I-aluminium die casting iguqula indlela abakhiqizi abadala ngayoamaphampu nama-compressor. Le ndlela inikeza izingxenye ukwakheka okuqinile kodwa okungasindi. Izimboni eziningi manje zithemba i-aluminium die casting ukuze ilethe ukusebenza okuhlala njalo nokuthembeka. Izindaba zempumelelo zibonisa ukuthi amaphampu nama-compressor afinyelela ukuphakama okusha ngale nqubo ethuthukisiwe.

Okuthathwayo Okubalulekile

- I-aluminium die casting ikhiqizaiphampu eqinile, engasindinezingxenye ze-compressor ezinokunemba okuphezulu nekhwalithi engaguquki, ethuthukisa ukusebenza nokuqina.

- Le ndlelaisheshisa ukukhiqizwafuthi yehlisa izindleko ngokusebenzisa isikhunta esisebenziseka kabusha kanye nezikhathi zomjikelezo osheshayo, okuyenza ilungele ukukhiqizwa kwenani elikhulu.

- I-Die casting ivumela imiklamo eyinkimbinkimbi, enezindonga ezincane enciphisa isisindo kanye nokusetshenziswa kwamandla, kuyilapho inikezela ukumelana nokugqwala okuhle kakhulu kwezingxenye ezihlala isikhathi eside.

I-Aluminium Die Casting vs. Izindlela Zendabuko Kumaphampu nama-Compressor

Umehluko Wenqubo Yokukhiqiza

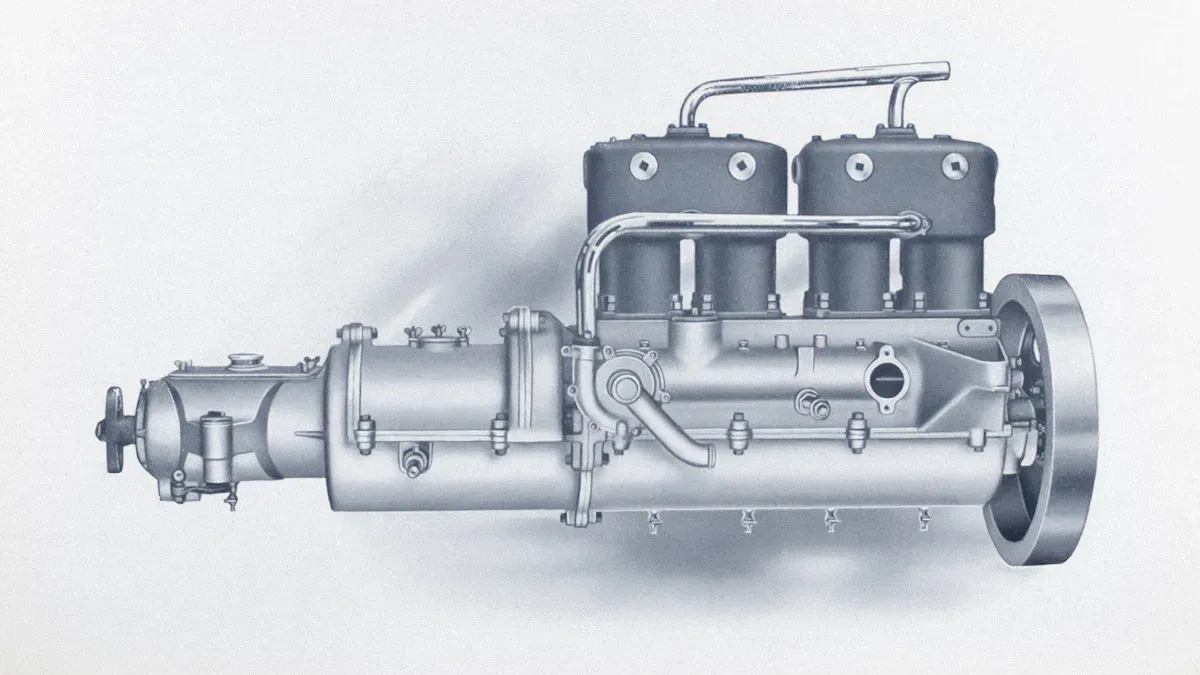

I-aluminium die casting iletha izinga elisha lokunemba nokusebenza kahle ekukhiqizeni amaphampu nama-compressor. Le nqubo isebenzisa isikhunta sensimbi esihlala unomphela, esibizwa ngokuthi i-dies, futhi ijova i-aluminium encibilikisiwe ngaphansi kwengcindezi ephezulu. Umphumela uba isistimu esheshayo, ezenzakalelayo ekhiqiza izinkulungwane zezingxenye ezifanayo ezinokuphela okuhle kakhulu kwendawo futhiukubekezelelana okuqinile.

Izindlela zendabuko, ezifana nokusakazwa kwesihlabathi nokutshala imali, zithembele ekubunjweni okusebenzisekayo. Ukubunjwa kwesihlabathi kusebenzisa isihlabathi nobumba ukwakha isikhunta ngasinye, esichithwa ngemva kokusetshenziswa ngakunye. Ukutshala izimali kudala izingxenye ezinemininingwane kodwa kuthatha isikhathi esiningi futhi kubiza kakhulu ngeyunithi ngayinye. Izitembu zensimbi zisebenzela izimo ezilula kodwa azikwazi ukuphatha imiklamo eyinkimbinkimbi.

I-Die casting igqama ngekhono layo lokudala izingxenye eziyinkimbinkimbi, ezinezindonga ezincane, nezinembe ngobukhulu ezinomshini omncane wesibili. Le nzuzo iholela ekukhiqizeni okusheshayo kanye nekhwalithi engaguquki, ebaluleke kakhulu kumaphampu nama-compressor.

Nasi ukuqhathanisa okusheshayo kwezindlela ezijwayelekile zokukhiqiza:

| Indlela Yokukhiqiza | Ukusetshenziswa Okuvamile Ku-Pump/Compressor Components | Izimpawu Zokusetshenziswa Kwempahla |

|---|---|---|

| I-Gravity Casting | Amapiston ezimoto, amakhanda angamasilinda | Ingase idinge i-aluminium eyinhloko eyengeziwe; ukugeleza kwensimbi okungalawulwa kancane; okungaba neziphambeko |

| I-Low Pressure Permanent Mold Casting | Izingxenye zesakhiwo | Ivumela izigaba ezizacile; isebenzisa ingcindezi ukugcwalisa isikhunta; idinga i-aluminium eyinhloko ukuze isebenze |

| Cindezela Ukusakaza | Izingxenye zokumiswa | Ikhiqiza izingxenye ezingenazimbotshana, ezikwazi ukumelana nokushisa; izakhiwo ezingcono zemishini |

| I-High Pressure Die Casting (HPDC) | Izindlu zamaphampu eziyinkimbinkimbi, izingxenye ze-compressor | Kuyashesha, kungabizi, kunembile; isiphetho esihle kakhulu; best for high-volume, izingxenye eziyinkimbinkimbi |

Ukusebenza Nekhwalithi Ukuqhathanisa

I-Aluminium die Casting iletha ukusebenza okuvelele kwamaphampu nama-compressor. Inqubo idala izingxenye ezinosayizi omuhle wokusanhlamvu, amandla aphezulu okusebenza, kanye nokuzinza kwe-dimensional. Lezi zimfanelo zisiza amaphampu nama-compressor ukuthi asebenze kahle futhi ahlale isikhathi eside.

Ama-alloys e-aluminium e-semi-solid, njenge-Al-Si-Mg-Cu, abonisa izici zomshini ezihlaba umxhwele lapho kuphathwa ukushisa. Isibonelo, ama-alloys aphethwe yi-T6 angafinyelela kumandla aqinile afinyelela ku-575 MPa, cishe ngama-30% aphezulu kunama-alloys angalashiwe. Izingxenye ze-aluminiyamu ezibunjwe Thixo ziphinde zibonise ukuqina okuncishisiwe kanye nokumelana nokukhathala okuthuthukisiwe, okuzenza zithembeke ezinhlelweni ezifunwa kakhulu.

Izimboni eziningi zikhetha izingxenye ze-die cast ngoba zinikeza amandla nokuqina okudingekayo kumaphampu nama-compressor. Inqubo iphinde inciphise ubungozi bokukhubazeka kwangaphakathi, iqinisekise ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziqinile zekhwalithi.

Izindleko Nokukhiqiza Ngempumelelo

I-aluminium die casting iguqula ukusebenza kahle kokukhiqiza kwamaphampu nama-compressor. Inqubo isebenzisa isikhunta sensimbi esisebenziseka kabusha kanye nomjovo onomfutho ophezulu, onciphisa izikhathi zomjikelezo futhi andise ukuphuma. Izikhathi zomjikelezo zingasukela kumasekhondi angu-2 nje ukuya kuminithi elingu-1, okuvumela abakhiqizi ukuthi bakhiqize amavolumu amakhulu ngokushesha.

Izindlela zendabuko, njengokubunjwa kwesihlabathi, zidinga ukulungiswa kwesikhunta eside futhi zibhubhise isikhunta ngemva kokusetshenziswa ngakunye. Lokhu kuholela ekukhiqizweni kancane kanye nezindleko eziphezulu zabasebenzi. Ngokuphambene, i-die casting isekela ukukhiqizwa okukhulu ngekhwalithi engaguquki nomsebenzi omncane wokuqeda.

- I-Die casting kunciphisa izikhathi zokuhola futhi yehlise izindleko zengxenye ngayinye esikalini.

- Inqubo ikhiqiza izingxenye ezinamandla amakhulu emishini kanye nokuminyana okufanayo.

- Abakhiqizi bayazuza ekuphindaphindweni okungcono kanye nokumosha okuncane.

I-Aluminium die Casting inika izinkampani amandla okuhlangabezana nezikhathi eziqinile futhi zilethe amaphampu nama-compressor adlula lokho obekulindelwe. Inhlanganisela yesivinini, ukunemba, nokonga izindleko kukhuthaza ukuzethemba kuyo yonke iphrojekthi.

Izinzuzo Eziyinhloko Ze-Aluminium Die Casting yamaphampu nama-Compressor

Amandla-kuya-Isisindo Isilinganiso Nokuqina

I-aluminium die castingiletha isilinganiso esimangalisayo samandla nesisindo. Le nzuzo isho ukuthi abakhiqizi bangakha izingxenye eziqinile ngaphandle kokwengeza inqwaba engadingekile. Amaphampu nama-compressor ayazuza kule ndawo, njengoba izingxenye ezilula zinciphisa ukusetshenziswa kwamandla futhi zithuthukisa ukusebenza kahle. Ama-alloys e-aluminium athuthukisiwe, njenge-LM25 ne-AlSi9Cu3, anikeza amandla aphezulu nokumelana nokuguga. Lawa ma-alloys amelana nokucindezeleka kwemishini futhi alondoloze ukusebenza ngaphansi kwezimo ezinzima.

Ukuqina kuma njengophawu lwezingxenye ze-aluminium die cast. Inqubo ikhiqiza izingxenye ezinezinhlaka ezinhle zokusanhlamvu kanye ne-porosity encane. Lokhu kubangela izingxenye ezimelana nokuqhekeka nokuguqulwa, ngisho nangemva kweminyaka yokusebenza. Izimboni eziningi zithembele kulezi zingxenye ezihlala isikhathi eside ukuze zigcine amaphampu nama-compressor asebenza kahle, usuku nosuku.

Ukumelana Nokugqwala Nokuphila Isikhathi Eside

Ama-alloys e-aluminium ngokwemvelo amelana nokugqwala. Lesi sakhiwo sibenza balungele amaphampu nama-compressor avezwa umswakama, amakhemikhali, noma izindawo ezinokhahlo. Ama-alloys afana ne-LM6 ne-LM9 ahlinzeka ngokuvikeleka okuhle kakhulu ekuhlaseleni ukugqwala nokuhlaselwa kwamakhemikhali. Abakhiqizi bavame ukuthuthukisa lokhu kumelana nokwelashwa okungaphezulu okufana ne-anodizing noma i-powder coating.

Ukuphila isikhathi eside kuba ngokoqobo ngezingxenye ze-aluminium die cast. Lezi zingxenye zigcina ubuqotho nokubukeka kwazo ngokuhamba kwesikhathi. Zidinga ukulungiswa okuncane nokushintshwa, okuholela ekwehliseni izindleko zesikhathi eside. Izinkampani ezishintshela ku-aluminium die casting ngokuvamile zibona ukonga okubalulekile ngenxa yokuncishiswa kokulahlwa kwezinto ezibonakalayo kanye nempilo yesevisi eyandisiwe.

Ithiphu: Ukukhetha ingxubevange efanele ye-aluminium kanye nokuqedwa kwendawo kungathuthukisa ukumelana nokugqwala, kuqinisekise ukuthi amaphampu nama-compressor asebenza ngokuthembekile kunoma isiphi isilungiselelo.

Ukunemba, Ukuguquguquka Komklamo, kanye Nokuqina

I-aluminium die casting ihamba phambili ngokunemba nokuguquguquka komklamo. Ukubunjwa komshini we-CNC kuqinisekisa ukunemba kobukhulu kanye nokuqedwa kwendawo okubushelelezi. I-aluminium encibilikisiwe igcwalisa ngisho nezici zesikhunta eziyinkimbinkimbi kakhulu, ithwebula imininingwane eyinkimbinkimbi kalula. Le nqubo isekela ukwakhiwa kwezingxenye ezinodonga oluncane, ezingasindi izindlela zendabuko ezilwela ukuzifeza.

Abakhiqizi bajabulela izinzuzo eziningana:

- Ukubekezelelana okuqinile kunciphisa noma kuqede isidingo somshini wesibili.

- Izikhathi zomjikelezo osheshayo zisekela ukukhiqizwa kwevolumu ephezulu.

- Ikhwalithi engaguquki inciphisa amaphutha nokumosha.

- I-scalability ivumela izinkampani ukuthi zihlangabezane nesidingo esikhulayo ngaphandle kokunyuka kwezindleko ezinkulu.

- Izingxenye ze-aluminium ezingasindi zithuthukisa ukusebenza komkhiqizo, ikakhulukazi kumaphampu nama-compressor.

Ikhono lokukhiqiza amajiyometri athuthukisiwe kanye nokukhiqizwa kwe-ramp up ngokushesha linikeza abakhiqizi umkhawulo wokuncintisana. Uma isifafaze senziwe, ukukhuphula kuyaphumelela futhi kubiza izindleko.

Izicelo Zomhlaba Wangempela kanye Nempumelelo Yemboni

Izimboni emhlabeni jikelele zithemba i-aluminium die casting kumaphampu nama-compressor. Imizimba yama-valve enembe kakhulu, ama-multifolds, nezindlu zibonisa ukuguquguquka kwenqubo. Abakhiqizi bezimoto, ama-hydraulics, kanye ne-pneumatics bathembele ku-die cast aluminium kukho kokubili i-aftermarket nempahla yokuqala.

- Izindikimba zamavalvu esango legesi yemvelo zisebenzisa i-dies cast aluminium ukuze zibe namandla nokumelana nokugqwala.

- Izingxenye zokupholisa uwoyela ngokwezifiso ziyazuza enguqulweni yedizayini yenqubo.

- Izindlu ze-Compressor kanye nama-rotor enziwe ngama-alloys e-aluminium anciphisa isisindo futhi athuthukise ukuchithwa kokushisa.

Ezilungiselelweni zomhlaba wangempela, lezi zingxenye ziletha ukusebenza okuvelele. Isibonelo, imizimba yephampu nama-impeller akhiqizwa i-low-press die casting abonisa i-porosity ephansi, ukuqedwa okuphezulu okuhle kakhulu, kanye nezakhiwo ezithuthukisiwe zemishini. Lezi zimfanelo ziqinisekisa ukusebenza okuthembekile ku-oyela negesi, amakhemikhali, nasezikhungweni zokuhlanza amanzi.

Qaphela: Impumelelo ye-aluminium die cast ezimbonini ezihlukene ifakazela ukubaluleka kwayo. Izinkampani zithola ukonga kwezindleko, ukusebenza kahle okuthuthukisiwe, nokusebenza okuhlala isikhathi eside kumaphampu nama-compressor.

I-aluminium die casting imile njengenketho ephezulu yamaphampu nama-compressor. Abaholi bemboni bagqamisa ikhono layo lokuletha:

- Ukukhiqizwa kwevolumu ephezulu yezingxenye eziyinkimbinkimbi, ezinodonga oluncane

- Ukunemba okukhethekile, ukuphindaphinda, nokuqedwa kwendawo

- Ikhwalithi engaguquki yezinkulungwane zezingxenye ezifanayo

Intuthuko yesikhathi esizayoku-automation, ubuhlakani bokwenziwa, nama-alloys athuthukisiwe athembisa ukusebenza okukhulu nokusimama. Amaphampu nama-compressor azoqhubeka nokuhlomula kulokhu okusha, ukubeka izindinganiso ezintsha zokwethembeka nokusebenza kahle.

FAQ

Yini eyenza i-aluminium die casting ilungele izingxenye zepompo ne-compressor?

I-aluminium die castingkwakha izingxenye eziqinile, ezingasindi. Abakhiqizi bathola ukunemba okuphezulu nokuqina. Le nqubo ikhuthaza ukuzethemba ezimbonini ezifuna ukusebenza okuthembekile.

I-aluminium die casting isiza kanjani ukunciphisa izindleko?

- Izinkampani zonga imali ngokukhiqiza okusheshayo.

- Amaphutha ambalwa asho ukumosha okuncane.

- Ukugijima kwevolumu ephezulu kwehlisa intengo ingxenye ngayinye.

Ingabe izingxenye ze-aluminium die cast zingasingatha izindawo ezinokhahlo?

Isikhathi sokuthumela: Aug-04-2025