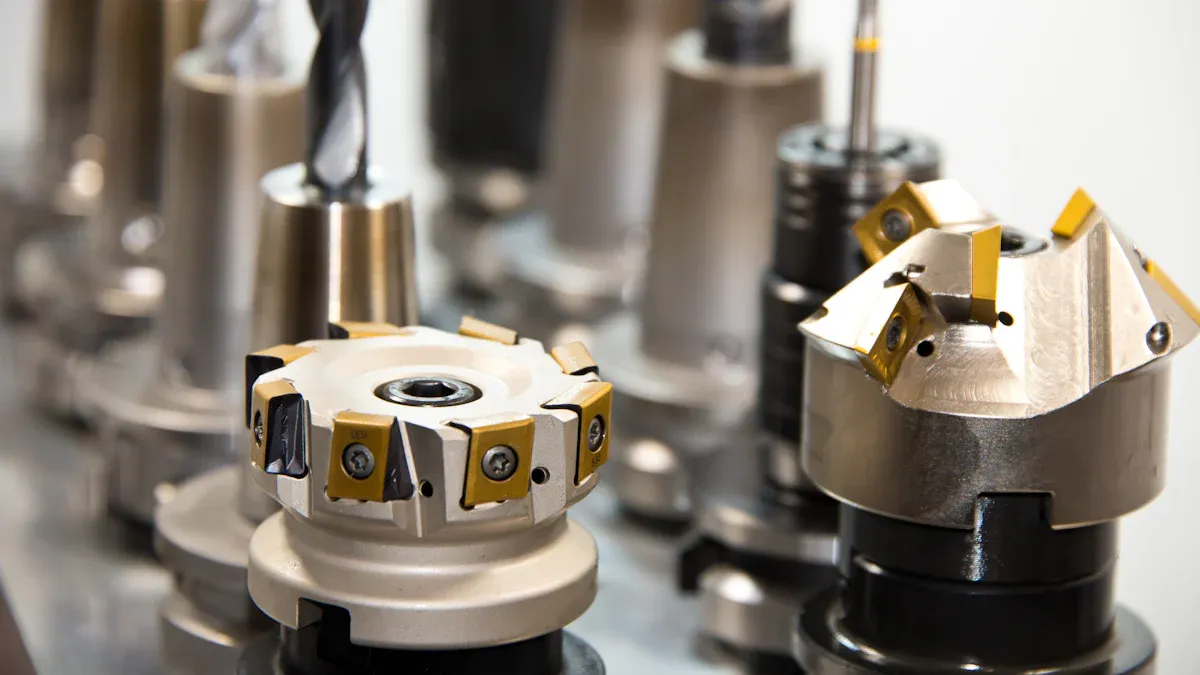

Iwe unoona yakakwirira-kudzvanya kufa kukandira kuseta chiyero mukugadzirwa kwealuminium yakakandwa. Iyi nzira inotonga indasitiri, inobata pamusoro pe78% mari yemugove muna 2024. Zvikamu zvakawanda, kunyanya.motokarikugadzira, vimba pairi kugadzira zviremera, zvikamu chaizvo zvinovandudza kushanda kwemafuta uye kuita.

Key Takeaways

- High-pressure die castinginogadzira yakasimba, chaiyo aruminiyamu zvikamu nekukasira, zvichiita kuti ive yakanakira kugadzirwa kwepamusoro-soro nemagadzirirwo akaomarara.

- Iyi nzira inogadzira zvikamu zvakareruka zvine kupedzisa kwepamusoro uye kushivirira kwakasimba, kuderedza kudiwa kwekuwedzera kupedzisa basa.

- Tekinoroji yepamusoro uye kutonga kwemhandomukukanda kufa kunonatsiridza kuenderana kwechigadzirwa, kuderera mutengo, uye kutsigira inoenderera yekugadzira maitiro.

Chii chinoita kuti High-Pressure Die Casting yakasarudzika yeCast Aluminium

Iyo High-Pressure Die Casting process

Iwe unotangahigh-pressure die casting processnekugadzira mold yesimbi. Vashandi vanochenesa nekuzora mold kubatsira kudzora tembiricha uye kuita kuti zvive nyore kubvisa chikamu chakapedzwa. Tevere, unonyungudutsa aruminiyamu alloy muchoto. Iwe wobva waendesa simbi yakanyungudutswa muchidimbu chepfuti, kazhinji mukamuri inotonhora nekuti aluminiyamu inonyunguduka pakupisa kwakanyanya. Piston inopinza aruminiyamu yakanyungudutswa muforoma yakavharwa nekumanikidzwa kwakanyanya-dzimwe nguva kusvika 1200 bar. Simbi inozadza zvese zve mold nekukurumidza uye inoomesa pasi pekumanikidzwa. Kamwe chikamu chacho chikatonhora, ejector pini anoisundira kunze kwe mold. Pakupedzisira, unocheka chero chinhu chakawedzerwa. Kuita uku kunoita kuti ugadzire zvikamu zvealuminium zvakakandwa zvine madziro matete uye maumbirwo akaomarara mumasekondi mashoma.

Yakasiyana Yakanakira Pamusoro Dzimwe Nzira dzekukanda

High-pressure die casting inomira kunze kubva kune dzimwe nzira nekuda kwekumhanya kwayo, kurongeka, uye kugona kugadzira zvikamu zvine hudzamu. Iwe unogona kuona misiyano zvakajeka mutafura iri pazasi:

| Feature | High-Pressure Die Casting (HPDC) | Dzimwe Aluminium Kukanda Nzira |

|---|---|---|

| Injection Pressure | Yakakwirira kwazvo (700–2500 bar) | Zvakanyanya kuderera (0.7-1.5 bar) |

| Cycle Time | Very fast (masekondi) | Zvishoma (maminitsi) |

| Kukora Kwemadziro | Mutete (0.4–1 mm) | Kobvu |

| Dimensional Kururama | Excellent | Zvakanaka, asi zvishoma chaizvo |

| Surface Finish | Excellent | Zvakanaka, zvingada kumwe kupedzisa |

| Kugadzirwa Kukodzera | High-volume, zvikamu zvakaoma | Inzwi rakaderera, zvikamu zviri nyore |

Iwe unobatsirwa nekukurumidza kugadzirwa uye yakakwirira kudzokorora. Iyo nzira inokupa iwe kushivirira kwakasimba uye yakatsetseka nzvimbo, zvinoreva kushoma kupedza basa.High-pressure die castingyakanakira kana iwe uchida huwandu hukuru hweakakandirwa aruminiyamu zvikamu zvine akasimba uye akadzama.

Performance Benefits yeHigh-Pressure Die Casting muCast Aluminium

Kururamisa uye Kuenderana

Iwe unowana mukana mukuru nehigh-pressure die castingapo iwe unoda chaiyo uye inowirirana yakakandwa zvikamu zvealuminium. Iyi nzira inoshandisa yakasimba simbi mold uye yakakwirira jekiseni kumanikidza, izvo zvinokutendera iwe kuti ugadzire zvikamu zvine maumbirwo akaoma uye zvakanaka ruzivo. Iwe unogona kuwana madziro matete uye kushivirira kwakasimba, izvo zvakaoma nedzimwe nzira dzekukanda. Semuyenzaniso, kukanda jecha kunowanzosiya nzvimbo dzakashata uye madziro akakora, ukuwo kufa kunoburitsa mapedziso akapfava uye hukuru hwakanyanya.

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Geometry Complexity | High; dzakaomarara uye dzakanakisa ruzivo rwunogoneka | Limited; magadzirirwo akareruka anodiwa |

| Kukora Kwemadziro | Madziro matete anogoneka (anotsigira akareruka zvikamu) | Madziro akakora nekuda kwekugumira mold |

| Dimensional Kururama | High; kushoma kudiwa kwekupedzisa mashandiro | Lower; kazhinji kunoda kumwe kupedzisa |

| Surface Finish | Smooth, high quality | Yakakasharara, yakagadzirwa nejecha mold |

Iwe unogona kuona kuti kufa kukanda kunomira kunze kwekugona kwayo kuunza mhedzisiro inowirirana, kunyanya kana iwe uchida zviuru zvakafanana.cast aluminum components. Nepo maitiro acho ega asingakwanise kugara achisvika kune akaomesesa kushivirira (senge ± 0.01 mm), unogona kushandisa CNC machining mushure mekukanda kuti uwane aya chaiwo zviyero. Kugara uchiongorora uye nekuchenjerera maitiro ekudzora kunobatsira iwe kuchengetedza mhando yepamusoro kubva kune chikamu kuenda kune chikamu.

Zano:Kana iwe uchida iyo yepamusoro yepamusoro kupedzisa uye dimensional kurongeka kune ako akakandwa aruminiyamu zvikamu, yakakwira-kumanikidza kufa kukandira ndiyo sarudzo yepamusoro.

Mechanical Simba uye Kusimba

Paunosarudza high-pressure die casting, iwe unowana akakandwa zvikamu zvealuminium zvine simba remagetsi rinoshamisa uye kusimba. Iko kukurumidza kutonhora panguva yekuita kunogadzira yakanaka-grained microstructure, iyo inowedzera zvose simba uye pamusoro pemhando. Iwe unobatsirwa kubva kune aruminiyamu yakakwira simba-kusvika-huremu reshiyo, ichiita kuti ive yakakwana kune yakareruka asi yakaoma zvikamu.

- Jekiseni repamusoro-soro rinoderedza kuremara senge porosity uye shrinkage, saka zvikamu zvako zvinogara kwenguva refu.

- Aluminium's yakanakisa kupisa conductivity inobatsira nhengo dzako kubata kupisa, izvo zvakakosha pakushandisa mota nemagetsi.

- Chimiro chezviyo chakanaka kubva pakukurumidza kusimba chinowedzera zvose ductility uye kurwisana nekuputika.

Semuyenzaniso, mamwe HPDC aruminiyamu alloys anogona kusvika goho rinosvika 321 MPa uye ekupedzisira tensile masimba e425 MPa mushure mekupisa kurapwa. Nhamba idzi dzinoratidza kuti unogona kuvimba nezvikamu zvealuminium zvakakandwa pamabasa anodiwa, kubva painjini dzemotokari kusvika kumafuremu emuchadenga.

Kubudirira Kwemari uye Kubudirira

Iwe unochengetedza nguva nemari ne-high-pressure die casting. Maitiro acho anobvumidza iwe kuburitsa huwandu hukuru hweakakanda aluminium zvikamu nekukurumidza, nekuda kwekukurumidza kutenderera nguva uye mold inogona kushandiswa zvakare. Iwe unogona kugadzira maumbirwo akaoma mumasekondi, zvinoreva kuti iwe unopindura nekukurumidza kune zvinodiwa pamusika.

- Otomatiki masisitimu uye epamberi mold dhizaini inoderedza kuremara uye kuderera.

- Iwe kazhinji unoda kushoma machining uye kupedzisa, izvo zvinodzikisa mutengo wako wese.

- Mienzaniso yepasirese chaiyo inoratidza kusvika 20% mapfupi ekugadzira uye 30% yakaderera mitengo yekugadzira yezvimwe zvigadzirwa.

| Post-Processing Danho | Tsanangudzo | Kukanganisa paKugadzira Nguva uye Hunhu |

|---|---|---|

| Kugadzirisa uye Kubvisa | Inobvisa zvinhu zvakawandisa zvenzvimbo dzakatsetseka | Yakakosha kune yakasimba kushivirira uye mhando |

| Precision Machining | Inowana kushivirira kwakakosha uye kugadzirira gungano | Inowedzera nguva asi inovimbisa kuti zvakatemwa zvinosangana |

| Kupisa Kurapa | Inovandudza simba uye ductility | Inowedzera kusimba, kunyanya kushandiswa kwakaoma |

Iwe unogona kuona kuti nepo imwe post-processing ichidikanwa, iyo yakazara kumhanya uye kushanda kweyakanyanya-kudzvanya kufa kukanda kunoita kuti ive sarudzo yakangwara yeakakwira-vhoriyamu cast aluminium kugadzirwa.

Zvakatipoteredza uye Kugara Kwakanakira

Iwe unobatsira nharaunda kana iwe uchishandisa yakakwira-kudzvanya kufa kukandira kune yakakandwa aluminium zvikamu. Iyo nzira inotsigira kudzokorodza uye inoderedza marara, izvo zvakakosha pakugadzirwa kwakasimba.

- Unogona kushandisa aruminiyamu alloys akadzokororwa, ayo anochengetedza kusvika 95% yesimba zvichienzaniswa nekugadzira aluminium itsva kubva musimbi.

- Maitiro acho anoburitsa zvimedu zvishoma nekuda kwekurongeka kwayo, uye unogona kudzoreredza nekushandisa zvakare trim zvimedu.

- Huremu hweAluminium huremu hunoreva kuti zvigadzirwa zvakaita semota nendege zvinoshandisa mafuta mashoma, zvichideredza kuburitswa kwehupenyu hwavo hwose.

- Vagadziri vazhinji vanoshandisa mavira ane simba-anoshanda uye magetsi anovandudzwa kuti awedzere kutema kuburitsa kabhoni.

Cherechedza:Nekusarudza yakakwira-kumanikidza kufa kukanda, iwe unotsigira hupfumi hwakatenderedza uye unobatsira kuzadzisa zvinangwa zvepasi rose.

Kuwana Kunakisa muCast Aluminium neAdvanced Technology

Basa reMazuvano Equipment uye Automation

Iwe unowana yemhando yepamusoro uye kugona mukugadzirwa kwealuminium yakakandwa uchishandisa michina yemazuva ano uye otomatiki. Michina yemazuva ano yekukandira inoshandisa masensa uye chaiyo-nguva yekutarisa kugadzirisa maparamendi nekukurumidza. Iyi tekinoroji inokubatsira kuderedza zvikanganiso uye kuchengetedza mhedzisiro inowirirana. Automation zvakare inounza marobhoti ladles uye ekubata masisitimu mukufamba kwako kwekushanda. Aya marobhoti anovandudza kuchengetedzeka kwenzvimbo yebasa uye kuona kuti chikamu chega chega chinosangana nemiyero yakasimba.

Iwe unobatsirwa kubva kune akati wandei emberi emberi:

- Sensors mumashini inobvumira chaiyo-nguva kugadzirisa, kuderedza zvikanganiso.

- Simulation software inokubatsira kugadzira zvirinani mold uye kufanotaura mhedzisiro.

- Vacuum-inobatsirwa uye extrusion die casting nzira dzinovandudza kupedzwa kwepamusoro uye mhando yechigadzirwa.

- Marobhoti masisitimu anobata mabasa ane njodzi, achichengetedza timu yako.

- Magetsi-anoshanda nesimba uye mhute inovhara mutengo wakaderera uye kutsigira kusimba.

- IIoT (Industrial Internet yeZvinhu) inobatanidza michina yako yekugadzira yakangwara, kufungidzira kuchengetedza, uye nekukurumidza maitiro shanduko.

Nezvishandiso izvi, unogona kugadzira zvikamu zvealuminium zvakakandwa nekukurumidza, zvine hurema hushoma, uye nemutengo wakaderera.

Kukosha Kwekudzora Hunhu uye Simbiso

Iwe unofanirwa kutarisa pane kutonga kwemhando kuendesa yakavimbika cast aluminium zvikamu. Chaiyo-nguva yekutarisa masisitimu inoteedzera zvakakosha senge tembiricha, kudzvanywa, uye kutenderera nguva. Aya masisitimu anokupa iwe kuona matambudziko nekukurumidza uye kugadzirisa nekukurumidza. Otomatiki ongororo yekuona uye yekupisa yekufungidzira inobata kukanganisa isati yasvika kune vatengi.

Kudzora kwemhando yepamusoro-kudzvanya kufa kukanda kazhinji kunotevera akasimba indasitiri zviyero. Semuenzaniso, zvikamu zvemotokari uye zvemuchadenga zvinoda IATF 16949 uye ISO 9001 zvitupa. Iwe unoshandisa nzira dzinoverengeka kuve nechokwadi chemhando:

| Quality Control Danho | Tsanangudzo |

|---|---|

| Pre-Production Planning | Kuongororwa kwenjodzi, kusimbiswa kwemaitiro, zvidzidzo zvekugona |

| In-Process Control | Chaiyo-nguva yekutarisa, SPC, otomatiki kuongorora |

| Post-Production Testing | X-ray, CT scans, kudzvanywa uye kuomarara kuyedzwa |

Yepamberi yekuongorora maturusi senge X-ray uye CT scanning inoratidza yakavanzika yakavanzika mukati meakakandirwa aluminium zvikamu. Aya matekinoroji anokubatsira kuti uwane ma voids kana makatsemuka ausingaone kubva kunze. Nekushandisa nzira idzi, unovandudza kuvimbika kwechigadzirwa uye unosangana nemhando yepamusoro yeindasitiri.

Iwe unoseta chiyero cheyakakandwa aluminium zvikamu paunosarudzahigh-pressure die casting. Tsvagiridzo inoratidza kuti iyi nzira inopa simba risingaenzaniswi, kunyatsoita, uye kuvimbika. Vagadziri vanoifarira yekukurumidza kutenderera, zvikamu zvakatetepa-madziro, uye inowirirana mhando.

- Kurumidza kugadzira kutenderera

- High dimensional kururama

- Superior mechanical properties

FAQ

Ndeapi maindasitiri anoshandisa high-pressure die casting kune zvikamu zvealuminium?

Unowanahigh-pressure die castingmumotokari, zvemagetsi, aerospace, uye zvinhu zvevatengi. Aya maindasitiri anoda lightweight, akasimba, uye chaiwo aruminiyamu zvikamu.

Kukanda kwepamusoro-kudzvanya kufa kunovandudza sei chikamu chemhando?

Iwe unowana zvirinani chikamu chemhando nekuti maitiro anoshandisa yakakwira kumanikidza uye simbi molds. Izvi zvinogadzira nzvimbo dzakatsetseka, kushivirira kwakasimba, uye hurema hushoma.

Unogona here kudzokorodza aluminium inoshandiswa mukukanda kwepamusoro-kumanikidza kufa?

Ehe! Unogonarecycle aluminiumzvimedu kubva pakuita. Kudzokororazve kunochengetedza simba uye kunotsigira kugadzirwa kwakasimba.

Nguva yekutumira: Aug-08-2025