I see aluminum a popular material for die casting in many industries today. When I look at why, I notice several key reasons:

1. Manufacturers want lighter vehicles for better fuel economy.

2. New technology makes OEM aluminum die casting even stronger.

3. Strong rules push for lower emissions and lighter parts.

Because of these changes, I always trust aluminum for die casting spare parts.

Key Takeaways

- Aluminum offers a strong yet lightweight option for die casting, helping reduce fuel use and improve vehicle performance.

- Its natural resistance to corrosion and good thermal stability make aluminum durable and reliable in tough environments.

- Aluminum die casting saves time and money with fast production cycles and supports sustainability through easy recycling and energy efficiency.

Aluminum a Popular Material for Die Casting: Superior Properties and Cost Advantages

High Strength-to-Weight Ratio and Durability

When I choose materials for die casting spare parts, I always look for the best balance between strength and weight. Aluminum stands out because it gives me both. I see that aluminum has a lower density than zinc, which means it is lighter. Even though zinc parts can be stronger, they are much heavier. In my experience, aluminum a popular material for die casting, especially when I need to reduce weight in cars or airplanes.

- Aluminum has a lower density than zinc, resulting in a better strength-to-weight ratio.

- Zinc die cast parts are generally more than twice as strong as aluminum parts but are denser and heavier.

- Aluminum’s combination of considerable strength and light weight makes it ideal for applications where weight reduction is critical, such as aerospace and automotive sectors.

- Overall, aluminum offers a balanced strength with lightweight, making it preferable over zinc when weight is a key factor.

I often see engineers pick aluminum for parts that need to be both strong and light. This helps vehicles use less fuel and makes them easier to handle. I also notice that aluminum parts last a long time, even when used every day.

Corrosion Resistance and Thermal Performance

I trust aluminum a popular material for die casting because it resists rust and corrosion. In harsh places like factories or near the ocean, aluminum parts do not rust as quickly as steel. Aluminum alloys usually handle tough environments well, such as marine or high humidity conditions. Zinc also resists corrosion, but sometimes it can rust if the conditions are right. Stainless steel does better than aluminum in very tough industrial jobs, but it is much heavier and more expensive.

- Aluminum alloys have good corrosion resistance but are vulnerable to sodium chloride (salt) corrosion.

- Stainless steel generally offers superior corrosion and rust resistance, making it more versatile in industrial environments.

- Stainless steel is preferred for applications requiring high heat resistance and heavy-duty industrial use.

- Aluminum is favored for lighter weight and lower heat applications.

When I work with electronics, I see that aluminum performs better than magnesium in high temperatures. Aluminum stays stable above 100°C, while magnesium can break down. Aluminum also has natural corrosion resistance, so I do not need to add extra coatings. This makes aluminum a popular material for die casting in electronics and other industries that need long-lasting parts.

| Factor | Aluminum Advantage |

|---|---|

| Thermal Stability | Aluminum performs better in high-temperature environments, maintaining stability where magnesium degrades (e.g., above 100°C). |

| Corrosion Resistance | Aluminum has natural corrosion resistance, unlike magnesium which requires coatings to prevent corrosion. |

| Durability | Aluminum is preferred for applications requiring long-term durability and minimal corrosion, critical for electronic components. |

Cost Savings and Manufacturing Efficiency

I always look for ways to save money and time in manufacturing. Aluminum die casting helps me do both. The process uses high-pressure injection and quick cooling, so I can make parts in just seconds. This is much faster than other methods like sand casting or forging.

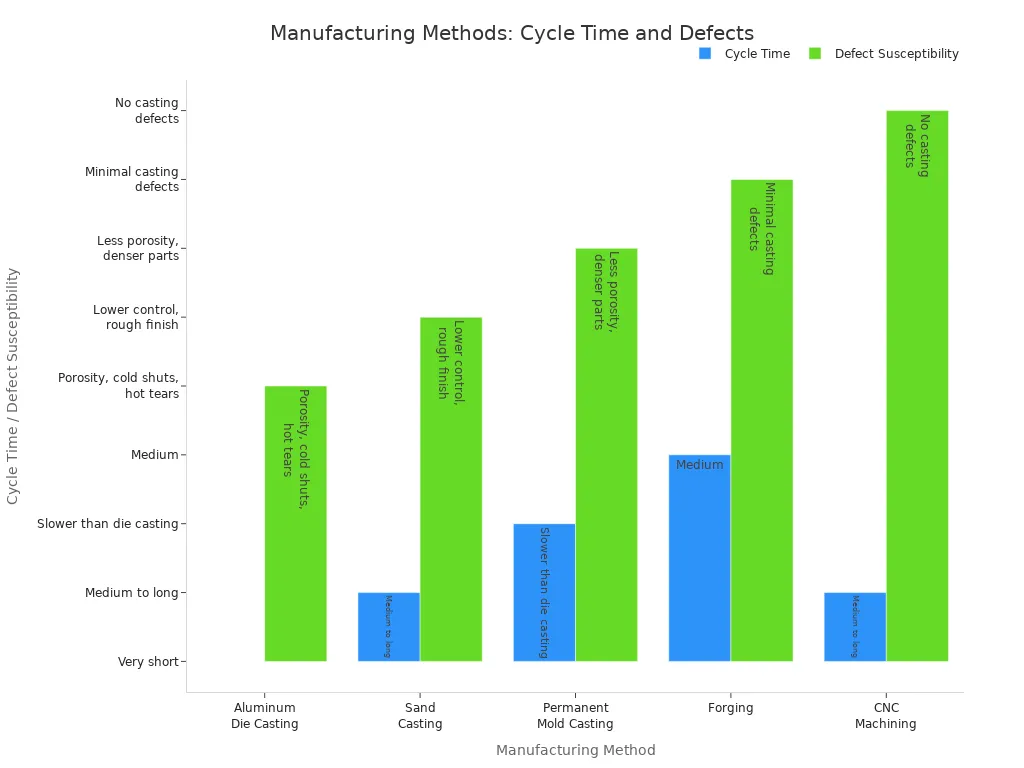

Here is how aluminum die casting compares to other methods:

| Manufacturing Method | Cycle Time | Defect Susceptibility | Notes |

|---|---|---|---|

| Aluminum Die Casting | Very short (seconds) | Susceptible to gas/shrinkage porosity, cold shuts, hot tears; manageable with process control | Fastest cycle time due to high-pressure injection and quick cooling; high upfront tooling cost but low unit cost in volume |

| Sand Casting | Medium to long | Lower control over defects; rougher surface finish | Slower process, cheaper tooling, suitable for low volume or large parts |

| Permanent Mold Casting | Slower than die casting | Less porosity, denser parts | Gravity fill results in stronger, less porous parts but slower cycle time |

| Forging | Medium | Minimal casting defects; superior mechanical strength | Highest strength but limited design complexity and higher cost |

| CNC Machining | Medium to long | No casting defects; subtractive process | High precision, no tooling cost but longer cycle times and material waste |

I know that aluminum die casting can have some defects, like gas bubbles or cracks. I use special designs and careful controls to prevent these problems. When I manage the process well, I get high-quality parts quickly and at a lower cost. This makes aluminum a popular material for die casting, especially when I need to make many parts fast.

Aluminum a Popular Material for Die Casting: Sustainability and 2025 Innovations

Recyclability and Environmental Benefits

When I work with aluminum, I see how easy it is to recycle. I can melt down old aluminum parts and use them again without losing quality. This process uses much less energy than making new aluminum from raw materials. Because of this, I help lower greenhouse gas emissions and reduce the carbon footprint of my projects. I also notice that recycling aluminum keeps more waste out of landfills. Many factories now use closed-loop recycling, where they collect and reuse metal scraps right in the plant. This supports pollution control and helps me meet strict environmental goals.

I choose aluminum a popular material for die casting because it fits well with new sustainability rules. In 2025, government agencies like the EPA and Department of Energy encourage me to use recycled aluminum and energy-saving methods. These rules push me to pick low-carbon alloys and eco-friendly casting techniques. I see more companies investing in recycling lines and green casting methods to meet these standards.

Tip: Recycling aluminum saves up to 95% of the energy needed to make new aluminum from ore.

Energy Efficiency in Production

I always look for ways to save energy in my work. Aluminum die casting helps me do that. The process uses less energy than many other metalworking methods. I can control how much material I use, so I waste less. This means I use fewer resources and lower my energy bills.

I also see that aluminum is light. When I use it in cars or planes, the vehicles need less fuel. This cuts down on emissions over the whole life of the product. Many companies now measure their carbon footprint using Environmental Product Declarations (EPDs). These reports show how much energy and carbon each step of the process uses. I follow international standards like ISO 14040 and ISO 14044 to make sure my reports are accurate. Third-party groups check these reports, so my customers trust the results.

Here is a table that shows why aluminum a popular material for die casting when I want to lower environmental impact:

| Benefit | Description |

|---|---|

| High Recyclability | Aluminum keeps its properties after recycling, so I can use it again and again. |

| Lower Energy Use | Die casting aluminum uses less energy than other methods. |

| Lightweight | Lighter parts mean less fuel used in cars and planes. |

| Less Waste | I can control the process to use only what I need, so I throw away less. |

Industry Trends and Technological Advances in 2025

In 2025, I see many new trends making aluminum a popular material for die casting. Companies use artificial intelligence (AI) and machine learning to spot problems before they happen. Robots and automation help me make parts faster and with fewer mistakes. I use green casting methods, like closed-loop water cooling and bio-based oils, to protect the environment.

- I use digital twins and smart foundries to test designs on computers before making real parts. This saves time and materials.

- Vacuum die casting helps me make stronger parts with fewer air bubbles.

- I see big car companies, like Tesla and Ford, building their own die casting plants. They use new giga-casting methods to make large parts quickly.

- More factories in Asia and North America are making aluminum parts for electric vehicles. This meets the growing demand for lightweight, high-performance spare parts.

Sustainability drives many of these changes. I see more recycled aluminum and energy-saving methods in every step. Companies invest in new technology to meet strict rules and help the planet. I believe these trends will keep aluminum a popular material for die casting for many years.

I see aluminum a popular material for die casting because it gives me strong, light, and cost-effective parts. I notice supply chain changes and new tariffs in 2025 make me plan carefully. Industry certifications help me meet strict standards and build trust with my customers.

FAQ

What makes aluminum better than other metals for die casting?

I choose aluminum because it is light, strong, and easy to recycle. I see it saves money and energy compared to steel or zinc.

Tip: Aluminum parts last longer in tough environments.

Can I use recycled aluminum for die casting spare parts?

Yes, I use recycled aluminum often. It keeps its strength and quality. I help the environment by choosing recycled material.

How does aluminum die casting help with sustainability in 2025?

I notice aluminum die casting uses less energy and creates less waste. I meet strict green rules by recycling and using smart production methods.

By:Daphne

Email:daphne@haihongxintang.com

Phone:Sales: 0086-134 8641 8015

Post time: Aug-27-2025