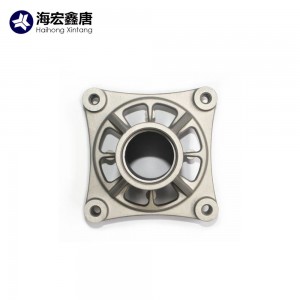

Ukunemba kudlala indima ebalulekile ekukhiqizeniukufa kokusakazaCNC machining izingxenye ezisele, ikakhulukazi ezimbonini ezifana zezimoto. Uthembele kulezi zingxenye ukuze uqinisekise ukuthi imoto yakho isebenza kahle futhi ngokuphepha. Ukuthola ukunemba okuphezulu kungaba inselele ngenxa yezinto ezifana nezakhiwo zezinto ezibonakalayo nobunkimbinkimbi bemishini. Lezi zinselele zithinta ngqo ukusebenza nokuthembeka komkhiqizo. I-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD iyahamba phambili ekukhiqizenidie casting CNC mechaning izingxenye eziselengokuhlanganisa ubuchwepheshe obuthuthukisiwe nokuhlolwa kwekhwalithi okuqinile. Ikhono labo lokuletha ukunemba kanyeukusakaza kunikeza izinsizakalo ze-OEMubahlukanisa njengomholi wemboni othembekile.

Okuthathwayo Okubalulekile

- Khetha izinto ezifana ne-aluminiumaqinile, alula, futhi abumbeka kalula ukuze kube nemiphumela engcono yokusakaza ifa.

- Hlola futhi ulungise amathuluzi ngokuvamile ukumisa umonakalo futhi ugcine ikhwalithi iqinile ekwenzeni izingxenye.

- Lungisa imishini ye-CNC njalo ukuze ihlale inemba futhi ugweme amaphutha abizayo ezingxenyeni eziyisipele.

- Sebenzisa ama-coolants noma ezinye izindlela ukuzelawula ukushisa futhi umise izinkingangesikhathi somshini.

- Zama amathuluzi athuthukile nesofthiwe ukuze usebenze ngobumo abakhohlisayo futhi wenze imiklamo enemininingwane ngokuphelele.

Ukukhetha Okubalulekile Nokuvumelana

Ukukhetha izinto ezifanele ze-die casting CNC machining izingxenye ezisele

Ukukhetha izinto ezifanele kuyisisekelo sokukhiqiza okunembayo. Udinga izinto ezikwazi ukumelana nomfutho ophezulu ngesikhathi senqubo yokufa. I-Aluminiyamu ivamise ukuba yinto ekhethwayo ngoba ayisindi, iqinile, futhi imelana nokugqwala. Lezi zakhiwo ziyenza ilungele izinhlelo zokusebenza zezimoto, lapho amandla nokuthembeka kubaluleke kakhulu.

Lapho ukhetha izinto zokwakha, kufanele futhi ucabangele ukusebenza kwazo. Izinto ezisebenza kalula ngomshini zinciphisa isikhathi sokukhiqiza futhi ziqinisekise ikhwalithi engaguquki. Isibonelo, ama-alloys e-aluminium ahlinzeka ngokusebenza okuhle kakhulu, okuvumela imiklamo eyinkimbinkimbi kanye nokuqedwa okubushelelezi.

Ithiphu:Ngaso sonke isikhathi beka phambili izinto ezilinganisa amandla, isisindo, kanye nokusebenza kahle ukuze usebenze kahle ezingxenyeni eziyisipele zomshini we-CNC.

Ukuqinisekisa ukuhambisana kwezinto ezibonakalayo nezinqubo zemishini ye-CNC

Ukuhambisana kwezinto kudlala indima ebalulekile ekuzuzeni ukunemba ngesikhathi somshini we-CNC. Kufanele uqinisekise ukuthi impahla ekhethiwe ihambisana namandla emishini yakho ye-CNC. Isibonelo, ezinye izinto zingase zidinge amathuluzi okusika athile noma isivinini ukugwema ukuguga noma ukungapheleli kwendawo.

Izici ezishisayo zezinto ezibonakalayo nazo zinendaba. Ngesikhathi somshini, ukushisa kungakha futhi kuthinte ukwakheka kwezinto. I-Aluminium, ene-thermal conductivity ephezulu, ihlakaza ukushisa ngokuphumelelayo, igcine ukuqina kwe-dimensional.

Ukuqinisekisa ukuhambisana, kufanele uhlole izinto ezisetshenziswayo ngaphansi kwezimo zangempela zomshini. Lokhu kusiza ukuhlonza izinkinga ezingaba khona njengokuguga kwamathuluzi noma ukonakala kwendawo ekuqaleni kwenqubo.

I-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD iqinisekisa kanjani ikhwalithi yezinto ezibonakalayo eziphezulu

I-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD ibeka phambili ikhwalithi yezinto ezibonakalayo ukuze ilethehigh-nemba die casting izingxenye ezisele zemishini ye-CNC. Inkampani isebenzisa ama-alloys e-aluminium e-premium ahlangabezana nezindinganiso eziqinile zemboni. Lezi zinto zivivinywa kanzima ukuze kuqinisekiswe ukuthi zingakwazi ukusingatha ukukhishwa kwengcindezi ephezulu kanye nezinqubo zemishini ye-CNC ngaphandle kokubeka engcupheni ikhwalithi.

Le nkampani iphinde ifake imali emishinini ethuthukisiwe yokuhlola izakhiwo zezinto ezibonakalayo njengamandla, ubulukhuni, kanye ne-thermal conductivity. Lokhu kuqinisekisa ukuthi yonke inqwaba yezinto iyahambisana nezikhungo zabo zemishini ye-CNC kanye nemishini yokulawula izinombolo.

Ukwengeza, i-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD isebenzisa ithimba lochwepheshe ukuze lihlole ukusebenza kwempahla. Izinqubo zabo zokuhlola kwangaphakathi ziqinisekisa ukuthi impahla ngayinye inegalelo ekunembeni nasekuthembekeni komkhiqizo wokugcina.

Qaphela:Ngokugxila kukhwalithi yezinto ezibonakalayo, i-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD iqinisekisa ukuthi izingxenye eziyisipele ze-CNC machining yazo zihlangabezana nezindinganiso eziphakeme kakhulu zokuqina nokusebenza.

Ukugqoka Kwamathuluzi Nokunakekela

Umthelela wokugqoka kwamathuluzi ekunembeni nekhwalithi yomkhiqizo

Ukugqoka kwamathuluzi kuthinta ngqoukunemba kwenqubo yakho yokukhiqiza. Njengoba amathuluzi ehla, alahlekelwa ukubukhali kwawo, okungaholela ekusikekeni okungalingani kanye nokungalungi kobukhulu. Lokhu kubeka engcupheni ikhwalithi yomkhiqizo wokugcina. Ezingxenyeni ezisele zemishini ye-CNC yokufa, ngisho nokuchezuka okuncane kungaholela ekusebenzeni okungalungile noma ukunciphisa ukusebenza.

Amathuluzi agugile aphinde andise ubungozi bokulimala kwendawo, njengokuqedwa okuqinile noma ama-burrs. Lokhu kungapheleli akuthinti nje kuphela ukubukeka kwengxenye kodwa kungase kwenze buthaka ubuqotho bayo besakhiwo. Ukuqapha njalo ukuguga kwamathuluzi kukusiza ukuthi ugcine ikhwalithi engashintshi futhi ugweme ukusetshenzwa kabusha okumba eqolo noma ukumosheka kwezinto.

Ithiphu:Ngaso sonke isikhathi hlola amathuluzi ukuze uthole izimpawu zokuguga, njengokuchopha noma imiphetho ebuthuntu, ukuze uvimbele izinkinga zokunemba.

Izindlela zokulungisa ezisebenzayo zamathuluzi omshini we-CNC

Ukunakekelwa okufanele kuqinisekisa ukuthi amathuluzi akho asebenza kahle kakhulu. Qala ngokuhlanza amathuluzi ngemva kokusetshenziswa ngakunye ukuze ususe imfucumfucu futhi uvimbele ukunqwabelana. Ukugcoba izingxenye ezihambayo kunciphisa ukungqubuzana futhi kunciphisa ukuguga. Kufanele futhi ugcine amathuluzi endaweni eyomile, ehlelekile ukuze uwavikele emonakalweni.

Ukuhlola okuvamile kubalulekile. Hlola ukuqhekeka, ukuguga, noma ukungahambi kahle ngaphambi kokuqala noma iyiphi inqubo yokwenza imishini. Ukushintsha amathuluzi agugile ngokushesha kuvimbela ukulimala okwengeziwe kumishini yakho futhi kuqinisekisa imiphumela engaguquki.

Ukudala ishejuli yokulungisa ikusiza ukuthi uhlale usebenza. Ukusebenza kwethuluzi lokubhala kanye namaphethini okugqoka kukuvumela ukuthi ubikezele lapho kudingekile ukushintshwa noma ukulungiswa.

Izembatho ezithuthukisiwe nezinto ezisetshenziswa ukwelula impilo yamathuluzi

Amathuluzi esimanje ngokuvamile aneziciezinengilazi eziphambili ezithuthukisa ukuqina. Izembatho ezinjenge-titanium nitride (TiN) noma ikhabhoni efana nedayimane (DLC) inciphisa ukungqubuzana nokwanda kokushisa ngesikhathi somshini. Lokhu kwandisa impilo yethuluzi futhi kuthuthukisa ukusebenza kahle kokusika.

Izinto ezisebenza kahle kakhulu, njenge-carbide noma i-ceramic, nazo zidumile ngamathuluzi omshini we-CNC. Lezi zinto zimelana nokuguga futhi zigcina ubukhali bazo isikhathi eside kunamathuluzi ensimbi yendabuko. Ngokutshala imali kumathuluzi ahlanganisiwe noma ekhwalithi ephezulu, unganciphisa isikhathi sokuphumula futhi uthuthukise ukunemba kwenqubo yakho yokukhiqiza.

Qaphela:Ukusebenzisa amathuluzi athuthukile akugcini nje ngokunweba impilo yabo kodwa futhi kuthuthukisa ikhwalithi yezingxenye ezisele zomshini wakho we-CNC.

Ukulinganisa Umshini Nokunemba

Ukubaluleka kokulinganiswa okunembile kumashini we-CNC

Ukulinganisa okunembile kuwumgogodla wokunemba kumashini we-CNC. Lapho imishini yakho ilinganiswe kahle, ikhiqiza izingxenye ezihlangabezana nemininingwane eqondile. Lokhu kuqinisekisa ukuthi yonke ingxenye ilingana kahle futhi isebenza ngendlela ehlosiwe. Ukulinganisa kususa amaphutha abangwe ukungaqondani kahle noma izilinganiso ezingalungile, ezingaholela ekulimaleni okubizayo noma kusetshenzwe kabusha.

Ezimbonini ezifana nezezimoto, lapho ukunemba kubaluleke khona, ngisho nokuchezuka okuncane kungonakalisa ukusebenza kwengxenye. Ngokwesibonelo,die casting CNC machining izingxenye eziselekumele ahlangabezane nokubekezelelana okuqinile ukuze aqinisekise ukuthi ahlanganisa ngaphandle komthungo ezimotweni. Ukulinganisa okulungile kuqinisekisa ukuthi lezi zingxenye zigcina ubuqotho bazo besakhiwo nokuthembeka.

Ithiphu:Hlola njalo ukulinganiswa komshini wakho ukuze ugcine ikhwalithi engashintshi futhi ugweme ukubambezeleka kokukhiqiza okungalindelekile.

Amaphutha okulinganisa ajwayelekile nokuthi ungawagwema kanjani

Amaphutha okulinganisa ngokuvamile avela emininingwaneni enganakiwe. Iphutha elilodwa elivamile ukunganaki ukulandisa ngokunwetshwa kokushisa. Imishini ikhiqiza ukushisa ngesikhathi sokusebenza, okungabangela izingxenye ukuthi zande futhi zithinte izilinganiso. Ukuze ugweme lokhu, kufanele ulinganise imishini yakho lapho isezingeni lokushisa lokusebenza.

Enye inkinga evamile ukusebenzisa amathuluzi okulinganisa agugile noma awonakele. Lawa mathuluzi anganikeza ukufundwa okungalungile, okuholela kumaphutha enqubweni yomshini. Njalo hlola amathuluzi akho okulinganisa ngaphambi kokuwusebenzisa futhi uwushintshe uma kunesidingo.

Izici zemvelo, njengokudlidliza noma izindawo ezingalingani, zingaphazamisa nokulinganiswa. Qinisekisa ukuthi imishini yakho ifakwe ezisekelweni ezizinzile futhi isebenza ezindaweni ezilawulwayo.

Qaphela:Ukugcina ilogi enemininingwane yemisebenzi yokulinganisa kukusiza ukuthi ubone amaphethini futhi ubhekane nezinkinga eziphindelelayo ngempumelelo.

Izinqubo zokulinganisa e-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD

Kwa-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD, ukulinganisa kuyinqubo ecophelelayo. Inkampani isebenzisa amathuluzi okulinganisa athuthukile ukuqinisekisa ukuthi imishini yabo ye-CNC isebenza ngokunemba kokukhomba. Umshini ngamunye uhlolwa njalo ukuze uqinisekise ukuqondanisa, ukuma, kanye nokususwa kwamathuluzi.

Ithimba liphinde lisebenzisa izindawo ezilawulwa izinga lokushisa ukuze linciphise umthelela wokunwetshwa kokushisa ngesikhathi sokulinganisa. Lokhu kuqinisekisa ukuthi izingxenye zabo eziyisipele ze-CNC zomshini wokufa zihlangabezana nezindinganiso eziphakeme zokunemba.

Ukwengeza, i-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ilandela uhlelo oluqinile lokulinganisa. Ngokunamathela kulo mkhuba, bagcina ukusebenza okufanayo kuzo zonke izikhungo zabo zemishini ye-CNC ezingama-39 kanye nemishini yokulawula izinombolo eyi-15. Ukuzinikela kwabo ekunembeni kukhombisa ikhwalithi nokuthembeka kwayo yonke ingxenye abayikhiqizayo.

I-callout:Thembela kumkhiqizi obeka phambili ukulinganisa ukuze alethe izingxenye ezeqa obulindelekile.

Ukuphathwa Kokushisa

Ukuthi ukushisa kukuthinta kanjani ukunemba ezingxenyeni eziyisipele zomshini we-CNC

Ukushisa kudlala indima ebalulekile enqubweni yokukhiqiza. Kungabangela ukuba izinto zokwakha zande, okuholela ekunganembi kobukhulu. Niniimishini ye-aluminium, ukushisa ngokweqile kungase kuguqule ukwakheka kwayo, kubangele ukungapheleli kwendawo noma amandla ancishisiwe. Lezi zinkinga zithinta ngokuqondile ukunemba kwezingxenye ezisele zomshini we-CNC.

Ukushisa kuphinde kuthinte amathuluzi asetshenziswa ekwenzeni imishini. Amazinga okushisa aphezulu angasheshisa ukugqokwa kwamathuluzi, anciphise ubukhali bawo kanye nokusebenza kahle kokusika. Lokhu kuholela ekusikekeni okungalingani kanye nokuqedwa kwekhwalithi embi. Ukuphatha ukushisa kuqinisekisa ngempumelelo ukuthi kokubili okokusebenza namathuluzi kugcina ubuqotho bakho ngesikhathi sokukhiqiza.

Ithiphu:Qaphela amazinga okushisa ngesikhathi somshini ukuze uvimbele izinkinga ezihlobene nokushisa futhi ugcine ukunemba.

Amasu okuphatha ukushisa okusebenzayo ngesikhathi sokukhiqiza

Ungasebenzisa amasu amaningana okuphatha ukushisa ngesikhathi sokukhiqiza. Qala ngokusebenzisaukusika uketshezi noma okokupholisa. Lezi ziphuzo zinciphisa ukungqubuzana futhi ziqede ukushisa, zigcine okokusebenza namathuluzi kupholile.

Enye indlela ephumelelayo ukukhulisa isivinini sokusika. Izivinini ezihamba kancane zikhiqiza ukushisa okuncane, kuyilapho isivinini esisheshayo singadinga izinyathelo zokupholisa ezengeziwe. Ukulungisa isivinini ngokusekelwe ezintweni ezibonakalayo kusiza ukugcina ukuqina kokushisa.

Ukukhetha amathuluzi nakho kubalulekile. Amathuluzi enziwe ngezinto ezikwazi ukumelana nokushisa, njenge-carbide, enza kangcono ngaphansi kwamazinga okushisa aphezulu. Ukuhlola njalo nokushintsha amathuluzi agugile kuvimbela ukunqwabelana kokushisa okubangelwa ukungqubuzana.

I-callout:Ukusebenzisa lawa maqhinga kuthuthukisa ukunemba futhi kunwebe ubude besikhathi semishini yakho.

Indima yezinhlelo zokupholisa ekugcineni ukuqina kokushisa

Amasistimu okupholisa abalulekile ekulawuleni ukushisa ngesikhathi somshini. Azungeza izinto ezipholile ukuze amunce futhi asuse ukushisa endaweni yokusika. Lokhu kuvimbela ukushisa ngokweqile futhi kuqinisekisa ukusebenza okungaguquki.

Amasistimu okupholisa athuthukile, njengenkungu noma ukupholisa izikhukhula, anikeza izixazululo eziqondiwe. Ukupholisa inkungu kufafaza amaconsi amahle endaweni yokusika, kuyilapho ukupholisa izikhukhula kunikeza ukugeleza koketshezi okuqhubekayo. Zombili izindlela zilawula ngempumelelo ukushisa futhi zithuthukise ukunemba.

E-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD, amasistimu okupholisa ahlanganiswe ezikhungweni zawo zemishini ye-CNC. Lezi zinhlelo zigcina ukuzinza kwe-thermal, ziqinisekisa ukuthi izingxenye ezisele zemishini ye-CNC zihlangabezana nokucaciswa okuqondile.

Qaphela:Ukutshala imali ezinhlelweni zokupholisa ezinokwethenjelwa kuvikela inqubo yakho yokukhiqiza ezinseleleni ezihlobene nokushisa.

Ukuphatha i-Complex Geometries

Izinselele ekwenzeni imiklamo eyinkimbinkimbi kanye nokwakheka

Ukwenza imiklamo eyinkimbinkimbi iletha izinselele eziyingqayizivele. Amajiyometri ayinkimbinkimbi ngokuvamile ahlanganisa ukubekezelelana okuqinile, ama-engeli abukhali, nezindawo ezigobile. Lezi zici zidinga ukunemba okwedlulele ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nokucaciswa okuqondile. Ungase uhlangabezane nobunzima lapho usebenza ngezinto ezijwayele ukonakala noma ukwakheka kokushisa ngesikhathi somshini.

Enye inselele ivela ekufinyeleleni kwamathuluzi. Ukufinyelela ezindaweni ezijulile noma ezincane engxenyeni ethile kungaba nzima, ikakhulukazi uma usebenzisa amathuluzi ajwayelekile. Lokhu kungaholela ekusikekeni okungalingani noma emininingwaneni egejiwe. Ukwengeza, ukugcina ukuvumelana kuzo zonke izingxenye eziningi ngemiklamo eyinkimbinkimbi kudinga imishini ethuthukisiwe nokuhlela okucophelelayo.

Ithiphu:Hlale uhlola ubunkimbinkimbi bomklamo kanye nezakhiwo ezibonakalayo ngaphambi kokuqala inqubo yokwenza imishini.

Amathuluzi namasu okuzuza ukunemba kumajometri ayinkimbinkimbi

Ukuze ufinyelele ukunemba kumajometri ayinkimbinkimbi, udinga amathuluzi akhethekile namasu. Imishini ye-Multi-axis CNC, efana nesistimu ye-axis engu-5, ikuvumela ukuthi usondele engxenyeni ukusuka kuma-engeli amaningi. Leli khono liqinisekisa ukucutshungulwa okunembile kwezici eziyinkimbinkimbi.

Ukusebenzisa amathuluzi okusika anesivinini esiphezulu enziwe ngezinto ezihlala isikhathi eside njenge-carbide noma i-ceramic kuthuthukisa ukunemba. Lawa mathuluzi agcina ubukhali bawo, ngisho noma enza amadizayini ayinselele. Ukusebenzisa amasu afana nokugaya i-trochoidal nakho kungasiza. Le ndlela inciphisa ukucindezeleka kwamathuluzi futhi ithuthukise ukunemba ngokusebenzisa izindlela zokusika ezincane, eziyindilinga.

I-callout:Ukutshala imali kumathuluzi namasu athuthukile kuqinisekisa ikhwalithi engaguquki yemiklamo eyinkimbinkimbi.

Ukulingisa okusebenzisekayo kanye nesoftware yemiklamo yezingxenye eziyinkimbinkimbi

Isofthiwe yokulingisa idlala indima ebalulekile ekuphatheni amajiyometri ayinkimbinkimbi. Ngokusebenzisa izinhlelo ze-CAD/CAM, ungakwazi ukubona ngeso lengqondo inqubo yokwenza imishini ngaphambi kokuqala kokukhiqiza. Lokhu kukusiza ukuthi ubone izinkinga ezingaba khona, njengokushayisana kwamathuluzi noma ukumosheka kwezinto, ngasekuqaleni kwesigaba sokuklama.

Isoftware ethuthukisiwe futhi ikuvumela ukuthi uthuthukise izindlela zamathuluzi ukuze usebenze kahle kakhulu. Isibonelo, ungakwazi ukulingisa ama-engeli okusika nesivinini ukuze unciphise amaphutha futhi uthuthukise ukuqedwa kwendawo. E-NINGBO HAIHONG XINTANG MECHANICAL CO., LTD, amathuluzi okulingisa abalulekile ekukhiqizeni izingxenye eziyisipele ze-CNC ze-die casting zekhwalithi ephezulu. Lawa mathuluzi aqinisekisa ukuthi ingxenye ngayinye ihlangabezana nokucaciswa okudingekayo, kungakhathaliseki ukuthi umklamo oyinkimbinkimbi kangakanani.

Qaphela:Ukusebenzisa isofthiwe yokulingisa kunciphisa ukuzama kanye namaphutha, ukonga isikhathi nezinsiza enqubweni yokukhiqiza.

Ukuthola ukunemba okuphezulu ekusakazeni okufayo kwezingxenye eziyisipele ze-CNC kudinga inhlanganisela yezinto ezifanele, ukugcinwa kwamathuluzi okufanele, ukulinganiswa komshini okunembile, ukuphathwa kokushisa okusebenzayo, kanyeamasu athuthukile okuphathaijometri eyinkimbinkimbi. Ngokulandela lawa maqhinga, ungaqinisekisa ikhwalithi nokusebenza okungaguquki enqubweni yakho yokukhiqiza.

I-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ibonisa ukusebenza kahle okungaguqukiukuzibophezela kokunemba kanye nekhwalithi. Ubuchwepheshe babo, ubuchwepheshe obuthuthukisiwe, nokuhlolwa kwekhwalithi okuqinile kubenza babe ozakwethu abathembekile bezingxenye eziyisipele ezisebenza kahle.

Ukwamukela lezi zinqubo ezihamba phambili kuzokusiza ukuthi ukhiqize imikhiqizo ethembekile ehlangabezana nezindinganiso zomkhakha futhi yeqe okulindelwe ngamakhasimende.

FAQ

1. Yiziphi izimboni ezizuza kakhulu ngokufaka izingxenye ezisele zemishini ye-CNC?

Die casting CNC machining izingxenye eziselezisetshenziswa kakhulu ezimbonini zezimoto, i-aerospace, kanye ne-electronics. Lezi zingxenye ziqinisekisa ukunemba okuphezulu nokuqina, okuzenza zilungele izinhlelo zokusebenza ezidinga ukubekezelelana okuqinile nokusebenza okuthembekile.

Ithiphu:Njalo khetha umkhiqizi onolwazi embonini yakho ukuze uthole imiphumela engcono kakhulu.

2. Ngabe imishini ye-CNC ikuthuthukisa kanjani ukunemba kwezingxenye ezisele?

Imishini ye-CNC isebenzisa amathuluzi alawulwa ngekhompuyutha ukuze kwakheke izingxenye ezinobukhulu obuqondile. Le nqubo isusa iphutha lomuntu futhi iqinisekisa ikhwalithi engashintshi kuzo zonke izingxenye. Iphinde ivumele imiklamo eyinkimbinkimbi kanye nokubekezelelana okuqinile.

3. Kungani i-aluminiyamu iwumsebenzi odumile wezinsimbi eziyisipele ezisansimbi?

I-Aluminiyamu ayisindi, iqinile, futhi imelana nokugqwala. Iphinde ibe ne-thermal conductivity enhle kakhulu, okuyenza ilungele ukusakaza okunomfutho ophezulu wegazi. Ukuhleleka kwayo kuvumela imiklamo enembile neyinkimbinkimbi.

Qaphela:Ama-alloys e-aluminium avame ukusetshenziselwa izinhlelo zezimoto ngenxa yokuqina nokuthembeka kwawo.

4. Ungaqinisekisa kanjani ikhwalithi yezingxenye ezisele zemishini ye-CNC?

Ungaqinisekisa ikhwalithi ngokukhetha umkhiqizi onempahla ethuthukisiwe, ukuhlolwa kwekhwalithi okuqinile, kanye nezitifiketi ezifana ne-ISO 9001. Ukuhlolwa okuvamile nokuhlolwa kwezinto ezibonakalayo nakho kusiza ukugcina amazinga aphezulu.

5. Yini eyenza i-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ibe ngumkhiqizi owethembekile?

I-NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ihlanganisaubuchwepheshe obuphambili, izinto ze-premium, nokuhlolwa kwekhwalithi okuqinile. Ubuchwepheshe babo ku-aluminium die casting kanye ne-CNC machining buqinisekisa ukunemba nokuthembeka kuzo zonke izingxenye abazikhiqizayo.

I-callout:Xhumana nabo namuhla ukuze uzizwele isevisi yabo eyingqayizivele nemikhiqizo yekhwalithi ephezulu.

Isikhathi sokuthumela: May-25-2025