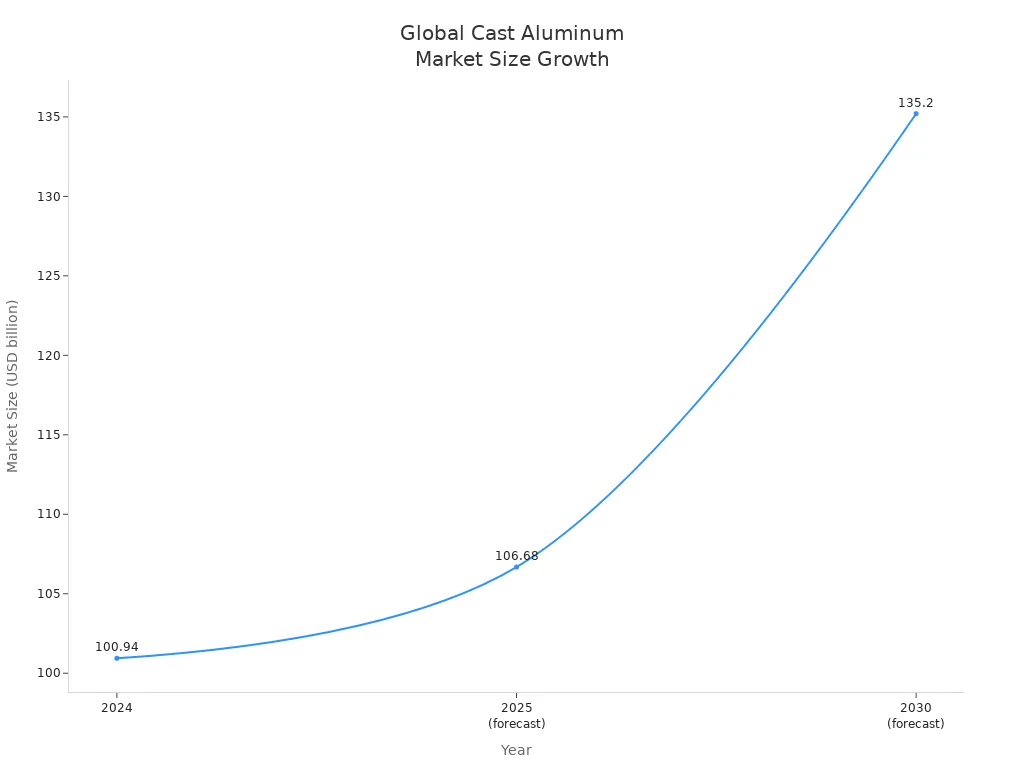

You see cast aluminum driving innovation across industrial sectors. The market reached $100.94 billion in 2024 and is projected to grow rapidly, powered by advancements like high-pressure die casting and eco-friendly processes.

| Aspect | Data / Description |

|---|---|

| Market Size 2024 | USD 100.94 billion |

| Automobile Usage | Largest end user |

| Key Applications | Pipe Fittings, more |

Key Takeaways

- Cast aluminum offers a strong, lightweight, and durable solution that improves fuel efficiency and supports sustainability across automotive, aerospace, electronics, and construction industries.

- Growing demand in automotive and industrial markets drives innovation in advanced alloys, casting technologies, and recycling methods, helping meet stricter environmental and performance standards.

- Industry partnerships and new manufacturing processes overcome technical and supply challenges, enabling cast aluminum to deliver high-quality, cost-effective parts for modern industrial needs.

Cast Aluminum Performance in Industrial Applications

Strengths in Automotive and Industrial Use

You see cast aluminum as a top choice in many industries because it delivers a unique blend of strength, light weight, and durability. In the automotive sector, you benefit from its use in engine blocks, cylinder heads, transmission cases, suspension components, and wheels. These parts help vehicles achieve better fuel efficiency and lower emissions. The excellent heat transfer properties of cast aluminum also keep engines cool and running smoothly.

In aerospace, you rely on cast aluminum for structural parts, engine housings, wing structures, and landing gear. The high strength-to-weight ratio and corrosion resistance make it ideal for aircraft that must remain both strong and light. Electronics manufacturers use cast aluminum for electrical enclosures, heat sinks, and connectors. The material’s thermal and electrical conductivity ensures reliable heat dissipation and electrical performance.

You also find cast aluminum in construction and architecture. It appears in window frames, facades, and decorative elements, offering both durability and a modern look. Industrial equipment such as pumps, valves, compressors, and hydraulic systems use cast aluminum for its machinability and resistance to corrosion. Even in consumer goods and medical equipment, you see the benefits of this material—lightweight, easy to shape, and long-lasting.

Key Applications of Cast Aluminum:

- Automotive: Engine blocks, wheels, suspension parts

- Aerospace: Aircraft structures, engine housings

- Electronics: Heat sinks, enclosures, connectors

- Construction: Window frames, facades, decorative items

- Industrial Equipment: Pumps, valves, compressors

- Consumer Goods: Cookware, lighting, furniture

- Medical Equipment: Frames, support structures

Limitations and Performance Boundaries

You recognize that every material has its boundaries, and cast aluminum is no exception. While it excels in many demanding environments, you must consider its performance limits. Cast aluminum works best in applications where moderate to high strength, light weight, and corrosion resistance are required. It handles heat well, but you should avoid using it in situations that demand extreme strength or exposure to very high temperatures for long periods.

You may notice that cast aluminum is not always the first choice for heavy-duty structural parts in construction or for components that face constant, intense mechanical stress. In these cases, you might turn to steel or other alloys. However, for most industrial and automotive uses, cast aluminum offers a balance of properties that meet your needs for efficiency, durability, and cost-effectiveness.

Cast Aluminum Market Outlook

Demand Trends in Automotive Sectors

You see the automotive industry driving strong demand for aluminum components. Manufacturers focus on lightweight vehicles to improve fuel efficiency and reduce emissions. This trend pushes you to adopt more aluminum parts in cars and trucks. The rise of electric vehicles (EVs) accelerates this shift. You now use aluminum for battery housings, chassis, and structural parts in EVs.

Advanced casting technologies, such as high-pressure die casting and thixoforming, help you create complex shapes with better performance and lower costs. You also benefit from additive manufacturing, which allows for more intricate designs. Sustainability remains a top priority. You use more recycled aluminum and eco-friendly production methods to meet environmental goals. Industry 4.0 technologies, like IoT sensors and predictive analytics, help you improve efficiency and reduce waste.

Key Trends in Automotive Demand:

- Lightweighting for fuel efficiency and emissions reduction

- Increased use of aluminum in EV battery housings and chassis

- Adoption of advanced casting and manufacturing technologies

- Focus on sustainability and recycling

- Growth led by Asia, especially China, due to a large automotive base and EV market

You also notice that the U.S. market is growing quickly. Federal incentives and stricter emissions regulations support this trend. You see new alloys developed for EVs, offering better thermal management, strength, and recyclability. Companies that align with these trends gain a competitive edge.

Growth in Broader Industrial Markets

You find that demand for aluminum extends beyond the automotive sector. The industrial segment, which includes agricultural, construction, and mining equipment, shows steady growth. Ongoing infrastructure development, especially in Asia, increases the need for construction machinery and equipment made from aluminum.

The global aluminum die casting market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2025 to 2030. In North America, you expect a CAGR of 4.8% for aluminum products, including cast components, from 2025 to 2032. Construction companies use more aluminum die castings for windows, cladding, and curtain walls. These applications support sustainability and energy efficiency goals.

You see urbanization and infrastructure projects driving demand for durable, lightweight, and corrosion-resistant materials. As a result, you rely on aluminum to meet these needs in various industrial applications.

Regional and Global Market Projections

You observe that Asia-Pacific leads the global market for aluminum products. China stands out with its large automotive manufacturing base and rapid EV adoption. This region invests heavily in advanced casting technologies and recycling capacity to meet growing demand.

In North America and Europe, you see strong growth supported by regulatory frameworks that emphasize sustainability and emissions reduction. Federal and state initiatives in the U.S. promote aluminum recycling, aiming for a 50% scrap recycling rate by 2030. These efforts encourage you to adopt advanced recycling technologies and greener production methods.

Globally, you expect the aluminum die casting market to expand as manufacturers invest in new technologies and capacity. The shift toward electric vehicles, urbanization, and infrastructure development will continue to shape demand. You position yourself for success by focusing on innovation, sustainability, and efficiency.

Innovations in Cast Aluminum Technology

Advanced Alloys and Material Enhancements

You benefit from new alloy developments that push the boundaries of cast aluminum performance. Engineers have designed advanced alloys to deliver higher strength and better durability, especially for parts exposed to high temperatures. The table below highlights how these new alloys compare:

| Alloy Name | Composition Elements | Key Mechanical Improvements | Heat Treatment | Fatigue Performance |

|---|---|---|---|---|

| Al-Q | AlSiCuMg | Improved tensile strength at high temperatures | Solution at 530°C, aging at 200°C | Slightly higher, but variable |

| ACMZ | AlCuMnZr | Superior tensile and yield strength above 200°C | Solution at 540°C, aging at 240°C | Similar to baseline, smaller defects |

| Baseline | A356+0.5%Cu | Good at low/intermediate temps, degrades above 200°C | Standard | Controlled by defect size |

You see that these alloys, along with others like AURAL-2 and Silafont-36, offer better strength and ductility than traditional options. Advanced manufacturing methods, such as selective laser melting, help you achieve complex shapes and refined microstructures.

Improved Casting Processes

You now use advanced casting processes to improve quality and efficiency. Modern simulation software lets you optimize designs and reduce errors. You can choose from new casting methods like electromagnetic pump low-pressure casting, extrusion die casting, and vacuum-assisted die casting. These methods give you better precision and surface finish. Automation and robotics streamline production, while sensors in high-pressure die casting machines allow real-time adjustments for fewer defects.

- 3D printed molds increase precision.

- Automation reduces labor costs.

- Sustainable casting techniques use more recycled alloys.

Lightweighting and Sustainability Initiatives

You rely on cast aluminum for lightweighting in vehicles and machinery. Lighter parts improve fuel efficiency and extend battery range in electric vehicles. You also support sustainability by recycling aluminum, which saves energy and reduces emissions. Closed-loop systems and energy-efficient technologies help you meet environmental goals. Certifications like the Aluminum Stewardship Initiative show your commitment to responsible production.

Cast Aluminum: Challenges and Solutions

Technical Barriers and Overcoming Them

You face technical barriers when you work with cast aluminum in demanding industrial settings. High-performance applications require you to achieve tight tolerances, superior surface finishes, and consistent mechanical properties. You often rely on advanced casting methods, such as high-pressure die casting and vacuum-assisted processes, to meet these requirements. Automation and real-time monitoring help you reduce defects and improve repeatability. You also see research partnerships driving innovation in alloy development and process control, making it easier for you to overcome technical limits.

Cost and Supply Chain Considerations

You must pay close attention to costs and supply chain stability when you choose cast aluminum for your projects. Several factors can affect pricing and availability:

- Raw material availability and aluminum price volatility increase production costs and influence pricing strategies.

- These cost fluctuations affect market stability for cast aluminum.

- Global supply chain dynamics and import-export trends impact the availability and demand of cast aluminum.

- The market is sensitive to international trade conditions and geopolitical developments, which contribute to supply chain volatility.

You manage these risks by diversifying suppliers, investing in recycling, and adopting flexible production strategies.

Industry Strategies for Broader Adoption

You see industry leaders forming partnerships with research institutions to accelerate the adoption of cast aluminum. These collaborations focus on new materials, automation, and digital tools. The table below highlights some key partnerships and their impact:

| Partnership / Program | Description | How it Accelerates Cast Aluminum Adoption |

|---|---|---|

| American Metalcasting Consortium (AMC) | Collaboration of metalcasting associations funded by DoD focusing on research projects (2023-2028) including new materials, automation, recycling, and data-driven design tools | Enables faster production, reduces costs and environmental impact, improves quality and reliability |

| AMC Emergent Metal Casting Solutions (EMCS) | Projects on investment casting: rapid production, recycling improvements, digital tools, defect modeling | Improves production speed, quality control, and sustainability |

| Aluminum Casting Performance Initiative (ACPI) | Projects (2025-2028) on machine learning defect detection, alloy data development, and automated production tools | Enhances defect detection, provides reliable alloy data, and automates production for better quality and efficiency |

| Advanced Casting Research Center (ACRC) at UC Irvine | Industry-university consortium managing innovative heat treating research for aluminum alloys | Advances material properties and processing techniques to improve cast aluminum performance |

| America Makes / NCDMM IMPACT Program | Focus on additive manufacturing and 3D printed sand molds for defense and commercial needs (2023-2026) | Promotes adoption of advanced manufacturing technologies, improves casting quality, and strengthens supply chain |

You benefit from these strategies as they help you access better materials, improved processes, and a more resilient supply chain.

Cast Aluminum Success Stories

Automotive Component Advancements

You see major improvements in vehicle performance and efficiency when you use cast aluminum components. An aluminum engine block can weigh up to 50% less than a similar cast iron block. This weight reduction helps you boost fuel efficiency and lower CO2 emissions. You also benefit from aluminum body panels, such as doors and hoods, which resist corrosion and extend the life of your vehicles.

When you choose aluminum die casting, you gain the ability to produce complex and precise parts. Engine blocks, transmission housings, cylinder heads, and suspension units all become lighter and stronger. These parts help you meet strict environmental regulations and improve the driving experience, especially in electric vehicles. You also find that die casting supports high-volume production, giving you consistent quality and cost savings.

Tip: Lightweight aluminum components help you offset the added weight of electric vehicle batteries, making your vehicles more efficient.

Industrial Machinery and Equipment Examples

You rely on cast aluminum for industrial machinery because it offers a strong balance of durability and light weight. In food production, for example, permanent mold casting creates components that handle harsh environments and meet food safety standards. You see these parts used in equipment that dusts flavorings on snacks, where corrosion resistance and easy cleaning matter most.

Aluminum die casting also supports agricultural, construction, and manufacturing equipment. You benefit from its excellent thermal conductivity and wear resistance. The table below shows how cast aluminum properties improve operational efficiency:

| Feature/Property | Impact on Operational Efficiency |

|---|---|

| Strength-to-weight ratio | Easier handling, lower energy use |

| Corrosion resistance | Less maintenance, longer lifespan |

| Dimensional stability | Reliable performance in tough conditions |

| Design flexibility | Optimized shapes for better integration |

You see Cast Aluminum meeting the rising demands of modern industry. Its lightweight strength, recyclability, and advanced manufacturing methods drive innovation in automotive and beyond. While you face challenges in quality control and sustainability, new alloys and process improvements promise a bright future for cast aluminum across global markets.

FAQ

What makes cast aluminum a preferred material in automotive manufacturing?

You choose cast aluminum for its light weight, strength, and corrosion resistance. These properties help you improve fuel efficiency and meet strict emission standards.

Tip: Lighter vehicles often mean lower fuel costs.

How does cast aluminum support sustainability goals?

You benefit from cast aluminum’s recyclability. You can reuse scrap aluminum, which saves energy and reduces environmental impact.

- ♻️ Recycling aluminum uses up to 95% less energy than producing new metal.

Can you use cast aluminum for high-precision industrial parts?

You achieve high precision with advanced die casting and CNC machining. These methods allow you to produce complex shapes with tight tolerances and consistent quality.

Post time: Aug-05-2025