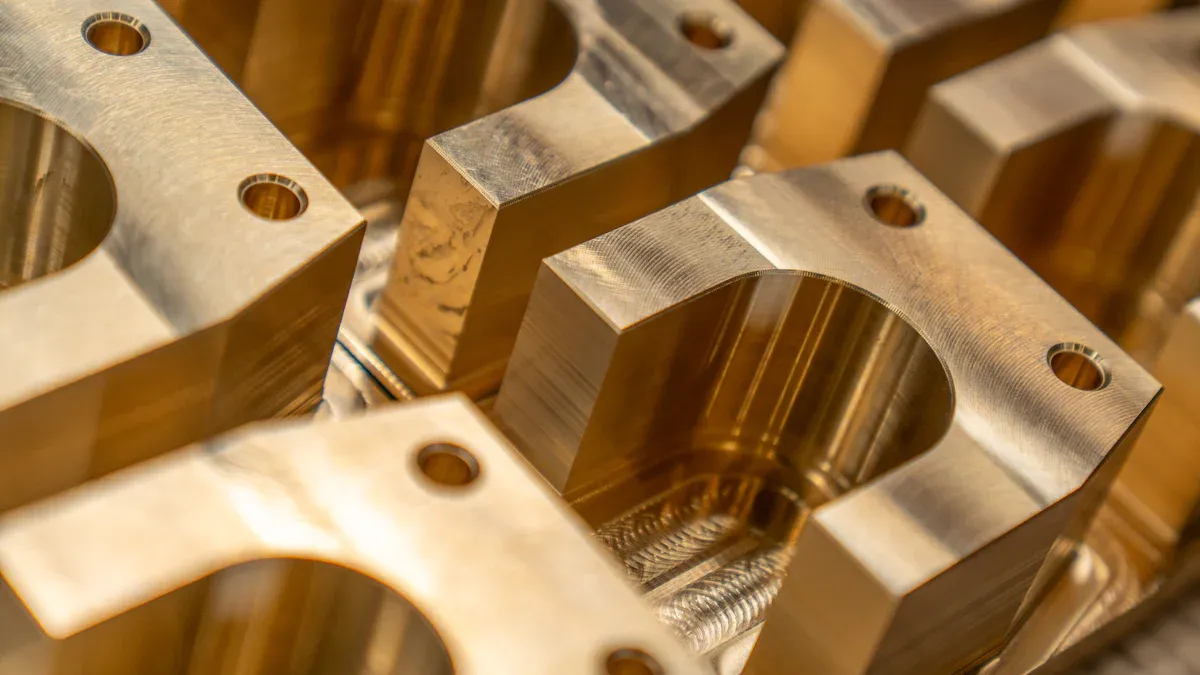

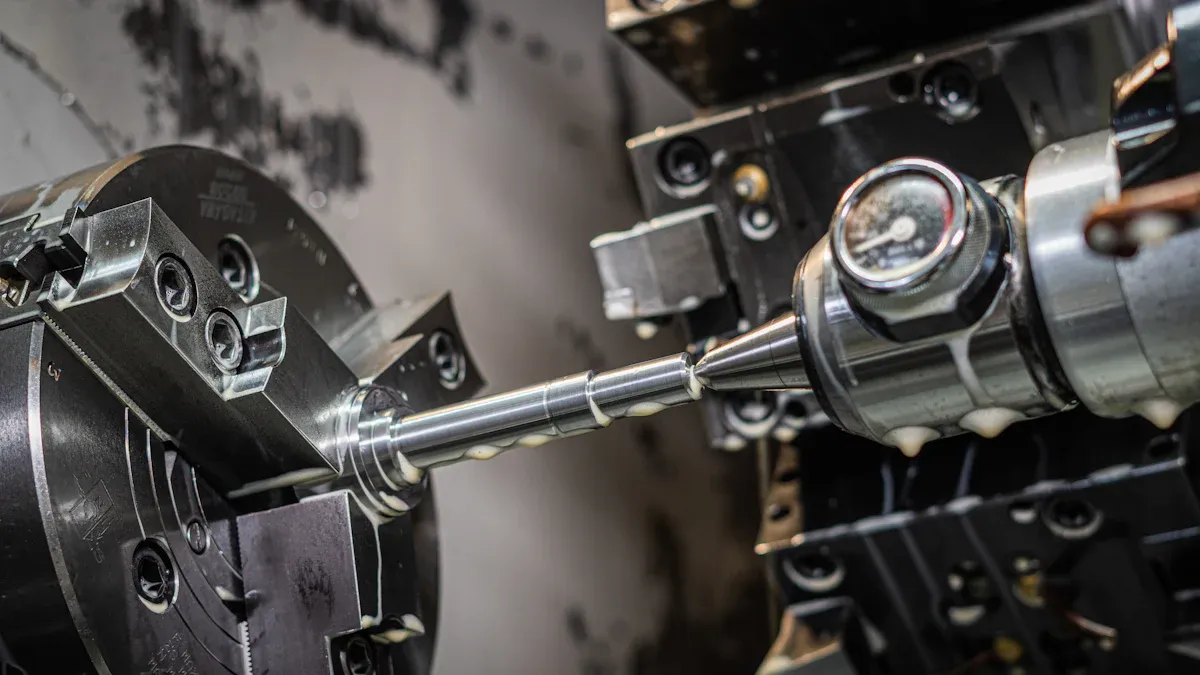

Amasu omshini we-CNC wokunemba

Imishini ye-CNC idlala indima ebalulekileindima ekucwengisiseni izingxenye zemishini ye-CNC. Kufanele usebenzise amathuluzi omshini wejubane eliphezulu ukuze ufinyelele ukuqedwa okubushelelezi nokubekezelelana okuqinile. Imishini ye-Multi-axis CNC ikuvumela ukuthi udale amajiyometri ayinkimbinkimbi kalula. Le mishini ithuthukisa ukunemba futhi inciphise isidingo sokusebenza kwesibili.

- Amasu asemqoka okufanele acatshangelwe:

- Sebenzisa amathuluzi okusika i-carbide ukuze uqine futhi unembile.

- Lungiselela izindlela zamathuluzi ukuze unciphise isikhathi somshini.

- Sebenzisa amasistimu okupholisa ukuvimbela ukushisa ngokweqile ngesikhathi somshini.

Qaphela: Linganisa njalo imishini yakho ye-CNC. Ukulinganisa okulungile kuqinisekisa imiphumela engaguquki futhi kuvimbela amaphutha wobukhulu.

Tshala imali ku-software ethuthukisiwe yokuhlela imishini ye-CNC. Le softhiwe ikusiza ukuthi ulingise inqubo yokwenza imishini futhi uhlonze izinkinga ezingaba khona ngaphambi kokuthi ukukhiqizwa kuqale.

Ukunciphisa amaphutha ngesikhathi sokukhiqiza

Ukukhubazeka kungabukela phansi ikhwalithi yezingxenye zakho zemishini ye-CNC yokufa. Kufanele ugxile ekuhlonzeni nasekususeni izinkinga ezivamile ezifana nokuvuleka, ukuqhekeka, nokungapheleli kwendawo. Yenza ukuhlolwa okuphelele kuzo zonke izigaba zokukhiqiza. Ukutholwa kusenesikhathi kukuvumela ukuthi ubhekane nezinkinga ngaphambi kokuthi zande.

Sebenzisa izinyathelo zokulawula ikhwalithi njengokuhlola i-X-ray nokuhlolwa kwe-ultrasonic. Lezi zindlela zikusiza ukuthi ubone iziphambeko zangaphakathi ezingabonakali ngeso lenyama. Gcina ukulawula okuqinile ezicini zendawo ezungezile njengomswakama nezinga lokushisa. Ukushintshashintshashintsha kungase kube nomthelela ezintweni ezibonakalayo futhi kuholele ekushintshashintsheni.

I-callout: Ukuqeqesha ithimba lakho ngamasu okuvikela ukukhubazeka kubalulekile. Ama-opharetha anamakhono angabona izinkinga ngokushesha futhi athathe isinyathelo sokulungisa.

Sebenzisa isilawuli senqubo yezibalo (SPC) ukuze ugade idatha yokukhiqiza. I-SPC ikusiza ukuthi ubone amathrendi futhi wenze izinguquko ukuze ugcine ikhwalithi. Okokugcina, sebenzisana nabahlinzeki bakho ukuze uqinisekise ukuthi izinto zokusetshenziswa zihlangabezana nezimfuneko zakho. Izinto ezisezingeni eliphezulu zinciphisa amathuba okuba neziphambeko ngesikhathi sokukhiqiza.

Indima yokwelapha ukushisa kanye nezingubo zokufa

Ukwelashwa kokushisa kanye nezingubo zokufa kudlala indima ebalulekile ekuthuthukiseni ikhwalithi nokuqina kwezingxenye zemishini ye-CNC yokufa. Lezi zinqubo zithuthukisa izakhiwo zezinto ezibonakalayo, zandisa impilo yamathuluzi, futhi ziqinisekisa ukusebenza okungaguquki ezinhlelweni ezifunwayo. Ukuqonda ukubaluleka kwazo kukusiza ukuthi wenze izinqumo ezinolwazi ngesikhathi sokukhiqiza.

Izinzuzo Zokwelashwa Kokushisa

Ukwelashwa kokushisa kushintsha izici ezingokomzimba nezomshini zezinsimbi, kuzenze zifaneleke kakhulu izinhlelo zokusebenza ezithile. Ungasebenzisa le nqubo ukuthuthukisa amandla, ubulukhuni, nokumelana nokugqoka.

- Izinzuzo eziyinhloko zokwelapha ukushisa:

- Amandla Athuthukisiwe: Ukwelashwa kokushisa kwandisa amandla ezingxenye, okuzivumela ukuthi zimelane nemithwalo ephakeme.

- Ukuqina Okuthuthukisiwe: Izingxenye ezilashiwe zimelana nokuguga nokuguga, okuqinisekisa ubude bempilo ende.

- Ukunciphisa Ingcindezi: Inqubo inciphisa ukucindezeleka kwangaphakathi okubangelwa ukusakaza noma umshini, ukuvimbela ukuqhekeka nokuhlanekezela.

Ithiphu: Khetha indlela efanele yokwelapha ukushisa ngokusekelwe ezintweni zakho kanye nesicelo sakho. Izindlela ezijwayelekile zifaka i-anneal, ukucisha, kanye nokushisa.

Isibonelo, ukucisha okulandelwa ukufuthelana kungadala ukulingana phakathi kokuqina nokuqina, kukwenze kube ilungele izingxenye zezimoto noma ze-aerospace.

Ukubaluleka kwe-Die Coatings

Izingubo zokufa zivikela isikhunta futhi zithuthukise ikhwalithi yezingxenye eziphonsiwe. Lawa ma-coating anciphisa ukungqubuzana, avimbele ukuguga, futhi athuthukise isiphetho esingaphezulu semikhiqizo yakho.

- Kungani kufanele usebenzise ama-die coatings:

- I-Friction Encishisiwe: Izembatho zinciphisa ukungqubuzana phakathi kwensimbi encibilikisiwe nendawo yokufa, iqinisekisa ukugeleza kwezinto ezibushelelezi.

- Impilo Yethuluzi Enwetshiwe: Izendlalelo ezivikelayo zivikela ukufa ekulimaleni okushisayo nokwemishini, zehlisa izindleko zokuyilungisa.

- I-Surface Finish ethuthukisiwe: Ama-coated dies akhiqiza izingxenye ezinokukhubazeka okumbalwa, njengendawo emagebhugebhu noma i-porosity.

I-callout: Hlola njalo futhi usebenzise kabusha ama-die coating ukuze ugcine ukusebenza kwawo. Izingubo ezigugile zingaholela emiphumeleni engahambisani namazinga aphezulu okukhubazeka.

Ukuhlanganisa Ukwelashwa Kokushisa kanye Nezingubo Zokufa

Uma uhlanganisa ukwelashwa kokushisa nezingubo zokufa, ufinyelela imiphumela ephakeme kakhulu. Izingxenye eziphethwe ukushisa zithola amandla nokuqina okudingekayo ekusetshenzisweni okudingayo, kuyilapho i-coated dies iqinisekisa ukunemba nokuvumelana ngesikhathi sokukhiqiza.

| Inqubo | Inzuzo Eyinhloko | Isibonelo sohlelo lokusebenza |

|---|---|---|

| Ukwelashwa Kokushisa | Yandisa amandla nobulukhuni | Izingxenye zenjini yezimoto |

| Ama-Die Coatings | Ithuthukisa ukuphela kwendawo nempilo yamathuluzi | Izivalo ze-elekthronikhi ezinembayo eziphezulu |

Ngokuhlanganisa lezi zinqubo ekuhambeni komsebenzi wakho wokukhiqiza, ungakhiqiza izingxenye zomshini ze-CNC zekhwalithi ephezulu ezihlangabezana nezindinganiso zomkhakha.

Qaphela: Xhumana nochwepheshe ukuze uthole inhlanganisela engcono kakhulu yokwelapha ukushisa kanye nama-die coatings ephrojekthi yakho ethile. Isiqondiso sabo siqinisekisa imiphumela emihle kanye nokusebenza kahle kwezindleko.

Izinyathelo Zokulawula Ikhwalithi ku-Die Casting CNC Machining

Izindlela zokuhlola zokunemba kwe-dimensional

Ukunemba kobukhuluiqinisekisa ukuthi izingxenye ziyalingana futhi zisebenza ngendlela ehlosiwe. Ungasebenzisa amasu ambalwa okuhlola ukuze uqinisekise ubukhulu bezingxenye zemishini ye-CNC yokufa. Enye indlela ephumelelayo ukuhlanganisa imishini yokulinganisa (ama-CMM). Le mishini ikala ubukhulu bengxenye ngokunemba okuphezulu. Bangakwazi ukubona ngisho nokuchezuka okuncane kakhulu ekucacisweni komklamo.

Elinye ithuluzi eliwusizo amasistimu okuhlola amehlo. Lezi zinhlelo zisebenzisa amakhamera namalaser ukuskena indawo engaphezulu. Bakha imodeli ye-3D ongayiqhathanisa nomklamo wangempela. Le ndlela iyashesha futhi isebenza kahle kumajometri ayinkimbinkimbi.

Ithiphu: Njalo hlola izilinganiso ezibucayi kuqala. Lezi yizilinganiso ezithinta ngqo ukusebenza kwengxenye.

Ukusebenzisa ama-gauge nama-caliper kungenye indlela ewusizo. Lawa mathuluzi kulula ukuwasebenzisa futhi ahlinzeka ngemiphumela esheshayo. Nokho, zifaneleka kakhulu izilinganiso eziyisisekelo. Ukuze uthole izingxenye eziyinkimbinkimbi, amasu athuthukile njengama-CMM noma amasistimu okubona athembeke kakhulu.

Izindlela zokuhlola ubuqotho bezinto ezibonakalayo

Ubuqotho bezinto ezibonakalayoinquma amandla nokuqina kwezingxenye zakho. Ungasebenzisa izindlela ezimbalwa zokuhlola ukuze uqinisekise ukuthi izinto ezisetshenziswayo zihlangabezana nezindinganiso zekhwalithi. Ukuhlola okungabhubhisi (NDT) kungenye yezindlela eziphumelela kakhulu. Ikuvumela ukuthi uhlole ukukhubazeka kwangaphakathi ngaphandle kokulimaza ingxenye. Izindlela ezijwayelekile ze-NDT zifaka ukuhlolwa kwe-X-ray nokuhlolwa kwe-ultrasonic.

- Ukuhlolwa kwe-X-ray: Le ndlela yembula amaphutha angaphakathi afana ne-porosity noma imifantu. Iwusizo ikakhulukazi ezingxenyeni ezinemiklamo eyinkimbinkimbi.

- Ukuhlolwa kwe-ultrasonic: Le nqubo isebenzisa amaza omsindo ukuthola amaphutha. Isebenza kahle ekuboneni ama-voids noma ukungahambisani kokubalulekile.

Ngokulimala kwezinga eliphezulu, ungasebenzisa ukuhlola ukungena kodayi. Le ndlela ihilela ukusebenzisa udayi ebusweni bengxenye. Udayi ungena emifantwini noma emaphutheni, okwenza kubonakale ngaphansi kokukhanya kwe-UV.

I-callout: Ukuhlola okokusebenza okuvamile kukusiza ukuthi ugcine ikhwalithi engaguquki. Kuphinde kunciphise ubungozi bokwehluleka kwengxenye ezinhlelweni ezibucayi.

Ukuhlolwa kwemishini kungesinye isinyathelo esibalulekile. Ukuhlolwa okufana namandla aqinile kanye nokuhlola ubulukhuni kuhlola ikhono lezinto ezibonakalayo lokumelana nengcindezi. Lezi zivivinyo ziqinisekisa ukuthi izingxenye zingakwazi ukusebenza ngokwethembeka ngaphansi kwezimo zomhlaba wangempela.

Ukusebenzisa ukuhlolwa okungaphakathi kwenqubo

Ukuhlola okungaphakathi kwenqubo kukusiza ukuthi ubambe iziphambeko ekuqaleni kwenqubo yokukhiqiza. Le ndlela yonga isikhathi futhi inciphisa ukumosha. Ungasebenzisa amasistimu azenzakalelayo ukuqapha amapharamitha angukhiye ngesikhathi sokukhiqiza. Isibonelo, izinzwa zingakwazi ukulandelela izinga lokushisa, ingcindezi, nokugeleza kwezinto ngesikhathi sokusakaza.

Ukuhlola okubukwayo nakho kubalulekile. Qeqesha ithimba lakho ukuhlonza iziphambeko ezivamile njengokungapheleli kwendawo noma ukungaqondani kahle. Ukwenza lokhu kuhlola ngezikhathi ezithile kuqinisekisa ukuthi izinkinga zilungiswa ngokushesha.

Qaphela: Ukuhlolwa okungaphakathi kwenqubo akuthathi indawo yokuhlolwa kwekhwalithi kokugcina. Ibaphelelisa ngokuhlonza izinkinga ngaphambi kokuba zande.

Ukulawulwa kwenqubo yezibalo (SPC) kungenye ithuluzi elisebenzayo. I-SPC ibandakanya ukuqoqa nokuhlaziya idatha evela kunqubo yokukhiqiza. Kukusiza ukuthi ubone amathrendi futhi wenze izinguquko ukuze ugcine ikhwalithi.

Ngokuhlanganisa amasistimu azenzakalelayo, ukuhlola okubukwayo, ne-SPC, ungakha isu eliqinile lokuhlola ngaphakathi kwenqubo. Le ndlela iqinisekisa ukuthi izingxenye zakho zemishini ye-CNC yokufa zihlangabezana nezindinganiso eziphakeme kakhulu zekhwalithi.

Ukubaluleka kokulinganiswa komshini nokugcinwa kokuvikela

Ukulinganiswa komshini nokugcinwa kokuvikela kubalulekile ekukhiqizeni izingxenye zomshini ze-CNC zekhwalithi ephezulu. Lezi zinqubo ziqinisekisa ukuthi okokusebenza kwakho kusebenza ngendlela esezingeni eliphezulu, kuncishiswa amaphutha futhi kwandise isikhathi sokuphila somshini wakho. Ukuzishaya indiva kungase kubangele ukungalungi kobukhulu, ukwehla kwesikhathi esikhulayo, kanye nezindleko zokukhiqiza eziphakeme.

Kungani Kubalulekile Ukulinganiswa Komshini

Ukulinganisa kuqinisekisa ukuthi imishini yakho ikhiqiza izingxenye ezinobukhulu obunembile nokubekezelela. Ngokuhamba kwesikhathi, ukuguga kungabangela imishini yakho ukuthi isuke kuzilungiselelo zayo zasekuqaleni. Lokhu ku-drift kuthinta ukunemba kwezingxenye zakho, okuholela ekulimaleni nokungahambi kahle.

- Izinzuzo ezibalulekile zokulinganisa okuvamile:

- Ukunemba Okuthuthukisiwe: Iqinisekisa ukuthi izingxenye zihlangabezana nokucaciswa komklamo.

- Ikhwalithi Engaguquki: Yehlisa ukuhlukahluka ekukhiqizeni.

- Udoti Owehlisiwe: Yehlisa ukulahleka kwezinto ngenxa yamaphutha.

Ithiphu: Hlela ukuhlola ukulinganisa ngezikhathi ezithile. Sebenzisa amathuluzi aqinisekisiwe namazinga ukuze uqinisekise ukunemba komshini wakho.

Isibonelo, umshini we-CNC ongakaliwe ungase ukhiqize izingxenye ezinendawo engalingani noma izilinganiso ezingalungile. Lezi zinkinga zingafaka engozini ukusebenza komkhiqizo wakho wokugcina.

Iqhaza Lokulondolozwa Kokuvimbela

Ukunakekela okuvikelayo kubandakanya ukuhlolwa okujwayelekile kanye nokuseviswa ukuze ugcine imishini yakho isesimweni esifanele. Le ndlela yokwenza izinto ikusiza ukuthi ubone izinkinga ezingaba khona ngaphambi kokuba zidlulele ezinkingeni ezinkulu.

- Imisebenzi yokunakekela ebalulekile:

- Ukuthambisa: Igcina izingxenye ezihambayo zisebenza kahle.

- Ukuhlanza: Isusa udoti ongathinta ukusebenza.

- Ukuhlola: Ikhomba ukuguga kanye nokudilika kwezingxenye ezibalulekile.

- Ukumiselela: Iqinisekisa ukuthi izingxenye ezigugile zishintshwa ngokushesha.

I-callout: Umshini onakekelwa kahle usebenza ngokuphumelelayo, unciphisa ukusetshenziswa kwamandla nezindleko zokukhiqiza.

Ukuhlanganisa Ukulinganisa kanye Nokugcinwa

Uma uhlanganisa ukulinganisa nokugcinwa kokuvimbela, udala isistimu eqinile yokuqinisekisa ikhwalithi. Ukulinganisa kuqinisekisa ukunemba, kuyilapho ukulungiswa kugcina imishini yakho ithembekile futhi isebenza kahle.

| Prakthiza | Inzuzo Eyinhloko | Imvamisa |

|---|---|---|

| Ukulinganisa Umshini | Iqinisekisa ukunemba kobukhulu | Njalo ezinyangeni ezi-3-6 |

| Ukugcinwa Kokuvimbela | Inweba impilo yomshini | Maviki onke noma nyanga zonke |

Qaphela: Gcina amarekhodi anemininingwane emisebenzi yokulinganisa nokulungisa. Lawa marekhodi akusiza ukuthi ulandelele amathrendi okusebenza futhi uhlele isevisi yesikhathi esizayo.

Indlela Yokuyisebenzisa Le mikhuba

Qala ngokwakha ishejuli yokulungisa eyenzelwe okokusebenza kwakho. Bandakanya imisebenzi ethile namafrikhwensi anconyiwe. Qeqesha iqembu lakho ukuthi lenze ukunakekelwa okuyisisekelo futhi libone izimpawu zokuguga. Ukuze ulinganise, tshala kumathuluzi okulinganisa ekhwalithi ephezulu futhi ubambisane nochwepheshe abaqinisekisiwe.

Isikhumbuzi se-Emoji:

Isikhathi sokuthumela: Jun-06-2025