Ke bona aluminium e le thepa e tsebahalang bakeng sa ho etsa die casting liindastering tse ngata kajeno. Ha ke sheba lebaka, ke hlokomela mabaka a 'maloa a bohlokoa:

1. Baetsi ba batla likoloi tse bobebe bakeng sa moruo o motle oa mafura.

2. Theknoloji e ncha e etsaOEM aluminium die castingle ho feta.

3. Melao e matla e sutumelletsa ho fokotsa mesi le likarolo tse bobebe.

Ka lebaka la liphetoho tsena, kamehla ke tšepa aluminium bakeng sashoa ho lahlela likaroloana tse setseng.

Lintlha tsa bohlokoa

- Aluminium e fana kae matla empa e le bobebekhetho bakeng sa ho lahla, ho thusa ho fokotsa tšebeliso ea mafura le ho ntlafatsa ts'ebetso ea koloi.

- Ho hanyetsa ha eona ha tlhaho ho senya le botsitso bo botle ba mocheso ho etsa hore aluminium e tšoarelle le ho tšepahala libakeng tse thata.

- Aluminium die casting e boloka nako le chelete kalipotoloho tse potlakileng tsa tlhahisohape e ts'ehetsa ts'ebetso ea ts'ebetso ka ho e sebelisa habonolo le ho sebetsa hantle ha matla.

Aluminium Ntho e Tummeng bakeng sa Die Casting: Thepa e Phahameng ka ho Fetisisa le Melemo ea Litšenyehelo

Karolelano e Phahameng ea Matla le Boima le ho tšoarella

Ha ke khetha thepa bakeng sashoa ho lahlela likaroloana tse setseng, Ke lula ke batla ho leka-lekana ho molemo ka ho fetisisa pakeng tsa matla le boima ba 'mele. Aluminium e hlahella hobane e mpha ka bobeli. Ke bona hore aluminium e na leboima bo tlase ho feta zinki, ho bolelang hore e bobebe. Le hoja likarolo tsa zinki li ka ba matla, li boima haholo. Boiphihlelo ba ka, aluminium ke thepa e tsebahalang bakeng sa ho etsa die casting, haholo ha ke hloka ho fokotsa boima ba 'mele likoloing kapa lifofaneng.

- Aluminium e na le boima bo tlase ho feta zinki, e bakang karo-karolelano e betere ea matla ho isa ho boima.

- Likarolo tsa zinc die cast ka kakaretso li matla ho feta habeli likarolo tsa aluminium empa li teteaneng ebile li boima ho feta.

- Motsoako oa aluminium oa matla a mangata le boima bo bobebe o etsa hore e be e loketseng lits'ebetso tseo ho tsona ho leng bohlokoa ho fokotsa boima ba 'mele, joalo ka mafapha a sefofane le a likoloi.

- Ka kakaretso, aluminium e fana ka matla a leka-lekaneng le a bobebe, a etsa hore e be molemo ho feta zinki ha boima e le ntlha ea bohlokoa.

Hangata ke bona lienjiniere li khetha aluminium bakeng sa likarolo tse hlokang ho ba matla le tse bobebe. Sena se thusa likoloi ho sebelisa mafura a fokolang le ho etsa hore ho be bonolo ho li tšoara. Ke boetse ke hlokomela hore likarolo tsa aluminium li nka nako e telele, leha li sebelisoa letsatsi le leng le le leng.

Ho hanyetsa Corrosion le Thermal Performance

Ke tšepa aluminiamo e le thepa e tsebahalang bakeng sa ho etsa diecast hobane e hanela mafome le ho bola. Libakeng tse thata joaloka lifektheri kapa haufi le leoatle, likarolo tsa aluminium ha li ruse kapele joaloka tšepe.Lisebelisoa tsa aluminium hangata li sebetsana le maemo a thata hantle, joalo ka maemo a leoatle kapa mongobo o phahameng. Zinc e boetse e hanela ho bola, empa ka linako tse ling e ka rusa haeba maemo a nepahetse. Tšepe e sa hloekang e sebetsa hantle ho feta aluminium mesebetsing e thata haholo ea indasteri, empa e boima haholo ebile e turu ho feta.

- Li-alloys tsa aluminium li na le khanyetso e ntle ea kutu empa li joalokotsing ea ho bola ea sodium chloride (letsoai)..

- Ka kakaretso tšepe e sa hloekang e fana ka kutu e phahameng le ho hanyetsa mafome, e leng se etsang hore e feto-fetohe haholoanyane libakeng tsa indasteri.

- Ts'epe e sa hloekang e khethoa bakeng sa lits'ebetso tse hlokang ho hanyetsa mocheso o phahameng le tšebeliso e boima ea indasteri.

- Aluminium e ratoa bakeng sa boima bo bobebe le lisebelisoa tse tlase tsa mocheso.

Ha ke sebetsa ka lisebelisoa tsa elektronike, ke bona hore aluminium e sebetsa hantle ho feta magnesium ka mocheso o phahameng. Aluminium e lula e tsitsitse ka holimo ho 100 ° C, ha magnesium e ka senyeha. Aluminium e boetse e na le khanyetso ea tlhaho ea kutu, kahoo ha ho hlokahale hore ke kenye liaparo tse eketsehileng. Sena se etsa hore aluminium e be thepa e tsebahalang bakeng sa lisebelisoa tsa elektroniki le liindasteri tse ling tse hlokang likarolo tsa nako e telele.

| Ntlha | Molemo oa Aluminium |

|---|---|

| Thermal Stability | Aluminium e sebetsa hantle libakeng tse phahameng tsa mocheso, ho boloka botsitso moo magnesium e senyehang (mohlala, ka holimo ho 100 ° C). |

| Khanyetso ea Corrosion | Aluminium e na le khanyetso ea tlhaho ea kutu, ho fapana le magnesium e hlokang lirafshoa ho thibela kutu. |

| Ho tšoarella | Aluminium e ratoa bakeng sa lisebelisoa tse hlokang ho tšoarella ha nako e telele le ho senya ho fokolang, tse bohlokoa bakeng sa lisebelisoa tsa elektroniki. |

Poloko ea Litšenyehelo le Katleho ea Tlhahiso

Ke lula ke batla litsela tsa ho boloka chelete le nako ha ho etsoa tlhahiso. Aluminium die casting e nthusa ho etsa ka bobeli. Mokhoa ona o sebelisa ente e nang le khatello e phahameng le ho pholisa kapele, kahoo nka etsa likarolo ka metsotsoana feela. Sena se potlakile haholo ho feta mekhoa e meng joalo ka ho lahla lehlabathe kapa ho forging.

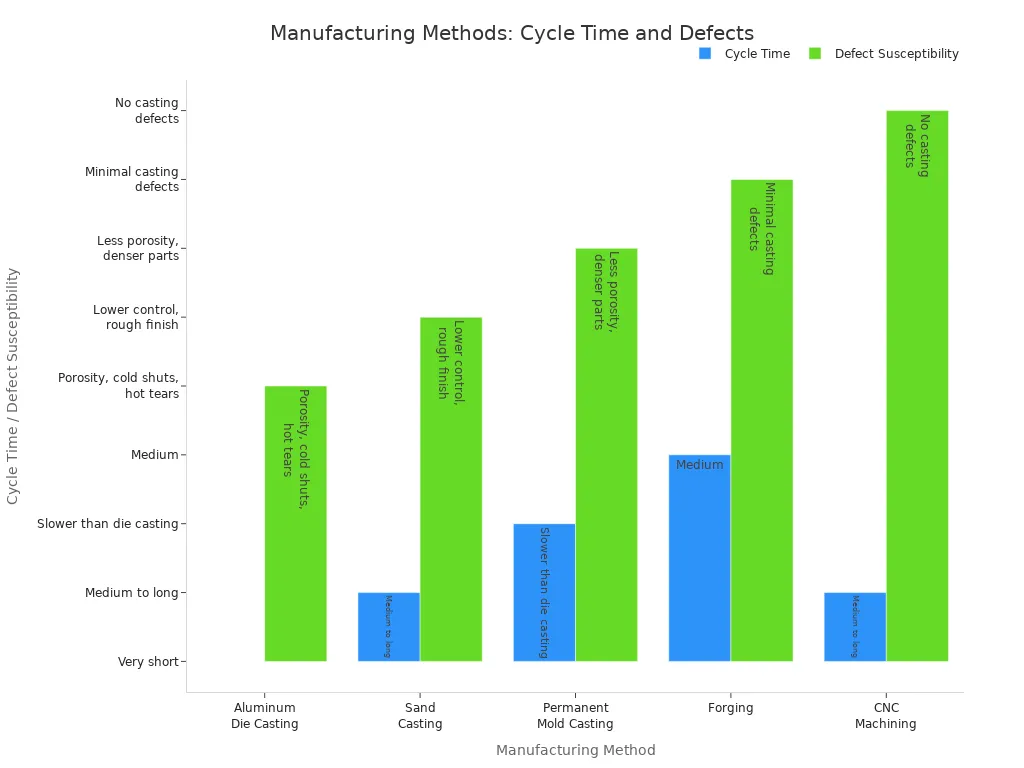

Mona ke kamoo aluminium die casting e bapisoang le mekhoa e meng:

| Mokhoa oa ho Etsa | Nako ea Cycle | Sekoli ho Sceptibility | Lintlha |

|---|---|---|---|

| Aluminium Die Casting | E khuts'oane haholo (metsotsoana) | E ka hlaseloa ke porosity ea khase / shrinkage, li- shuts tse batang, likhapha tse chesang; e laolehang ka taolo ea ts'ebetso | Nako e potlakileng ea potoloho ka lebaka la ente ea khatello e phahameng le ho pholisa kapele; theko e phahameng ea lisebelisoa tsa pele empa theko e tlase ea yuniti ka molumo |

| Ho Lahlela Lehlabathe | Nako e mahareng ho isa ho e telele | Taolo e tlase holim'a mefokolo; rougher surface finish | Ts'ebetso e liehang, lisebelisoa tse theko e tlaase, tse loketseng molumo o tlase kapa likarolo tse kholo |

| Phello ea Mold e sa Feleng | Bonya hofeta die casting | Porosity e fokolang, likarolo tse teteaneng | Matla a khoheli a fella ka likarolo tse matla, tse se nang masoba empa nako ea potoloho e liehang |

| Ho qapa | Mahareng | Mefokolo e fokolang ea ho lahla; matla a phahameng a mochini | Matla a phahameng ka ho fetisisa empa ho rarahana ha moralo o fokolang le litšenyehelo tse phahameng |

| Mochini oa CNC | Nako e mahareng ho isa ho e telele | Ha ho na liphoso tsa ho lahla; subtractive process | Ho nepahala ho phahameng, ha ho na litšenyehelo tsa lisebelisoa empa nako e telele ea potoloho le litšila tsa thepa |

Kea tseba hore aluminium die casting e ka ba le mefokolo e itseng, joalo ka lipudula tsa khase kapa mapetsong. Ke sebelisa meralo e khethehileng le taolo e hlokolosi ho thibela mathata ana. Ha ke tsamaisa tšebetso hantle, ke fumana likarolo tsa boleng bo holimo kapele le ka theko e tlaase. Sena se etsahalaaluminium thepa e tsebahalang bakeng sa die casting, haholo-holo ha ke hloka ho etsa likarolo tse ngata kapele.

Aluminium Ntho e Tsebahalang bakeng sa Die Casting: Moshoelella le Lintlafatso tsa 2025

Recyclability le Melemo ea Tikoloho

Ha ke sebetsa ka aluminium, ke bona kamoo ho leng bonolo ho e sebelisa hape. Ke khona ho qhibilihisa likarolo tsa khale tsa aluminium ebe ke li sebelisa hape ntle le ho lahleheloa ke boleng. Ts'ebetso ena e sebelisa matla a fokolang haholo ho feta ho etsa aluminium e ncha ka thepa e tala. Ka lebaka lena, ke thusa ho fokotsa mocheso oa khase e futhumatsang lefatše le ho fokotsa khabone ea merero ea ka. Ke boetse ke hlokomela seoho sebelisa aluminium hape ho boloka litšila tse ngata ho tsoa litsing tsa lithōle. Hona joale lifeme tse ngata li sebelisa li-curl-loop recycling, moo li bokellang le ho sebelisa makumane a tšepe hona femeng. Sena se tšehetsa taolo ea tšilafalo 'me se nthusa ho finyella lipakane tse tiileng tsa tikoloho.

Ke khetha aluminium ntho e tsebahalang bakeng sa ho etsa diecast hobane e lumellana hantle le melao e mecha ea ts'ebetso.Ka 2025, mekhatlo ea mmuso e kang EPA le Lefapha la Matla li nkhothalletsa ho sebelisa aluminium e nchafalitsoeng.le mekhoa ea ho boloka matla. Melao ena e ntšusumelletsa ho khetha li-alloys tse nang le carbon e tlaase le mekhoa ea ho lahla eco-friendly. Ke bona lik'hamphani tse ngata tse tsetelang mekhoeng ea ho tsosolosa le mekhoa e tala ho finyella litekanyetso tsena.

Keletso:Ho sebelisa aluminium hape ho boloka ho fihla ho 95% ea matla a hlokahalang ho etsa aluminium e ncha ka tšepe.

Katleho ea Matla Tlhahisong

Ke lula ke batla litsela tsa ho boloka matla mosebetsing oa ka. Aluminium die casting e nthusa ho etsa joalo. Mokhoa ona o sebelisa matla a fokolang ho feta mekhoa e meng e mengata ea tšepe. Ke khona ho laola hore na ke sebelisa lintho tse ngata hakae, kahoo ke senya hanyenyane. Sena se bolela hore ke sebelisa lisebelisoa tse fokolang le ho theola likoloto tsa ka tsa matla.

Ke boetse ke bona hore aluminium e bobebe. Ha ke e sebelisa likoloing kapa lifofaneng, likoloi li hloka mafura a fokolang. Sena se fokotsa likhase tse tsoang bophelong bohle ba sehlahisoa. Hona joale lik'hamphani tse ngata li lekanya sebaka sa bona sa khabone ka ho sebelisaLiphatlalatso tsa Sehlahisoa sa Tikoloho (EPDs). Litlaleho tsena li bontša hore na mohato ka mong oa tšebetso o sebelisa matla le khabone e kae. Ke latela litekanyetso tsa machaba tse kang ISO 14040 le ISO 14044 ho netefatsa hore litlaleho tsa ka li nepahetse. Lihlopha tsa mekhatlo ea boraro li hlahloba litlaleho tsena, kahoo bareki ba ka ba tšepa liphetho.

Tafole ke ena e bontšang lebakaaluminium ntho e tsebahalangbakeng sa ho lahlela lefu ha ke batla ho theola tšusumetso ea tikoloho:

| Molemo | Tlhaloso |

|---|---|

| Phahameng ka ho Recyclability | Aluminium e boloka thepa ea eona ka mor'a hore e sebelisoe hape, e le hore nka e sebelisa khafetsa. |

| Tšebeliso ea Matla a Tlase | Die casting aluminium e sebelisa matla a fokolang ho feta mekhoa e meng. |

| E bobebe | Likarolo tse bobebe li bolela mafura a fokolang a sebelisoang likoloing le lifofaneng. |

| Nyenyane e Senya | Ke khona ho laola mokhoa oa ho sebelisa feela seo ke se hlokang, kahoo ke lahla hanyenyane. |

Mekhoa ea Indasteri le Tsoelo-pele ea Theknoloji ka 2025

Ka 2025, ke bona mekhoa e mengata e mecha e etsang aluminium thepa e tsebahalang bakeng sa ho etsa diecast.Likhamphani li sebelisa bohlale ba maiketsetso (AI) le ho ithuta ka mochiniho bona mathata pele a etsahala. Liroboto le li-automation li nthusa ho etsa likarolo kapele le ka liphoso tse fokolang. Ke sebelisa mekhoa e tala ea ho lahla, joalo ka pholiso ea metsi a koetsoeng le oli e thehiloeng ho bio, ho sireletsa tikoloho.

- Ke sebelisa mafahla a dijithale le lisebelisoa tse bohlale ho lekola meralo ea likhomphutha pele ke etsa likarolo tsa 'nete. Sena se boloka nako le thepa.

- Vacuum die casting e nthusa ho etsa likarolo tse matla ka lipululo tse fokolang tsa moea.

- Ke bona lik'hamphani tse kholo tsa makoloi, joalo ka Tesla le Ford, ba ikahela limela tsa bona tsa ho lahla. Ba sebelisa mekhoa e mecha ea giga-casting ho etsa likarolo tse kholo kapele.

- Lifeme tse ling tsa Asia le Amerika Leboea li etsa likarolo tsa aluminium bakeng sa likoloi tsa motlakase. Sena se kopana le tlhokahalo e ntseng e hola ea likarolo tse ling tse bobebe, tse sebetsang hantle haholo.

Ho tšoarella ho tsamaisa tse ngata tsa liphetoho tsena. Ke bona mekhoa e mengata ea aluminium e sebelisoang hape le ho boloka matla mohatong o mong le o mong. Likhamphani li tsetela ho theknoloji e ncha ho fihlela melao e thata le ho thusa polanete. Ke lumela hore litloaelo tsena li tla boloka aluminium e le thepa e tsebahalang bakeng sa ho lahla lefu ka lilemo tse ngata.

Ke bona aluminiamo e le thepa e tsebahalang bakeng sa die casting hobane e mpha likarolo tse matla, tse bobebe le tse baballang chelete e ngata. Ke hlokomela liphetoho tsa phepelo lelitefiso tse ncha ka 2025etsa hore ke rere hantle.Setifikeiti sa indasterinthuse ho fihlela litekanyetso tse thata le ho aha tšepo ho bareki ba ka.

LBH

Ke eng e etsang hore aluminium e be betere ho feta litšepe tse ling bakeng sa ho lahla?

Ke khethaaluminiumhobane e bobebe, e matla, ebile e bonolo ho e sebelisa hape. Ke bona e boloka chelete le matla ha li bapisoa le tšepe kapa zinki.

Keletso:Likarolo tsa aluminium li tšoarella nako e telele libakeng tse thata.

A na nka sebelisa aluminium e nchafalitsoeng bakeng sa likarolo tse setseng tsa lefu?

E, ke sebelisa aluminium e sebelisoang hape hangata. E boloka matla le boleng ba eona. Ke thusa tikoloho ka ho khetha thepa e sebelisoang hape.

Aluminium die casting e thusa joang ka botsitso ka 2025?

Kea hlokomelaaluminium diecastinge sebedisa matla a manyane mme e baka tshenyo e nyane. Ke kopana le melao e thata e tala ka ho tsosolosa le ho sebelisa mekhoa e bohlale ea tlhahiso.

Ka: Daphne

Email:daphne@haihongxintang.com

Mohala: Lithekiso: 0086-134 8641 8015

Nako ea poso: Aug-27-2025