Aluminium die casting inoshandura nzira iyo vagadziri vanogadzirapombi uye compressors. Iyi nzira inopa zvikamu zvakasimba asi zvisingaremi kuvaka. Maindasitiri mazhinji zvino anovimba nealuminium die casting kuendesa kushanda kwekusingaperi uye kuvimbika. Nhau dzekubudirira dzinoratidza kuti mapombi uye macompressor anosvika pakakwirira neiyi advanced process.

Key Takeaways

- Aluminium die casting inogadzirapombi yakasimba, isingaremiuye compressor zvikamu zvine hupamhi hwepamusoro uye hunoenderana mhando, inovandudza kuita uye kusimba.

- Iyi nzirainokurumidza kugadzirwauye inoderedza mari nekushandisa molds inogona kushandiswa zvakare uye nekukurumidza kutenderera nguva, zvichiita kuti ive yakanakira kugadzirwa kwakakura.

- Die casting inobvumira dhizaini yakaoma, yakatetepa-yakavakirwa iyo inoderedza huremu uye kushandiswa kwesimba, uku ichipa yakanakisa corrosion kuramba kwezvikamu zvinogara kwenguva refu.

Aluminium Die Casting vs. Traditional Methods mumapombi uye Compressors

Manufacturing Process Differences

Aluminium die casting inounza imwe nhanho yekurongeka uye kugona mukugadzirwa kwemapombi nemacompressor. Iyi nzira inoshandisa semi-permanent simbi molds, inonzi inofa, uye inobaya aluminium yakanyungudutswa pasi pekumanikidzwa kwakanyanya. Mhedzisiro yacho inokurumidza, otomatiki sisitimu inogadzira zviuru zvezvikamu zvakafanana zvine kunaka kwepamusoro kupera uyetight tolerances.

Nzira dzechinyakare, dzakaita sejecha nekukanda mari, dzinotsamira pazviumbwa zvinodhura. Kukanda jecha kunoshandisa jecha nevhu kugadzira mold imwe neimwe, inoparadzwa mushure mekushandiswa kwese. Investment casting inogadzira yakadzama zvikamu asi inotora nguva yakawanda uye inodhura yakawanda payuniti. Metal stamping inoshanda kune akareruka zvimiro asi haigone kubata madhizaini akaomarara.

Die casting inomira kunze kwekugona kwayo kugadzira yakaoma, yakatetepa-yakavakirwa, uye mativi akaenzana zvikamu zvine mashoma echipiri machining. Iyi mukana inotungamira kukurumidza kugadzirwa uye inowirirana mhando, kunyanya yakakosha kumapombi uye compressors.

Heino kukurumidza kuenzanisa kweakajairika nzira dzekugadzira:

| Manufacturing Method | Kushandiswa kwakajairika muPombi / Compressor Zvikamu | Material Utilization Hunhu |

|---|---|---|

| Gravity Casting | Motokari pistons, humburumbira misoro | Inogona kuda imwe yekutanga aluminium; kuderera kwesimbi kuderera; zvinogona kukanganisa |

| Yakaderera Kudzvinyirira Permanent Mold Kukanda | Zviumbwa zvezvikamu | Inobvumira zvikamu zvitete; inoshandisa kumanikidza kuzadza mold; inoda imwe yekutanga aluminium ye ductility |

| Squeeze Casting | Suspension components | Inogadzira pore-isina, zvikamu zvinopisa kupisa; nani ma mechanical properties |

| High Pressure Die Casting (HPDC) | Complex pombi dzimba, compressor zvikamu | Inokurumidza, inodhura-inoshanda, yakarurama; kupera kwakanaka; zvakanakisisa kune yakakwirira-vhoriyamu, yakaoma zvikamu |

Kuita uye Kuenzanisa Kwemhando

Aluminium die casting inopa yakanakisa kuita kwemapombi uye compressor. Iyo nzira inogadzira zvikamu zvine saizi yakanaka yezviyo, kusimba kwemagetsi kwakakwira, uye kugadzikana kwedimensional. Aya hunhu anobatsira mapombi nemacompressor kuti afambe zvakanaka uye anogara kwenguva refu.

Semi-solid aruminiyamu alloys, akadai seAl-Si-Mg-Cu, anoratidza zvinokatyamadza zvemichina kana kupisa kunorapwa. Semuyenzaniso, T6-yakarapwa alloys anogona kusvika kusimba masimba anosvika 575 MPa, anenge 30% akakwirira kupfuura asina kubatwa alloys. Thixoformed aluminium zvikamu zvinoratidzawo kuderedzwa porosity uye kunatsiridza kuneta kuramba, zvichiita kuti ive yakavimbika kune inoda maapplication.

Maindasitiri mazhinji anosarudza die cast zvikamu nekuti anopa simba uye kusimba kunodiwa pamapombi uye compressor. Iyo nzira zvakare inoderedza njodzi yekuremara kwemukati, kuve nechokwadi chekuti chikamu chimwe nechimwe chinosangana neakasimba emhando zviyero.

Mutengo uye Kubudirira Kwekugadzira

Aluminium die casting inoshandura kugadzirwa kwemapombi uye compressors. Maitiro acho anoshandisa reusable simbi molds uye high-pressure jekiseni, iyo inopfupisa nguva yekutenderera uye inowedzera throughput. Nguva dzekutenderera dzinogona kubva pamasekonzi maviri chete kusvika paminiti imwe, zvichibvumira vanogadzira kugadzira mavhoriyamu akakura nekukurumidza.

Nzira dzechinyakare, sekukanda jecha, dzinoda kugadzirira kwenguva refu uye kuparadza mold mushure mekushandisa kwega kwega. Izvi zvinoita kuti kugadzirwa kunonoke uye kukwira kwemitengo yevashandi. Mukupesana, kufa kukandira kunotsigira kugadzirwa kwakawanda nemhando inowirirana uye kushoma kupedzisa basa.

- Die casting inoderedza nguva dzekutungamira uye inodzikisa pa-chikamu mutengo pachiyero.

- Iyo nzira inoburitsa zvikamu zvine simba remagetsi rakakura uye yunifomu density.

- Vagadziri vanobatsirwa kubva zvirinani kudzokorora uye kushomeka kwemarara.

Aluminium die casting inopa simba makambani kuti asangane nenguva dzakasimba uye kuendesa pombi nemacompressor anopfuura zvinotarisirwa. Iko kusanganiswa kwekumhanya, kurongeka, uye kuchengetedza mutengo kunokurudzira kuvimba mune yega yega chirongwa.

Yakakosha Yakanakira yeAluminium Die Casting yePombi uye Compressors

Simba-ku-Ku-Weight Ratio uye Kusimba

Aluminium die castinginopa simba rinoshamisa-ku-kurema reshiyo. Iyi mukana inoreva kuti vagadziri vanogona kugadzira zvinhu zvakasimba pasina kuwedzera huwandu husina kufanira. Mapombi uye macompressor anobatsirwa kubva kune ichi chivakwa, sezvo zvikamu zvakareruka zvinoderedza kushandiswa kwesimba uye kugadzirisa kushanda zvakanaka. Yepamberi aruminiyamu alloys, akadai seLM25 uye AlSi9Cu3, inopa yakakwirira simba uye kupfeka kuramba. Aya ma alloys anomira kushushikana kwemechani uye anochengetedza mashandiro pasi pemamiriro ekuda.

Durability inomira sechiratidzo chealuminium die cast parts. Iyo nzira inoburitsa zvikamu zvine yakanaka zviyo zvimiro uye shoma porosity. Izvi zvinoguma nezvikamu zvinoramba kutsemuka uye deformation, kunyangwe mushure memakore ekushanda. Maindasitiri mazhinji anovimba nezvinhu izvi zvinogara kwenguva refu kuchengetedza mapombi nemacompressor achishanda zvakanaka, zuva nezuva.

Corrosion Resistance uye Hurefu Hwehupenyu

Aluminium alloys anowanzo ramba corrosion. Ichi chivakwa chinovaita chakanakira mapombi uye compressor akaoneswa kune hunyoro, makemikari, kana hutsinye nharaunda. Alloys seLM6 uye LM9 inopa yakanakisa dziviriro kubva kuura uye kurwisa kwemakemikari. Vagadziri vanowanzo wedzera kuramba uku nekurapa kwepamusoro senge anodizing kana poda coating.

Hupenyu hurefu hunova hwechokwadi nealuminium die cast components. Izvi zvikamu zvinochengetedza kuvimbika kwavo uye chitarisiko nekufamba kwenguva. Vanoda kuchengetedza zvishoma uye kuchinjwa, izvo zvinotungamirira kuderedza mari yenguva refu. Makambani anochinjira kuita aluminium die casting anowanzoona mari yakakosha nekuda kwekuderedzwa kwemarara uye hupenyu hwesevhisi hwakawedzerwa.

Zano: Kusarudza iyo chaiyo aruminiyamu alloy uye kupera kwepasi kunogona kuwedzera kusimba kwekusagadzikana, kuve nechokwadi chekuti mapombi nemacompressor anoita zvakavimbika mune chero marongero.

Precision, Dhizaini Kuchinjika, uye Scalability

Aluminium die casting inokunda mukurongeka uye dhizaini inoshanduka. CNC-machini molds inovimbisa kurongeka kwedimensional uye kupera kwakatsetseka kwepamusoro. Aluminiyamu yakanyungudutswa inozadza kunyangwe iyo yakaoma kwazvo mold maficha, inotora yakaoma kunzwisisa zviri nyore. Iyi nzira inotsigira kugadzirwa kwezvikamu zvakatetepa-zvakatetepa, zvisingaremi izvo nzira dzechinyakare dzinonetsa kuwana.

Vagadziri vanonakidzwa nezvakawanda zvakanaka:

- Tight tolerances inoderedza kana kubvisa kudiwa kwechipiri machining.

- Nguva dzekukurumidza kutenderera dzinotsigira kugadzirwa kwepamusoro-vhoriyamu.

- Hunhu hwakafanana hunoderedza kuremara nemarara.

- Scalability inobvumira makambani kusangana nekukura kwekuda pasina kuwedzera kukuru kwemutengo.

- Aruminiyamu akareruka zvikamu zvinosimudzira kuita kwechigadzirwa, kunyanya mumapombi nemacompressor.

Iko kugona kugadzira epamberi geometries uye kukwira kumusoro kugadzirwa nekukurumidza kunopa vanogadzira muganho wemakwikwi. Kana iyo kufa yagadzirwa, kukwirisa kunova kunoshanda uye kunodhura-inoshanda.

Real-World Applications uye Indasitiri Kubudirira

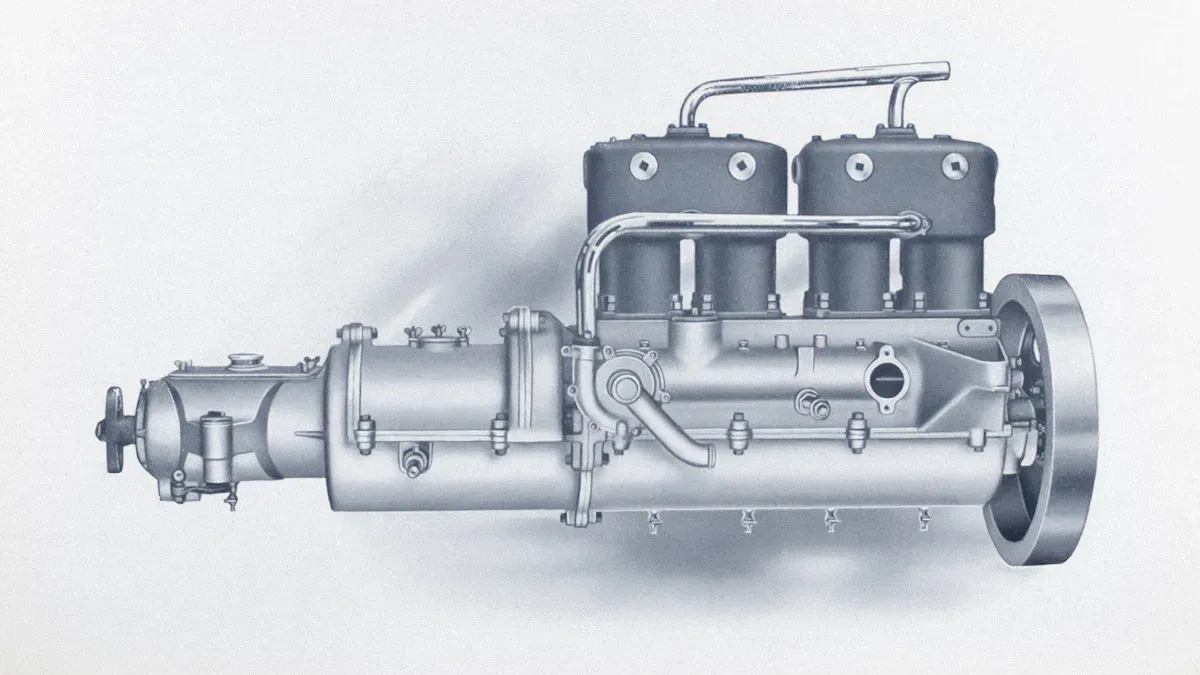

Maindasitiri kutenderera pasirese anovimba nealuminium die casting yemapombi nemacompressor. Yepamusoro-chaiyo mavharuvhu miviri, manifolds, uye dzimba dzinoratidza kuita kwakasiyana-siyana. Vagadziri mumotokari, hydraulics, uye pneumatics vanotsamira pane die cast aluminium kune ese ari maviri emarket uye ekutanga michina.

- Natural gasi gedhi mavharuvhu miviri inoshandisa die cast aluminium kune simba uye nekuora kwekudzivirira.

- Tsika oiri inotonhorera zvikamu zvinobatsira kubva mukugadzirisa dhizaini inoshanduka.

- Compressor housings uye rotor yakagadzirwa kubva kualuminium alloys inoderedza uremu uye inovandudza kupisa.

Muzvirongwa zvepasirese, izvi zvikamu zvinopa kuita kwakatanhamara. Semuyenzaniso, miviri yepombi uye mapombi anogadzirwa neakaderera-kudzvanya kufa kukandira anoratidza yakaderera porosity, yakanakisa kupedzwa kwepamusoro, uye yakagadziridzwa michina zvinhu. Aya hunhu anovimbisa kushanda kwakavimbika muoiri & gasi, makemikari, uye zvidyarwa zvekuchenesa mvura.

Cherechedza: Kubudirira kwealuminium die casting mumaindasitiri akasiyana kunoratidza kukosha kwayo. Makambani anoona kuchengetwa kwemutengo, kuvandudza kushanda zvakanaka, uye kushanda kwenguva refu mumapombi nemacompressor.

Aluminium die casting inomira seyepamusoro sarudzo yemapombi nemacompressor. Vatungamiri veindasitiri vanosimbisa kugona kwayo kuburitsa:

- Kugadzirwa kwepamusoro-soro kwezvikamu zvakaoma, zvitete-madziro

- Kurongeka kwakasarudzika, kudzokorora, uye kupera kwepamusoro

- Hunhu hunoenderana zviuru zvezvikamu zvakafanana

Kufambira mberi kweramangwanamune otomatiki, hungwaru hwekugadzira, uye alloys epamberi anovimbisa kuita kwakanyanya uye kusimba. Mapombi uye macompressor acharamba achibatsirwa kubva kune izvi zvitsva, kuseta mitsva mitsva yekuvimbika uye kushanda nesimba.

FAQ

Chii chinoita kuti aluminium kufa kukanda kwakanakira pombi uye compressor zvikamu?

Aluminium die castinginogadzira zvikamu zvakasimba, zvisingaremi. Vagadziri vanowana yakanyanya kurongeka uye kusimba. Iyi nzira inokurudzira kuvimba mumaindasitiri anoda kushanda kwakavimbika.

Aluminium die casting inobatsira sei kuderedza mitengo?

- Makambani anochengetedza mari kuburikidza nekukurumidza kugadzira.

- Kuremara kushoma kunoreva kutambisa kushoma.

- High-volume inomhanya inodzikisa mutengo pachikamu.

Aluminium die cast cast zvikamu zvinogona kubata nharaunda dzakaomarara?

Nguva yekutumira: Aug-04-2025