Ndibona i-aluminiyam iyimathiriyeli eyaziwayo yokufa kumashishini amaninzi namhlanje. Xa ndijonga isizathu, ndiphawula izizathu ezininzi eziphambili:

1. Abavelisi bafuna iimoto ezikhaphukhaphu ukwenzela ukonga amafutha.

2. Iteknoloji entsha yenzaOEM aluminiyam die castingyomelele ngakumbi.

3. Imithetho eyomeleleyo ityhala izinto ezikhutshwayo ezisezantsi kunye namalungu alula.

Ngenxa yolu tshintsho, ndihlala ndiyithemba i-aluminiumkufa ukuphosa iindawo ezisecaleni.

Izinto eziphambili zokuThatha

- IAluminiyam inikezela ngewomelele kodwa ukhaphukhaphuukhetho lokuphosa ukufa, ukunceda ukunciphisa ukusetyenziswa kwamafutha kunye nokuphucula ukusebenza kwesithuthi.

- Ukuchasana kwayo kwendalo kwi-corrosion kunye nokuzinza okulungileyo kwe-thermal kwenza i-aluminium yomelele kwaye ithembekile kwiindawo ezinzima.

- Aluminiyam die casting konga ixesha kunye nemali ngeimijikelo yemveliso ekhawulezayokwaye ixhasa uzinzo ngokurisayikilishwa ngokulula kunye nokusebenza kakuhle kwamandla.

IAluminiyam iSisixhobo esidumileyo sokuCalwa kweDie: iiPropati eziPhezulu kunye neeNdleko eziluncedo

Ubungakanani bobunzima obuphezulu kunye nokuqina

Xa ndikhetha imathiriyelikufa ukuphosa iindawo ezisecaleni, Ndihlala ndijonge eyona ndlela ilungileyo phakathi kwamandla kunye nobunzima. I-Aluminiyam igqamile kuba indinika zombini. Ndiyabona ukuba i-aluminiyam ineUxinzelelo oluphantsi kunezinc, okuthetha ukuba kukhanya ngakumbi. Nangona iindawo ze-zinc zinokuba namandla, zinzima kakhulu. Kumava am, i-aluminiyam iyinto ethandwayo yokuphosa ukufa, ngakumbi xa ndifuna ukunciphisa ubunzima kwiimoto okanye kwiinqwelomoya.

- I-Aluminiyam inoxinano olusezantsi kunezinc, okukhokelela kumlinganiselo ongcono wamandla ukuya kubunzima.

- I-Zinc die cast parts yomelele ngokuphindwe kabini njengeenxalenye ze-aluminiyam kodwa zixinene kwaye zinzima.

- Indibaniselwano yeAluminiyam yamandla amakhulu kunye nobunzima obulula buyenza ilungele usetyenziso apho ukuncitshiswa kobunzima kubaluleke kakhulu, njenge-aerospace kunye necandelo leemoto.

- Ngokubanzi, i-aluminiyam inika amandla alungeleleneyo kunye ne-lightweight, iyenza ikhetheke ngaphezu kwe-zinc xa ubunzima buyinto ephambili.

Ndihlala ndibona iinjineli zikhetha i-aluminium kwiindawo ezifuna ukuba zomelele kwaye zibe khaphukhaphu. Oku kunceda iimoto ukuba zisebenzise amafutha amancinci kwaye zenze kube lula ukuziphatha. Ndikwaqaphela ukuba iinxalenye ze-aluminium zihlala ixesha elide, nokuba zisetyenziswa yonke imihla.

Ukuchasana nokuNgquba kunye nokuSebenza kweThermal

Ndiyayithemba i-aluminiyam njengesixhobo esithandwayo sokuphosa ukufa kuba ixhathisa umhlwa kunye nokuhlwa. Kwiindawo ezirhabaxa njengemizi-mveliso okanye kufutshane nolwandle, iinxalenye zealuminiyam azirhasi ngokukhawuleza njengentsimbi.Iialloyi ze-aluminiyam zihlala zibamba iindawo ezinzima kakuhle, ezifana neemeko zaselwandle okanye zokufuma okuphezulu. I-Zinc iphinda ixhathise ukubola, kodwa ngamanye amaxesha inokugqwala ukuba iimeko zilungile. Intsimbi engacocekanga yenza ngcono kune-aluminiyam kwimisebenzi yemizi-mveliso enzima kakhulu, kodwa inzima kakhulu kwaye ibiza kakhulu.

- Iialloyi ze-aluminiyam zinokumelana nokugqwala okuhle kodwa zinjaloUsengozini kwi-sodium chloride (ityuwa) yokubola.

- Intsimbi engatyiwayo ngokubanzi ibonelela ngokugqwesa okuphezulu kunye nokuxhathisa umhlwa, nto leyo eyenza ukuba isebenze kwizinto ezininzi kwiindawo zemizi-mveliso.

- Insimbi engenasici ikhethwa kwizicelo ezifuna ukumelana nobushushu obuphezulu kunye nokusetyenziswa kwemizi-mveliso enzima.

- Ialuminiyam ithandwa kubunzima obukhaphukhaphu kunye nezicelo ezisezantsi zobushushu.

Xa ndisebenza nge-electronics, ndiyabona ukuba i-aluminium iqhuba ngcono kune-magnesium kumaqondo aphezulu. I-Aluminiyam ihlala izinzile ngaphezu kwe-100 ° C, ngelixa i-magnesium inokuphuka. I-aluminiyam ikwanazo ukumelana nokugqwala kwendalo, ngoko akufuneki ukuba ndongeze ezinye izinto zokwaleka. Oku kwenza i-aluminiyam ibe yimathiriyeli eyaziwayo yokufa kwi-electronics nakwamanye amashishini afuna iindawo ezihlala ixesha elide.

| Umba | IAluminiyam eluncedo |

|---|---|

| Ukuzinza kweThermal | I-Aluminiyam yenza ngcono kwiindawo eziphezulu zokushisa, igcina uzinzo apho i-magnesium iyancipha (umzekelo, ngaphezu kwe-100 ° C). |

| Ukunyangwa kokuMhlwa | I-Aluminiyam inokumelana ne-corrosion yendalo, ngokungafaniyo ne-magnesium efuna iingubo zokukhusela ukubola. |

| Ukuqina | I-Aluminiyam ikhethwa kwizicelo ezifuna ukuqina kwexesha elide kunye ne-corrosion encinci, ibaluleke kakhulu kumalungu e-elektroniki. |

Ukongiwa kweendleko kunye nokuSebenza ngokuLungileyo

Ndihlala ndijonge iindlela zokugcina imali kunye nexesha kwimveliso. Ukuphoswa kweAluminiyam kuyandinceda ukuba ndizenze zombini. Inkqubo isebenzisa inaliti yoxinzelelo oluphezulu kunye nokupholisa ngokukhawuleza, ngoko ke ndingenza iinxalenye ngemizuzwana nje. Oku kukhawuleza kakhulu kunezinye iindlela ezifana nokugalela isanti okanye ukubunjwa.

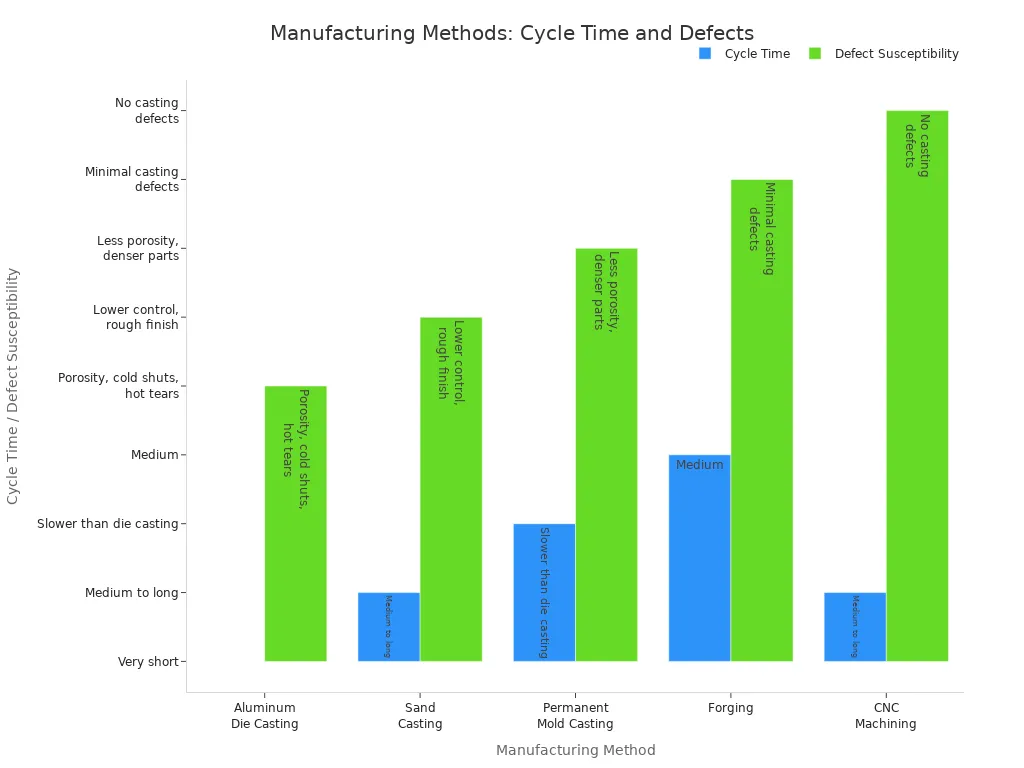

Nantsi indlela ukuphosa ukufa kwe-aluminiyam kuthelekiswa nezinye iindlela:

| Indlela Yokuvelisa | Ixesha lomjikelo | Isiphene ukuba siSesichengeni | Amanqaku |

|---|---|---|---|

| Aluminiyam Die Casting | Mfutshane kakhulu (imizuzwana) | Ukuxhatshazwa kwegesi / i-shrinkage porosity, ukuvala okubandayo, iinyembezi ezishushu; iyalawuleka ngolawulo lwenkqubo | Ixesha elikhawulezayo lomjikelo ngenxa yesitofu soxinzelelo oluphezulu kunye nokupholisa ngokukhawuleza; ixabiso eliphezulu lezixhobo zokusebenza kodwa ixabiso leyunithi eliphantsi kumthamo |

| Isanti yokuphosa | Phakathi ukuya kwinde | Ulawulo oluphantsi kwiziphene; ukugqitywa komphezulu ongaphezulu | Inkqubo ephantsi, i-tooling ephantsi, ifanelekile umthamo ophantsi okanye iindawo ezinkulu |

| Ukusatywa kokungunda okusisigxina | Icotha kunokuphosa ukufa | I-porosity encinci, iindawo ezixineneyo | Ukuzaliswa kobunzima bomxhuzulane kuphumela kwiindawo ezomeleleyo, ezingaphantsi kwamabhobhodlo kodwa ixesha lomjikelo olucothayo |

| Ukuqulunqa | Phakathi | Ubuncinci bokuphosa iziphene; amandla omatshini aphezulu | Awona mandla aphakamileyo kodwa ukuntsonkotha koyilo olulinganiselweyo kunye neendleko eziphezulu |

| CNC Machining | Phakathi ukuya kwinde | Akukho ziphene zokuphosa; inkqubo yokuthabatha | Ukuchaneka okuphezulu, akukho ndleko yezixhobo kodwa amaxesha omjikelo omde kunye nenkcitho yezinto eziphathekayo |

Ndiyazi ukuba ukujulwa kwe-aluminiyam kunokuba neziphene, njengamaqamza erhasi okanye iintanda. Ndisebenzisa uyilo olukhethekileyo kunye nokulawula ngononophelo ukuthintela ezi ngxaki. Xa ndilawula inkqubo kakuhle, ndifumana iinxalenye ezikumgangatho ophezulu ngokukhawuleza nangexabiso eliphantsi. Oku kwenzai-aluminiyam yinto eyaziwayo yokuphosa ukufa, ngakumbi xa kufuneka ndenze amalungu amaninzi ngokukhawuleza.

I-Aluminiyam iMathiriyeli edumileyo yeDie Casting: Uzinzo kunye noTshintsho luka-2025

Ukusebenziseka kwakhona kunye neeNzuzo zokusiNgqongileyo

Xa ndisebenza nge-aluminiyam, ndiyabona ukuba kulula kangakanani ukurisayikilisheka. Ndiyakwazi ukunyibilikisa iinxalenye ezindala ze-aluminiyam kwaye ndiphinde ndizisebenzise ngaphandle kokuphulukana nomgangatho. Le nkqubo isebenzisa amandla amancinci kakhulu kunokwenza i-aluminiyam entsha kwizinto ezikrwada. Ngenxa yoku, ndincedisa ekunciphiseni ukukhutshwa kwegesi ye-greenhouse kunye nokunciphisa i-carbon footprint yeeprojekthi zam. Ndikwaqaphela ukubaukurisayikilisha ialuminiyam igcina inkunkuma eninzi kwitiphu. Iifektri ezininzi ngoku zisebenzisa i-close-loop recycling, apho ziqokelela kwaye ziphinde zisebenzise iintsimbi ezilahliweyo kanye kumzi-mveliso. Oku kuxhasa ulawulo longcoliseko kwaye kundinceda ndihlangabezane neenjongo ezingqongqo zokusingqongileyo.

Ndikhetha i-aluminiyam into eyaziwayo yokuphosa ukufa kuba ihambelana kakuhle nemithetho emitsha yokuzinza.Ngo-2025, ii-arhente zikarhulumente ezifana ne-EPA kunye neSebe lezaMandla zindikhuthaza ukuba ndisebenzise i-aluminium ehlaziyiweyo.kunye neendlela zokonga amandla. Le mithetho indityhala ukuba ndikhethe i-alloys enekhabhoni ephantsi kunye neendlela zokuphosa eco-friendly. Ndibona iinkampani ezininzi zenza utyalo-mali kwimigca yokurisayikilisha kunye neendlela zokulahla eziluhlaza ukuhlangabezana nale migangatho.

Ingcebiso:Ukurisayikilisha ialuminiyam konga ukuya kutsho kuma-95% amandla afunekayo ukwenza ialuminiyam entsha kwintsimbi ekrwada.

Ukusebenza kakuhle kwamandla kwiMveliso

Ndihlala ndikhangela iindlela zokonga amandla emsebenzini wam. Ukuphoswa kweAluminiyam kuyandinceda ukuba ndenze oko. Inkqubo isebenzisa amandla amancinci kunezinye iindlela ezininzi zesinyithi. Ndiyakwazi ukulawula ubungakanani bemathiriyeli endiyisebenzisayo, ngoko ke ndimosha kancinci. Oku kuthetha ukuba ndisebenzisa izixhobo ezimbalwa kwaye ndithobe amatyala am amandla.

Ndiyabona kwakhona ukuba i-aluminiyam ilula. Xa ndiyisebenzisa ezimotweni okanye kwiinqwelo-moya, izithuthi zifuna amafutha amancinci. Oku kunciphisa ukukhutshwa kubomi bonke bemveliso. Iinkampani ezininzi ngoku zilinganisa i-carbon footprint yazo zisebenzisaIzibhengezo zeMveliso yokusiNgqongileyo (EPDs). Ezi ngxelo zibonisa ukuba angakanani amandla kunye nekhabhoni inyathelo ngalinye lenkqubo elisebenzisayo. Ndilandela imigangatho yamazwe ngamazwe efana ne-ISO 14040 kunye ne-ISO 14044 ukuqinisekisa ukuba iingxelo zam zichanekile. Amaqela eqela lesithathu ajonga ezi ngxelo, ukuze abathengi bam bathembe iziphumo.

Nantsi itheyibhile ebonisa ukuba kuthenii-aluminiyam yinto eyaziwayongokuphosa ukufa xa ndifuna ukuthoba impembelelo yokusingqongileyo:

| Inzuzo | Inkcazo |

|---|---|

| High Recyclability | I-Aluminiyam igcina iimpawu zayo emva kokurisayikilishwa, ngoko ndingayisebenzisa ngokuphindaphindiweyo. |

| Ukusetyenziswa kwamandla aphantsi | I-aluminiyam yokufa isebenzisa amandla amancinci kunezinye iindlela. |

| Ikhaphukhaphu | Amalungu alula athetha amafutha amancinci asetyenziswa kwiimoto kunye neenqwelomoya. |

| Inkunkuma encinci | Ndiyakwazi ukulawula inkqubo yokusebenzisa kuphela into endiyidingayo, ngoko ndilahla ngaphantsi. |

Iindlela zoShishino kunye neNtuthuko yeTekhnoloji ngo-2025

Ngo-2025, ndibona iindlela ezininzi ezintsha zokwenza i-aluminiyam ibe yinto edumileyo yokuphosa ukufa.Iinkampani zisebenzisa i-Artificial Intelligence (AI) kunye nokufunda koomatshiniukubona iingxaki ngaphambi kokuba zenzeke. Iirobhothi kunye ne-automation zindinceda ukuba ndenze iinxalenye ngokukhawuleza kunye neempazamo ezimbalwa. Ndisebenzisa iindlela zokuphosa eziluhlaza, njengokupholisa amanzi avaliweyo kunye neoyile esekwe kwi-bio, ukukhusela indalo.

- Ndisebenzisa amawele edijithali kunye nee-smart foundries ukuvavanya uyilo kwiikhompyuter ngaphambi kokwenza amalungu okwenene. Oku konga ixesha kunye nezixhobo.

- Ukuphosa ukufa kwevacuum kundinceda ndenze iindawo ezomeleleyo ezinamaqamza omoya ambalwa.

- Ndibona iinkampani ezinkulu zeemoto, ezinje ngoTesla kunye neFord, bezakhela ezabo izityalo zokulahla. Basebenzisa iindlela ezintsha zokuphosa igiga ukwenza iindawo ezinkulu ngokukhawuleza.

- Iifektri ezininzi eAsia naseMntla Melika zenza iinxalenye ze-aluminiyam kwizithuthi zombane. Oku kuhlangabezana nemfuno ekhulayo yobunzima obukhaphukhaphu, iinxalenye ezisebenza ngokuphezulu.

Uzinzo luqhuba uninzi lwezi nguqu. Ndibona ialuminiyam esetyenzisiweyo ngakumbi kunye neendlela zokonga amandla kwinqanaba ngalinye. Iinkampani zityala imali kwitekhnoloji entsha ukuhlangabezana nemithetho engqongqo kunye nokunceda iplanethi. Ndiyakholelwa ukuba ezi ndlela ziya kugcina i-aluminiyam iyimathiriyeli eyaziwayo yokufa iminyaka emininzi.

Ndibona i-aluminiyam iyimathiriyeli ethandwayo yokuphosa ukufa kuba indinika iindawo ezomeleleyo, ezilula, nezingabizi kakhulu. Ndiqaphela utshintsho lwekhonkco lonikezelo kunyeamaxabiso amatsha ngo-2025ndenze ndicwangcise kakuhle.Izatifikethi zeshishinindincede ndihlangabezane nemigangatho engqongqo kwaye ndakhe ukuthembana kubathengi bam.

FAQ

Yintoni eyenza i-aluminiyam ibengcono kunezinye iintsimbi zokuphosa ukufa?

ndiyakhethaaluminiyamkuba ilula, yomelele, kwaye kulula ukuyirisayikilisheka. Ndiyayibona igcina imali kunye namandla xa kuthelekiswa nentsimbi okanye i-zinc.

Ingcebiso:Amalungu e-aluminiyam ahlala ixesha elide kwiindawo ezinzima.

Ngaba ndingasebenzisa ialuminiyam esetyenzisiweyo ukulahla iinxalenye ezisecaleni?

Ewe, ndisebenzisa ialuminiyam esetyenzisiweyo rhoqo. Igcina amandla kunye nomgangatho wayo. Ndinceda okusingqongileyo ngokukhetha imathiriyeli esetyenzisiweyo.

I-aluminiyam yokufa inceda njani ukuzinza ngo-2025?

Ndiyaqaphelai-aluminium die castingisebenzisa amandla amancinci kwaye idala inkcitho encinci. Ndidibana nemithetho engqongqo eluhlaza ngokuphinda ndisebenzise iindlela zokuvelisa ezikrelekrele.

Ngu: Daphne

imeyile:daphne@haihongxintang.com

Ifowuni: Intengiso: 0086-134 8641 8015

Ixesha lokuposa: Aug-27-2025