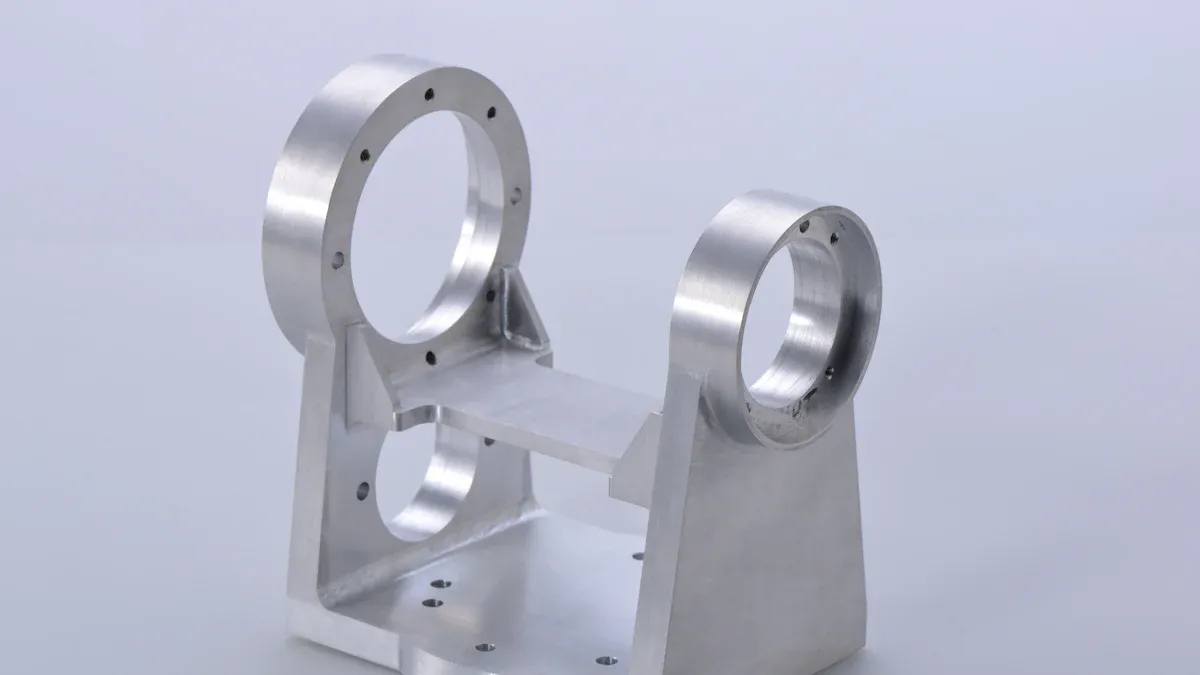

Baetsi ba Machaena ba sebelisa Aluminium Die Casting e tsoetseng pele ho thehaprecision die - likarolo tsa castbakeng saLisebelisoa tsa likoloi tsa OEM. Lihlopha tse nang le litsebo li sebelisa mechine ea CNC 'me li sebelisa mohlala oa 3D. Tlhahlobo e ikemetseng e fokotsa liphoso. Mekhoa ena e thusaaluminium die - likarolo tsa koloi tse lahliloengfinyella nako e telele le ho tšepahala libakeng tse hlokang likoloi.

Lintlha tsa bohlokoa

- Theknoloji e nepahetsengjoalo ka CNC machining le 3D modelling e thusa ho theha likarolo tsa koloi tse matla, tse nepahetseng tse tšoarellang nako e telele le ho lekana hantle.

- Tlhahlobo e ikemetseng le liteko tse sa senyeheng li tšoasa esale pele, ho netefatsa hore likarolo tsa boleng bo holimo feela li fihla ho bareki.

- Maemo a tiileng a boleng, lipatlisiso tse tsoelang pele, le koetliso ea basebetsi li thusa bahlahisi ho fana ka likarolo tsa koloi tse tšepahalang, tse tšoarellang tse fihlelang litlhoko tsa lefats'e.

Karolo ea Precision ho Aluminium Die Casting bakeng sa likarolo tsa Auto

Bohlokoa ba ho tšoarella ho Likopo tsa Likoloi

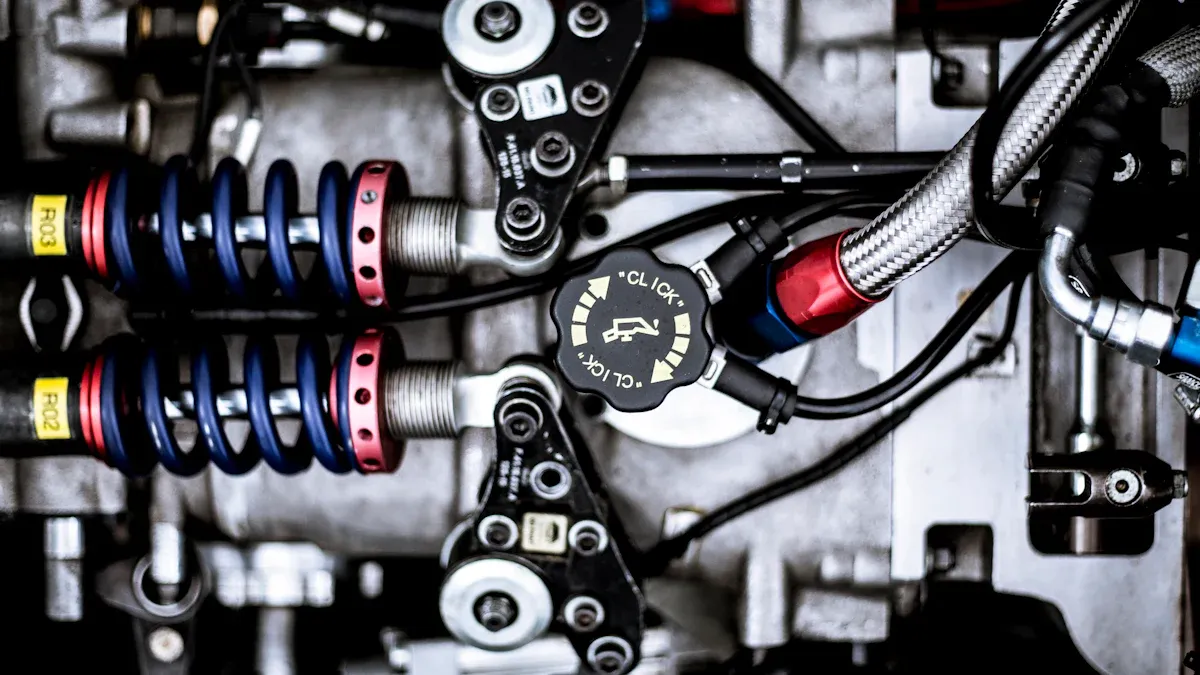

Durability e eme e le tlhokahalo ea mantlha ea likarolo tsa koloi. Likoloi li sebetsa maemong a thata. Li tobana le ho thothomela kamehla, ho fetoha ha mocheso, le ho pepesehela mongobo. Likarolo tsa koloi li tlameha ho hanela ho senyeha le ho taboha ho netefatsa polokeho le ts'ebetso. Ha karolo e itseng e sa sebetse, e ka lebisa ho lokisoeng ha chelete e ngata kapa esita le likotsi. Baetsi ba shebana le ho tšoarella ho fihlela maemo a thata a indasteri le litebello tsa bareki.

Aluminium Die Castinge fana ka tharollo e matla bakeng sa ho hlahisa likarolo tse tšoarellang. Ts'ebetso ena e theha likarolo tse nang le likarohano tse ntle tsa matla ho boima. Likarolo tse bobebe li thusa ho ntlafatsa ts'ebetso ea mafura le ho fokotsa khase. Ka nako e ts'oanang, likarolo tsena li tlameha ho mamella litlhoko tsa ho khanna letsatsi le leng le le leng. Ho tšoarella ho ts'epahalang ho ts'ehetsa nako e telele ea bophelo ba koloi le litšenyehelo tse tlase tsa tlhokomelo.

Theknoloji ea Precision le Tšusumetso ea Eona Bophelong bo Bolelele ba Karolo

Theknoloji e nepahetsenge bapala karolo ea bohlokoa ho Aluminium Die Casting. Mechini e tsoetseng pele e theha karolo e 'ngoe le e' ngoe ka mamello e thata. Litekanyo tse tsitsitseng li fokotsa kotsi ea lintlha tse fokolang kapa mefokolo. Sistimi ea othomathike e hlahloba lintlha tsohle, ho netefatsa hore karolo ka 'ngoe e kopana hantle le litlhaloso.

Keletso: Ho nepahala ho fokotsa monyetla oa ho hloleha ha karolo ea pele le ho eketsa ts'epo ka kakaretso.

Baenjiniere ba sebelisa k'homphieutha ho etsa likarolo tse sebetsanang le khatello ea kelello le mocheso ka katleho. Li etsisa maemo a sebele a lefatše pele tlhahiso e qala. Mokhoa ona o thusa ho tseba le ho lokisa mathata a ka bang teng esale pele. Ka lebaka leo, theknoloji e nepahetseng e lelefatsa bophelo ba likarolo tsa koloi le ho matlafatsa boitšepo ba bareki.

Litheknoloji tsa Advanced Precision ho Aluminium Die Casting

CNC Machining le Tight Tolerances

Mochini oa CNC o bohareng ba Aluminium Die Casting ea sejoale-joale. Basebelisi ba nang le litsebo ba sebelisa mechine e laoloang ke k'homphieutha ho etsa likarolo tsa eona ka mokhoa o nepahetseng haholo. Mechini ena e seha, ea phunya, 'me ea phethela lintho tsa ho etsa lintho ho latela litekanyo tse nepahetseng.Mamello e thataetsa bonnete ba hore karolo e 'ngoe le e 'ngoe ea koloi e lumellana hantle 'me e sebetsa kamoo e reriloeng kateng. Esita le liphoso tse nyenyane li ka lebisa libakeng tse fokolang kapa ho hlōleha kapele. CNC machining e fokotsa likotsi tsena ka ho fana ka liphetho tse tsitsitseng.

Hangata bahlahisi ba sebelisa lethathamo la tlhahlobo ho boloka mamello e tiileng:

- Beakanya mechini pele tlhahiso ka 'ngoe e qala

- Hlahloba lisebelisoa tsa ho apara 'me u li fetole ha ho hlokahala

- Lekola mocheso le mongobo ka har'a workshop

- Rekota litekanyo bakeng sa sehlopha se seng le se seng

Tlhokomeliso: Ho mamellana ho thata ho thusa likarolo tsa koloi ho hanela khatello ea maikutlo le ho tšoarella nako e telele tseleng.

3D Modelling, Simulation, le Design Optimization

Baenjineri ba tšepile mohlala oa 3D ho rala likarolo tse rarahaneng tsa koloi bakeng sa Aluminium Die Casting. Ba theha mefuta ea dijithale e bonts'ang lintlha tsohle tsa karolo. Mefuta ena e lumella lihlopha ho leka libopeho le lisebelisoa tse fapaneng pele li etsa karolo ea 'mele. Software ea ho etsisa e bolela esale pele hore na karolo e tla itšoara joang mocheso, khatello le ho thothomela. Ts'ebetso ena e thusa baenjiniere ho bona libaka tse fokolang le ho ntlafatsa moralo.

Ntlafatso ea moralo e sebelisa lintlha tsa lipapiso ho etsa hore likarolo li be matla le ho ba bobebe. Baenjiniere ba fetola botenya ba lebota, ba eketsa likhopo tsa tšehetso, kapa ba fetola motsoako oa alloy. Liphetoho tsena li ntlafatsa ho tšoarella ntle le ho eketsa boima bo eketsehileng. Sephetho ke karolo e finyellang litekanyetso tse thata tsa likoloi le ho sebetsa hantle maemong a sebele a lefatše.

Tafole e bonolo e bontša melemo ea mokhoa ona:

| Mohato | Molemo |

|---|---|

| Mohlala oa 3D | Liqapi tse nepahetseng |

| Ketsiso | Ho lemoha bothata esale pele |

| Ntlafatso ea Moqapi | Likarolo tse matla, tse bobebe |

Mekhoa e Ikemetseng ea Tlhahlobo le Tekanyo

Sistimi ea boithuto e ikemetseng e bapala karolo ea bohlokoa taolong ea boleng bakeng sa Aluminium Die Casting. Litsamaiso tsena li sebelisa lik'hamera, li-laser le li-sensor ho lekola karolo e 'ngoe le e 'ngoe. Ba lekanya boholo, bokaholimo ba bokaholimo le sebopeho sa kahare. Lisebelisoa tse ikemetseng li sebetsa ka potlako le ka nepo ho feta licheke tsa matsoho. Ba tšoara likoli kapele, e leng ho fokotsa litšila le ho boloka chelete.

Litsamaiso tse ling li sebelisa bohlale ba maiketsetso ho bona mekhoa ea mefokolo. Theknoloji ena e thusa bahlahisi ho fumana sesosa sa mathata le ho a lokisa kapele. Tlhahlobo e ikemetseng e netefatsa hore likarolo tsa boleng bo holimo feela li fihla ho moreki.

Keletso: Sistimi ea ho metha e itšebetsang e thusa ho boloka maemo a holimo le ho theha tšepo ho baetsi ba likoloi.

Netefatso ea Boleng le Ntlafatso e Tsoelang Pele ho Aluminium Die Casting

Litifikeiti tsa Indasteri le Tumellano ea Maemo

Baetsi ba Machaena ba utloisisa hore litifikeiti tsa indasteri li theha tšepo ho baetsi ba likoloi ba lefats'e. Ba sebetsa ka thata ho fumana litifikeiti tse kang ISO 9001, IATF 16949, le ISO 14001. Litekanyetso tsena li beha melao e thata ea taolo ea boleng, boikarabello ba tikoloho, le taolo ea ts'ebetso. Likhamphani li tlameha ho etsa litlhahlobo tsa khafetsa ho boloka litifikeiti tsena. Bahlahlobi ba hlahloba lirekoto, ba hlahloba lits'ebeletso, le ho hlahloba mananeo a koetliso.

Tafole e ka tlase e bonts'a litifikeiti tse tloaelehileng le maikutlo a tsona:

| Setifikeiti | Sebaka sa Tsepamiso |

|---|---|

| ISO 9001 | Tsamaiso ea Boleng |

| IATF 16949 | Boleng ba Likoloi |

| ISO 14001 | Tsamaiso ea Tikoloho |

Ho finyella litekanyetso tsena ho thusa bahlahisi ho fana ka likarolo tsa koloi tse sireletsehileng le tse tšepahalang. Bareki ba tseba hore ba ka lebella boleng bo tsitsitseng ho tsoa ho barekisi ba netefalitsoeng.

Tlhokomeliso: Lisetifikeiti li bontša boitlamo ba k'hamphani ho boleng le mekhoa e metle ea lefats'e.

Teko e sa Senyeheng le Taolo ea Boleng ba Ts'ebetso ea Lintlha

Teko e sa senyeheng (NDT) e lumella bahlahisi ho hlahloba likarolo ntle le ho baka tšenyo. Ba sebelisa mekhoa e kang X-ray, ultrasonic, le dae e phunyeletsang liteko. Liteko tsena li fumana mapetsong, li-void, kapa liphoso tse ling tse patiloeng ka har'a li-castings. NDT e thusa lik'hamphani ho tšoara mathata pele likarolo li fihla ho bareki.

Taolo ea boleng bo tsamaisoang ke data e sebelisa lisebelisoa tsa dijithale ho latela mohato o mong le o mong oa tlhahiso. Li-sensor li bokella lintlha ka mocheso, khatello le linako tsa potoloho. Baenjiniere ba hlahloba lintlha tsena ho bona mekhoa le ho thibela liphoso. Sistimi ea othomathike e lemosa basebetsi haeba ho na le phoso. Mokhoa ona o fokotsa litšila mme o ntlafatsa ts'epahalo ea karolo.

Mokhoa o tloaelehileng oa taolo ea boleng o kenyelletsa:

- Ho hlahloba lisebelisoa pele u li beha

- Mechini ea ho beha leihlo nakong ea tlhahiso

- Ho lekola likarolo tse felileng ka mekhoa ea NDT

- Ho rekota le ho sekaseka liphetho tsa liteko

Keletso: Lisebelisoa tse tsamaisoang ke lintlha li thusa lihlopha ho lokisa mathata kapele le ho qoba ho pheta liphoso.

R&D, Tlhokomelo ea Lisebelisoa, le Koetliso ea Basebetsi

Lihlopha tsa lipatlisiso le nts'etsopele (R&D) li bapala karolo ea bohlokoa ho ntlafatseng Aluminium Die Casting. Ba leka li-alloys tse ncha, ba leka liphahlo tse tsoetseng pele, 'me ba nts'etsapele mekhoa e metle ea ho lahla. R&D e thusa lik'hamphani ho theha likarolo tse tšoarellang nako e telele le tse sebetsang hantle.

Tlhokomelo ea kamehla ea thepa e boloka mechine e sebetsa hantle. Litsebi li hlahloba le mechine ea litšebeletso ka kemiso e behiloeng. Ba nka sebaka sa likarolo tse tsofetseng ebe ba ntlafatsa software. Lisebelisoa tse hlokometsoeng hantle li hlahisa li-castings tse nepahetseng le tse ka tšeptjoang.

Koetliso ea basebetsi e netefatsa hore basebetsi ba tseba mekhoa ea morao-rao le melao ea polokeho. Likhamphani li tšoara lithupelo le lithupelo bakeng sa basebetsi ba bacha le ba nang le boiphihlelo. Basebetsi ba nang le tsebo ba ka bona mathata esale pele mme ba latela mekhoa e metle.

Callout: Ho tsoela pele ho ithuta le ho tsetela ho batho ho lebisa lihlahisoa tse ntle le libaka tse sireletsehileng tsa mosebetsi.

Bahlahisi ba Sechaena ba fihlella nako e telele ea nako e telele holikarolo tsa koloika ho sebelisa mekhoa e tsoetseng pele ea ho nepahala le tiisetso ea boleng bo tiileng.

- Lihlopha tse hloahloa le lisebelisoa tsa sejoale-joale li thusa ho fihlela maemo a lefats'e.

- Mekhoa ena e fana ka likarolo tse ka tšeptjoang, tse tšoarellang nako e telele tse thusang baetsi ba likoloi le bakhanni.

LBH

Ke eng e etsang hore theknoloji e nepahetseng e be ea bohlokoa ho aluminium die casting?

Theknoloji e nepahetsenge thusa bahlahisi ho etsa likarolo tse nang le litekanyo tse nepahetseng. Sena se fokotsa likoli mme se eketsa matla le nako ea bophelo ea likarolo tsa koloi.

Keletso: Likarolo tse nepahetseng li lekana hantle 'me li tšoarella nako e telele likoloing.

Baetsi ba Machaena ba netefatsa boleng ba likarolo tsa likoloi tsa die-cast joang?

Ba sebelisa tlhahlobo e ikemetseng, tlhahlobo e sa senyeheng, le e thatabolenglitekanyetso. Mehato ena e thusa ho tšoara liphoso kapele le ho netefatsa ts'ebetso e tšepahalang.

Na likarolo tsa aluminium tsa die-cast li ka sebetsana le maemo a feteletseng?

Ee. Likarolo tsa aluminium tsa die-cast li hanela mocheso, ho thothomela le ho bola. Lienjiniere li li rala hore li sebetse hantle libakeng tse thata tsa likoloi.

- Likarolo tsa aluminium li lula li le matla esita le tlas'a khatello ea maikutlo.

- Liaparo tse nepahetseng li eketsa tšireletso e eketsehileng.

Nako ea poso: Jul-14-2025