Chinese manufacturers use advanced Aluminum Die Casting to create precision die – cast components for OEM auto accessories. Skilled teams operate CNC machines and use 3D modeling. Automated inspection reduces flaws. These practices help aluminum die – cast auto parts achieve greater durability and reliability in demanding automotive environments.

Key Takeaways

- Precision technology like CNC machining and 3D modeling helps create strong, accurate auto parts that last longer and fit better.

- Automated inspection and non-destructive testing catch defects early, ensuring only high-quality parts reach customers.

- Strict quality standards, ongoing research, and staff training help manufacturers deliver reliable, durable auto parts that meet global demands.

The Role of Precision in Aluminum Die Casting for Auto Parts

Importance of Durability in Automotive Applications

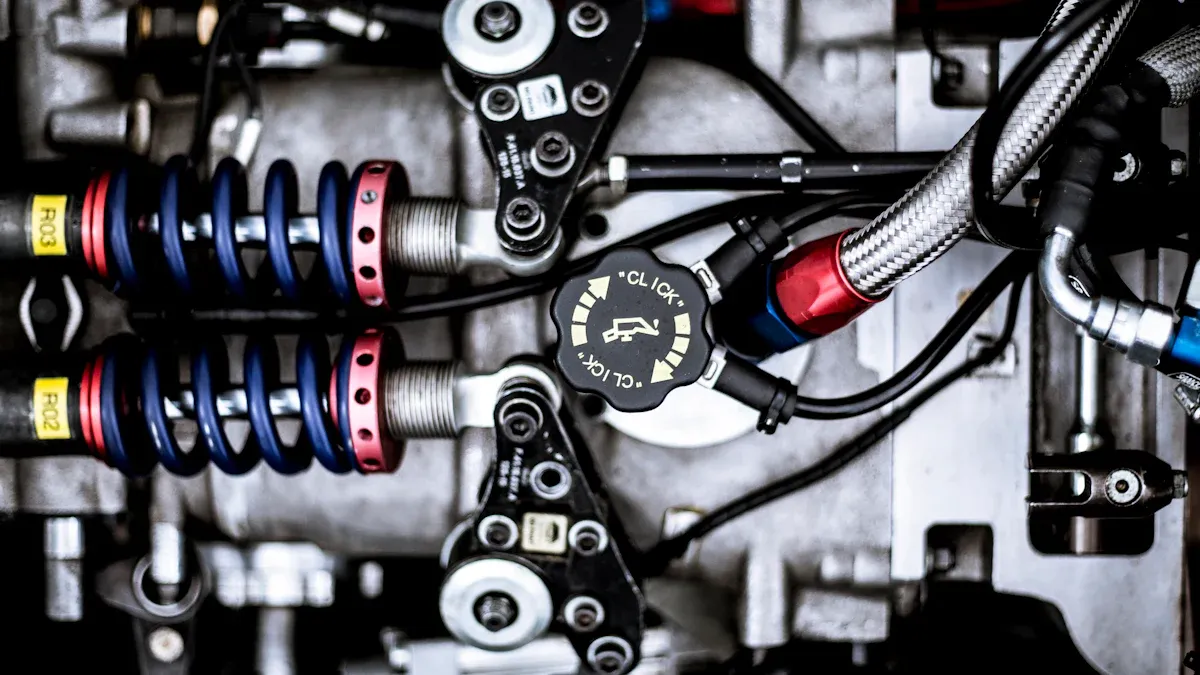

Durability stands as a key requirement for auto parts. Vehicles operate in harsh environments. They face constant vibration, temperature changes, and exposure to moisture. Auto parts must resist wear and tear to ensure safety and performance. When a part fails, it can lead to costly repairs or even accidents. Manufacturers focus on durability to meet strict industry standards and customer expectations.

Aluminum Die Casting offers a strong solution for producing durable components. This process creates parts with excellent strength-to-weight ratios. Lightweight parts help improve fuel efficiency and reduce emissions. At the same time, these parts must withstand the demands of daily driving. Reliable durability supports longer vehicle lifespans and lower maintenance costs.

Precision Technology and Its Impact on Part Longevity

Precision technology plays a vital role in Aluminum Die Casting. Advanced machinery shapes each part with tight tolerances. Consistent dimensions reduce the risk of weak points or defects. Automated systems check every detail, ensuring each component meets exact specifications.

Tip: Precision reduces the chance of early part failure and increases overall reliability.

Engineers use computer modeling to design parts that handle stress and heat efficiently. They simulate real-world conditions before production begins. This approach helps identify and fix potential problems early. As a result, precision technology extends the life of auto parts and boosts customer confidence.

Advanced Precision Technologies in Aluminum Die Casting

CNC Machining and Tight Tolerances

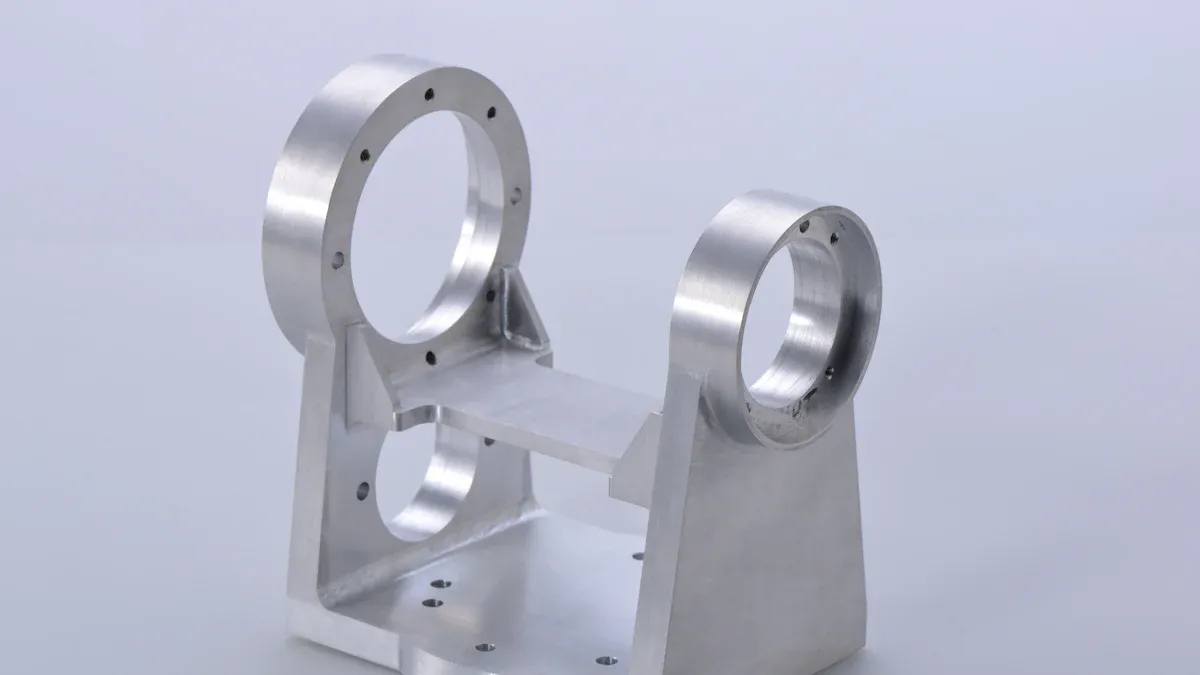

CNC machining stands at the heart of modern Aluminum Die Casting. Skilled operators use computer-controlled machines to shape parts with extreme accuracy. These machines cut, drill, and finish castings to meet exact measurements. Tight tolerances ensure that each auto part fits perfectly and performs as designed. Even small errors can lead to weak spots or early failure. CNC machining reduces these risks by delivering consistent results.

Manufacturers often use a checklist to maintain tight tolerances:

- Calibrate machines before each production run

- Inspect tools for wear and replace them as needed

- Monitor temperature and humidity in the workshop

- Record measurements for every batch

Note: Tight tolerances help auto parts resist stress and last longer on the road.

3D Modeling, Simulation, and Design Optimization

Engineers rely on 3D modeling to design complex auto parts for Aluminum Die Casting. They build digital models that show every detail of a component. These models allow teams to test different shapes and materials before making a physical part. Simulation software predicts how a part will react to heat, pressure, and vibration. This process helps engineers spot weak areas and improve the design.

Design optimization uses data from simulations to make parts stronger and lighter. Engineers adjust wall thickness, add support ribs, or change the alloy mix. These changes improve durability without adding extra weight. The result is a part that meets strict automotive standards and performs well in real-world conditions.

A simple table shows the benefits of this approach:

| Step | Benefit |

|---|---|

| 3D Modeling | Accurate designs |

| Simulation | Early problem detection |

| Design Optimization | Stronger, lighter parts |

Automated Inspection and Measurement Systems

Automated inspection systems play a key role in quality control for Aluminum Die Casting. These systems use cameras, lasers, and sensors to check every part. They measure dimensions, surface finish, and internal structure. Automated systems work faster and more accurately than manual checks. They catch defects early, which reduces waste and saves money.

Some systems use artificial intelligence to spot patterns in defects. This technology helps manufacturers find the root cause of problems and fix them quickly. Automated inspection ensures that only high-quality parts reach the customer.

Tip: Automated measurement systems help maintain high standards and build trust with automakers.

Quality Assurance and Continuous Improvement in Aluminum Die Casting

Industry Certifications and Standards Compliance

Chinese manufacturers understand that industry certifications build trust with global automakers. They work hard to achieve certifications such as ISO 9001, IATF 16949, and ISO 14001. These standards set strict rules for quality management, environmental responsibility, and process control. Companies must pass regular audits to keep these certifications. Auditors check records, inspect facilities, and review training programs.

A table below shows common certifications and their focus:

| Certification | Focus Area |

|---|---|

| ISO 9001 | Quality Management |

| IATF 16949 | Automotive Quality |

| ISO 14001 | Environmental Management |

Meeting these standards helps manufacturers deliver safe and reliable auto parts. Customers know they can expect consistent quality from certified suppliers.

Note: Certifications show a company’s commitment to quality and global best practices.

Non-Destructive Testing and Data-Driven Quality Control

Non-destructive testing (NDT) allows manufacturers to check parts without causing damage. They use methods like X-ray, ultrasonic, and dye penetrant testing. These tests find cracks, voids, or other hidden flaws inside castings. NDT helps companies catch problems before parts reach customers.

Data-driven quality control uses digital tools to track every step of production. Sensors collect data on temperature, pressure, and cycle times. Engineers review this data to spot trends and prevent defects. Automated systems alert staff if something goes wrong. This approach reduces waste and improves part reliability.

A typical quality control process includes:

- Inspecting raw materials before casting

- Monitoring machines during production

- Testing finished parts with NDT methods

- Recording and analyzing test results

Tip: Data-driven systems help teams fix problems quickly and avoid repeating mistakes.

R&D, Equipment Maintenance, and Staff Training

Research and development (R&D) teams play a key role in improving Aluminum Die Casting. They test new alloys, try advanced coatings, and develop better casting techniques. R&D helps companies create parts that last longer and perform better.

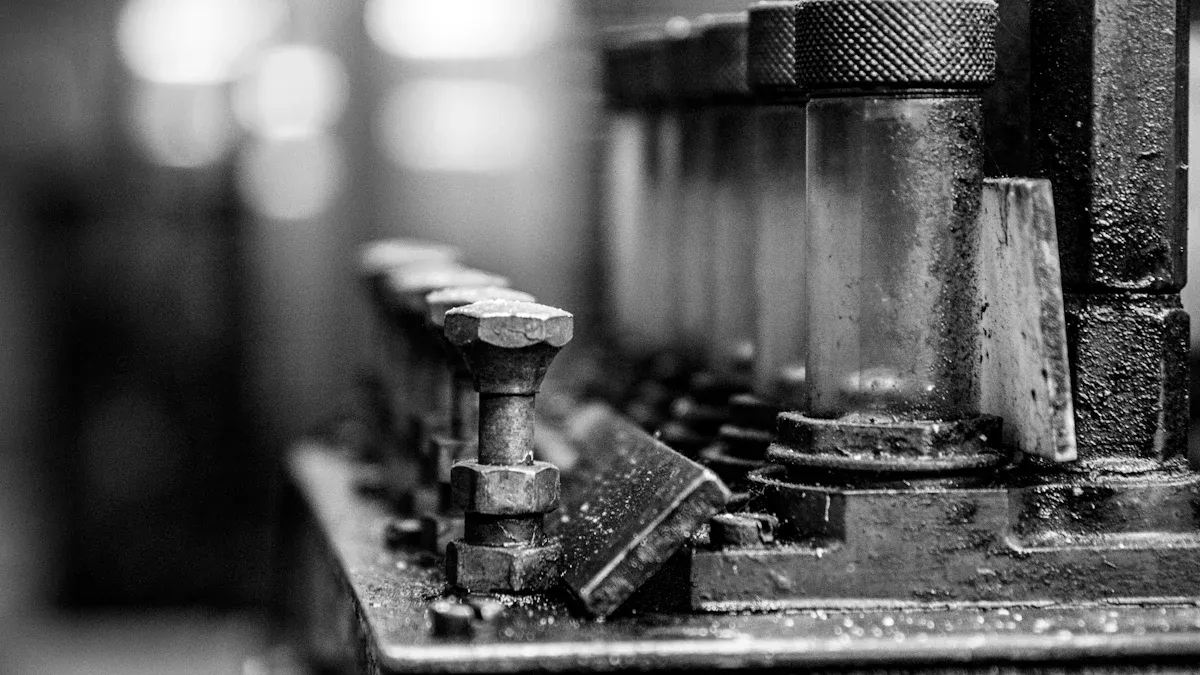

Regular equipment maintenance keeps machines running smoothly. Technicians check and service machines on a set schedule. They replace worn parts and update software. Well-maintained equipment produces more accurate and reliable castings.

Staff training ensures that workers know the latest methods and safety rules. Companies hold workshops and training sessions for new and experienced employees. Skilled workers can spot problems early and follow best practices.

Callout: Continuous learning and investment in people lead to better products and safer workplaces.

Chinese manufacturers achieve high durability in auto parts by using advanced precision technologies and strict quality assurance.

- Skilled teams and modern equipment help meet global standards.

- These practices deliver reliable, long-lasting components that benefit both automakers and drivers.

FAQ

What makes precision technology important in aluminum die casting?

Precision technology helps manufacturers create parts with exact measurements. This reduces defects and increases the strength and lifespan of auto parts.

Tip: Accurate parts fit better and last longer in vehicles.

How do Chinese manufacturers ensure quality in die-cast auto parts?

They use automated inspection, non-destructive testing, and strict quality standards. These steps help catch defects early and guarantee reliable performance.

Can aluminum die-cast parts handle extreme conditions?

Yes. Aluminum die-cast parts resist heat, vibration, and corrosion. Engineers design them to perform well in harsh automotive environments.

- Aluminum parts stay strong even under stress.

- Proper coatings add extra protection.

Post time: Jul-14-2025