Aluminum die casting transforms the way manufacturers create pumps and compressors. This method gives components a strong yet lightweight build. Many industries now trust aluminum die casting to deliver lasting performance and reliability. Success stories show that pumps and compressors reach new heights with this advanced process.

Key Takeaways

- Aluminum die casting produces strong, lightweight pump and compressor parts with high precision and consistent quality, improving performance and durability.

- This method speeds up production and lowers costs by using reusable molds and fast cycle times, making it ideal for large-scale manufacturing.

- Die casting allows complex, thin-walled designs that reduce weight and energy use, while offering excellent corrosion resistance for long-lasting components.

Aluminum Die Casting vs. Traditional Methods in Pumps and Compressors

Manufacturing Process Differences

Aluminum die casting brings a new level of precision and efficiency to the manufacturing of pumps and compressors. This process uses semi-permanent steel molds, called dies, and injects molten aluminum under high pressure. The result is a fast, automated system that produces thousands of identical parts with excellent surface finish and tight tolerances.

Traditional methods, such as sand casting and investment casting, rely on expendable molds. Sand casting uses sand and clay to form each mold, which is destroyed after every use. Investment casting creates detailed parts but takes more time and costs more per unit. Metal stamping works for simple shapes but cannot handle complex designs.

Die casting stands out for its ability to create complex, thin-walled, and dimensionally accurate parts with minimal secondary machining. This advantage leads to rapid production and consistent quality, especially important for pumps and compressors.

Here is a quick comparison of common manufacturing methods:

| Manufacturing Method | Common Use in Pump/Compressor Components | Material Utilization Characteristics |

|---|---|---|

| Gravity Casting | Automotive pistons, cylinder heads | May require more primary aluminum; less controlled metal flow; potential for defects |

| Low Pressure Permanent Mold Casting | Structural components | Allows thinner sections; uses pressure to fill mold; needs more primary aluminum for ductility |

| Squeeze Casting | Suspension components | Produces pore-free, heat-treatable parts; better mechanical properties |

| High Pressure Die Casting (HPDC) | Complex pump housings, compressor parts | Fast, cost-effective, precise; excellent finish; best for high-volume, complex parts |

Performance and Quality Comparison

Aluminum die casting delivers outstanding performance for pumps and compressors. The process creates parts with fine grain size, high mechanical strength, and dimensional stability. These qualities help pumps and compressors run smoothly and last longer.

Semi-solid aluminum alloys, such as Al-Si-Mg-Cu, show impressive mechanical properties when heat treated. For example, T6-treated alloys can reach tensile strengths up to 575 MPa, about 30% higher than untreated alloys. Thixoformed aluminum parts also display reduced porosity and improved fatigue resistance, making them reliable for demanding applications.

Many industries choose die cast components because they offer the strength and durability needed for pumps and compressors. The process also reduces the risk of internal defects, ensuring each part meets strict quality standards.

Cost and Production Efficiency

Aluminum die casting transforms production efficiency for pumps and compressors. The process uses reusable steel molds and high-pressure injection, which shortens cycle times and increases throughput. Cycle times can range from just 2 seconds to 1 minute, allowing manufacturers to produce large volumes quickly.

Traditional methods, like sand casting, require longer mold preparation and destroy the mold after each use. This leads to slower production and higher labor costs. In contrast, die casting supports mass production with consistent quality and minimal finishing work.

- Die casting reduces lead times and lowers per-part costs at scale.

- The process produces parts with high mechanical strength and uniform density.

- Manufacturers benefit from better repeatability and less waste.

Aluminum die casting empowers companies to meet tight deadlines and deliver pumps and compressors that exceed expectations. The combination of speed, accuracy, and cost savings inspires confidence in every project.

Key Advantages of Aluminum Die Casting for Pumps and Compressors

Strength-to-Weight Ratio and Durability

Aluminum die casting delivers a remarkable strength-to-weight ratio. This advantage means manufacturers can create robust components without adding unnecessary bulk. Pumps and compressors benefit from this property, as lighter parts reduce energy consumption and improve efficiency. Advanced aluminum alloys, such as LM25 and AlSi9Cu3, offer high strength and wear resistance. These alloys withstand mechanical stress and maintain performance under demanding conditions.

Durability stands as a hallmark of aluminum die cast parts. The process produces components with fine grain structures and minimal porosity. This results in parts that resist cracking and deformation, even after years of operation. Many industries rely on these durable components to keep pumps and compressors running smoothly, day after day.

Corrosion Resistance and Longevity

Aluminum alloys naturally resist corrosion. This property makes them ideal for pumps and compressors exposed to moisture, chemicals, or harsh environments. Alloys like LM6 and LM9 provide excellent protection against rust and chemical attack. Manufacturers often enhance this resistance with surface treatments such as anodizing or powder coating.

Longevity becomes a reality with aluminum die cast components. These parts maintain their integrity and appearance over time. They require less maintenance and replacement, which leads to lower long-term costs. Companies that switch to aluminum die casting often see significant savings due to reduced material waste and extended service life.

Tip: Choosing the right aluminum alloy and surface finish can further boost corrosion resistance, ensuring pumps and compressors perform reliably in any setting.

Precision, Design Flexibility, and Scalability

Aluminum die casting excels in precision and design flexibility. CNC-machined molds guarantee dimensional accuracy and a smooth surface finish. Molten aluminum fills even the most complex mold features, capturing intricate details with ease. This process supports the creation of thin-walled, lightweight parts that traditional methods struggle to achieve.

Manufacturers enjoy several benefits:

- Tight tolerances reduce or eliminate the need for secondary machining.

- Quick cycle times support high-volume production.

- Consistent quality minimizes defects and waste.

- Scalability allows companies to meet growing demand without major cost increases.

- Lightweight aluminum components enhance product performance, especially in pumps and compressors.

The ability to produce advanced geometries and ramp up production quickly gives manufacturers a competitive edge. Once the die is made, scaling up becomes efficient and cost-effective.

Real-World Applications and Industry Success

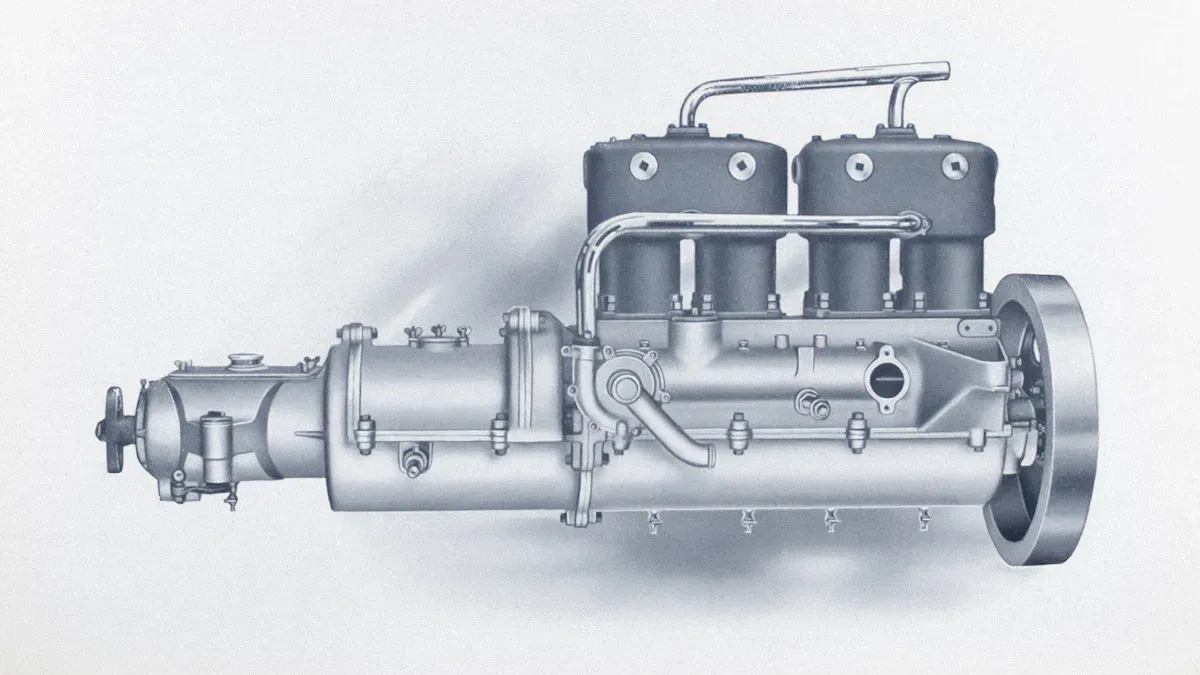

Industries around the world trust aluminum die casting for pumps and compressors. High-precision valve bodies, manifolds, and housings showcase the process’s versatility. Manufacturers in automotive, hydraulics, and pneumatics rely on die cast aluminum for both aftermarket and original equipment.

- Natural gas gate valve bodies use die cast aluminum for strength and corrosion resistance.

- Custom oil cooler components benefit from the process’s design flexibility.

- Compressor housings and rotors made from aluminum alloys reduce weight and improve heat dissipation.

In real-world settings, these components deliver outstanding performance. For example, pump bodies and impellers produced by low-pressure die casting exhibit low porosity, excellent surface finish, and enhanced mechanical properties. These qualities ensure reliable operation in oil & gas, chemical, and water treatment plants.

Note: The success of aluminum die casting in diverse industries proves its value. Companies experience cost savings, improved efficiency, and long-lasting performance in pumps and compressors.

Aluminum die casting stands as the top choice for pumps and compressors. Industry leaders highlight its ability to deliver:

- High-volume production of complex, thin-walled parts

- Exceptional accuracy, repeatability, and surface finish

- Consistent quality for thousands of identical components

Future advancements in automation, artificial intelligence, and advanced alloys promise even greater performance and sustainability. Pumps and compressors will continue to benefit from these innovations, setting new standards for reliability and efficiency.

FAQ

What makes aluminum die casting ideal for pump and compressor parts?

Aluminum die casting creates strong, lightweight parts. Manufacturers achieve high precision and durability. This process inspires confidence in industries that demand reliable performance.

How does aluminum die casting help reduce costs?

- Companies save money through faster production.

- Fewer defects mean less waste.

- High-volume runs lower the price per part.

Can aluminum die cast components handle harsh environments?

Post time: Aug-04-2025