Koj pom lub zog siab tuag casting teeb tsa tus qauv hauv cam khwb cia txhuas tsim. Cov txheej txheem no dominates kev lag luam, tuav tshaj 78% cov nyiaj tau los sib faib nyob rau hauv 2024. Ntau yam sectors, tshwj xeeb tshaj yogtshebmanufacturing, cia siab rau nws los tsim lub teeb yuag, meej qhov chaw uas txhim kho roj efficiency thiab kev ua tau zoo.

Ntsiab Cai

- High-pressure tuag castingtsim muaj zog, meej aluminium qhov chaw sai sai, ua rau nws zoo tagnrho rau high-volume manufacturing nrog complex designs.

- Cov txheej txheem no tsim cov khoom sib sib zog nqus nrog zoo heev nto tiav thiab nruj tolerances, txo qhov xav tau rau kev ua hauj lwm ntxiv.

- Advanced technology thiab kev tswj kom zoonyob rau hauv tuag casting txhim kho cov khoom sib xws, txo tus nqi, thiab txhawb kev tsim khoom lag luam.

Dab tsi ua rau High-Pressure Tuag Casting Cim rau Cast Aluminium

Cov txheej txheem High-Pressure Tuag Casting

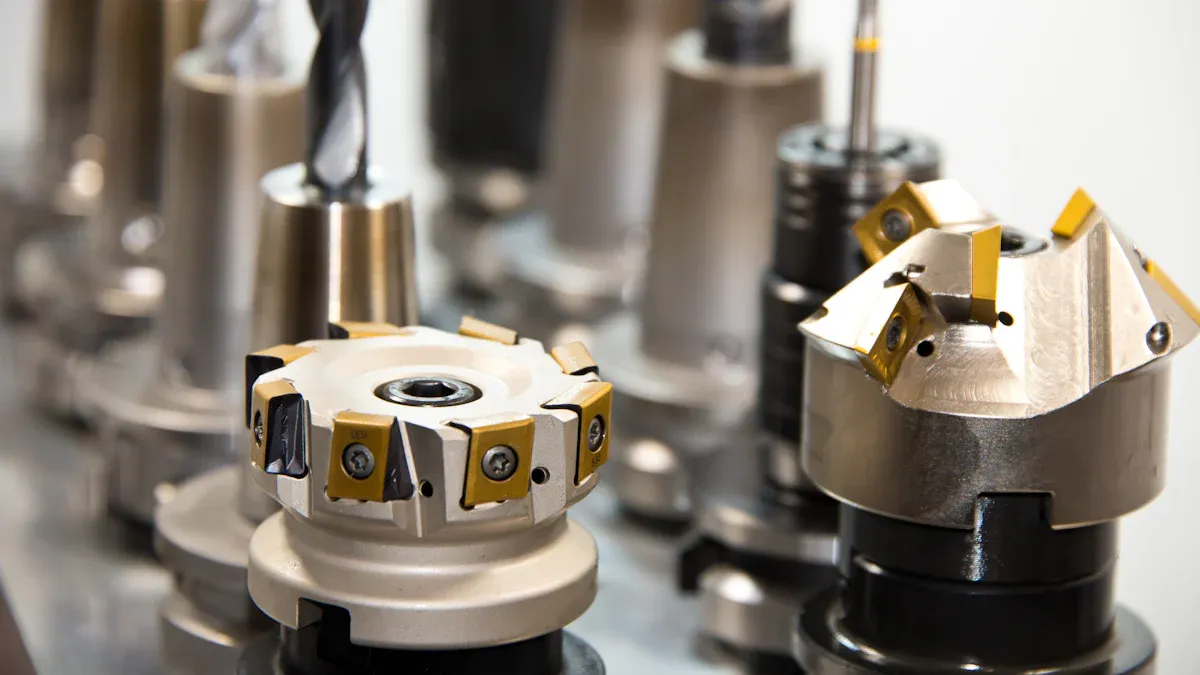

Koj pib lubhigh-pressure tuag casting txheej txheemlos ntawm kev npaj cov hlau pwm. Cov neeg ua haujlwm ntxuav thiab lubricate lub pwm los pab tswj qhov kub thiab txias thiab ua kom yooj yim tshem tawm qhov ua tiav. Tom ntej no, koj yaj cov aluminium alloy nyob rau hauv lub cub tawg. Tom qab ntawd koj hloov cov hlau molten mus rau hauv lub tes tsho txhaj tshuaj, feem ntau nyob rau hauv lub txias chamber system vim aluminium melts ntawm kub. Ib lub piston txhaj cov molten aluminium rau hauv cov pwm kaw ntawm qhov siab heev-qee zaum txog 1200 bar. Cov hlau sau txhua qhov nthuav dav ntawm cov pwm sai sai thiab ua kom muaj zog nyob rau hauv siab. Thaum qhov chaw txias, ejector pins thawb nws tawm ntawm pwm. Thaum kawg, koj txiav tawm tej yam khoom ntxiv. Cov txheej txheem no tso cai rau koj los tsim cov txhuas qhov chaw nrog cov phab ntsa nyias thiab cov duab nyuaj hauv vib nas this.

Distinct Advantages dua lwm txoj kev Casting

High-pressure tuag casting stands los ntawm lwm txoj kev vim nws ceev, precision, thiab muaj peev xwm ua kom ntxaws qhov chaw. Koj tuaj yeem pom qhov sib txawv kom meej hauv cov lus hauv qab no:

| Feature | High-Pressure Tuag Casting (HPDC) | Lwm txoj kev Aluminium Casting |

|---|---|---|

| Txhaj Tshuaj | Siab heev (700-2500 bar) | Tsawg heev (0.7-1.5 bar) |

| Lub Sijhawm Sijhawm | Ceev heev (seconds) | qeeb (feeb) |

| Phab ntsa Thickness | Nyias (0.4-1mm) | Thicker |

| Dimensional raug | Zoo heev | Zoo, tab sis tsawg dua |

| Nto tiav | Zoo heev | Zoo, tej zaum yuav xav tau ntau dua |

| Kev tsim khoom tsim nyog | High-ntim, complex qhov chaw | Tsawg ntim, qhov yooj yim dua |

Koj tau txais txiaj ntsig los ntawm kev tsim khoom sai thiab rov ua haujlwm siab. Cov txheej txheem muab rau koj nruj tolerances thiab du nto, uas txhais tau hais tias tsawg kawg ua hauj lwm.High-pressure tuag castingyog qhov zoo tshaj plaws thaum koj xav tau ntau cov cam khwb cia txhuas qhov chaw uas muaj zog thiab nthuav dav.

Cov txiaj ntsig kev ua tau zoo ntawm High-Pressure Tuag Casting hauv Cast Aluminium

Precision thiab sib npaug

Koj tau txais txiaj ntsig loj nroghigh-pressure tuag castingthaum koj xav tau qhov tseeb thiab zoo ib yam cam khwb cia txhuas qhov chaw. Cov txheej txheem no siv cov pwm steel muaj zog thiab kev txhaj tshuaj siab, uas tso cai rau koj tsim cov khoom nrog cov duab nyuaj thiab cov ntsiab lus zoo. Koj tuaj yeem ua tiav cov phab ntsa nyias thiab nruj tolerances, uas yog nyuaj nrog rau lwm txoj kev casting. Piv txwv li, xuab zeb casting feem ntau tawm ntawm qhov chaw ntxhib thiab cov phab ntsa tuab, thaum tuag casting ua kom tiav smoother thiab qhov ntev dua.

| Feature | Tuag Casting | Xuab zeb Casting |

|---|---|---|

| Geometry complexity | Siab; intricate thiab zoo cov ntsiab lus ua tiav | txwv; yooj yim designs nyiam |

| Phab ntsa Thickness | Cov phab ntsa nyias ua tau (txhawb nqa qhov hnyav) | Cov phab ntsa tuab dua vim muaj kev txwv pwm |

| Dimensional raug | Siab; tsawg xav tau kev ua haujlwm tiav | qis; feem ntau yuav tsum tau ua tiav ntxiv |

| Nto tiav | Smooth, siab zoo | Rougher, textured los ntawm xuab zeb pwm |

Koj tuaj yeem pom tias tuag casting sawv tawm rau nws lub peev xwm los xa cov txiaj ntsig zoo ib yam, tshwj xeeb tshaj yog thaum koj xav tau ntau txhiab tus tib yamcam khwb cia aluminium Cheebtsam. Thaum cov txheej txheem ib leeg tsis tuaj yeem ncav cuag qhov nruj tshaj plaws (xws li ± 0.01 hli), koj tuaj yeem siv CNC machining tom qab casting kom ua tiav cov kev ntsuas no. Kev tshuaj xyuas tsis tu ncua thiab kev tswj xyuas cov txheej txheem ua tib zoo pab koj tswj xyuas qhov zoo ntawm ib feem mus rau ib feem.

Tswv yim:Yog tias koj xav tau qhov zoo tshaj plaws saum npoo tiav thiab qhov tseeb qhov tseeb rau koj cov khoom siv txhuas cam khwb cia, kev kub siab tuag casting yog qhov kev xaiv sab saum toj.

Mechanical Strength thiab Durability

Thaum koj xaiv high-pressure tuag casting, koj tau cam khwb cia txhuas qhov chaw nrog impressive mechanical zog thiab durability. Kev ua kom txias sai sai thaum lub sijhawm ua cov txheej txheem tsim cov microstructure nplua nuj, uas txhawb nqa lub zog thiab qhov zoo. Koj tau txais txiaj ntsig los ntawm txhuas lub zog-rau-hnyav piv, ua kom nws zoo meej rau cov khoom hnyav tsis tau tawv.

- Kev txhaj tshuaj tiv thaiv siab txo qhov tsis xws luag xws li porosity thiab shrinkage, yog li koj qhov chaw nyob ntev dua.

- Aluminium qhov zoo tshaj plaws thermal conductivity pab koj qhov chaw tuav cov cua sov, uas yog ib qho tseem ceeb rau kev siv tsheb thiab hluav taws xob.

- Cov txheej txheem nplua nplej los ntawm kev ua kom nrawm nrawm nce ob qho tib si ductility thiab tiv thaiv kev tawg.

Piv txwv li, qee qhov HPDC aluminium alloys tuaj yeem ncav cuag qhov muaj zog ntawm 321 MPa thiab qhov kawg tensile zog ntawm 425 MPa tom qab kev kho cua sov. Cov lej no qhia tau tias koj tuaj yeem tso siab rau cov khoom siv txhuas rau cov haujlwm xav tau, los ntawm lub cav tsheb mus rau aerospace thav ntawv.

Nqi Efficiency thiab Productivity

Koj txuag sijhawm thiab nyiaj txiag nrog kev kub siab tuag casting. Cov txheej txheem tso cai rau koj los tsim cov lej loj ntawm cam khwb cia txhuas qhov chaw sai, ua tsaug rau lub sijhawm ceev ceev thiab cov pwm tuaj yeem siv tau. Koj tuaj yeem ua cov duab nyuaj hauv vib nas this, uas txhais tau hais tias koj teb sai dua rau kev xav tau kev lag luam.

- Automated systems thiab advanced pwm tsim txo qhov tsis xws luag thiab downtime.

- Koj feem ntau xav tau machining tsawg dua thiab ua tiav, uas txo koj cov nqi tag nrho.

- Cov piv txwv tiag tiag hauv ntiaj teb qhia txog 20% luv luv lub voj voog thiab 30% qis dua cov nqi tsim khoom rau qee yam khoom.

| Cov kauj ruam tom qab ua tiav | Kev piav qhia | Kev cuam tshuam rau lub sij hawm tsim khoom thiab kev ua tau zoo |

|---|---|---|

| Trimming thiab Deburring | Tshem tawm cov khoom siv ntau dhau rau qhov chaw du | Qhov tseem ceeb rau nruj tolerances thiab zoo |

| Precision Machining | Ua tiav qhov tseem ceeb tolerances thiab kev npaj ua ke | Ntxiv sijhawm tab sis xyuas kom meej cov ntsiab lus tau ua tiav |

| Kev kho cua sov | Txhim kho lub zog thiab ductility | Ua kom durability, tshwj xeeb tshaj yog rau kev siv tawv |

Koj tuaj yeem pom tias thaum qee qhov kev ua haujlwm tom qab xav tau, tag nrho cov kev ceev thiab kev ua haujlwm ntawm kev kub siab tuag casting ua rau nws yog qhov kev xaiv ntse rau high-volume cam khwb cia aluminium ntau lawm.

Environmental thiab Sustainability Advantages

Koj pab ib puag ncig thaum koj siv lub siab tuag casting rau cam khwb cia txhuas qhov chaw. Cov txheej txheem txhawb nqa rov ua dua tshiab thiab txo cov khoom pov tseg, uas yog qhov tseem ceeb rau kev tsim khoom ruaj khov.

- Koj tuaj yeem siv cov khoom siv txhuas rov ua dua tshiab, uas txuag tau li 95% ntawm lub zog piv rau kev ua cov txhuas tshiab los ntawm ore.

- Cov txheej txheem tsim cov khoom seem tsawg dua vim nws qhov tseeb, thiab koj tuaj yeem rov ua dua thiab rov siv cov khoom seem.

- Aluminium lub teeb yuag txhais tau hais tias cov khoom xws li tsheb thiab dav hlau siv roj tsawg, txo qis emissions dhau lawv lub neej.

- Ntau lub tuam txhab siv lub tshuab hluav taws xob siv hluav taws xob thiab cov khoom siv hluav taws xob txuas ntxiv mus ntxiv kom txo qis carbon emissions.

Nco tseg:Los ntawm kev xaiv lub siab tuag casting, koj txhawb kev lag luam ncig thiab pab ua kom tau raws li lub hom phiaj kev ruaj ntseg thoob ntiaj teb.

Ua tiav Excellence hauv Cast Aluminium nrog Advanced Technology

Lub luag haujlwm ntawm cov cuab yeej siv niaj hnub thiab automation

Koj ua tiav zoo dua thiab ua haujlwm zoo hauv kev tsim cov txhuas txhuas los ntawm kev siv cov cuab yeej siv niaj hnub thiab automation. Niaj hnub no cov tshuab tuag casting siv cov sensors thiab saib xyuas lub sijhawm tiag tiag los kho cov txheej txheem tsis tau tam sim. Cov cuab yeej no pab koj txo qhov yuam kev thiab tswj cov txiaj ntsig zoo ib yam. Automation tseem coj cov ladles neeg hlau thiab tuav cov tshuab rau hauv koj qhov kev ua haujlwm. Cov neeg hlau no txhim kho kev nyab xeeb ntawm chaw ua haujlwm thiab xyuas kom txhua qhov ua tau raws li cov qauv nruj.

Koj tau txais txiaj ntsig los ntawm ntau qhov kev nce qib tsis ntev los no:

- Sensors hauv tshuab tso cai rau kev hloov kho lub sijhawm, txo qhov yuam kev.

- Simulation software pab koj tsim pwm zoo dua thiab kwv yees cov txiaj ntsig.

- Nqus-pab thiab extrusion tuag casting txoj kev txhim kho nto tiav thiab cov khoom zoo.

- Robotic systems ua haujlwm txaus ntshai, ua kom koj pab neeg muaj kev nyab xeeb.

- Lub zog txuag lub cev muaj zog thiab huab cua npog cov nqi qis thiab txhawb kev ruaj khov.

- IIoT (Industrial Internet of Things) txuas koj lub tshuab rau kev tsim ntse, kev saib xyuas, thiab kev hloov pauv ceev.

Nrog rau cov cuab yeej no, koj tuaj yeem tsim cov khoom cam khwb cia aluminium sai dua, nrog tsawg dua qhov tsis xws luag, thiab tus nqi qis dua.

Qhov tseem ceeb ntawm Kev Tswj Xyuas Zoo thiab Kev Pov Hwm

Koj yuav tsum tsom mus rau kev tswj xyuas kom zoo kom xa cov khoom siv txhuas txhim khu kev qha. Lub sijhawm saib xyuas lub sijhawm tiag tiag taug qab cov ntsiab lus tseem ceeb xws li kub, siab, thiab lub sijhawm voj voog. Cov tshuab no tso cai rau koj pom cov teeb meem ntxov thiab kho sai. Kev soj ntsuam tsis pom kev tsis pom kev thiab thermal imaging ntes cov teeb meem ua ntej lawv mus txog cov neeg siv khoom.

Kev tswj kom zoo nyob rau hauv high-pressure tuag casting feem ntau ua raws li cov qauv kev lag luam nruj. Piv txwv li, automotive thiab aerospace qhov chaw yuav tsum tau IATF 16949 thiab ISO 9001 ntawv pov thawj. Koj siv ntau txoj hauv kev los xyuas kom zoo:

| Kauj Ruam Zoo | Kev piav qhia |

|---|---|

| Kev Npaj Ua Ntej Ua Ntej | Kev soj ntsuam kev pheej hmoo, txheej txheem validation, kev tshawb fawb muaj peev xwm |

| Nyob rau hauv-Process Control | Kev saib xyuas lub sijhawm tiag tiag, SPC, kev tshuaj xyuas tsis siv neeg |

| Tom qab kev tsim khoom | X-ray, CT scans, siab thiab hardness kuaj |

Cov cuab yeej tshuaj xyuas qib siab zoo li X-ray thiab CT scanning qhia qhov tsis xws luag hauv cov khoom siv txhuas. Cov thev naus laus zis no pab koj pom qhov khoob lossis qhov tawg uas koj tsis tuaj yeem pom los ntawm sab nraud. Los ntawm kev siv cov txheej txheem no, koj txhim kho cov khoom lag luam kev ntseeg siab thiab ua tau raws li cov qauv kev lag luam siab tshaj plaws.

Koj teeb tsa tus qauv rau cam khwb cia txhuas cov khoom thaum koj xaivhigh-pressure tuag casting. Kev tshawb fawb qhia tau hais tias cov txheej txheem no muab qhov tsis sib xws ntawm lub zog, qhov tseeb, thiab kev ntseeg siab. Cov neeg tsim khoom nyiam nws rau lub voj voog nrawm, nyias-walled qhov chaw, thiab zoo ib yam.

- Kev tsim tawm sai sai

- Siab qhov tseeb

- Superior mechanical zog

FAQ

Dab tsi industries siv high-pressure tuag casting rau txhuas qhov chaw?

Koj pomhigh-pressure tuag castinghauv automotive, electronics, aerospace, thiab cov khoom siv. Cov kev lag luam no xav tau lub teeb yuag, muaj zog, thiab meej aluminium Cheebtsam.

Yuav ua li cas thiaj li high-pressure tuag casting txhim kho qhov zoo?

Koj tau txais qhov zoo dua qub vim tias cov txheej txheem siv cov pwm siab thiab steel pwm. Qhov no tsim cov npoo du, nruj tolerances, thiab tsawg dua qhov tsis xws luag.

Koj puas tuaj yeem rov ua dua txhuas siv hauv high-pressure tuag casting?

Yog lawm! Koj ua taurecycle aluminiumkhib nyiab los ntawm txoj kev. Recycling txuag lub zog thiab txhawb kev tsim khoom lag luam.

Post lub sij hawm: Aug-08-2025