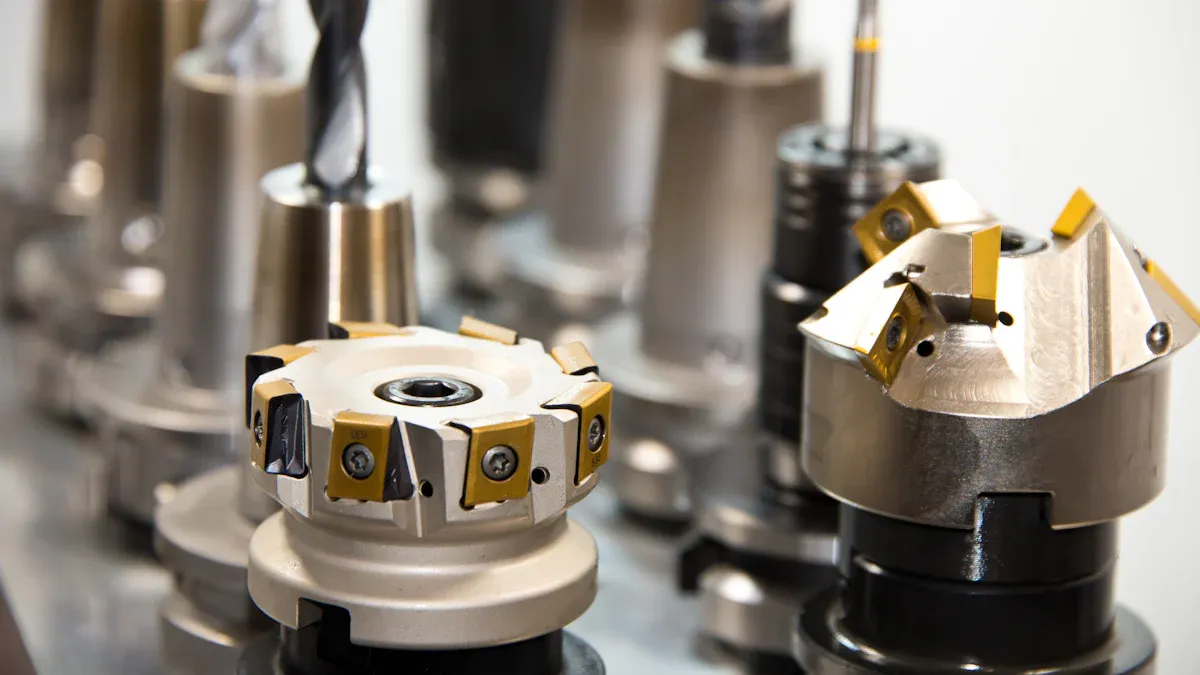

Kuna ganin babban simintin simintin ɗimbin matsi yana saita ma'auni a masana'antar simintin aluminum. Wannan tsari ya mamaye masana'antar, yana riƙe sama da kashi 78% na kudaden shiga a cikin 2024. Yawancin sassa, musammanmotamasana'antu, dogara da shi don ƙirƙirar sassauƙa, daidaitattun sassa waɗanda ke haɓaka ingancin mai da aiki.

Key Takeaways

- Babban matsi mutu simintinyana samar da ƙarfi, daidaitattun sassan aluminum da sauri, yana mai da shi manufa don ƙira mai girma tare da ƙira mai rikitarwa.

- Wannan tsari yana haifar da sassa masu nauyi tare da kyakkyawan ƙarewa da kuma jure juriya, rage buƙatar ƙarin aikin gamawa.

- Babban fasaha da sarrafa ingancia cikin simintin mutuwa yana haɓaka daidaiton samfur, ƙananan farashi, da goyan bayan ayyukan masana'antu masu dorewa.

Abin da ke Sa Babban Matsi Ya mutu Simintin gyare-gyare na Musamman don Aluminum Cast

Tsarin Simintin Ƙarƙashin Ƙarfafa Ƙwararru

Ka fara dababban matsi mutu tsarin simintin gyaran kafata hanyar shirya karfen karfe. Ma'aikata suna tsaftacewa da shafa mai don taimakawa sarrafa zafin jiki da sauƙaƙe cire ɓangaren da ya ƙare. Bayan haka, kuna narke aluminum gami a cikin tanderu. Kuna canja wurin narkakkar karfen zuwa hannun rigar harbi, yawanci a cikin tsarin ɗakin sanyi saboda aluminum yana narkewa a babban zafin jiki. Piston yana shigar da narkakkar aluminium cikin rufaffiyar yumbu a babban matsi-wani lokaci har zuwa mashaya 1200. Ƙarfe yana cika kowane daki-daki na ƙirar da sauri kuma yana ƙarfafawa a ƙarƙashin matsin lamba. Da zarar ɓangaren ya huce, fitilun ejector suna tura shi daga cikin ƙirar. A ƙarshe, kuna datse kowane ƙarin kayan. Wannan tsari yana ba ku damar ƙirƙirar sassa na aluminum da simintin gyare-gyare tare da bangon sirara da sarƙaƙƙiya a cikin daƙiƙa kaɗan.

Fa'idodi masu ban sha'awa akan sauran hanyoyin simintin gyare-gyare

Yin simintin ɗimbin matsi ya bambanta da sauran hanyoyin saboda saurinsa, daidaitonsa, da ikon yin cikakken sassa. Kuna iya ganin bambance-bambance a fili a cikin tebur da ke ƙasa:

| Siffar | Babban-Matsi Die Casting (HPDC) | Sauran Hanyoyin Simintin Aluminum |

|---|---|---|

| Matsin allura | Mafi girma (700-2500 mashaya) | Ƙananan ƙananan (0.7-1.5 mashaya) |

| Lokacin Zagayowar | Yayi sauri (dakika) | Sannu a hankali (mintuna) |

| Kaurin bango | Bakin ciki (0.4-1 mm) | Kauri |

| Daidaiton Girma | Madalla | Da kyau, amma kasa daidai |

| Ƙarshen Sama | Madalla | Da kyau, yana iya buƙatar ƙarin ƙarewa |

| Dacewar samarwa | Babban girma, sassa masu rikitarwa | Ƙananan ƙararrawa, sassa masu sauƙi |

Kuna amfana daga samarwa da sauri da kuma maimaitawa mai yawa. Tsarin yana ba ku ƙwaƙƙwaran tolerances da filaye masu santsi, wanda ke nufin ƙarancin kammala aikin.Babban matsi mutu simintinyana da kyau lokacin da kuke buƙatar manyan lambobi na simintin gyare-gyaren aluminum waɗanda ke da ƙarfi da dalla-dalla.

Fa'idodin Aiki na Ƙarfin Matsi na Mutuwar Cast Aluminum

Daidaito da daidaito

Kuna samun babbar fa'ida dababban matsi mutu simintin gyare-gyarelokacin da kuke buƙatar daidaitattun sassan simintin aluminum. Wannan tsari yana amfani da gyare-gyaren ƙarfe mai ƙarfi da matsa lamba mai girma, wanda zai baka damar ƙirƙirar sassa tare da siffofi masu rikitarwa da cikakkun bayanai. Kuna iya cimma ganuwar bakin ciki da juriya mai ƙarfi, wanda ke da wahala tare da sauran hanyoyin simintin. Misali, yin simintin yashi sau da yawa yana barin filaye masu kauri da kauri, yayin da yin simintin mutuwa yana samar da mafi santsi da ma'auni.

| Siffar | Mutuwar Casting | Yashi Casting |

|---|---|---|

| Rukunin Geometry | Maɗaukaki; cikakkun bayanai masu banƙyama da ƙayatarwa | Iyakance; mafi sauki kayayyaki fĩfĩta |

| Kaurin bango | Ganuwar bakin ciki mai yiwuwa (yana goyan bayan sassa marasa nauyi) | Ganuwar masu kauri saboda ƙarancin ƙima |

| Daidaiton Girma | Maɗaukaki; ƙarancin buƙata don kammala ayyukan | Ƙananan; sau da yawa yana buƙatar ƙarin ƙarewa |

| Ƙarshen Sama | M, high quality | Rougher, textured da yashi molds |

Kuna iya ganin cewa jefa simintin gyare-gyaren mutuƙar ya fito don iyawar sa don isar da ingantaccen sakamako, musamman lokacin da kuke buƙatar dubunnan iri ɗayajefa aluminum aka gyara. Yayin da tsari kadai ba zai iya kaiwa ga mafi tsananin juriya ba (kamar ± 0.01 mm), zaku iya amfani da injin CNC bayan yin simintin don cimma waɗannan ma'auni daidai. Bincika na yau da kullun da kulawar tsari a hankali yana taimaka muku kiyaye babban inganci daga sashi zuwa sashi.

Tukwici:Idan kuna son mafi kyawun ƙarewar farfajiya da daidaiton girman ga sassan aluminum ɗinku na simintin gyare-gyaren simintin gyare-gyaren simintin gyare-gyare, babban zaɓin babban zaɓi.

Ƙarfin Injini da Dorewa

Lokacin da kuka zaɓi babban simintin simintin ɗimbin matsi, zaku sami sassan simintin aluminum tare da ƙarfin injina mai ban sha'awa da dorewa. Saurin kwantar da hankali a yayin aiwatarwa yana haifar da ƙananan ƙwayoyin cuta masu kyau, wanda ke ƙarfafa ƙarfin duka da ingancin saman. Kuna amfana daga girman girman ƙarfin-zuwa-nauyi na aluminum, yana mai da shi cikakke don sassauƙa masu nauyi amma masu tauri.

- Babban matsi na allurar yana rage lahani kamar porosity da shrinkage, don haka sassan ku sun daɗe.

- Kyawawan ingancin zafin jiki na Aluminum yana taimaka wa sassan ku sarrafa zafi, wanda ke da mahimmanci don amfani da motoci da lantarki.

- Tsarin hatsi mai kyau daga m solidification yana ƙaruwa duka ductility da juriya ga fatattaka.

Misali, wasu allunan aluminium na HPDC na iya kaiwa ga samar da ƙarfi har zuwa 321 MPa da ƙarfin ƙarfi na ƙarshe na 425 MPa bayan maganin zafi. Waɗannan lambobin suna nuna cewa za ku iya dogara ga simintin gyaran gyare-gyare na aluminum don neman ayyuka, daga injin mota zuwa firam ɗin sararin samaniya.

Ƙimar Kuɗi da Haɓakawa

Kuna adana lokaci da kuɗi tare da babban matsa lamba mutu simintin. Tsarin yana ba ku damar samar da adadi mai yawa na simintin gyaran gyare-gyare na aluminum da sauri, godiya ga lokutan sake zagayowar da kuma sake amfani da ƙira. Kuna iya yin hadaddun sifofi a cikin daƙiƙa, wanda ke nufin kuna amsawa da sauri ga buƙatun kasuwa.

- Tsarukan sarrafa kansa da ƙirar ƙira na ci gaba suna rage lahani da raguwar lokaci.

- Yawancin lokaci kuna buƙatar ƙarancin injina da ƙarewa, wanda ke rage ƙimar ku gabaɗaya.

- Misalai na ainihi suna nuna har zuwa 20% guntuwar kera masana'anta da 30% ƙananan farashin samarwa don wasu samfuran.

| Matakin Gabatarwa | Bayani | Tasiri kan Lokacin samarwa da inganci |

|---|---|---|

| Gyara da Deburring | Yana kawar da abubuwan da suka wuce gona da iri don filaye masu santsi | Mahimmanci ga m tolerances da inganci |

| Daidaitaccen Machining | Yana samun haƙuri mai mahimmanci da shirye-shiryen taro | Yana ƙara lokaci amma yana tabbatar da ƙayyadaddun bayanai sun cika |

| Maganin Zafi | Yana inganta ƙarfi da ductility | Yana ƙara ɗorewa, musamman don amfani mai tsauri |

Kuna iya ganin cewa yayin da ake buƙatar wasu ayyukan bayan-aiki, gabaɗayan gudu da inganci na simintin ɗimbin matsi mai ƙarfi ya sa ya zama zaɓi mai wayo don samar da simintin aluminum mai girma.

Amfanin Muhalli da Dorewa

Kuna taimakawa yanayi lokacin da kuke amfani da simintin simintin ɗimbin matsi don sassa na aluminum. Tsarin yana tallafawa sake yin amfani da shi kuma yana rage sharar gida, wanda ke da mahimmanci ga masana'anta mai dorewa.

- Za ka iya amfani da sake fa'ida aluminum gami, wanda ceton har zuwa 95% na makamashi idan aka kwatanta da yin sabon aluminum daga tama.

- Tsarin yana haifar da ƙarancin juzu'i saboda daidaitaccen sa, kuma zaku iya sake narkewa da sake amfani da datsa.

- Hasken Aluminum yana nufin samfura kamar motoci da jirage suna amfani da ƙarancin mai, yana rage fitar da hayaki tsawon rayuwarsu.

- Yawancin masana'antun suna amfani da tanderu mai inganci da sabbin hanyoyin samar da makamashi don ƙara rage hayaƙin carbon.

Lura:Ta zabar simintin ɗimbin matsi mai ƙarfi, kuna tallafawa tattalin arziƙin madauwari kuma kuna taimakawa cimma burin dorewar duniya.

Samun Nasara a cikin Cast Aluminum tare da Fasaha mai Ci gaba

Matsayin Kayan Aiki na Zamani da Kerawa

Kuna samun inganci mafi girma da inganci a samar da simintin aluminum ta amfani da kayan aiki na zamani da sarrafa kansa. Injin simintin simintin mutuwa na yau suna amfani da na'urori masu auna firikwensin da sa ido na ainihi don daidaita sigogin tsari nan take. Wannan fasaha tana taimaka muku rage kurakurai da kiyaye daidaiton sakamako. Automation kuma yana kawo ladles na mutum-mutumi da tsarin sarrafawa cikin aikin ku. Waɗannan robots suna haɓaka amincin wurin aiki kuma suna tabbatar da kowane sashi ya cika ƙaƙƙarfan ƙa'idodi.

Kuna amfana daga ci gaba da yawa kwanan nan:

- Na'urori masu auna firikwensin a cikin injuna suna ba da damar gyare-gyare na ainihin lokaci, rage kurakurai.

- Software na kwaikwaiyo yana taimaka muku ƙira mafi kyawu da tsinkayar sakamako.

- Vacuum-taimaka da extrusion mutu simintin hanyoyin inganta saman gama da ingancin samfur.

- Tsarin na'ura mai kwakwalwa suna ɗaukar ayyuka masu haɗari, suna kiyaye ƙungiyar ku.

- Motoci masu amfani da makamashi da hazo suna rufe ƙananan farashi da tallafawa dorewa.

- IIoT (Intanet na Masana'antu) yana haɗa injin ku don masana'anta mai wayo, kiyaye tsinkaya, da canje-canjen tsari cikin sauri.

Tare da waɗannan kayan aikin, zaku iya samar da sassan aluminum da aka jefa cikin sauri, tare da ƙarancin lahani, kuma a ƙaramin farashi.

Muhimmancin Kulawa da Tabbatarwa

Dole ne ku mai da hankali kan sarrafawa mai inganci don isar da ingantaccen kayan aikin simintin aluminum. Tsarin sa ido na ainihi yana bin mahimman abubuwan kamar zafin jiki, matsa lamba, da lokacin zagayowar. Waɗannan tsarin suna ba ku damar gano matsaloli da wuri kuma ku yi saurin gyarawa. Binciken hangen nesa mai sarrafa kansa da hoton zafi yana kama lahani kafin su isa ga abokan ciniki.

Kula da inganci a cikin simintin ɗimbin matsi yakan bi tsauraran matakan masana'antu. Misali, abubuwan kera motoci da na sararin samaniya suna buƙatar takaddun shaida na IATF 16949 da ISO 9001. Kuna amfani da hanyoyi da yawa don tabbatar da inganci:

| Matakin Kula da Inganci | Bayani |

|---|---|

| Tsare-tsaren Gabatarwa | Binciken haɗari, ingantaccen tsari, nazarin iya aiki |

| In-Process Control | Sa ido na ainihi, SPC, dubawa ta atomatik |

| Gwajin Bayan Haihuwa | X-ray, CT scans, matsa lamba da gwajin taurin |

Babban kayan aikin dubawa kamar X-ray da CT scanning suna bayyana ɓoyayyun lahani a cikin sassan simintin aluminum. Waɗannan fasahohin suna taimaka muku nemo ɓoyayyiya ko tsaga waɗanda ba za ku iya gani daga waje ba. Ta amfani da waɗannan hanyoyin, kuna haɓaka amincin samfur kuma ku hadu da mafi girman matsayin masana'antu.

Kuna saita ma'auni don simintin kayan aikin aluminum lokacin da kuka zaɓababban matsi mutu simintin gyare-gyare. Bincike ya nuna wannan tsari yana ba da ƙarfin da bai dace ba, daidaito, da aminci. Masu sana'anta sun fi son shi don saurin hawan keke, sassa na bangon bakin ciki, da daidaiton inganci.

- Zagayen samarwa da sauri

- Daidaitaccen girman girma

- Mafi kyawun kayan aikin injiniya

FAQ

Wadanne masana'antu ke amfani da simintin ɗimbin matsi don sassan aluminum?

Ka samubabban matsi mutu simintin gyare-gyarea cikin motoci, lantarki, sararin samaniya, da kayan masarufi. Waɗannan masana'antu suna buƙatar sassauƙa, ƙarfi, da ingantattun abubuwan aluminum.

Ta yaya babban matsi na simintin gyare-gyare na haɓaka ingancin sashi?

Kuna samun mafi kyawun sashi saboda tsarin yana amfani da babban matsin lamba da ƙirar ƙarfe. Wannan yana haifar da filaye masu santsi, matsananciyar haƙuri, da ƙarancin lahani.

Za ku iya sake sarrafa aluminum da ake amfani da ita a cikin simintin ɗimbin matsi?

Ee! Za ka iyasake sarrafa aluminumgoge daga tsari. Sake amfani da makamashi yana adana makamashi kuma yana tallafawa masana'antu mai dorewa.

Lokacin aikawa: Agusta-08-2025