Ina ganin aluminium sanannen abu don simintin mutuwa a masana'antu da yawa a yau. Lokacin da na kalli dalilin, na lura da dalilai masu mahimmanci:

1. Masu kera suna son motoci masu sauƙi don ingantaccen tattalin arzikin mai.

2. Sabuwar fasahar saOEM aluminum mutu simintin gyaran kafama fi karfi.

3. Dokoki masu ƙarfi suna tura ƙananan hayaki da sassa masu sauƙi.

Saboda waɗannan canje-canje, koyaushe ina dogara ga aluminummutu jefa kayayyakin gyara.

Key Takeaways

- Aluminum yana bayar da amai ƙarfi amma mara nauyizaɓi don yin simintin mutuwa, yana taimakawa rage amfani da mai da haɓaka aikin abin hawa.

- Juriyarsa na dabi'a ga lalata da ingantaccen yanayin zafi yana sa aluminum mai dorewa kuma abin dogaro a cikin yanayi mai wahala.

- Aluminum mutu simintin gyare-gyare yana adana lokaci da kuɗi tare dasaurin samar da hawan kekekuma yana goyan bayan dorewa ta hanyar sake amfani da sauƙi da ingantaccen makamashi.

Aluminum Shahararriyar Material don Fitar da Simintin Mutuwa: Babban Kayayyaki da Fa'idodin Kuɗi

Babban Ƙarfi-zuwa-Nauyi Ratio da Dorewa

Lokacin da na zaɓi kayan donmutu jefa kayayyakin gyara, Kullum ina neman mafi kyawun daidaito tsakanin ƙarfi da nauyi. Aluminum ya tsaya a waje saboda yana ba ni duka. Ina ganin cewa aluminum yana da waniƙananan yawa fiye da zinc, wanda ke nufin ya fi sauƙi. Ko da yake sassan zinc na iya zama da ƙarfi, sun fi nauyi. A cikin gwaninta, aluminum sanannen abu ne don yin simintin mutuwa, musamman lokacin da nake buƙatar rage nauyi a cikin motoci ko jirgin sama.

- Aluminum yana da ƙananan yawa fiye da zinc, yana haifar da mafi kyawun ƙarfin-zuwa nauyi rabo.

- Sassan simintin gyare-gyare na Zinc gabaɗaya suna da ƙarfi fiye da sau biyu kamar sassan aluminum amma sun fi yawa kuma sun fi nauyi.

- Haɗin Aluminum na babban ƙarfi da nauyi mai nauyi ya sa ya dace don aikace-aikace inda rage nauyi ke da mahimmanci, kamar sararin samaniya da sassan kera motoci.

- Gabaɗaya, aluminum yana ba da ƙarfin daidaitacce tare da nauyi mai nauyi, yana sa ya fi dacewa akan zinc lokacin da nauyi shine babban mahimmanci.

Sau da yawa ina ganin injiniyoyi suna ɗaukar aluminum don sassan da ke buƙatar zama duka mai ƙarfi da haske. Wannan yana taimaka wa ababen hawa yin amfani da ƙarancin mai kuma yana sauƙaƙa sarrafa su. Na kuma lura cewa sassan aluminum suna dadewa na dogon lokaci, koda lokacin amfani da su kowace rana.

Juriya na Lalacewa da Ayyukan Zazzabi

Na amince da aluminum sanannen abu don yin simintin mutuwa saboda yana tsayayya da tsatsa da lalata. A wurare masu tsanani kamar masana'antu ko kusa da teku, sassan aluminum ba sa yin tsatsa da sauri kamar karfe.Aluminum alloys yawanci kula da m yanayi da kyau, kamar yanayin ruwa ko yanayin zafi mai yawa. Zinc kuma yana tsayayya da lalata, amma wani lokacin yana iya yin tsatsa idan yanayin ya dace. Bakin karfe yayi kyau fiye da aluminium a cikin ayyukan masana'antu masu tauri, amma ya fi nauyi da tsada.

- Aluminum alloys suna da kyakkyawan juriya na lalata amma sunam ga sodium chloride (gishiri) lalata.

- Bakin karfe gabaɗaya yana ba da mafi girman lalata da juriya, yana mai da shi mafi dacewa a cikin mahallin masana'antu.

- An fi son bakin karfe don aikace-aikacen da ke buƙatar juriya mai zafi da amfani da masana'antu masu nauyi.

- An fi son Aluminum don ƙarancin nauyi da ƙananan aikace-aikacen zafi.

Lokacin da nake aiki da kayan lantarki, na ga cewa aluminum yana aiki mafi kyau fiye da magnesium a cikin yanayin zafi. Aluminum yana tsayawa sama da 100 ° C, yayin da magnesium zai iya rushewa. Aluminum kuma yana da juriya na lalata na halitta, don haka ba na buƙatar ƙara ƙarin sutura. Wannan ya sa aluminum ya zama sanannen abu don yin simintin mutuwa a cikin kayan lantarki da sauran masana'antu waɗanda ke buƙatar sassa na dindindin.

| Factor | Amfanin Aluminum |

|---|---|

| Zaman Lafiya | Aluminum yana aiki mafi kyau a cikin yanayin zafi mai zafi, yana kiyaye kwanciyar hankali inda magnesium ke raguwa (misali, sama da 100 ° C). |

| Juriya na Lalata | Aluminum yana da juriya na lalata na halitta, sabanin magnesium wanda ke buƙatar sutura don hana lalata. |

| Dorewa | An fi son Aluminum don aikace-aikacen da ke buƙatar dorewa na dogon lokaci da ƙarancin lalacewa, mai mahimmanci ga kayan lantarki. |

Tattalin Kuɗi da Ƙarfin Ƙirƙira

A koyaushe ina neman hanyoyin adana kuɗi da lokaci a masana'antu. Aluminum mutu simintin gyare-gyare yana taimaka min yin duka biyun. Tsarin yana amfani da allura mai ƙarfi da sanyaya mai sauri, don haka zan iya yin sassa a cikin daƙiƙa kaɗan. Wannan yana da sauri fiye da sauran hanyoyin kamar simintin yashi ko ƙirƙira.

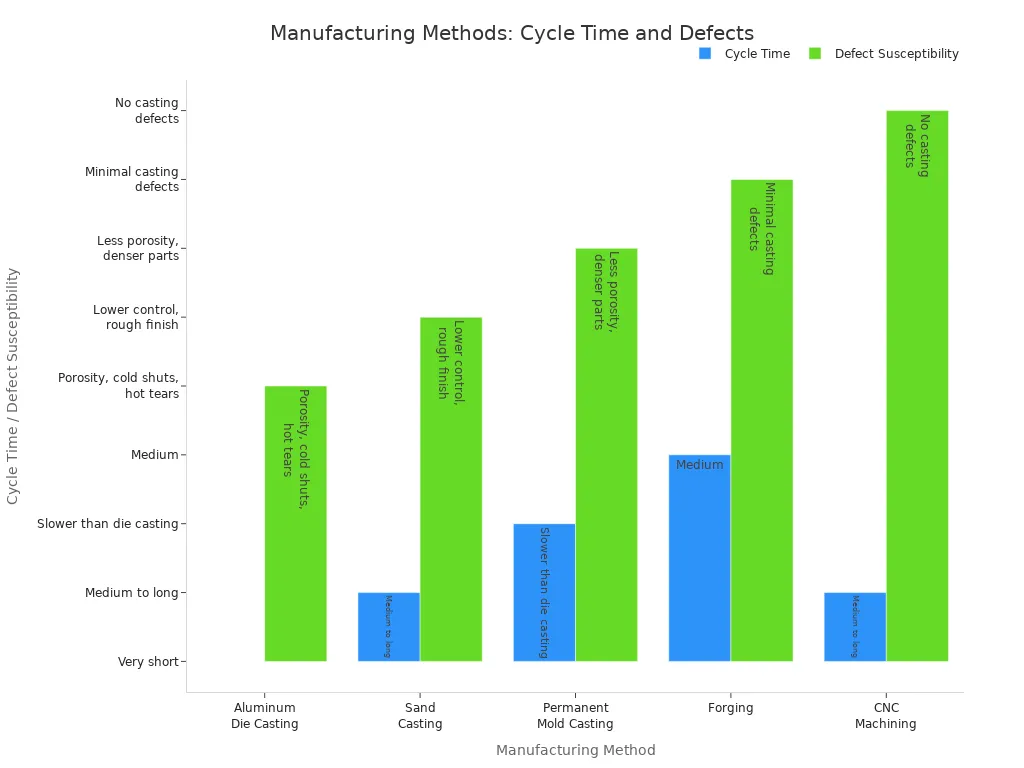

Anan ga yadda aluminium mutu simintin ya kwatanta da sauran hanyoyin:

| Hanyar sarrafawa | Lokacin Zagayowar | Rashin Lalacewa | Bayanan kula |

|---|---|---|---|

| Aluminum Die Casting | gajere sosai (dakika) | Mai saukin kamuwa da iskar gas / raguwa, rufewar sanyi, hawaye mai zafi; sarrafawa tare da sarrafa tsari | Mafi sauri lokacin sake zagayowar saboda babban matsa lamba da kuma sanyaya mai sauri; high upfront kayan aiki tsada amma low naúrar kudin a girma |

| Yashi Casting | Matsakaici zuwa tsayi | Ƙananan iko akan lahani; m surface gama | Tsarin hankali, kayan aiki mai rahusa, dacewa da ƙananan ƙararrawa ko manyan sassa |

| Dindindin Simintin Gyaran Halitta | Sannu a hankali fiye da mutuwar simintin | Ƙananan porosity, sassa masu yawa | Cika nauyi yana haifar da ƙarfi, ƙarancin sassa masu ƙarfi amma lokacin zagayowar hankali |

| Ƙirƙira | Matsakaici | Ƙananan lahani; m inji ƙarfi | Ƙarfi mafi girma amma ƙayyadaddun ƙira da ƙira mafi girma |

| Farashin CNC | Matsakaici zuwa tsayi | Babu lahani na simintin gyaran kafa; tsarin ragewa | Babban madaidaici, babu farashin kayan aiki amma tsawon lokacin sake zagayowar da sharar kayan abu |

Na san cewa simintin gyare-gyare na aluminum na iya samun wasu lahani, kamar kumfa gas ko fasa. Ina amfani da zane-zane na musamman da kulawa da hankali don hana waɗannan matsalolin. Lokacin da na sarrafa tsari da kyau, Ina samun sassa masu inganci da sauri kuma a farashi mai sauƙi. Wannan ya saaluminum sanannen abu ne don yin simintin mutuwa, musamman lokacin da nake buƙatar yin sassa da yawa cikin sauri.

Aluminum Shahararriyar Material don Casting Din: Dorewa da Sabbin 2025

Maimaituwa da Amfanin Muhalli

Lokacin da nake aiki da aluminium, na ga yadda sauƙin sake yin fa'ida yake. Zan iya narke tsoffin sassan aluminum kuma in sake amfani da su ba tare da rasa inganci ba. Wannan tsari yana amfani da ƙarancin kuzari fiye da yin sabon aluminum daga albarkatun ƙasa. Saboda wannan, Ina taimakawa rage hayakin iskar gas da rage sawun carbon na ayyukana. Ina kuma lura da hakansake yin amfani da aluminium yana kiyaye ƙarin sharar gida daga wuraren sharar ƙasa. Yawancin masana'antu yanzu suna amfani da sake amfani da rufaffiyar madauki, inda suke tattarawa da sake amfani da tarkacen karfe a cikin shuka. Wannan yana goyan bayan sarrafa gurɓatawa kuma yana taimaka mini in cimma matsananciyar manufofin muhalli.

Na zaɓi aluminum sanannen abu don yin simintin mutuwa saboda ya dace da sabbin ƙa'idodin dorewa.A cikin 2025, hukumomin gwamnati kamar EPA da Sashen Makamashi suna ƙarfafa ni in yi amfani da aluminum da aka sake sarrafada hanyoyin ceton makamashi. Waɗannan ƙa'idodin sun ingiza ni in ɗauki allunan ƙaramar carbon da dabarun simintin ɗabi'a. Ina ganin ƙarin kamfanoni suna saka hannun jari a cikin sake yin amfani da layukan sake yin amfani da su da hanyoyin simintin gyare-gyaren kore don cika waɗannan ƙa'idodi.

Tukwici:Sake yin amfani da aluminum yana adana kusan kashi 95% na makamashin da ake buƙata don yin sabon aluminum daga tama.

Amfanin Makamashi a Samar da Samfura

A koyaushe ina neman hanyoyin adana kuzari a cikin aikina. Aluminum mutu simintin gyare-gyare yana taimaka min yin hakan. Tsarin yana amfani da ƙarancin kuzari fiye da yawancin hanyoyin aikin ƙarfe. Zan iya sarrafa yawan kayan da nake amfani da su, don haka na rage ɓarna. Wannan yana nufin ina amfani da ƙarancin albarkatu da rage kuɗin kuzarina.

Na kuma ga cewa aluminum haske ne. Lokacin da nake amfani da shi a cikin motoci ko jirgin sama, motocin suna buƙatar ƙarancin mai. Wannan yana rage fitar da hayaki a tsawon rayuwar samfurin. Yawancin kamfanoni yanzu suna auna sawun carbon ɗin su ta amfani da suBayanin Samfuran Muhalli (EPDs). Waɗannan rahotanni sun nuna yawan kuzari da carbon kowane mataki na tsari ke amfani da shi. Ina bin ka'idodin kasa da kasa kamar ISO 14040 da ISO 14044 don tabbatar da rahotanni na daidai ne. Ƙungiyoyin ɓangare na uku suna duba waɗannan rahotanni, don haka abokan cinikina sun amince da sakamakon.

Ga tebur da ke nuna dalilinaluminum sanannen abudon yin simintin mutuwa lokacin da nake son rage tasirin muhalli:

| Amfani | Bayani |

|---|---|

| Babban Maimaituwa | Aluminum yana kiyaye kaddarorin sa bayan sake yin amfani da shi, don haka zan iya amfani da shi akai-akai. |

| Ƙananan Amfani da Makamashi | Die simintin aluminum yana amfani da ƙarancin kuzari fiye da sauran hanyoyin. |

| Mai nauyi | Ƙananan sassa na nufin ƙarancin man da ake amfani da su a cikin motoci da jiragen sama. |

| Kadan Sharar gida | Zan iya sarrafa tsari don amfani da abin da nake buƙata kawai, don haka na zubar da ƙasa kaɗan. |

Canjin Masana'antu da Ci gaban Fasaha a cikin 2025

A cikin 2025, na ga sabbin abubuwa da yawa waɗanda ke sa aluminum ya zama sanannen abu don yin simintin mutuwa.Kamfanoni suna amfani da basirar wucin gadi (AI) da koyon injindon gano matsalolin kafin su faru. Robots da aiki da kai suna taimaka mini yin sassa cikin sauri kuma tare da ƙananan kurakurai. Ina amfani da hanyoyin simintin koren, kamar rufaffiyar ruwa mai sanyaya ruwa da mai tushen halittu, don kare muhalli.

- Ina amfani da tagwaye na dijital da masana'anta masu wayo don gwada ƙira akan kwamfutoci kafin yin sassa na gaske. Wannan yana adana lokaci da kayan aiki.

- Vacuum die simintin yana taimaka mani yin sassa masu ƙarfi tare da ƙarancin kumfa.

- Ina ganin manyan kamfanonin mota, kamar Tesla da Ford, suna gina nasu tsire-tsire na simintin gyare-gyare. Suna amfani da sababbin hanyoyin simintin giga-giga don yin manyan sassa cikin sauri.

- Ƙarin masana'antu a Asiya da Arewacin Amirka suna yin sassan aluminum don motocin lantarki. Wannan ya dace da haɓakar buƙatun kayan sassauƙa masu nauyi, manyan ayyuka.

Dorewa yana haifar da yawancin waɗannan canje-canje. Ina ganin ƙarin sabuntar aluminum da hanyoyin ceton makamashi a kowane mataki. Kamfanoni suna saka hannun jari a cikin sabbin fasaha don saduwa da tsauraran dokoki da taimakawa duniya. Na yi imanin waɗannan abubuwan da ke faruwa za su ci gaba da kasancewa aluminium sanannen abu don yin simintin mutuwa na shekaru masu yawa.

Ina ganin aluminum sanannen abu ne don yin simintin mutuwa saboda yana ba ni ƙarfi, haske, da sassa masu tsada. Ina lura da canje-canjen sarkar kayayyaki dasabon tariffs a 2025yi min shiri da kyau.Takaddun shaida na masana'antuTaimaka mini in cika ƙaƙƙarfan ƙa'idodi da gina aminci tare da abokan cinikina.

FAQ

Menene ya sa aluminum ya fi sauran karafa don yin simintin mutuwa?

na zabaaluminumsaboda haske ne, mai ƙarfi, kuma mai sauƙin sake sarrafa shi. Ina ganin yana adana kuɗi da kuzari idan aka kwatanta da karfe ko zinc.

Tukwici:Sassan aluminium sun daɗe a cikin yanayi masu tauri.

Zan iya amfani da aluminum da aka sake yin fa'ida don fitar da kayan gyara mutun?

Ee, Ina amfani da aluminum da aka sake sarrafa sau da yawa. Yana kiyaye ƙarfinsa da ingancinsa. Ina taimakon muhalli ta hanyar zabar kayan da aka sake yin fa'ida.

Ta yaya aluminium mutu simintin taimaka tare da dorewa a 2025?

na luraaluminum mutu simintin gyaran kafayana amfani da ƙarancin kuzari kuma yana haifar da ƙarancin sharar gida. Na hadu da tsauraran dokokin kore ta hanyar sake yin amfani da su da kuma amfani da hanyoyin samar da wayo.

By: Daphne

Imel:daphne@haihongxintang.com

Waya: Siyarwa: 0086-134 8641 8015

Lokacin aikawa: Agusta-27-2025