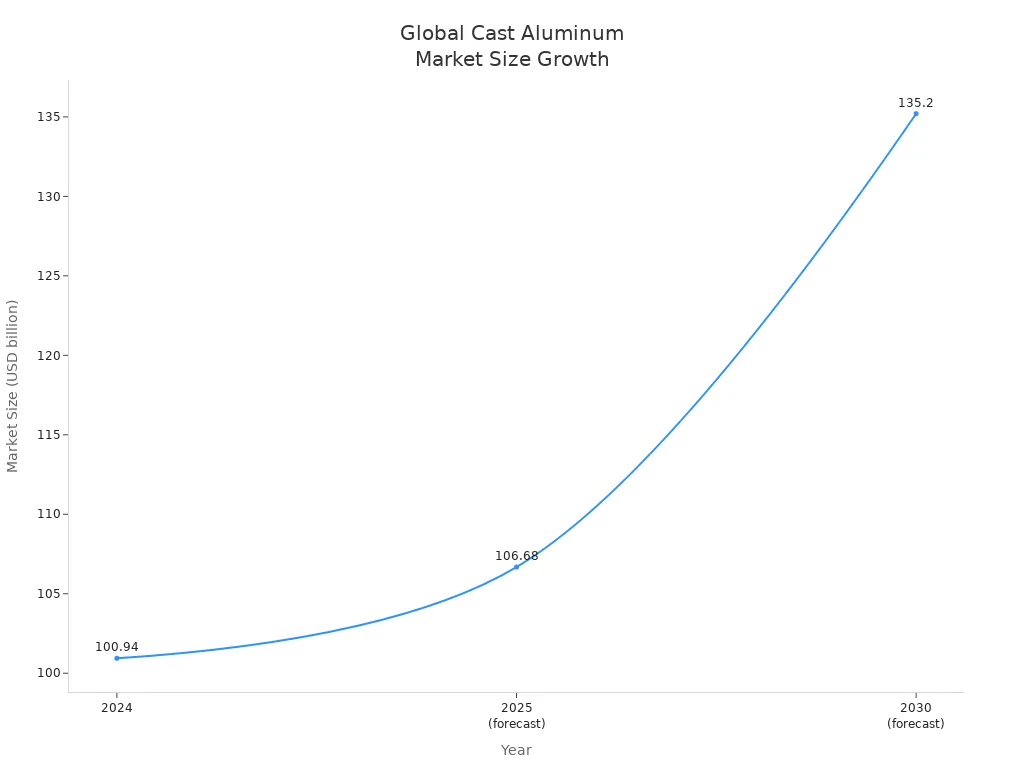

Koj pom cam khwb cia txhuas tsav tsheb innovation nyob rau hauv industrial sectors. Kev ua lag luam tau mus txog $ 100.94 nphom hauv 2024 thiab tau npaj kom loj hlob sai, txhawb nqa los ntawm kev nce qib xws li kev kub siab tuag casting thiab cov txheej txheem hauv eco.

| Yam | Cov ntaub ntawv / piav qhia |

|---|---|

| Market Size 2024 | USD 100.94 billion |

| TshebKev siv | Cov neeg siv loj tshaj plaws |

| Cov ntawv thov tseem ceeb | Cov yeeb nkab fittings, ntau |

Ntsiab Cai

- Cast aluminium muab amuaj zog, hnav, thiab ruaj khovkev daws teeb meem uas txhim kho roj efficiency thiab txhawb kev ruaj ntseg thoob plaws hauv tsheb, aerospace, hluav taws xob, thiab kev tsim kho kev lag luam.

- Kev loj hlob thov nyob rau hauv tsheb thiab kev lag luam kev lag luam tsav kev tsim kho tshiab hauv cov alloys siab heev,casting technologies, thiab cov txheej txheem rov ua dua tshiab, pab ua kom muaj kev nruj dua ib puag ncig thiab cov qauv kev ua haujlwm.

- Kev koom tes hauv kev lag luam thiab cov txheej txheem tsim khoom tshiab kov yeej cov kev sib tw thiab cov khoom siv, ua kom cov cam khwb cia txhuas xa cov khoom zoo, tus nqi tsim nyog rau cov kev xav tau niaj hnub no.

Cast Aluminium Performance nyob rau hauv Industrial Applications

Lub zog muaj zog hauv Automotive thiab Industrial Siv

Koj pomcam khwb cia aluminiumraws li kev xaiv saum toj kawg nkaus hauv ntau qhov kev lag luam vim nws muab cov khoom sib xyaw tshwj xeeb ntawm lub zog, lub teeb yuag, thiab kav ntev. Hauv kev lag luam tsheb, koj tau txais txiaj ntsig los ntawm kev siv lub cav thaiv, lub tog raj kheej taub hau, kis kab mob, cov khoom raug tshem tawm, thiab lub log. Cov khoom no pab cov tsheb ua tau zoo dua roj efficiency thiab qis emissions. Cov khoom siv hluav taws xob zoo tshaj plaws ntawm cam khwb cia txhuas kuj ua kom cov cav txias thiab ua haujlwm zoo.

Nyob rau hauv aerospace, koj cia siab rau cam khwb cia txhuas rau cov khoom siv, cav vaj tse, tis qauv, thiab tsaws iav. Lub siab zog-rau-qhov hnyav piv thiab corrosion kuj ua rau nws zoo tagnrho rau cov dav hlau uas yuav tsum nyob twj ywm ob qho tib si muaj zog thiab lub teeb. Electronics manufacturers siv cam khwb cia txhuas rau hluav taws xob enclosures, heat sinks, thiab connectors. Cov khoom siv thermal thiab hluav taws xob conductivity ua kom ntseeg tau cov cua sov dissipation thiab hluav taws xob ua haujlwm.

Koj kuj pom cam khwb cia txhuas hauv kev tsim kho thiab architecture. Nws tshwm nyob rau hauv lub qhov rais thav duab, facades, thiab cov khoom zoo nkauj, muab ob qho tib si durability thiab niaj hnub saib. Cov khoom siv xws li twj tso kua mis, li qub, compressors, thiab hydraulic systems siv cam khwb cia txhuas rau nws cov machinability thiab tsis kam mus corrosion. Txawm nyob rau hauv cov khoom siv thiab cov khoom siv kho mob, koj pom cov txiaj ntsig ntawm cov khoom siv no - lub teeb yuag, yooj yim rau cov duab, thiab siv tau ntev.

Daim ntawv thov tseem ceeb ntawm Cast Aluminium:

- Automotive: Cav thaiv, log, ncua kev kawm qhov chaw

- Aerospace: Aircraft lug, cav vaj tse

- Electronics: Kub dab dej, enclosures, connectors

- Kev tsim kho: Qhov rai thav duab, facades, cov khoom zoo nkauj

- Cov cuab yeej siv: twj, valve, compressors

- Cov Khoom Siv Khoom Siv: Cookware, teeb pom kev zoo, rooj tog zaum

- Cov Khoom Siv Kho Mob: Cov ncej, cov qauv kev txhawb nqa

Kev txwv thiab kev ua haujlwm ciam teb

Koj paub tias txhua yam khoom muaj nws thaj tsam, thiab cam khwb cia txhuas tsis muaj qhov tshwj xeeb. Thaum nws ua tau zoo nyob rau hauv ntau qhov kev xav tau ib puag ncig, koj yuav tsum xav txog nws cov kev txwv kev ua haujlwm. Cam khwb cia txhuas ua haujlwm zoo tshaj plaws nyob rau hauv daim ntawv thov qhov nruab nrab mus rau siab zog, lub teeb yuag, thiab corrosion kuj yuav tsum tau. Nws tuav cov cua sov zoo, tab sis koj yuav tsum tsis txhob siv nws hauv cov xwm txheej uas xav tau lub zog loj lossis raug rau qhov kub siab heev rau lub sijhawm ntev.

Tej zaum koj yuav pom tias cam khwb cia txhuas tsis yog ib qho kev xaiv thawj zaug rau cov khoom siv hnyav hauv kev tsim kho lossis rau cov khoom uas muaj kev ntxhov siab tsis tu ncua. Nyob rau hauv cov ntaub ntawv no, koj yuav tig mus rau hlau los yog lwm yam alloys. Txawm li cas los xij, rau feem ntau kev lag luam thiab kev siv tsheb, cam khwb cia txhuas muaj qhov sib npaug ntawm cov khoom uas ua tau raws li koj cov kev xav tau rau kev ua tau zoo, kav ntev, thiab kev siv nyiaj.

Cast Aluminium Market Outlook

Kev xav tau Trends hauv Automotive Sectors

Koj pom kev lag luam tsheb tsav tsheb muaj zog thov rau cov khoom siv txhuas. Cov neeg tsim khoom tsom mus rau cov tsheb sib tw los txhim kho roj efficiency thiab txo qis emissions. Cov qauv no thawb koj kom txais yuav ntau qhov txhuas hauv cov tsheb thiab cov tsheb thauj khoom. Kev nce ntawm cov tsheb hluav taws xob (EVs) ua rau qhov kev hloov pauv no. Tam sim no koj siv txhuas rau roj teeb vaj tsev, chassis, thiab cov khoom siv hauv EVs.

Advanced casting technologies, xws li high-pressure tuag casting thiab thixoforming, pab koj tsim cov duab complex nrog kev ua tau zoo dua thiab cov nqi qis dua. Koj kuj tau txais txiaj ntsig los ntawm kev tsim khoom ntxiv, uas tso cai rau kev tsim ntau yam sib txawv. Sustainability tseem yog qhov tseem ceeb tshaj plaws. Koj siv ntau dua txhuas cov khoom siv rov ua dua tshiab thiab eco-friendly ntau lawm kom ua tau raws li cov hom phiaj ib puag ncig. Kev lag luam 4.0 thev naus laus zis, zoo li IoT sensors thiab kev ntsuas kwv yees, pab koj txhim kho kev ua haujlwm thiab txo cov khoom pov tseg.

Qhov tseem ceeb Trends hauv Automotive Demand:

- Lightweighting rau roj efficiency thiab txo emissions

- Kev siv ntau ntxiv ntawm txhuas hauv EV roj teeb vaj tsev thiab chassis

- Txais yuav advanced casting thiab manufacturing technologies

- Tsom ntsoov rau kev ruaj khov thiab rov ua dua tshiab

- Kev loj hlob coj los ntawm Asia, tshwj xeeb tshaj yog Tuam Tshoj, vim yog lub hauv paus tsheb loj thiab EV ua lag luam

Koj kuj pom tias Asmeskas kev lag luam loj hlob sai. Tsoom Fwv Teb Chaws kev txhawb siab thiab cov cai nruj dua emissions txhawb cov qauv no. Koj pom cov alloys tshiab tsim rau EVs, muab kev tswj kom zoo dua thermal, lub zog, thiab rov ua dua tshiab. Cov tuam txhab uas ua raws li cov qauv no tau txais kev sib tw.

Kev loj hlob hauv Broader Industrial Markets

Koj pom tias qhov kev thov rau txhuas txuas ntxiv dhau ntawm automotive sector. Cov ntu kev lag luam, uas suav nrog kev ua liaj ua teb, kev tsim kho, thiab cov khoom siv mining, qhia txog kev loj hlob tsis tu ncua. Kev tsim kho vaj tse tsis tu ncua, tshwj xeeb tshaj yog nyob rau hauv Asia, ua rau muaj kev xav tau kev tsim kho tshuab thiab khoom siv ua los ntawm txhuas.

Kev lag luam thoob ntiaj teb txhuas tuag casting yog kwv yees kom loj hlob ntawm qhov sib xyaw ua ke txhua xyoo kev loj hlob (CAGR) ntawm 5.8% txij xyoo 2025 txog 2030. Hauv North America, koj cia siab tias yuav muaj CAGR ntawm 4.8% rau cov khoom siv txhuas, suav nrog cov khoom cam khwb cia, txij xyoo 2025 txog 2032. Cov tuam txhab tsim kho siv ntau aluminium tuag castings rau lub qhov rais, cladding, thiab kab hlau rhuav phab ntsa. Cov ntawv thov no txhawb nqa kev ruaj khov thiab lub zog txuag lub hom phiaj.

Koj pom kev tsim kho hauv nroog thiab kev tsim kho vaj tse uas xav tau rau cov khoom siv ruaj khov, lub teeb yuag, thiab cov khoom siv tiv thaiv corrosion. Yog li ntawd, koj cia siab rau aluminium kom tau raws li cov kev xav tau no hauv ntau daim ntawv thov kev lag luam.

Regional and Global Market Projections

Koj pom tias Asia-Pacific ua lub lag luam thoob ntiaj teb rau cov khoom siv txhuas. Tuam Tshoj sawv tawm nrog nws txoj kev tsim tsheb loj loj thiab kev siv EV sai. Cov cheeb tsam no tau nqis peev ntau rau hauv cov thev naus laus zis siab tshaj plaws thiab cov peev txheej rov ua dua tshiab kom tau raws li qhov xav tau loj hlob.

Hauv North America thiab Europe, koj pom kev loj hlob muaj zog txhawb nqa los ntawm cov txheej txheem tswj hwm uas hais txog kev ruaj khov thiab txo qis emissions. Tsoom Fwv Teb Chaws thiab lub xeev cov thawj coj hauv Teb Chaws Asmeskas txhawb nqa cov khoom siv txhuas rov ua dua tshiab, tsom rau 50% cov khoom siv rov ua dua tshiab los ntawm 2030. Cov kev siv zog no txhawb kom koj siv cov thev naus laus zis rov ua dua tshiab thiab cov txheej txheem ntau lawm.

Thoob ntiaj teb, koj cia siab tias aluminium tuag casting lag luam yuav nthuav dav raws li cov tuam txhab lag luam nqis peev hauv cov thev naus laus zis tshiab thiab muaj peev xwm. Kev hloov mus rau lub tsheb hluav taws xob, kev tsim kho nroog, thiab kev tsim kho vaj tse yuav txuas ntxiv mus rau qhov xav tau. Koj tso koj tus kheej rau kev vam meej los ntawm kev tsom mus rau innovation, sustainability, thiab efficiency.

Kev tsim kho tshiab hauv Cast Aluminium Technology

Advanced Alloys thiab Khoom Txhim Kho

Koj tau txais txiaj ntsig los ntawm kev tsim cov hlau tshiab uas thawb cov ciam teb ntawm cam khwb cia aluminium kev ua tau zoo. Cov kws tshaj lij tau tsim cov alloys siab heev kom xa tau lub zog siab dua thiab ua haujlwm zoo dua qub, tshwj xeeb tshaj yog rau cov khoom raug kub kub. Cov lus hauv qab no qhia txog tias cov alloys tshiab no piv li cas:

| Alloy npe | Cov ntsiab lus sib xyaw | Kev txhim kho cov cuab yeej tseem ceeb | Kev kho cua sov | Fatigue Performance |

|---|---|---|---|---|

| Al-Q | AlSiCuMg | Txhim kho tensile lub zog ntawm qhov kub thiab txias | Kev daws ntawm 530 ° C, kev laus ntawm 200 ° C | Me ntsis siab dua, tab sis sib txawv |

| ACMZ | AlCuMnZr | Superior tensile thiab yield zog tshaj 200 ° C | Kev daws ntawm 540 ° C, kev laus ntawm 240 ° C | Zoo ib yam li cov hauv paus ntsiab lus, cov teeb meem me me |

| Lub hauv paus | A356 + 0.5% Cu | Zoo nyob rau hauv qis / nruab nrab temps, degrades saum 200 ° C | Txuj | Tswj los ntawm qhov loj me me |

Koj pom tias cov alloys no, nrog rau lwm tus xws li AURAL-2 thiab Silafont-36, muab lub zog zoo dua thiab kev ua haujlwm zoo dua li cov kev xaiv ib txwm muaj. Advanced manufacturing txoj kev, xws li xaiv laser melting, pab koj ua tiav cov duab complex thiab refined microstructures.

Txhim kho cov txheej txheem Casting

Tam sim no koj siv cov txheej txheem casting siab heev los txhim kho qhov zoo thiab ua haujlwm zoo. Niaj hnub nimno simulation software cia koj optimize tsim thiab txo qhov yuam kev. Koj tuaj yeem xaiv los ntawm cov tshiabtxoj kev castingzoo li electromagnetic twj tso kua mis low-pressure casting, extrusion tuag casting, thiab nqus-pab tuag casting. Cov txheej txheem no muab rau koj zoo dua precision thiab nto tiav. Automation thiab robotics streamline ntau lawm, thaum sensors nyob rau hauv high-pressure tuag casting tshuab tso cai rau lub sij hawm hloov kho rau tsawg dua.

- 3D luam tawm pwm nce precision.

- Automation txo cov nqi zog.

- Cov txheej txheem casting ruaj khov siv cov khoom siv rov ua dua tshiab.

Lub Teeb Pom Kev thiab Sustainability Initiatives

Koj cia siab rau cam khwb cia txhuas rau lub teeb yuag hauv tsheb thiab tshuab. Cov khoom sib zog ua kom cov roj siv tau zoo thiab txuas ntxiv roj teeb ntau hauv cov tsheb hluav taws xob. Koj kuj txhawb kev ruaj khov los ntawm kev rov ua dua tshiab ntawm txhuas, uas txuag lub zog thiab txo qis emissions. Lub kaw lus kaw thiab cov thev naus laus zis siv hluav taws xob pab koj ua tau raws li cov hom phiaj ib puag ncig. Cov ntawv pov thawj zoo li Aluminium Stewardship Initiative qhia koj txoj kev cog lus rau lub luag haujlwm tsim khoom.

Cast Aluminium: Kev Sib Tw thiab Kev daws teeb meem

Technical Barriers thiab kov yeej lawv

Koj ntsib teeb meem kev lag luam thaum koj ua haujlwm nrog cam khwb cia txhuas hauv kev xav tau kev lag luam. Cov ntawv thov kev ua haujlwm siab xav kom koj ua tiav qhov kev zam nruj, kev ua tiav zoo tshaj plaws, thiab cov khoom siv kho kom zoo ib yam. Koj feem ntau tso siab rau cov txheej txheem casting siab, xws li kev kub siab tuag casting thiab cov txheej txheem nqus-pab, kom ua tau raws li cov cai no. Automation thiab saib xyuas lub sijhawm tiag tiag pab koj txo qhov tsis xws luag thiab txhim kho rov ua dua. Koj kuj pom kev sib koom tes tshawb fawb tsav tsheb tshiab hauv kev txhim kho alloy thiab kev tswj cov txheej txheem, ua kom yooj yim rau koj kom kov yeej cov kev txwv.

Nqi thiab Supply Chain Considerations

Koj yuav tsum ua tib zoo saib xyuas cov nqi thiab cov saw hlau ruaj khov thaum koj xaiv cam khwb cia txhuas rau koj cov haujlwm. Ntau yam tuaj yeem cuam tshuam tus nqi thiab muaj nyob:

- Raw khoom muaj thiab txhuas tus nqi volatility nce nqi ntau lawm thiab cuam tshuam cov tswv yim pricing.

- Cov nqi hloov pauv no cuam tshuam rau kev lag luam ruaj khov rau cam khwb cia txhuas.

- Kev lag luam thoob ntiaj teb kev lag luam kev lag luam thiab kev lag luam ntshuam-tshuaj cuam tshuam rau kev muaj thiab kev thov ntawm cam khwb cia txhuas.

- Kev ua lag luam yog rhiab heev rau kev lag luam thoob ntiaj teb thiab kev tsim kho thaj chaw, uas ua rau cov khoom lag luam tsis hloov pauv.

Koj tswj hwm cov kev pheej hmoo no los ntawm kev faib cov neeg xa khoom sib txawv, nqis peev hauv kev rov ua dua tshiab, thiab siv cov tswv yim tsim khoom yooj yim.

Kev lag luam cov tswv yim rau kev siv dav dav

Koj pom cov thawj coj hauv kev lag luam tsim kev koom tes nrog cov koom haum tshawb fawb txhawm rau txhawm rau txhawm rau txais yuav cov cam khwb cia txhuas. Cov kev sib koom tes no tsom mus rau cov ntaub ntawv tshiab, automation, thiab cov cuab yeej digital. Cov lus hauv qab no qhia txog qee qhov kev koom tes tseem ceeb thiab lawv qhov cuam tshuam:

| Partnership / Program | Kev piav qhia | Yuav ua li cas nws Accelerates Cast Aluminium Adoption |

|---|---|---|

| American Metalcasting Consortium (AMC) | Kev koom tes ntawm cov koom haum metalcasting tau txais nyiaj los ntawm DoD tsom rau cov haujlwm tshawb fawb (2023-2028) suav nrog cov ntaub ntawv tshiab, automation, recycling, thiab cov ntaub ntawv tsim cov cuab yeej | Ua kom muaj kev tsim khoom sai dua, txo cov nqi thiab kev cuam tshuam ib puag ncig, txhim kho qhov zoo thiab kev ntseeg siab |

| AMC Emergent Metal Casting Solutions (EMCS) | Cov dej num ntawm kev nqis peev casting: kev tsim khoom sai, kev txhim kho rov ua dua tshiab, cov cuab yeej digital, kev ua qauv tsis raug | Txhim kho kev tsim khoom ceev, kev tswj kom zoo, thiab kev ruaj ntseg |

| Aluminium Casting Performance Initiative (ACPI) | Cov phiaj xwm (2025-2028) ntawm kev tshawb nrhiav lub tshuab tsis zoo, kev txhim kho cov ntaub ntawv alloy, thiab cov cuab yeej tsim khoom siv | Txhim kho qhov kev kuaj pom tsis zoo, muab cov ntaub ntawv alloy txhim khu kev qha, thiab ua kom cov khoom tsim tau zoo dua thiab ua haujlwm zoo |

| Advanced Casting Research Center (ACRC) ntawm UC Irvine | Kev lag luam-university consortium tswj kev kho cua sov kev tshawb fawb rau aluminium alloys | Txhim kho cov khoom siv thiab cov txheej txheem ua kom zoo dua cam khwb cia txhuas ua haujlwm |

| America Ua / NCDMM IMPACT Program | Tsom ntsoov rau kev tsim khoom ntxiv thiab 3D luam ntawv xuab zeb pwm rau kev tiv thaiv thiab kev lag luam xav tau (2023-2026) | Txhawb nqa kev tsim khoom siv thev naus laus zis, txhim kho cov khoom zoo, thiab ntxiv dag zog rau cov saw hlau |

Koj tau txais txiaj ntsig los ntawm cov tswv yim no vim lawv pab koj nkag mus rau cov ntaub ntawv zoo dua, txhim kho cov txheej txheem, thiab cov saw hlau muaj zog dua.

Cast Aluminium Success Dab Neeg

Automotive Component Advancements

Koj pom kev txhim kho loj hauv kev ua haujlwm ntawm lub tsheb thiab kev ua haujlwm zoo thaum koj siv cov khoom siv cam khwb cia txhuas. Ib qho txhuas lub cav thaiv tuaj yeem hnyav txog li 50% tsawg dua li qhov zoo sib xws cam khwb cia hlau thaiv. Qhov kev txo qhov hnyav no yuav pab koj txhawb kev siv roj thiab txo qis CO2 emissions. Koj kuj tau txais txiaj ntsig los ntawm aluminium lub cev vaj huam sib luag, xws li lub qhov rooj thiab lub hood, uas tiv thaiv corrosion thiab txuas lub neej ntawm koj lub tsheb.

Thaum koj xaivaluminium tuag casting, koj tau txais lub peev xwm los tsim cov complex thiab meej. Lub cav thaiv, cov vaj tsev sib kis, lub tog raj kheej taub hau, thiab cov chav tsev raug tshem tawm tag nrho ua kom sib zog thiab muaj zog dua. Cov khoom no pab koj ua tau raws li kev cai nruj ib puag ncig thiab txhim kho kev tsav tsheb, tshwj xeeb tshaj yog nyob rau hauv tsheb fais fab. Koj kuj pom tias tuag casting txhawb cov ntim ntau lawm, muab koj zoo ib yam thiab txuag nqi.

Tswv yim: Lub teeb yuag aluminium Cheebtsam pab koj offset qhov hnyav ntxiv ntawm lub tsheb fais fab, ua rau koj lub tsheb zoo dua.

Muaj Machinery thiab Khoom Piv Txwv

Koj tso siab raucam khwb cia aluminiumrau industrial machinery vim hais tias nws muaj ib tug muaj zog tshuav nyiaj li cas ntawm durability thiab lub teeb yuag. Hauv kev tsim khoom noj khoom haus, piv txwv li, cov pwm mus tas li tsim cov khoom siv uas ua haujlwm hnyav thiab ua tau raws li cov qauv kev nyab xeeb khoom noj. Koj pom cov khoom no siv hauv cov khoom siv uas ua rau cov khoom siv plua plav tawm ntawm cov khoom noj txom ncauj, qhov twg corrosion kuj thiab yooj yim tu teeb meem feem ntau.

Aluminium tuag casting kuj txhawb kev ua liaj ua teb, kev tsim kho, thiab kev tsim khoom. Koj tau txais txiaj ntsig los ntawm nws zoo heev thermal conductivity thiab hnav tsis kam. Cov lus hauv qab no qhia yuav ua li cas cam khwb cia txhuas cov khoom txhim kho kev ua haujlwm zoo:

| Feature / Khoom | Kev cuam tshuam rau kev ua haujlwm zoo |

|---|---|

| Strength-to-weight ratio | Kev tuav tau yooj yim dua, siv zog qis dua |

| Corrosion kuj | Tsawg txij nkawm, lub neej ntev dua |

| Dimensional stability | Txhim khu kev ua tau zoo hauv cov xwm txheej nyuaj |

| Tsim yooj | Optimized duab rau kev sib koom ua ke zoo dua |

Koj pom Cast Aluminium ntsib qhov kev xav tau ntawm kev lag luam niaj hnub no. Nws lub teeb yuag lub zog, rov ua dua tshiab, thiab cov txheej txheem tsim khoom siab heev tsav kev tsim kho tshiab hauv tsheb thiab dhau mus. Thaum koj ntsib cov kev sib tw hauv kev tswj xyuas kom zoo thiab kev ruaj khov, cov khoom siv tshiab thiab cov txheej txheem txhim kho cog lus rau lub neej yav tom ntej zoo rau cam khwb cia txhuas thoob ntiaj teb kev lag luam.

FAQ

Dab tsi ua rau cam khwb cia aluminium yog cov khoom nyiam hauv kev tsim tsheb?

Koj xaivcam khwb cia aluminiumrau nws lub teeb yuag, lub zog, thiab corrosion kuj. Cov khoom no pab koj txhim kho roj efficiency thiab ua tau raws li cov qauv emission nruj.

Tswv yim:Cov tsheb sib dua feem ntau txhais tau tias cov nqi roj qis dua.

Yuav ua li cas cam khwb cia aluminium txhawb cov hom phiaj sustainability?

Koj tau txais txiaj ntsig los ntawm cam khwb cia aluminium lub recyclability. Koj tuaj yeem rov siv cov khoom seem aluminium, uas txuag lub zog thiab txo kev cuam tshuam ib puag ncig.

- ♻️ Recycling aluminium siv li 95% tsawg zog dua li tsim cov hlau tshiab.

Koj puas tuaj yeem siv cam khwb cia aluminium rau high-precision industrial qhov chaw?

Koj ua tiavsiab precisionnrog kev tuag casting thiab CNC machining. Cov txheej txheem no tso cai rau koj los tsim cov duab nyuaj nrog nruj kam rau ua thiab zoo ib yam.

Post lub sij hawm: Aug-05-2025