Abakhiqizi baseShayina basebenzisa i-Aluminium Die Casting ethuthukisiwe ukuze bakheukunemba kufa - izingxenye zabalingisiokweIzesekeli ze-OEM auto. Amaqembu anamakhono asebenzisa imishini ye-CNC futhi asebenzisa ukumodela kwe-3D. Ukuhlola okuzenzakalelayo kunciphisa amaphutha. Le mikhuba iyasizaI-aluminium die - izingxenye ze-auto castukuzuza ukuqina okukhulu nokuthembeka ezindaweni ezifunwa izimoto.

Okuthathwayo Okubalulekile

- Ubuchwepheshe bokunembanjengokusebenza kwemishini kwe-CNC kanye nokumodela kwe-3D kusiza ekudaleni izingxenye zezimoto eziqinile, ezinembile ezihlala isikhathi eside futhi ezilingana kangcono.

- Ukuhlola okuzenzakalelayo kanye nokuhlola okungalimazi ukubamba amaphutha kusenesikhathi, okuqinisekisa ukuthi izingxenye zekhwalithi ephezulu kuphela ezifinyelela kumakhasimende.

- Izindinganiso eziqinile zekhwalithi, ucwaningo oluqhubekayo, nokuqeqeshwa kwezisebenzi kusiza abakhiqizi ukuletha izingxenye zezimoto ezithembekile, eziqinile ezihlangabezana nezidingo zomhlaba.

Iqhaza lokunemba ku-Aluminium Die Casting yezingxenye ezizenzakalelayo

Ukubaluleka Kokuqina Kuzinhlelo zokusebenza Zezimoto

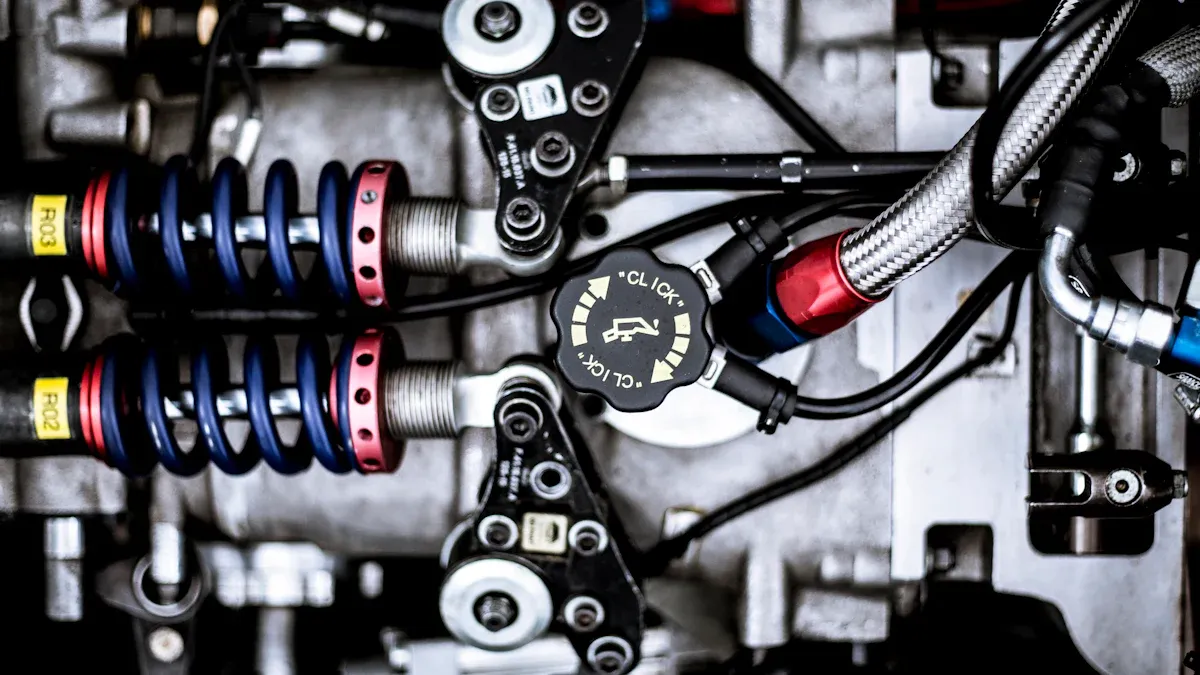

Ukuqina kumi njengemfuneko eyinhloko yezingxenye ezizenzakalelayo. Izimoto zisebenza ezindaweni ezinzima. Babhekana nokudlidliza njalo, ukushintsha kwezinga lokushisa, nokuchayeka emswanini. Izingxenye zezimoto kufanele zimelane nokuguga ukuze kuqinisekiswe ukuphepha nokusebenza. Lapho ingxenye ethile ingaphumeleli, ingaholela ekulungiseni okubizayo noma ngisho nasezingozini. Abakhiqizi bagxila ekuqineni ukuze bahlangabezane namazinga aqinile embonini kanye nokulindelwe ngamakhasimende.

I-Aluminium Die Castinginikeza isisombululo esiqinile sokukhiqiza izingxenye ezihlala isikhathi eside. Le nqubo idala izingxenye ezinezilinganiso ezinhle kakhulu zamandla nesisindo. Izingxenye ezingasindi zisiza ukuthuthukisa ukusebenza kahle kukaphethiloli futhi zinciphise ukungcola. Ngesikhathi esifanayo, lezi zingxenye kufanele zimelane nezidingo zokushayela kwansuku zonke. Ukuqina okuthembekile kusekela ukuphila kwezimoto ezinde kanye nezindleko zokunakekela eziphansi.

I-Precision Technology kanye Nomphumela Wayo Ekuphileni Okude Kwengxenye

Ubuchwepheshe bokunembaidlala indima ebalulekile ku-Aluminium Die Casting. Imishini ethuthukisiwe ibumba ingxenye ngayinye ngokubekezelelana okuqinile. Ubukhulu obufanayo bunciphisa ubungozi bamaphuzu abuthakathaka noma amaphutha. Amasistimu azenzakalelayo ahlola yonke imininingwane, aqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezimfuneko eziqondile.

Ithiphu: Ukunemba kunciphisa ithuba lokuhluleka kwengxenye yokuqala futhi kukhulisa ukwethembeka kukonke.

Onjiniyela basebenzisa ukumodela kwekhompuyutha ukuze baklame izingxenye eziphatha ingcindezi nokushisa kahle. Balingisa izimo zomhlaba wangempela ngaphambi kokuthi ukukhiqizwa kuqale. Le ndlela isiza ekuboneni nasekulungiseni izinkinga ezingaba khona kusenesikhathi. Ngenxa yalokho, ubuchwepheshe obunembayo bunweba impilo yezingxenye zezimoto futhi bukhuphule ukuzethemba kwamakhasimende.

I-Advanced Precision Technologies ku-Aluminium Die Casting

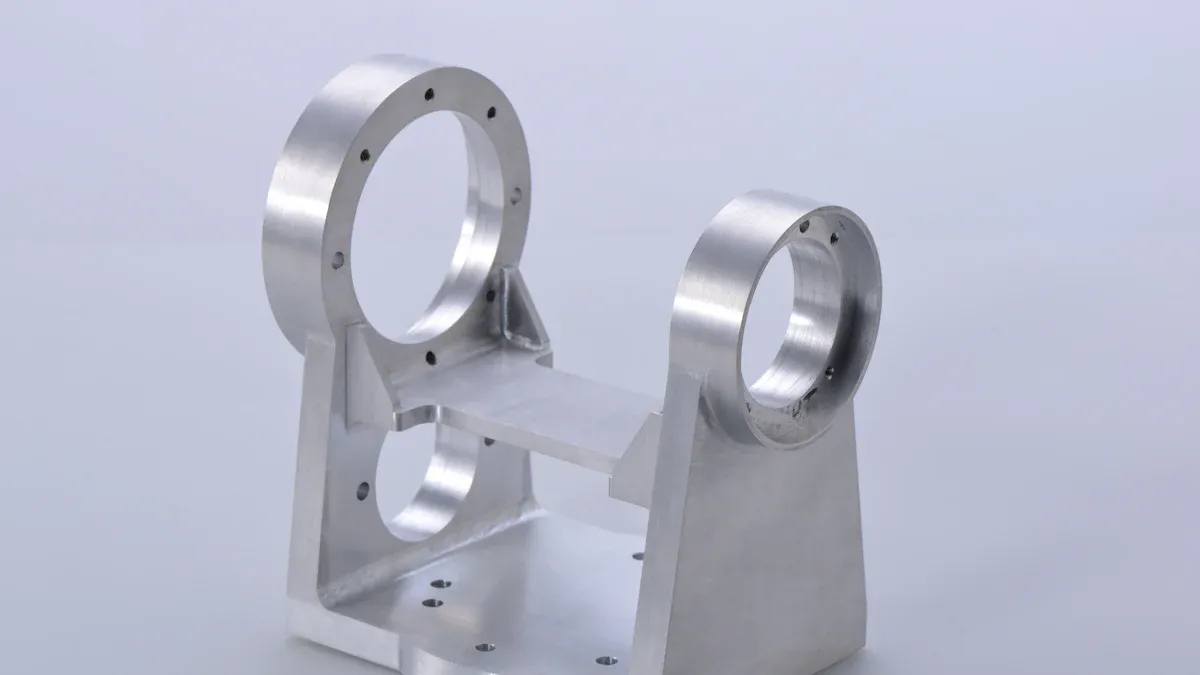

I-CNC Machining kanye Nokubekezelelana Okuqinile

Imishini ye-CNC ime enhliziyweni ye-Aluminium Die Casting yesimanje. Abaqhubi abanekhono basebenzisa imishini elawulwa ngekhompiyutha ukuze balolonge izingxenye ngokunemba okwedlulele. Le mishini iyasika, ibhoboze, futhi iqede ukulingisa ukuze ihlangabezane nezilinganiso eziqondile.Ukubekezelelana okuqinileqinisekisa ukuthi ingxenye ngayinye ezenzakalelayo ilingana kahle futhi isebenza ngendlela eklanywe ngayo. Ngisho namaphutha amancane angaholela ezindaweni ezibuthakathaka noma ukwehluleka kusenesikhathi. Imishini ye-CNC inciphisa lezi zingozi ngokuletha imiphumela engaguquki.

Abakhiqizi bavame ukusebenzisa uhlu lokuhlola ukuze bagcine ukubekezelelana okuqinile:

- Linganisa imishini ngaphambi kokuqala kokukhiqiza ngakunye

- Hlola amathuluzi okugqoka bese uwashintsha njengoba kudingeka

- Gada izinga lokushisa kanye nomswakama endaweni yokusebenzela

- Rekhoda izilinganiso zeqoqo ngalinye

Qaphela: Ukubekezelela okuqinile kusiza izingxenye ezizenzakalelayo ukumelana nengcindezi futhi zihlale isikhathi eside emgwaqeni.

Ukumodela kwe-3D, Ukulingisa, kanye Nokuthuthukisa Idizayini

Onjiniyela bathembele ekwenziweni kwemodeli ye-3D ukuze baklame izingxenye zezimoto eziyinkimbinkimbi ze-Aluminium Die Casting. Bakha amamodeli edijithali abonisa yonke imininingwane yengxenye. Lawa mamodeli avumela amaqembu ukuthi ahlole izimo ezihlukene nezinto zokwakha ngaphambi kokwenza ingxenye ebonakalayo. Isofthiwe yokulingisa ibikezela ukuthi ingxenye izosabela kanjani ekushiseni, ukucindezela, nokudlidliza. Le nqubo isiza onjiniyela babone izindawo ezibuthakathaka futhi bathuthukise idizayini.

Ukuthuthukisa idizayini kusebenzisa idatha evela ekulingiseni ukwenza izingxenye ziqine futhi zibelula. Onjiniyela balungisa ukujiya kodonga, bengeze izimbambo zokusekela, noma bashintshe imiksi yealloy. Lezi zinguquko zithuthukisa ukuqina ngaphandle kokwengeza isisindo esengeziwe. Umphumela uba yingxenye ehlangabezana nezindinganiso eziqinile zezimoto futhi esebenza kahle ezimeni zomhlaba wangempela.

Ithebula elilula libonisa izinzuzo zale ndlela:

| Isinyathelo | Zuza |

|---|---|

| Ukumodela kwe-3D | Imiklamo enembile |

| Ukulingisa | Ukutholwa kwenkinga kusenesikhathi |

| Ukuthuthukisa Idizayini | Izingxenye eziqinile, ezilula |

I-Automated Inspection and Measurement Systems

Amasistimu okuhlola azenzakalelayo adlala indima ebalulekile ekulawuleni ikhwalithi ye-Aluminium Die Casting. Lezi zinhlelo zisebenzisa amakhamera, amalaser, nezinzwa ukuhlola zonke izingxenye. Bakala ubukhulu, ukuphela kwendawo, kanye nesakhiwo sangaphakathi. Amasistimu azenzakalelayo asebenza ngokushesha futhi anembe kakhulu kunokuhlola mathupha. Babamba amaphutha kusenesikhathi, okunciphisa ukumosha futhi konge imali.

Amanye amasistimu asebenzisa ubuhlakani bokwenziwa ukuze abone amaphethini kumaphutha. Lobu buchwepheshe busiza abakhiqizi ukuthi bathole umsuka wezinkinga futhi bazilungise ngokushesha. Ukuhlola okuzenzakalelayo kuqinisekisa ukuthi izingxenye eziphezulu kuphela ezifinyelela ikhasimende.

Ithiphu: Amasistimu okulinganisa azenzakalelayo asiza ukugcina amazinga aphezulu futhi akhe ukwethenjwa ngabakhi bezimoto.

Ukuqinisekiswa Kwekhwalithi Nokuthuthukiswa Okuqhubekayo Kwe-Aluminium Die Casting

Izitifiketi Zomkhakha Nokuhambisana Namazinga

Abakhiqizi baseShayina bayaqonda ukuthi izitifiketi zomkhakha zakha ukwethembana nabakhiqizi bezimoto bomhlaba wonke. Basebenza kanzima ukuze bathole izitifiketi ezifana ne-ISO 9001, IATF 16949, ne-ISO 14001. Lawa mazinga abeka imithetho eqinile yokuphathwa kwekhwalithi, isibopho sendawo ezungezile, nokulawula inqubo. Izinkampani kufanele ziphase ukuhlolwa okujwayelekile ukuze zigcine lezi zitifiketi. Abacwaningi mabhuku bahlola amarekhodi, bahlole izinsiza, futhi babuyekeze izinhlelo zokuqeqesha.

Ithebula elingezansi libonisa izitifiketi ezijwayelekile nokugxila kwazo:

| Isitifiketi | Indawo okugxilwe kuyo |

|---|---|

| ISO9001 | Ukuphathwa Kwekhwalithi |

| I-IATF 16949 | Ikhwalithi Yezimoto |

| ISO 14001 | Ukuphathwa Kwemvelo |

Ukuhlangabezana nalawa mazinga kusiza abakhiqizi ukuletha izingxenye zezimoto eziphephile nezithembekile. Amakhasimende ayazi ukuthi angalindela ikhwalithi engaguquki kubahlinzeki abagunyaziwe.

Qaphela: Izitifiketi zibonisa ukuzibophezela kwenkampani kukhwalithi kanye nemikhuba ehamba phambili yomhlaba.

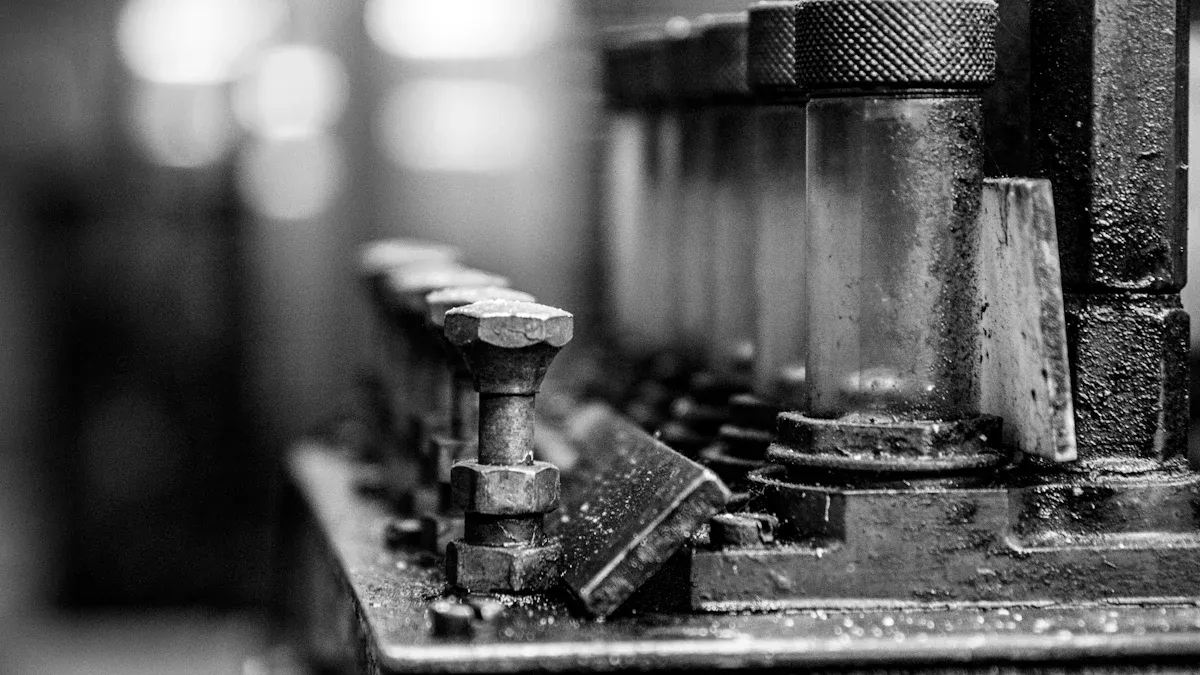

Ukuhlola Okungonakalisi Nokulawulwa Kwekhwalithi Eqhutshwa Ngedatha

Ukuhlola okungabhubhisi (NDT) kuvumela abakhiqizi ukuthi bahlole izingxenye ngaphandle kokudala umonakalo. Basebenzisa izindlela ezifana ne-X-ray, i-ultrasonic, nokuhlola ukungena kodayi. Lokhu kuhlola kuthola imifantu, i-voids, noma amanye amaphutha afihliwe ngaphakathi kokulingisa. I-NDT isiza izinkampani ukuba zibambe izinkinga ngaphambi kokuba izingxenye zifinyelele kumakhasimende.

Ukulawulwa kwekhwalithi eshayelwa yidatha kusebenzisa amathuluzi edijithali ukulandelela zonke izinyathelo zokukhiqiza. Izinzwa ziqoqa idatha ngezinga lokushisa, ingcindezi, nezikhathi zomjikelezo. Onjiniyela babuyekeza le datha ukuze babone amathrendi futhi bavimbele amaphutha. Amasistimu azenzakalelayo axwayisa abasebenzi uma kukhona okungahambi kahle. Le ndlela yehlisa imfucuza futhi ithuthukisa ukwethembeka kwengxenye.

Inqubo ejwayelekile yokulawula ikhwalithi ihlanganisa:

- Ukuhlola izinto zokusetshenziswa ngaphambi kokulingisa

- Imishini yokuqapha ngesikhathi sokukhiqiza

- Ukuhlola izingxenye eziqediwe ngezindlela ze-NDT

- Ukurekhoda nokuhlaziya imiphumela yokuhlolwa

Ithiphu: Amasistimu aqhutshwa yidatha asiza amaqembu ukuthi alungise izinkinga ngokushesha futhi agweme ukuphinda amaphutha.

I-R&D, Ukugcinwa Kwezisetshenziswa, Nokuqeqeshwa Kwabasebenzi

Amaqembu ocwaningo nentuthuko (i-R&D) adlala indima ebalulekile ekuthuthukiseni i-Aluminium Die Casting. Bahlola ama-alloys amasha, bazame ama-coatings athuthukile, futhi bathuthukise izindlela ezingcono zokuphonsa. I-R&D isiza izinkampani ukuthi zenze izingxenye ezihlala isikhathi eside futhi ezisebenza kangcono.

Ukunakekelwa kwemishini njalo kugcina imishini isebenza kahle. Ochwepheshe bahlola kanye nemishini yesevisi ohlelweni olumisiwe. Bashintsha izingxenye ezigugile futhi babuyekeze isofthiwe. Imishini enakekelwa kahle ikhiqiza ukulingisa okunembe kakhudlwana nokuthembekile.

Ukuqeqeshwa kwabasebenzi kuqinisekisa ukuthi abasebenzi bayazazi izindlela zakamuva nemithetho yokuphepha. Izinkampani ziba nemihlangano yokufundisa kanye nezikhathi zokuqeqesha abasebenzi abasha nabanolwazi. Abasebenzi abanamakhono bangabona izinkinga kusenesikhathi futhi balandele izinqubo ezingcono kakhulu.

I-Callout: Ukufunda okuqhubekayo nokutshala imali kubantu kuholela emikhiqizweni engcono nezindawo zokusebenza eziphephile.

Abakhiqizi baseShayina bathola ukuqina okuphezulu kuizingxenye zezimotongokusebenzisa ubuchwepheshe bokunemba okuthuthukile kanye nokuqinisekiswa kwekhwalithi okuqinile.

- Amaqembu anamakhono nemishini yesimanje isiza ukuhlangabezana namazinga omhlaba.

- Lezi zinqubo ziletha izingxenye ezithembekile, ezihlala isikhathi eside ezizuzisa kokubili abakhiqizi bezimoto nabashayeli.

FAQ

Yini eyenza ubuchwepheshe bokunemba bubaluleke ekusakazeni kwe-aluminium die?

Ubuchwepheshe bokunembaisiza abakhiqizi ukudala izingxenye ezinezilinganiso eziqondile. Lokhu kunciphisa amaphutha futhi kukhulisa amandla nempilo yezingxenye ezizenzakalelayo.

Ithiphu: Izingxenye ezinembile zilingana kangcono futhi zihlala isikhathi eside ezimotweni.

Abakhiqizi baseShayina baqinisekisa kanjani ikhwalithi ezingxenyeni zezimoto ze-die-cast?

Basebenzisa ukuhlola okuzenzakalelayo, ukuhlola okungabhubhisi, nokuqinileizingaizindinganiso. Lezi zinyathelo zisiza ukubamba amaphutha kusenesikhathi futhi ziqinisekise ukusebenza okuthembekile.

Ingabe izingxenye ze-aluminium die-cast zingasingatha izimo ezimbi kakhulu?

Yebo. Izingxenye ze-Aluminium die-cast zimelana nokushisa, ukudlidliza, nokugqwala. Onjiniyela baziklama ukuthi zisebenze kahle ezindaweni ezilukhuni zezimoto.

- Izingxenye ze-aluminium zihlala ziqinile ngisho nangaphansi kwengcindezi.

- Izembatho ezifanele zengeza ukuvikeleka okwengeziwe.

Isikhathi sokuthumela: Jul-14-2025