Ho netefatsa boleng bashoa ho lahlela likarolo tsa machining tsa CNCe bohlokoa bakeng sa ho fumana nako e telele le ho nepahala lihlahisoa tsa hau tsa ho qetela. Likarolo tse entsoeng hampe li ka lebisa mathateng a ts'ebetso, litšenyehelo tse phahameng, esita le likotsi tsa polokeho. U tlameha ho nka mokhoa o hlophisitsoeng oa ho boloka maemo a holimo. Sena se kenyelletsa ho shebana le ho nepahala ha moralo, ho khetha lisebelisoa tse nepahetseng, le ho latela mekhoa e nepahetseng ea tlhahiso. Ka mohlala, ho sebelisaOEM aluminium die castinge netefatsa liphetho tse ts'oanang, haholo bakeng sa lintho tse rarahaneng joalo kaaluminium shoela ho lahlela sethuthuthu sekoahelo. Taolo ea boleng le tšebelisano ea litsebi li u thusa ho fihlela likarolo tse tšepahalang le tse tšoarellang nako e telele.

Lintlha tsa bohlokoa

- Etsa bonnete ba horemoralo o nepahetsekahoo likarolo li lumellana hantle. Sebelisa lisebelisoa tsa CAD ho fumana litekanyo tse nepahetseng.

- Khetha thepa e thehiloeng hoseo ba ka se etsang. Aluminium e bobebe, 'me zinki e matla.

- Latela mehato e metle ea tlhahiso joalo ka ho boloka mocheso o tsitsitse. Sebelisa mechine ho qoba liphoso.

- Hlahloba le ho hlahloba likarolo hangata ho fumana mathata pele ho nako. Sebelisa X-rays kapa maqhubu a molumo ho hlahloba lisebelisoa.

- Sebetsa le bahlahisi ba nang le litsebo ho sebelisa tsebo ea bona. Li ka thusa ho ntlafatsa meralo le ho etsa likarolo tse betere.

Mehopolo ea Moralo oa Die Casting CNC Machining Parts

Bohlokoa ba ho nepahala ha sebopeho

Ho nepahala ha jiometri ho phetha karolo ea bohlokoa ho netefatsa ts'ebetso le ts'epahalo eashoa ho lahlela likarolo tsa machining tsa CNC. U hloka ho tsepamisa maikutlo ho litekanyo tse nepahetseng le mamello nakong ea mohato oa moralo. Esita le liphoso tse nyenyane li ka lebisa ho se nepahaleng kapa ho lekana ho sa lokelang, ho amang ts'ebetso ea sehlahisoa sa ho qetela. Ho sebelisa software e tsoetseng pele ea CAD ho u thusa ho theha meralo e qaqileng ka litekanyo tse nepahetseng. Sena se tiisa hore likarolo li kopana le litlhaloso tse hlokahalang le ho sebetsa ka mokhoa o tsitsitseng lits'ebetsong tsa tsona tse reriloeng.

Moralo bakeng sa tlhahiso

Moralo bakeng sa tlhahisoe nolofatsa tlhahiso le ho fokotsa litšenyehelo. U lokela ho ikemisetsa ho etsa meralo eo ho leng bonolo ho e hlahisa ntle le ho senya boleng. Likarolo tse joalo ka botenya ba lebota bo ts'oanang le phetoho e boreleli lipakeng tsa bokaholimo li thusa ho qoba mathata nakong ea ts'ebetso ea "die casting". Ho feta moo, ho fokotsa li-geometri tse rarahaneng ho fokotsa nako ea machining le litšila tsa thepa. Ho sebelisana 'moho le baenjiniere kapa bahlahisi ho netefatsa hore meralo ea hau e lumellana le bokhoni ba lisebelisoa tse sebelisetsoang tlhahiso.

Ho qoba liphoso tse tloaelehileng tsa moralo

Mefokolo e tloaelehileng ea moralo e ka lebisa ho bofokoli le ho se sebetse hantle hoa likarolo tsa mochini oa CNC. U lokela ho qoba likhutlo tse bohale, kaha li ka baka khatello ea maikutlo le ho fokolisa karolo. Ka mokhoa o ts'oanang, li-undercuts tse feteletseng kapa lintlha tse rarahaneng li ka thatafatsa mokhoa oa ho lahlela le ho eketsa kotsi ea liphoso. Ho etsa tlhahlobo e felletseng ea moralo oa hau ho u thusa ho tseba mathata a ka bang teng esale pele. Ho sebelisa lisebelisoa tsa papiso ho u fa monyetla oa ho lekola hore na moralo o sebetsa joang tlas'a maemo a sebele a lefats'e, ho netefatsa sehlahisoa se matla sa ho qetela.

Khetho ea Lintho bakeng sa Likarolo tsa Boemo bo Phahameng

Ho khetha li-alloys tse nepahetseng bakeng sa ho lahla lefu

Ho khetha motsoako o nepahetseng ke oa bohlokoa bakeng sa ho hlahisa likarolo tsa boleng bo holimo. U lokela ho tsepamisa maikutlo linthong tse fanang ka castability e babatsehang le durability. Lisebelisoa tsa aluminium li tumme ka lebaka la tlhaho ea tsona e bobebe le ho hanyetsa kutu. Li-alloys tsa zinc li fana ka matla a holimo 'me li loketse meralo e rarahaneng. Magnesium alloys e sebetsa hantle bakeng sa lits'ebetso tse hlokang likarohano tse phahameng tsa boima ba 'mele.

Keletso: Kamehla bapisa motsoako le litlhoko tse khethehileng tsa morero oa hau. Ka mohlala, li-alloys tsa aluminium li phethahetse bakeng sa likarolo tsa likoloi, ha li-alloys tsa zinc li ipabola likarolong tse khabisitsoeng.

Lintho tse bonahalang le phello ea tsona ho boleng

Lintho tse bonahalangama ka ho toba tshebetso le bophelo ba likarolo tsa hao. U hloka ho nahana ka lintlha tse kang matla a tsitsipano, conductivity ea mocheso, le ho hanyetsa ho apara. Matla a matla a phahameng a tiisa hore karolo e ka mamella khatello ea mochine. Thermal conductivity ke ea bohlokoa bakeng sa lits'ebetso tse amanang le ho fetisetsa mocheso. Ho hanyetsa ho apara ho thibela ho senyeha pele ho nako libakeng tse nang le likhohlano tse phahameng.

- Lintho tsa bohlokoa tse lokelang ho hlahlojoa:

- Matla le ho tšoarella

- Khanyetso ea kutu

- Boikemisetso

Ho utloisisa thepa ena ho u thusa ho khetha lisebelisoa tse khotsofatsang litlhoko tsa sehlahiswa sa hau le tsa tikoloho.

Ho leka-lekanya litšenyehelo le ts'ebetso khethong ea thepa

Ho leka-lekanya litšenyehelo le ts'ebetso ho bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea hau ea tlhahiso. U lokela ho ikemisetsa ho khetha thepa e fanang ka boleng bo hlokahalang ntle le ho feta tekanyetso ea hau.Lisebelisoa tsa aluminiumli na le litšenyehelo tse tlaase bakeng sa lisebelisoa tse bobebe, ha li-alloys tsa zinc li fana ka theko e tlaase bakeng sa likarolo tse matla haholo.

Hlokomela: Qoba ho sekisetsa boleng ho boloka litšenyehelo. Khetho e fosahetseng ea thepa e ka baka mathata le litšenyehelo tse phahameng tsa tlhokomelo hamorao.

Ka ho lekola litlhoko tsa projeke ea hau ka hloko, u ka fumana tekanyo e nepahetseng lipakeng tsa litšenyehelo le ts'ebetso. Sena se tiisa hore likarolo tsa hau tsa mochini oa CNC li fihlella lipheo tsa tekheniki le tsa lichelete.

Mekhoa ea Tlhahiso ho netefatsa Boleng

Mekhoa e metle ka ho fetisisa ea ho laola lefu

U ka finyellaliphetho tsa boleng bo holimo tsa lefuka ho latela mekhoa e netefalitsoeng. Qala ka ho etsa bonnete ba hore moralo oa die o ntlafalitsoe bakeng sa phallo e boreleli ea thepa. Sena se fokotsa kotsi ea lipokotho tsa moea le libaka tse sa tšoaneng. Boloka lithempereichara tse sa fetoheng nakong ea ts'ebetso ea ho lahla ho thibela likoli tse joalo ka shrinkage kapa warping. Kamehla hlahloba hlobo hore e senyehile. Mefuta e senyehileng e ka senya ho nepahala ha likarolo tsa hau.

Keletso: Preheat hlobo pele o etsa. Sena se fokotsa ho sisinyeha ha mocheso 'me se ntlafatsa bokaholimo ba likarolo tsa hau.

Sebelisa lisebelisoa tse ikemetseng ho laola lebelo la ente le khatello. Automation e netefatsa ho nepahala le ho fokotsa liphoso tsa batho. Ho feta moo, hloekisa hlobo hantle ka mor'a potoloho e 'ngoe le e 'ngoe. Ho bokellana ha masala ho ka ama boleng ba li-cast tse latelang.

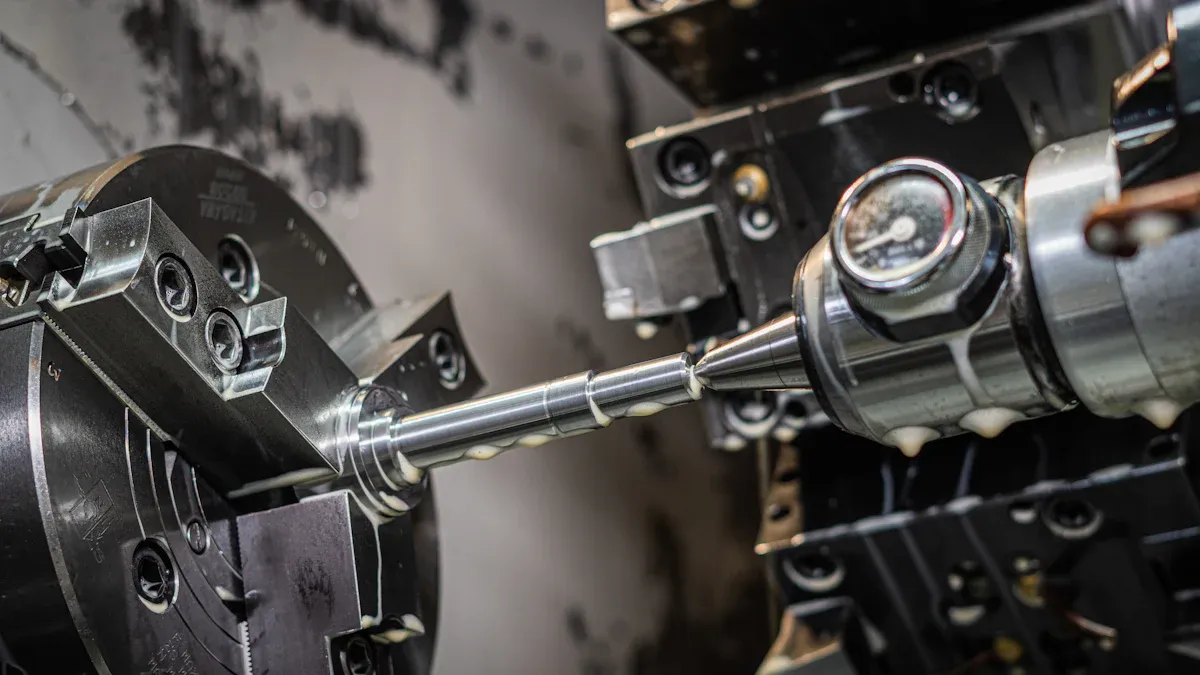

Mekhoa ea machining ea CNC bakeng sa ho nepahala

Machine oa CNC o bapala karolo ea bohlokoakarolo ea ho hloekisa likarolo tsa mochini oa CNC. U lokela ho sebelisa lisebelisoa tsa machining tsa lebelo le phahameng ho fihlela liphetho tse boreleli le mamello e thata. Mechini ea Multi-axis CNC e u lumella ho etsa li-geometri tse rarahaneng habonolo. Mechini ena e ntlafatsa ho nepahala le ho fokotsa tlhoko ea ts'ebetso ea bobeli.

- Mekhoa e ka sehloohong e lokelang ho nahanoa:

- Sebelisa lisebelisoa tsa ho seha carbide bakeng sa ho tšoarella le ho nepahala.

- Ntlafatsa mekhoa ea lisebelisoa ho fokotsa nako ea mochini.

- Kenya tšebetsong litsamaiso tse pholisang ho thibela mocheso o feteletseng nakong ea mochini.

Hlokomela: Kamehla lekanya mechini ea hau ea CNC. Tekanyetso e nepahetseng e netefatsa liphetho tse tsitsitseng mme e thibela liphoso tsa boholo.

Tsetela ho software e tsoetseng pele ea ho hlophisa mechini ea CNC. Software ena e u thusa ho etsisa mokhoa oa ho sebetsa le ho tseba mathata a ka bang teng pele tlhahiso e qala.

Ho fokotsa liphoso nakong ea tlhahiso

Mefokolo e ka nyenyefatsa boleng ba likarolo tsa mochini oa CNC oa ho lahla. U lokela ho tsepamisa maikutlo ho khetholla le ho felisa litaba tse tloaelehileng joalo ka porosity, mapetsong le ho se phethahale ha bokaholimo. Etsa litlhahlobo tse phethahetseng mothating o mong le o mong oa tlhahiso. Ho lemoha kapele ho u fa monyetla oa ho rarolla mathata pele a eketseha.

Kenya tšebetsong mehato ea taolo ea boleng joalo ka tlhahlobo ea X-ray le tlhahlobo ea ultrasonic. Mekhoa ena e u thusa ho lemoha mefokolo ea ka hare e sa bonahaleng ka mahlo. Boloka taolo e tiileng holim'a maemo a tikoloho joalo ka mongobo le mocheso. Ho feto-fetoha ha maemo ho ka ama thepa ea thepa le ho lebisa ho se lumellaneng.

Hoelehetsa: Ho koetlisa sehlopha sa hau ka mekhoa ea ho thibela likoli ho bohlokoa. Basebelisi ba nang le litsebo ba ka bona litaba kapele mme ba nka mehato ea ho lokisa.

Sebelisa statistical process control (SPC) ho beha leihlo lintlha tsa tlhahiso. SPC e u thusa ho tseba mekhoa le ho etsa liphetoho ho boloka boleng. Qetellong, sebelisana 'moho le barekisi ba hau ho netefatsa hore thepa e tala e fihlela litlhoko tsa hau. Lisebelisoa tsa boleng bo phahameng li fokotsa monyetla oa ho ba le liphoso nakong ea tlhahiso.

Karolo ea phekolo ea mocheso le liphahlo tsa lefu

Kalafo ea mocheso le liphahlo li bapala karolo ea bohlokoa ho ntlafatseng boleng le ho tšoarella ha likarolo tsa mochini oa CNC. Ts'ebetso ena e ntlafatsa thepa ea thepa, e lelefatsa bophelo ba lisebelisoa, 'me e netefatsa ts'ebetso e ts'oanang lits'ebetsong tse hlokahalang. Ho utloisisa bohlokoa ba tsona ho u thusa ho etsa liqeto tse nang le tsebo nakong ea tlhahiso.

Melemo ea Phekolo ea Mocheso

Kalafo ea mocheso e fetola thepa ea 'mele le ea mechine ea tšepe, e etsa hore e tšoanelehe bakeng sa lisebelisoa tse khethehileng. U ka sebelisa ts'ebetso ena ho ntlafatsa matla, boima, le ho hanyetsa ho roala.

- Melemo e ka sehloohong ea phekolo ea mocheso:

- Matla a Matlafalitsoeng: Phekolo ea mocheso e eketsa matla a matla a likarolo, a li lumella ho mamella meroalo e phahameng.

- Matla a ntlafetseng: Likarolo tse tšoaroang li hanana le deformation le ho senyeha, ho netefatsa nako e telele ea bophelo.

- Khatello ea Maikutlo: Ts'ebetso e fokotsa khatello ea maikutlo e ka hare e bakoang ke ho lahla kapa mechine, ho thibela mapetsong le ho sotha.

Keletso: Khetha mokhoa o nepahetseng oa phekolo ea mocheso ho latela thepa ea hau le tšebeliso ea hau. Mekhoa e tloaelehileng e kenyelletsa ho annealing, ho tima, le ho halefisa.

Ka mohlala, ho tima ho lateloa ke mocheso ho ka etsa hore ho be le ho leka-lekana pakeng tsa ho thatafala le ho thatafala, ho etsa hore e be e loketseng bakeng sa lisebelisoa tsa koloi kapa tsa sefofane.

Bohlokoa ba Die Coatings

Likotlolo tsa die li sireletsa hlobo le ho ntlafatsa boleng ba likarolo tse lahliloeng. Liaparo tsena li fokotsa likhohlano, li thibela ho khathala, 'me li ntlafatsa bokaholimo ba lihlahisoa tsa hau.

- Ke hobane'ng ha u lokela ho sebelisa liphahlo tsa lefu:

- Khohlano e fokotsehileng: Liaparo li fokotsa likhohlano pakeng tsa tšepe e qhibilihisitsoeng le bokaholimo ba metsi, ho netefatsa hore thepa e phalla hantle.

- Bophelo ba Sesebelisoa bo Atolositsoeng: Likarolo tse sirelletsang li sireletsa sekoahelo ho tsoa tšenyong ea mocheso le mochini, ho fokotsa litšenyehelo tsa tlhokomelo.

- Qetello ea Bokaholimo bo ntlafetseng: Li-coated dies li hlahisa likarolo tse nang le mefokolo e fokolang, joalo ka libaka tse mahoashe kapa porosity.

Hoelehetsa: Kamehla hlahloba le ho sebelisa lintja tsa "diesel" ho boloka ts'ebetso ea tsona. Liaparo tse tsofetseng li ka lebisa liphellong tse sa tsitsang le litekanyetso tse phahameng tsa bokooa.

Ho kopanya Phekolo ea Mocheso le Die Coatings

Ha o kopanya phekolo ea mocheso le liaparo tsa ho shoa, o fumana liphello tse phahameng. Likarolo tse nang le mocheso o futhumatsang li fumana matla le ho tšoarella tse hlokahalang bakeng sa lits'ebetso tse hlokang, ha li-coated dies li netefatsa ho nepahala le ho tsitsa nakong ea tlhahiso.

| Tshebetso | Molemo oa Pele | Mohlala oa Tšebeliso |

|---|---|---|

| Kalafo ea Mocheso | E eketsa matla le boima | Likarolo tsa enjene ea likoloi |

| Die Coatings | E ntlafatsa boleng ba lisebelisoa le lisebelisoa | Likamore tsa elektronike tse nepahetseng haholo |

Ka ho kopanya lits'ebetso tsena tšebetsong ea hau ea tlhahiso, o ka hlahisa likarolo tsa mochini tsa CNC tsa boleng bo holimo tse fihlelang litekanyetso tsa indasteri.

Hlokomela: Buisana le litsebi ho fumana motsoako o motle ka ho fetisisa oa phekolo ea mocheso le liphaephe tsa lefu bakeng sa morero oa hau o khethehileng. Tataiso ea bona e netefatsa liphetho tse nepahetseng le katleho ea litšenyehelo.

Mehato ea ho laola boleng ho Die Casting CNC Machining

Mekhoa ea ho hlahloba ho nepahala ha dimensional

Ho nepahala ha dimensionale netefatsa hore dikarolo di a lekana le ho sebetsa kamoo ho rerilweng kateng. U ka sebelisa mekhoa e mengata ea tlhahlobo ho netefatsa boholo ba likarolo tsa mochini oa CNC. Mokhoa o mong o sebetsang ke ho hokahanya metjhini e lekanyang (CMMs). Mechine ena e lekanya litekanyo tsa karolo ka nepo e phahameng. Ba khona ho lemoha le ho kheloha ho honyenyane ho tloha ho litlhaloso tsa moralo.

Sesebelisoa se seng sa bohlokoa ke litsamaiso tsa tlhahlobo ea optical. Litsamaiso tsena li sebelisa lik'hamera le lasers ho hlahloba bokaholimo ba karolo. Ba etsa mohlala oa 3D oo u ka o bapisang le oa pele. Mokhoa ona o potlakile ebile o sebetsa hantle bakeng sa li-geometri tse rarahaneng.

Keletso: Kamehla hlahloba litekanyo tsa bohlokoa pele. Tsena ke litekanyo tse amang ts'ebetso ea karolo ka kotloloho.

Ho sebelisa li-gauge le li-caliper ke mokhoa o mong o sebetsang. Lisebelisoa tsena li bonolo ho li sebelisa ebile li fana ka liphetho tse potlakileng. Leha ho le joalo, li loketse ka ho fetisisa bakeng sa litekanyo tsa motheo. Bakeng sa likarolo tse rarahaneng haholoanyane, mekhoa e tsoetseng pele joalo ka li-CMM kapa lisebelisoa tsa optical li tšepahala haholoanyane.

Mekhoa ea teko ea botšepehi ba lintho tse bonahalang

Botšepehi ba lintho tse bonahalange etsa qeto ea matla le ho tšoarella ha likarolo tsa hau. U ka sebelisa mekhoa e mengata ea tlhahlobo ho netefatsa hore thepa e fihlella maemo a boleng. Teko e sa senyeheng (NDT) ke e 'ngoe ea mekhoa e sebetsang haholo. E u lumella ho hlahloba liphoso tsa ka hare ntle le ho senya karolo. Mekhoa e tloaelehileng ea NDT e kenyelletsa tlhahlobo ea X-ray le tlhahlobo ea ultrasonic.

- Tlhahlobo ea X-ray: Mokhoa ona o senola mefokolo ea ka hare joalo ka porosity kapa mapetsong. E bohlokoa haholo bakeng sa likarolo tse nang le meralo e rarahaneng.

- Tlhahlobo ea Ultrasonic: Mokhoa ona o sebelisa maqhubu a molumo ho bona mefokolo. E sebetsa hantle bakeng sa ho khetholla li-voids kapa ho se lumellane ha thepa.

Bakeng sa mefokolo ea boemo bo holimo, o ka sebelisa tlhahlobo ea penetrant ea dae. Mokhoa ona o kenyelletsa ho sebelisa dae holim'a karolo. Dae e kenella mapetsong kapa mefokolong, e etsa hore e bonahale tlas'a khanya ea UV.

Hoelehetsa: Teko ea kamehla ea thepa e u thusa ho boloka boleng bo tsitsitseng. E boetse e fokotsa kotsi ea ho hloleha ha karolo lits'ebetsong tsa bohlokoa.

Teko ea mechine ke mohato o mong oa bohlokoa. Liteko tse kang ho tiea le ho lekola boima ba tsona li lekola bokhoni ba thepa ea ho mamella khatello ea maikutlo. Liteko tsena li netefatsa hore likarolo li ka sebetsa ka ts'epahalo tlasa maemo a nnete a lefats'e.

Ho kenya tšebetsong tlhahlobo e ntseng e tsoela pele

Tlhahlobo ea ts'ebetso e u thusa ho fumana liphoso qalong ea ts'ebetso ea tlhahiso. Mokhoa ona o boloka nako ebile o fokotsa litšila. U ka sebelisa litsamaiso tse ikemetseng ho lekola liparamente tsa bohlokoa nakong ea tlhahiso. Mohlala, li-sensor li ka lekola mocheso, khatello le phallo ea thepa nakong ea ho lahla.

Litlhahlobo tse bonoang le tsona ke tsa bohlokoa. Koetlisa sehlopha sa hau ho tseba liphoso tse atileng joalo ka bofokoli ba bokaholimo kapa mefokolo. Ho etsa licheke tsena nako le nako ho tiisa hore litaba li rarolloa ka potlako.

Hlokomela: Tlhahlobo e ntseng e tsoela pele ha se sebaka sa ho hlahloba boleng ba ho qetela. E a tlatselletsa ka ho hlwaya mathata pele a hola.

Statistical process control (SPC) ke sesebelisoa se seng se sebetsang. SPC e kenyelletsa ho bokella le ho sekaseka lintlha tse tsoang ts'ebetsong ea tlhahiso. E u thusa ho tseba mekhoa le ho etsa liphetoho ho boloka boleng.

Ka ho kopanya litsamaiso tse ikemetseng, licheke tsa pono, le SPC, o ka theha leano le matla la tlhahlobo ea ts'ebetso. Mokhoa ona o netefatsa hore likarolo tsa hau tsa mochini oa CNC li fihlella litekanyetso tse phahameng ka ho fetisisa tsa boleng.

Bohlokoa ba ho lekanya mochini le tlhokomelo e thibelang

Tekanyo ea mochini le tlhokomelo e thibelang e bohlokoa bakeng sa ho hlahisa likarolo tsa mochini tsa CNC tsa boleng bo holimo. Litloaelo tsena li netefatsa hore lisebelisoa tsa hau li sebetsa ka mokhoa o phahameng haholo, li fokotsa liphoso le ho lelefatsa nako ea bophelo ea mochini oa hau. Ho li hlokomoloha ho ka lebisa ho se nepahaleng ho itseng, ho fokotseha ha nako e eketsehileng, le litšenyehelo tse phahameng tsa tlhahiso.

Ke Hobane'ng ha ho Lekanya Mochini ho le Bohlokoa

Calibration e netefatsa hore mechini ea hau e hlahisa likarolo tse nang le litekanyo tse nepahetseng le mamello. Ha nako e ntse e ea, ho senyeha ho ka etsa hore lisebelisoa tsa hau li suthele ho tloha litlhophisong tsa eona tsa pele. Ho hoholeha hona ho ama ho nepahala ha likarolo tsa hau, ho lebisa ho bofokoli le ho se lumellane.

- Melemo ea bohlokoa ea ho lekanya kamehla:

- Ho Nepahala ho Ntlafetseng: E netefatsa hore likarolo li kopana le litlhaloso tsa moralo.

- Boleng bo Tletseng: E fokotsa ho fetoha ha tlhahiso.

- Litsila tse Fokotsoeng: E fokotsa tahlehelo ea thepa ka lebaka la liphoso.

Keletso: Etsa licheke tsa ho lekanya ka linako tse itseng. Sebelisa lisebelisoa le litekanyetso tse netefalitsoeng ho netefatsa ho nepahala ha mochini oa hau.

Mohlala, mochini oa CNC o sa lekanyetsoang o ka hlahisa likarolo tse nang le bokaholimo bo sa lekanang kapa litekanyo tse fosahetseng. Litaba tsena li ka senya ts'ebetso ea sehlahisoa sa hau sa ho qetela.

Karolo ea Tlhokomelo e Thibelang

Tlhokomelo e thibelang e kenyelletsa tlhahlobo le ts'ebeletso e tloaelehileng ho boloka mochini oa hau o le maemong a nepahetseng. Mokhoa ona oa ts'ebetso o u thusa ho tseba mathata a ka bang teng pele a fetoha mathata a maholo.

- Mesebetsi ea bohlokoa ea tlhokomelo:

- Lubrication: E boloka likarolo tse tsamaeang li sebetsa hantle.

- Ho hloekisa: E tlosa litšila tse ka amang ts'ebetso.

- Tlhahlobo: E hloaea ho senyeha ha likarolo tsa bohlokoa.

- Ho nkela sebaka: E netefatsa hore likarolo tse khathetseng li nkeloa sebaka hang hang.

Hoelehetsa: Mochine o hlokometsoeng hantle o sebetsa ka mokhoa o atlehileng haholoanyane, o fokotsa tšebeliso ea matla le litšenyehelo tsa tlhahiso.

Ho kopanya Calibration le Tlhokomelo

Ha o kopanya calibration le tlhokomelo ea thibelo, o theha tsamaiso e matla bakeng sa tiiso ea boleng. Calibration e netefatsa ho nepahala, ha tlhokomelo e boloka mechini ea hau e ts'epahala ebile e sebetsa hantle.

| Itloaetse | Molemo oa Pele | Khafetsa |

|---|---|---|

| Tekanyo ea Mochini | E netefatsa ho nepahala ha dimensional | Likhoeli tse ling le tse ling tse 3-6 |

| Tlhokomelo e Thibelang | E eketsa nako ea bophelo ba mochini | Beke kapa khoeli le khoeli |

Hlokomela: Boloka lirekoto tse qaqileng tsa mesebetsi ea calibration le tlhokomelo. Lirekoto tsena li u thusa ho latela mekhoa ea ts'ebetso le ho rera litšebeletso tsa nako e tlang.

Mokhoa oa ho Sebelisa Mekhoa Ena

Qala ka ho etsa kemiso ea tlhokomelo e lumellanang le lisebelisoa tsa hau. Kenyelletsa mesebetsi e khethehileng le maqhubu a khothaletsoang. Koetlisa sehlopha sa hau ho etsa tlhokomelo ea mantlha le ho lemoha matšoao a ho khathala. Bakeng sa ho lekanya, tsetela ho lisebelisoa tsa ho metha tsa boleng bo holimo 'me u sebelisane le litsebi tse netefalitsoeng.

Khopotso ea Emoji:

Nako ea poso: Jun-06-2025