I-aluminium die casting iguqula indlela abavelisi abadala ngayoiimpompo kunye necompressors. Le ndlela inika amacandelo ukwakhiwa olomeleleyo kodwa olukhaphukhaphu. Amashishini amaninzi ngoku athemba i-aluminium die casting ukuhambisa ukusebenza okungapheliyo kunye nokuthembeka. Amabali empumelelo abonisa ukuba iimpompo kunye neecompressors zifikelela kubude obutsha ngale nkqubo iphambili.

Izinto eziphambili zokuThatha

- I-aluminium die casting ivelisaimpompo eyomeleleyo, elulakunye neengxenye zecompressor ezichanekileyo eziphezulu kunye nomgangatho ongaguqukiyo, ukuphucula ukusebenza kunye nokuqina.

- Le ndlelaikhawulezisa imvelisokwaye ithobe iindleko ngokusebenzisa iimolds ezinokuphinda zisetyenziswe kunye namaxesha omjikelezo okhawulezayo, okwenza kube yinto efanelekileyo kwimveliso enkulu.

- I-Die casting ivumela uyilo oluntsonkothileyo, olunodonga olucekeceke olunciphisa ubunzima kunye nokusetyenziswa kwamandla, ngelixa lubonelela ngokugqwesa ukuxhathisa umhlwa kwizinto ezihlala ixesha elide.

I-Aluminium Die Casting vs. Iindlela zeMveli kwiiPumpu kunye neeCompressors

Iiyantlukwano zeNkqubo yokuVelisa

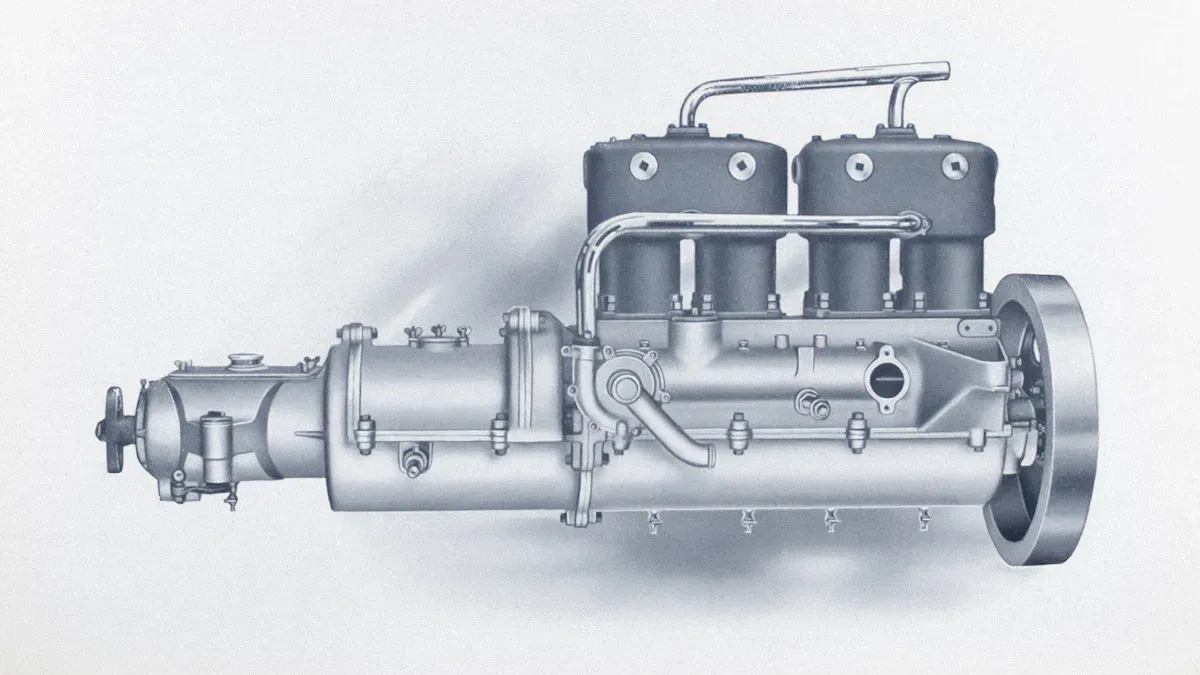

Ukuphoswa kwe-aluminiyam kuzisa inqanaba elitsha lokuchaneka kunye nempumelelo ekwenzeni iimpompo kunye neecompressors. Le nkqubo isebenzisa i-semi-permanent metal molds, ebizwa ngokuba yi-dies, kwaye ifake i-aluminium etyhidiweyo phantsi koxinzelelo oluphezulu. Isiphumo yinkqubo ekhawulezayo, ezenzekelayo evelisa amawaka eendawo ezifanayo ezinomphezulu ogqwesileyo kwayeukunyamezela okuqinileyo.

Iindlela zakwaNtu, ezifana nokugalelwa kwesanti kunye nokuphosa utyalo-mali, zixhomekeke kubumba obunokuchithwa. Ukubunjwa kwesanti kusebenzisa isanti kunye nodongwe ukwenza ukungunda ngalunye, olutshabalalayo emva kokusetyenziswa. Ukwenziwa kotyalo-mali kudala iindawo ezineenkcukacha kodwa kuthatha ixesha elingakumbi kunye neendleko ezingaphezulu kwiyunithi nganye. Isitampu sesinyithi sisebenzela iimilo ezilula kodwa asikwazi ukumelana noyilo oluntsonkothileyo.

I-Die casting igqamile kubuchule bayo bokudala iindawo ezintsonkothileyo, ezinodonga olucekethekileyo, kunye nomgangatho ochanekileyo ngoomatshini abancinci besibini. Le nzuzo ikhokelela ekuveliseni ngokukhawuleza kunye nomgangatho ohambelanayo, kubaluleke kakhulu kwiimpompo kunye neecompressors.

Nalu uthelekiso olukhawulezayo lweendlela eziqhelekileyo zokuvelisa:

| Indlela Yokuvelisa | Ukusetyenziswa okuqhelekileyo kwiPump / Compressor Components | Iimpawu zokuSetyenziswa kwezinto |

|---|---|---|

| Ukuphosa koMxhuzulane | Iipiston zeemoto, iintloko ze-cylinder | Isenokufuna i-aluminiyam yokuqala; ukuhamba kwentsimbi elawulwa ngaphantsi; ezinokuba neziphene |

| Uxinzelelo oluphantsi olusisigxina lokusatywa kokungunda | Amacandelo esakhiwo | Ivumela amacandelo amancinci; isebenzisa uxinzelelo lokuzalisa ukungunda; ifuna i-aluminiyam engaphezulu ye-ductility |

| Cofa Ukusasazwa | Amacandelo okunqunyanyiswa | Ivelisa iindawo ezingenazo iipore, eziphathwa ngobushushu; iimpawu ezingcono zoomatshini |

| I-High Pressure Die Casting (HPDC) | Izindlu zempompo eziyinkimbinkimbi, iinxalenye zecompressor | Ukukhawuleza, ukonga imali, ngokuchanekileyo; ukugqiba okulungileyo; okona kulungileyo kumthamo ophezulu, iindawo ezinzima |

Ukuthelekiswa koMgangatho wokuSebenza kunye noMgangatho

I-aluminium die casting inikezela ukusebenza okugqwesileyo kwiimpompo kunye neecompressors. Inkqubo idala iinxalenye ezinobukhulu obuziinkozo obucolekileyo, amandla aphezulu omatshini, kunye nokuzinza komda. Ezi mpawu zinceda iimpompo kunye neecompressors zihambe kakuhle kwaye zihlala ixesha elide.

I-alloys ye-aluminium ene-semi-solid, efana ne-Al-Si-Mg-Cu, ibonisa iimpawu ezichukumisayo zomatshini xa ubushushu buphathwa. Ngokomzekelo, ii-alloys eziphathwa nge-T6 zinokufikelela kumandla okuqina ukuya kuthi ga kwi-575 MPa, malunga ne-30% ephezulu kune-alloys engaphendulwanga. Amacandelo e-aluminium enziwe nge-aluminiyam anciphisa i-porosity kunye nokuphuculwa kokumelana nokudinwa, kubenza bathembeke kwizicelo ezifunayo.

Amashishini amaninzi akhetha amacandelo e-die cast kuba anika amandla kunye nokuqina okufunekayo kwiimpompo kunye neecompressors. Inkqubo iphinda inciphise umngcipheko weziphene zangaphakathi, ukuqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho engqongqo yomgangatho.

Iindleko kunye nokuSebenza ngokuSebenzayo

Ukuphosa ukufa kweAluminiyam kuguqula ukusebenza kakuhle kwemveliso kwiimpompo kunye neecompressors. Inkqubo isebenzisa iimolds zensimbi ezinokuphinda zisetyenziswe kunye nenaliti ephezulu yoxinzelelo, enciphisa amaxesha okujikeleza kunye nokwandisa ukuphuma. Amaxesha e-Cycle angavela kwi-2 imizuzwana ukuya kwi-1 iminithi, evumela abavelisi ukuba bavelise umthamo omkhulu ngokukhawuleza.

Iindlela zemveli, njengokugalelwa kwesanti, zifuna ukulungiswa komngundo ixesha elide kwaye zitshabalalise ukungunda emva kokusetyenziswa ngakunye. Oku kukhokelela kwimveliso ecothayo kunye neendleko eziphezulu zabasebenzi. Ngokwahlukileyo, ukuphosa ukufa kuxhasa imveliso eninzi enomgangatho ongaguqukiyo kunye nomsebenzi omncinci wokugqiba.

- I-Die casting inciphisa amaxesha okukhokelela kwaye ihlise iindleko zenxalenye nganye kwisikali.

- Inkqubo ivelisa iindawo ezinamandla amakhulu omatshini kunye nobuninzi obufanayo.

- Abavelisi baxhamla ngokuphindaphindwa ngcono kunye nenkcitho encinci.

Ukuphoswa kweAluminiyam kuxhobisa iinkampani ukuba zihlangabezane nexesha elibekiweyo kwaye zihambise iimpompo kunye neecompressor ezingaphezulu kobekulindelekile. Indibaniselwano yesantya, ukuchaneka, kunye nokugcinwa kweendleko kukhuthaza ukuzithemba kuyo yonke iprojekthi.

Izinto eziluncedo eziphambili zeAluminiyam Die Casting kwiiPumpu kunye neCompressors

Amandla-ukuya-Ubunzima bomlinganiselo kunye noZinzo

I-Aluminiyam yokuphosa ukufainika umlinganiselo omangalisayo wamandla ukuya kubunzima. Olu ncedo luthetha ukuba abavelisi banokudala amacandelo aqinileyo ngaphandle kokongeza isambuku esingeyomfuneko. Iipompo kunye neecompressors zixhamla kule propati, njengoko iindawo ezilula zinciphisa ukusetyenziswa kwamandla kunye nokuphucula ukusebenza kakuhle. I-alloys ephezulu ye-aluminium, efana ne-LM25 kunye ne-AlSi9Cu3, inika amandla aphezulu kunye nokumelana nokunxiba. Ezi alloys zimelana noxinzelelo lomatshini kwaye zigcine ukusebenza phantsi kweemeko ezifunekayo.

Ukuqina kume njengophawu lwamalungu e-aluminium die cast. Inkqubo ivelisa amacandelo anezakhiwo eziziinkozo ezintle kunye ne-porosity encinci. Oku kubangela ukuba iindawo ezichasene nokuqhekeka kunye nokuguqulwa, nasemva kweminyaka yokusebenza. Amashishini amaninzi athembele kula macandelo ahlala ixesha elide ukugcina iimpompo kunye neecompressors zisebenza kakuhle, usuku nosuku.

Ukuchasa ukonakala kunye nokuphila ixesha elide

Iialloyi zeAluminiyam ngokwendalo zixhathisa ukubola. Le propathi ibenza balungele iimpompo kunye neecompressor ezivezwe kukufuma, iikhemikhali, okanye imeko erhabaxa. I-alloys efana ne-LM6 kunye ne-LM9 inika ukhuseleko oluhle kakhulu kwi-rust kunye nokuhlaselwa kweekhemikhali. Abavelisi bahlala bephucula oku kuxhathisa ngonyango olungaphezulu olufana ne-anodizing okanye umgubo wokugquma.

Ubomi obude buba yinyani kunye namacandelo e-aluminium die cast. Ezi nxalenye zigcina ingqibelelo kunye nokubonakala kwazo ngokuhamba kwexesha. Bafuna ukugcinwa okuncinci kunye nokutshintshwa, okukhokelela ekunciphiseni iindleko zexesha elide. Iinkampani ezitshintshela kwi-aluminium die casting zihlala zibona ukonga okubalulekileyo ngenxa yokuncitshiswa kwenkunkuma yezinto kunye nobomi benkonzo obandisiweyo.

Ingcebiso: Ukukhetha i-alloy ye-aluminiyam elungileyo kunye nokugqiba komphezulu kunokonyusa ngakumbi ukunganyangeki komhlwa, ukuqinisekisa ukuba iimpompo kunye neecompressors zisebenza ngokuthembekileyo nakweyiphi na indawo.

Ukuchaneka, ukuGuquleka koYilo, kunye nokuKhawuleka

I-aluminium die casting igqwesile ngokuchaneka kunye nokuguquguquka koyilo. Iimolds ezenziwe ngoomatshini be-CNC ziqinisekisa ukuchaneka komgangatho kunye nokugqitywa komphezulu ogudileyo. I-aluminiyam etyhidiweyo igcwalisa nezona mpawu zokubumba ezintsonkothileyo, zithatha iinkcukacha ezintsonkothileyo ngokulula. Le nkqubo ixhasa ukuyilwa kweendonga ezibhityileyo, iindawo ezikhaphukhaphu ezithi iindlela zemveli zisokole ukuzifumana.

Abavelisi banandipha iingenelo ezininzi:

- Ukunyamezelana okuqinileyo kunciphisa okanye ukuphelisa imfuno yomatshini wesibini.

- Amaxesha omjikelezo okhawulezayo axhasa ukuveliswa kwevolumu ephezulu.

- Umgangatho ohambelanayo unciphisa iziphene kunye nenkcitho.

- I-Scalability ivumela iinkampani ukuba zihlangabezane nemfuno ekhulayo ngaphandle kokunyuka kweendleko ezinkulu.

- Amacandelo e-aluminium ekhaphukhaphu aphucula ukusebenza kwemveliso, ngakumbi kwiimpompo kunye neecompressors.

Ukukwazi ukuvelisa iijiyometri eziphambili kunye nokunyuka kwemveliso ngokukhawuleza kunika abavelisi umda wokukhuphisana. Nje ukuba ukufa kwenziwe, ukonyusa kuya kusebenza kakuhle kwaye kungabizi kakhulu.

Ii-Real-World Applications kunye neMpumelelo yoShishino

Imizi-mveliso kwihlabathi jikelele ithembela kwi-aluminiyam yokufa yokuphosa iimpompo kunye neecompressors. Imizimba yevalvu echanekileyo ephezulu, ukuphindaphindeka, kunye nezindlu zibonisa ubuninzi benkqubo. Abavelisi kwiimoto, iihydraulics, kunye ne-pneumatics baxhomekeke kwi-aluminium yokufa kuzo zombini i-aftermarket kunye nezixhobo zokuqala.

- Izidumbu zevalvu yerhasi yendalo zisebenzisa i-aluminiyam yokufa ukomelela kunye nokumelana nomhlwa.

- Amacandelo okupholisa ioyile ngokwesiqhelo ayazuza kububhetyebhetye boyilo lwenkqubo.

- Izindlu zeCompressor kunye ne-rotors ezenziwe kwi-aluminium alloys zinciphisa ubunzima kunye nokuphucula ukutshatyalaliswa kobushushu.

Kwiisetingi zehlabathi lokwenyani, la macandelo anikezela ukusebenza okugqwesileyo. Umzekelo, imizimba yempompo kunye ne-impellers eziveliswe ngoxinzelelo oluphantsi lokuphosa ukufa zibonisa i-porosity ephantsi, ukugqiba okugqwesileyo komphezulu, kunye neepropathi eziphuculweyo zoomatshini. Ezi mpawu ziqinisekisa ukusebenza okuthembekileyo kwi-oyile kunye negesi, iikhemikhali, kunye nezityalo zokunyanga amanzi.

Qaphela: Impumelelo yokwenziwa kwe-aluminiyam kwimizi-mveliso eyahlukeneyo ingqina ixabiso layo. Iinkampani zifumana ukongiwa kweendleko, ukusebenza kakuhle, kunye nokusebenza okuhlala ixesha elide kwiimpompo kunye neecompressors.

I-Aluminiyam yokuphosa ukufa imele njengokhetho oluphezulu lweempompo kunye neecompressors. Iinkokeli zeshishini ziqaqambisa amandla ayo okunikezela:

- Ukuveliswa komthamo ophezulu wezinto eziyinkimbinkimbi, ezincinci ezinodonga

- Ukuchaneka okugqwesileyo, ukuphinda-phinda, kunye nokugqitywa komphezulu

- Umgangatho ohambelanayo wamawaka eenxalenye ezifanayo

Inkqubela phambili yexesha elizayokwi-automation, ubukrelekrele bokwenziwa, kunye ne-alloys ephucukileyo zithembisa ukusebenza okukhulu kunye nozinzo. Iipompo kunye ne-compressors ziya kuqhubeka zixhamla kolu lutsha, ukubeka imigangatho emitsha yokuthembeka nokusebenza kakuhle.

FAQ

Yintoni eyenza i-aluminiyam yokufa ilungile kwimpompo kunye neendawo zecompressor?

I-Aluminiyam yokuphosa ukufayenza iindawo ezomeleleyo, ezikhaphukhaphu. Abavelisi bafumana ukuchaneka okuphezulu kunye nokuqina. Le nkqubo ikhuthaza ukuzithemba kumashishini afuna ukusebenza okuthembekileyo.

I-aluminium die casting inceda njani ukunciphisa iindleko?

- Iinkampani zonga imali ngemveliso ekhawulezayo.

- Iziphene ezimbalwa zithetha inkcitho encinci.

- Umthamo ophezulu uqhuba uthoba ixabiso ngenxalenye nganye.

Ngaba i-aluminiyam yokufa iyakwazi ukuphatha iindawo ezisingqongileyo?

Ixesha lokuposa: Aug-04-2025