Aluminum alloy motorcycle components often provide strength and low weight. Zinc alloy suits detailed or complex shapes in motorcycle die – cast parts. Many ODM motorcycle accessorie makers select materials based on part function. The table below shows key differences:

| Property | Aluminum Alloy | Zinc Alloy |

|---|---|---|

| Strength | High | Moderate |

| Weight | Light | Heavier |

Key Takeaways

- Aluminum alloy offers strong, lightweight parts ideal for frames, wheels, and engine covers, improving motorcycle speed and handling.

- Zinc alloy suits detailed, lower-stress parts like levers and decorative pieces, allowing complex shapes and cost-effective production.

- Choosing the right alloy based on strength, weight, design, cost, and environment helps motorcycle parts last longer and perform better.

Strength and Durability in Motorcycle Die-Cast Parts

Aluminum Alloy Strength and Durability

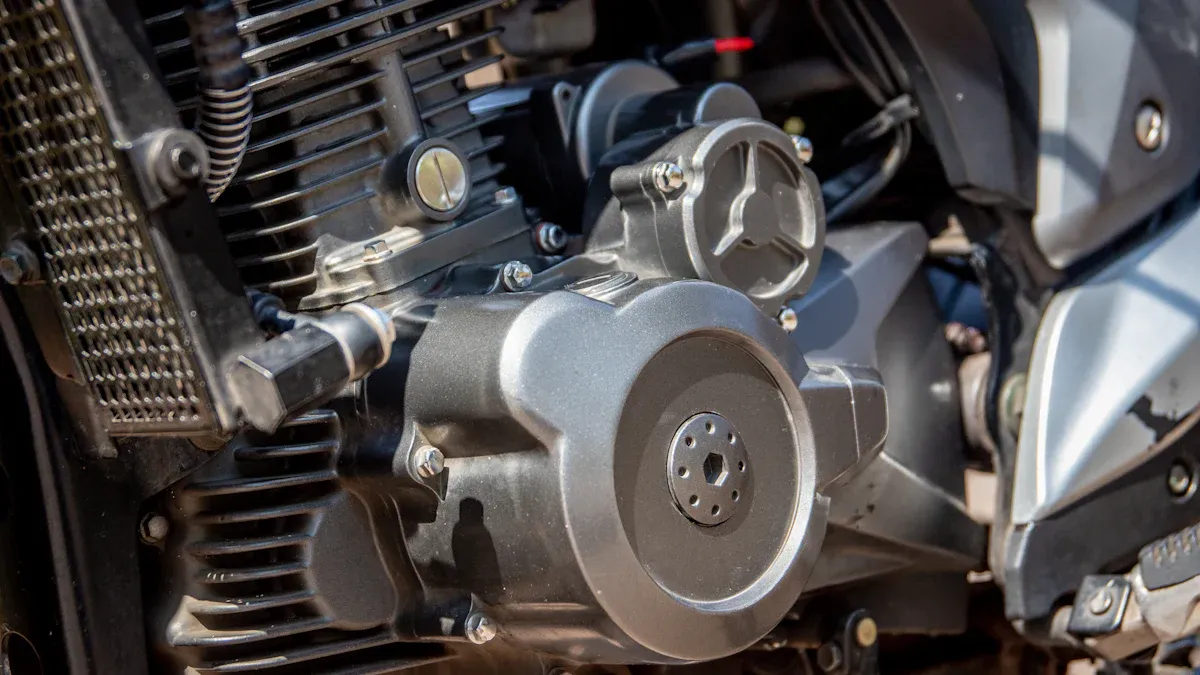

Aluminum alloy offers high strength for motorcycle die-cast parts. This material can handle heavy loads and strong impacts. Many engineers choose aluminum alloy for parts that need to last a long time. The metal resists bending and breaking under stress. Riders often trust aluminum alloy for frames, wheels, and engine covers. These parts must stay strong during fast rides and rough roads.

Tip: Aluminum alloy keeps its strength even after many years of use. This makes it a smart choice for parts that face daily wear and tear.

Zinc Alloy Strength and Durability

Zinc alloy provides moderate strength for motorcycle die-cast parts. It works well for parts that do not carry heavy loads. Zinc alloy can form detailed shapes, which helps when making small or complex parts. This material does not break easily, but it can bend if pushed too hard. Many manufacturers use zinc alloy for levers, brackets, and covers. These parts do not face as much stress as frames or wheels.

- Zinc alloy resists cracking in normal use.

- It can handle small impacts without damage.

- The material works best for parts that need fine details.

Performance in Real-World Motorcycle Applications

Motorcycle die-cast parts must perform well on the road. Aluminum alloy parts often appear in places where strength matters most. For example, a motorcycle frame made from aluminum alloy stays strong during sharp turns and sudden stops. Riders feel safer with these parts because they do not fail easily.

Zinc alloy parts show up in less demanding spots. A handlebar switch or a decorative trim piece often uses zinc alloy. These parts do not face much force, so moderate strength is enough. Zinc alloy also allows for creative designs, which helps with style and comfort.

Note: Choosing the right material for each part helps the motorcycle last longer and perform better.

Weight and Performance Impact for Motorcycle Die-Cast Parts

Aluminum Alloy Weight Advantages

Aluminum alloy stands out for its light weight. Engineers often choose this material when they want to reduce the overall mass of a motorcycle. Lighter parts help the motorcycle move faster and stop more quickly. Riders notice that motorcycles with aluminum alloy frames or wheels feel easier to handle. The low weight also means less strain on the engine. This can lead to better fuel efficiency.

Tip: Lighter motorcycle die – cast parts can make long rides less tiring for riders.

Zinc Alloy Weight Considerations

Zinc alloy weighs more than aluminum alloy. This extra weight can affect how a motorcycle feels on the road. Heavier parts may slow down acceleration. They can also make the motorcycle harder to control during sharp turns. However, zinc alloy works well for small or decorative parts where weight does not matter as much. Manufacturers use zinc alloy for pieces like emblems or switch housings.

- Zinc alloy suits parts that do not need to be light.

- The extra weight can add stability to some small components.

Effect on Motorcycle Handling and Efficiency

The weight of each part changes how a motorcycle handles. Lighter aluminum alloy parts help the motorcycle respond quickly to steering. Riders find it easier to make fast turns or sudden stops. Heavier zinc alloy parts can make the motorcycle feel more stable at low speeds, but they may reduce fuel efficiency. Choosing the right material for each part helps balance speed, control, and comfort.

Cost and Production Efficiency of Motorcycle Die-Cast Parts

Aluminum Alloy Cost Factors

Aluminum alloy often costs more than zinc alloy. The price comes from both the raw material and the energy needed to melt aluminum. Factories need special equipment to handle the higher melting point. This can raise the cost of making motorcycle die – cast parts. Aluminum molds also wear out faster, so companies must replace them more often. These factors make aluminum alloy a bigger investment for manufacturers.

Zinc Alloy Cost Factors

Zinc alloy usually offers a lower cost for production. The metal melts at a lower temperature, which saves energy. Factories can use less expensive equipment. Zinc molds last longer because the process is gentler on the tools. This helps keep costs down for small or complex parts. Many companies choose zinc alloy when they want to save money on large production runs.

Production Speed and Complexity Comparison

Zinc alloy allows for faster production cycles. The metal cools and hardens quickly, so factories can make more parts in less time. Zinc also fills molds easily, which helps with detailed shapes. Aluminum alloy takes longer to cool and may need extra steps for complex designs. Companies must balance speed, cost, and part quality when choosing between these materials.

Tip: Faster production with zinc alloy can help meet tight deadlines for motorcycle die – cast parts.

Surface Finish and Corrosion Resistance in Motorcycle Die-Cast Parts

Aluminum Alloy Surface Quality and Protection

Aluminum alloy gives a smooth and clean surface to many motorcycle parts. Manufacturers can polish or paint these surfaces for a shiny look. Some use powder coating to add extra protection. This coating helps prevent scratches and keeps the part looking new. Aluminum alloy also accepts anodizing, which adds a hard layer on the outside. This layer protects against wear and gives a bright color. Riders often see aluminum alloy on visible parts because it looks modern and stays attractive.

Tip: Anodized aluminum parts resist fading and scratching better than plain metal.

Zinc Alloy Surface Quality and Protection

Zinc alloy creates very detailed shapes in motorcycle die – cast parts. The surface feels smooth and can show fine lines or logos. Manufacturers often use chrome plating or painting to protect zinc alloy. These finishes add shine and help stop rust. Zinc alloy parts can look like polished metal or have a matte finish. The surface stays strong in normal use, but heavy scratches may show more easily.

- Zinc alloy works well for parts that need a fancy or complex design.

- Chrome plating gives a mirror-like finish.

Corrosion Resistance Comparison

Aluminum alloy resists corrosion well, especially after anodizing or painting. It forms a thin oxide layer that blocks moisture. Zinc alloy also fights corrosion, but it needs a good surface finish for best results. Chrome or paint helps zinc parts last longer. In wet or salty places, aluminum alloy usually lasts longer without rust. Both materials need care, but aluminum alloy often wins for outdoor use.

| Feature | Aluminum Alloy | Zinc Alloy |

|---|---|---|

| Natural Corrosion Resistance | High | Moderate |

| Needs Extra Coating | Sometimes | Often |

| Best for Wet Conditions | Yes | Sometimes |

Application Suitability for Motorcycle Die-Cast Parts

Best Uses for Aluminum Alloy in Motorcycles

Aluminum alloy fits best in parts that need to be strong and light. Engineers often select this material for the main frame of a motorcycle. The frame supports the rider and the engine, so it must handle heavy loads and strong forces. Aluminum alloy also works well for wheels. These wheels help the motorcycle move faster and stop quickly. Riders notice better handling when the wheels weigh less.

Other good uses for aluminum alloy include:

- Swingarms, which connect the rear wheel to the frame.

- Engine covers, which protect important parts from dirt and damage.

- Foot pegs and handlebars, which need to be both strong and light.

Note: Aluminum alloy helps reduce the total weight of the motorcycle. This makes the ride smoother and easier to control.

Best Uses for Zinc Alloy in Motorcycles

Zinc alloy suits parts that have complex shapes or need fine details. Manufacturers often use zinc alloy for small parts that do not face much stress. For example, levers and brackets made from zinc alloy can have detailed designs. These parts do not carry heavy loads, so moderate strength is enough.

Common uses for zinc alloy include:

- Decorative trim pieces, such as emblems or badges.

- Switch housings and control buttons.

- Small covers and brackets that hold wires or cables.

Zinc alloy also works well for parts that need a smooth surface or shiny finish. Chrome plating on zinc alloy gives a mirror-like look, which many riders like.

Real-World Examples of Motorcycle Die-Cast Parts

Many motorcycles use both aluminum alloy and zinc alloy in different places. Each material fits a special job. Here are some real-world examples:

| Part Name | Common Material | Reason for Choice |

|---|---|---|

| Main Frame | Aluminum Alloy | Needs high strength and low weight |

| Wheel Rims | Aluminum Alloy | Improves speed and handling |

| Engine Cover | Aluminum Alloy | Protects engine, resists impact |

| Handlebar Switch | Zinc Alloy | Allows detailed shapes |

| Decorative Emblem | Zinc Alloy | Needs fine detail and smooth finish |

| Brake Lever | Zinc Alloy | Handles light stress, detailed |

Tip: Motorcycle makers choose the material based on the job each part must do. Using the right alloy helps motorcycle die – cast parts last longer and work better.

Practical Decision Guide for Choosing Motorcycle Die-Cast Parts Material

Checklist for Selecting the Right Alloy

Choosing the best material for motorcycle parts can feel challenging. A simple checklist helps make the process easier. Here are important points to consider:

- Strength Needs: Decide if the part must handle heavy loads or impacts.

- Weight Importance: Think about how much the part’s weight affects performance.

- Part Complexity: Check if the part has fine details or complex shapes.

- Cost Limits: Set a budget for materials and production.

- Surface Finish: Choose if the part needs a shiny, smooth, or detailed look.

- Corrosion Resistance: Consider if the part will face rain, mud, or salty roads.

- Production Speed: Decide if fast manufacturing is important.

Post time: Jul-18-2025