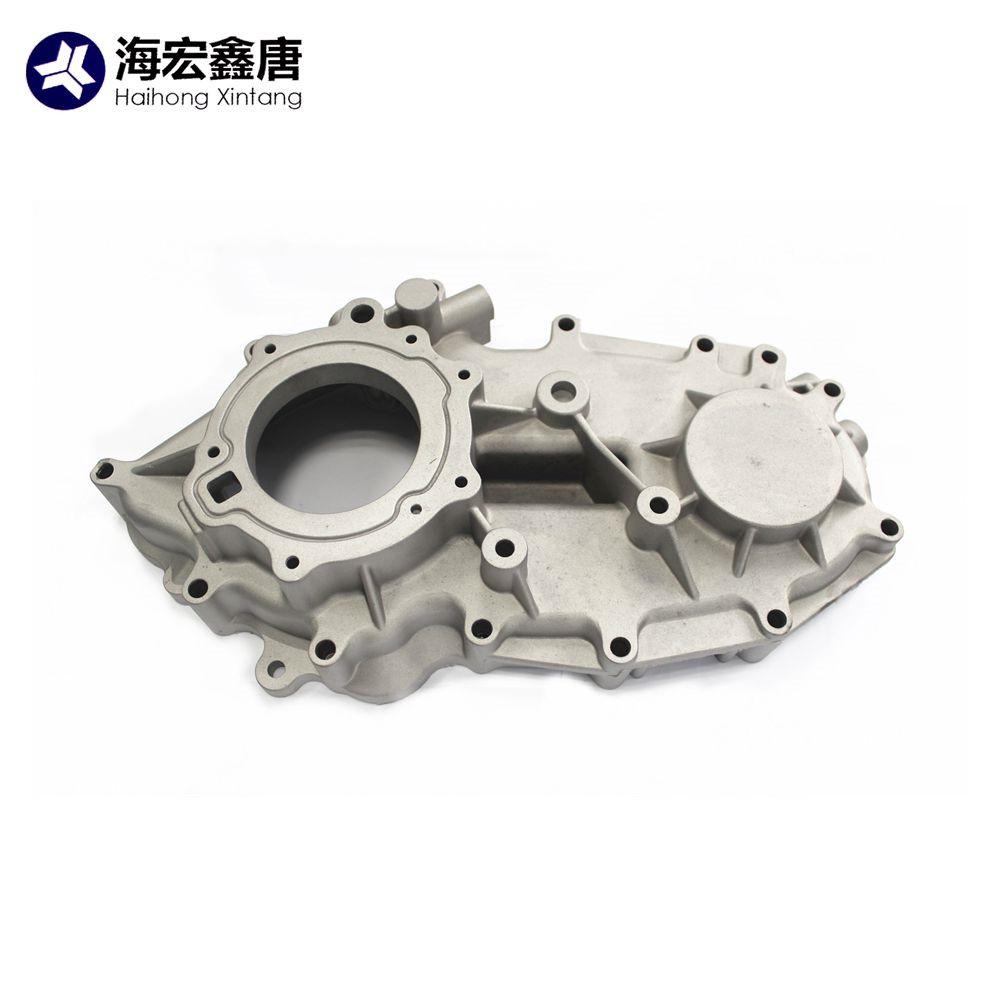

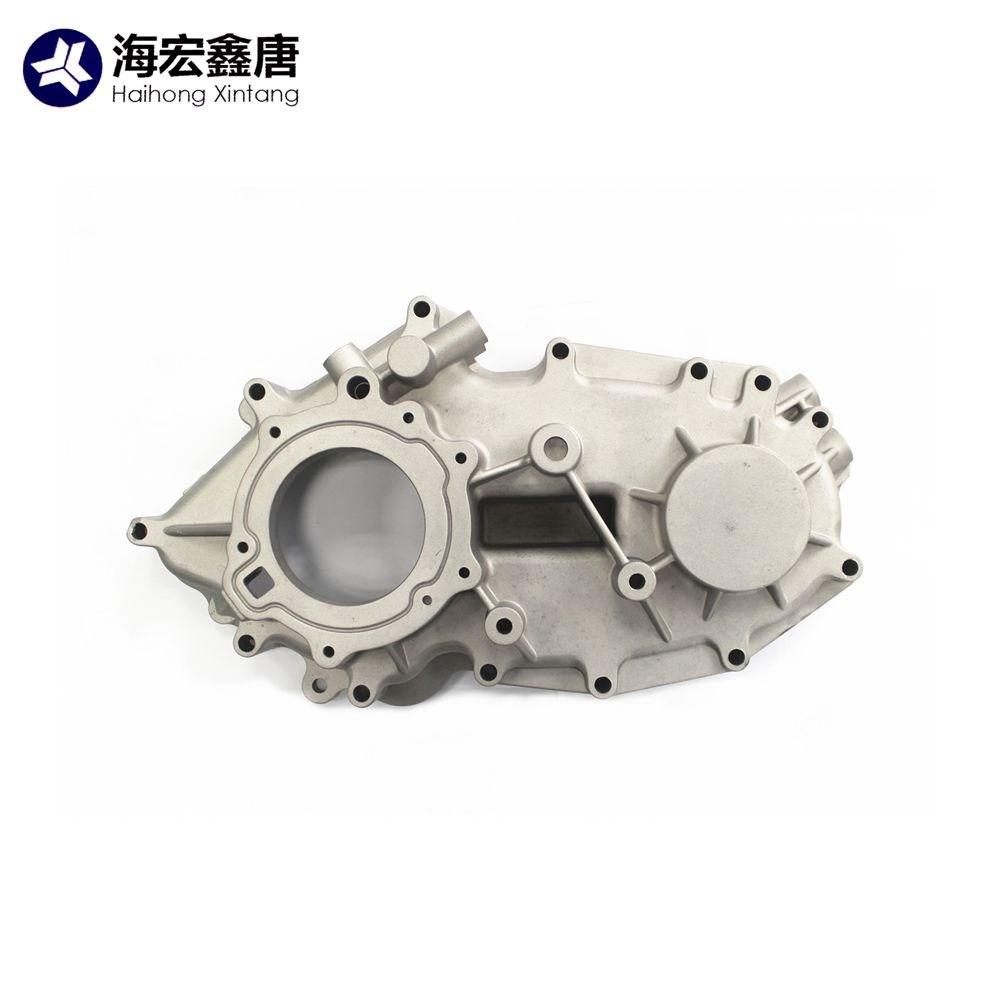

Iibhokisi ze-aluminiyam ezichanekileyo zokuphosa izindlukhokela imarike ngo-2025. Iinjineli zikhetha ezi zindlu ngenxa yamandla azo alula kunye nokuqina okumangalisayo. IUkwenziwa kwe-aluminium ephezulu echanekileyoinkqubo ivumela abavelisi ukuba benze iindawo ezihambelana neemfuno ngqo.Iibhokisi ze-Aluminiyam zokuphosa izindlukananjalo ukuxhathisa umhlwa, nto leyo ebanceda ukuba bahlale ixesha elide kwiimeko ezinzima. Amashishini amaninzi axabisa ezi mpawu kuba afuna izisombululo ezithembekileyo nezingabizi kakhulu.

Izinto eziphambili zokuThatha

- Izindlu zebhokisi ze-aluminiyam ezichanekileyo zidibanisa ubunzima obulula kunyeukuqina olomeleleyo, ukuphucula isantya sesithuthi kunye nokusebenza kakuhle kwamafutha.

- Ezi zindlu zixhathisa umhlwa kakuhle, nto leyo eyandisa ubomi bazo kwaye ithobe iindleko zokuyilungisa kwindawo enzima.

- Iindlela zokuvelisa eziphucukileyoqinisekisa ubungakanani obuchanekileyo kunye nezakhiwo ezizinzileyo, ezikhokelela ekusebenzeni kakuhle kwegiya kunye neziphene ezimbalwa.

- Uyilo oluqhelekileyo kunye nokukhetha kwezinto eziphathekayo zivumela ukulingana ngokugqibeleleyo kumashishini ahlukeneyo, ukunciphisa ixesha lokuhlanganisa kunye neemfuno zokulungisa.

- Ukusebenzisa ezi zindlu konga imali ngokuhamba kwexesha ngokunciphisa iindleko zokuthumela ngenqanawa, ukunciphisa inkcitho, kunye nokunciphisa ixesha lokunciphisa umatshini.

Izinto eziNzuzo zokuSebenza eziPhambili ze-Precision Aluminium yokuCasa iiBhokisi zeZindlu

Amandla aKhala okuBanga izicelo

Iibhokisi ze-aluminiyam ezichanekileyo zokuphosa izindlu zibonelela ngokudityaniswa kokukhanya kunye namandla. Iinjineli zikhetha ezi zindlu zeenqwelo-mafutha kunye noomatshini abafuna ukuhamba ngokukhawuleza okanye ukuthwala imithwalo enzima. I-aluminium alloys, njenge-ADC12 kunye ne-A380, inika amandla aphezulu ngelixa igcina ubunzima obuphantsi. Olu phawu lunceda iimoto ezifana neToyota Corolla kunye ne-Audi R8 ziphumeze ukusebenza kakuhle kwamafutha kunye nokukhawuleziswa kwesantya.

Ingcebiso: Izindlu zeebhokisi zegiya ezikhaphukhaphu zinciphisa ubunzima bubonke besithuthi. Olu tshintsho lunokuphucula zombini isantya kunye nokonga amandla.

Abavelisi abafana nokusetyenziswa kwe-HHXTiindlela zokusakha eziphambiliukwenza iidizayini ezinodonga olucekethekileyo ngaphandle kokuncama ukuqina. Ezi zindlu zijongana neemeko ezinzima kwiimoto, i-aerospace, kunye ne-industrial setting. Isiphumo siyimveliso exhasa ukusebenza okuphezulu kwiindawo ezifunayo.

Ukunyangwa kokuNgqwesa okuPhezulu

I-aluminiyam imelana nomhlwa kunye nomhlwa ngcono kakhulu kunezinye iintsimbi ezininzi. Iibhokisi zezixhobo ze-aluminiyam ezichanekileyo zihlala ixesha elide ngenxa yokuba aziqhekeki ngokulula xa zibekwe emanzini, ityuwa, okanye iikhemikhali. Le ndawo ibenza balungele iimoto, iilori, kunye noomatshini abasebenza ngaphandle okanye kwiimeko zemozulu ezinzima.

Unyango olungaphezulu, olufana ne-anodizing kunye ne-powder coating, yongeza ukhuseleko olongezelelweyo. I-HHXT ibonelela ngeendlela ezininzi zokugqiba ukuhlangabezana neemfuno ezahlukeneyo. Olu nyango lunceda indawo yokuhlala yebhokisi yegiya igcine inkangeleko yayo kunye nokusebenza kwayo ngokuhamba kwexesha.

- Iingenelo zokuxhathisa umhlwa:

- Ubomi obude benkonzo

- Iindleko zokulungisa ezisezantsi

- Ukusebenza okuthembekileyo kwiindawo ezinzima

Ukuchaneka koMda oPhezulu kunye nokuzinza

Iibhokisi ze-aluminiyam ezichanekileyo zokuphosa izindlu zihambisa iimilo kunye nobukhulu obuchanekileyo. Abavelisi basebenzisa i-high-pressure die casting kunye ne-CNC machining ukufezekisa ukunyamezela okuqinileyo. Le nkqubo iqinisekisa ukuba indlu nganye ihambelana ngokugqibeleleyo namanye amacandelo kwinkqubo yegiya.

Imilinganiselo echanekileyo ithetha ukungcangcazela okuncinci kunye nengxolo ngexesha lokusebenza. Indlu yebhokisi yegiya ihlala izinzile naphantsi kwemithwalo enzima okanye isantya esiphezulu. I-HHXT ijonga imveliso nganye ngohlolo olungqongqo ukuqinisekisa umgangatho kunye nokungaguquguquki.

| Uphawu | Inzuzo |

|---|---|

| Ukunyamezela okuqinileyo | Ukusebenza kwesixhobo esigudileyo |

| Ulwakhiwo oluzinzileyo | Ukuguga okuncinci |

| Umgangatho ohambelanayo | Iziphene ezimbalwa kunye nokusilela |

Ezi zibonelelo zenza ukuchaneka kwe-aluminiyam yokuphosa iibhokisi zegiya zezindlu zibe lukhetho oluphezulu kumashishini afuna ukuthembeka kunye nokuchaneka.

Iindleko-zokusebenza kunye neXabiso leXesha elide

Abavelisi kunye neenjineli zijonga izisombululo ezonga imali kwaye zihlala ixesha elide. Iibhokisi ze-aluminiyam ezichanekileyo zokuphosa iibhokisi zezindlu zibonelela zombini. Ezi zindlu zisebenzisa izinto ezincinci kuba i-aluminiyam ilula kodwa yomelele. Olu phawu luthoba iindleko zokuthumela ngenqanawa kwaye lwenza ukuphatha lula kwimizi-mveliso.

Isebenzisa iHHXTiindlela zokusalwa eziphambili kunye noomatshini. Ezi ndlela zinciphisa inkunkuma kwaye ziphucula ukusebenza kakuhle. Iinkampani akufuneki ukuba zichithe imali eyongezelelweyo ekulungiseni okanye ekutshintsheni ngenxa yokuba izindlu zixhathisa ukubola kunye nokuguga. Ubomi benkonzo ende buthetha ukonakaliswa okumbalwa kunye nexesha elincinci lokungasebenzi koomatshini.

Qaphela: Ukukhetha indlu ezinzileyo kunceda iinkampani ziphephe iindleko ezingalindelekanga kwixesha elizayo.

Amashishini amaninzi abona ixabiso kwisakhono sokwenza ngokwezifiso izindlu zebhokisi yegiya. I-HHXT ibonelela ngeenkonzo ze-OEM kunye ne-ODM. Abathengi banokuodola izindlu ezihambelana neemfuno zabo. Oku kuguquguquka kunciphisa imfuno yamalungu angaphezulu okanye ukulungiswa ngexesha lokuhlanganisana.

Itheyibhile yokuthelekisa ibonisa iindlela eziphambili ezi zindlu zonga imali:

| Uphawu | Ixabiso leNzuzo |

|---|---|

| Izinto ezilula | Iindleko zokuthumela ezisezantsi |

| Ukumelana nomhlwa okuphezulu | Kufuneka ukutshintshwa okumbalwa |

| Ukwenziwa ngokuchanekileyo | Inkunkuma encinci, iziphene ezimbalwa |

| Iinketho zokwenza ngokwezifiso | Akukho kufakwa kongezelelweyo okufunekayo |

| Ubomi benkonzo ende | Iindleko zolondolozo ezicuthiweyo |

Iinkampani ezenza utyalo-mali kwi-aluminiyam echanekileyo yokuphosa iibhokisi zezindlu zifumana ixabiso lexesha elide. Bachitha imali encinci ekulungiseni nasekutshintsheni. Oomatshini babo basebenza kakuhle kangangeminyaka. Olu tyalo-mali luhlakaniphile luxhasa ukukhula kwaye lugcina ukusebenza kakuhle.

IiNkqubo zoMveliso eziNqobileyo zoKuchaneka kweAluminiyam yokuCasa iiBhokisi zeZindlu

Uxinzelelo oluphezulu lweTekhnoloji yokuCasa iDie

Ukuphoswa koxinzelelo oluphezulu kume njengeyona ndlela iphambili yokwenza izindlu zebhokisi yegiya. Le nkqubo isebenzisa oomatshini abomeleleyo ukunyanzela i-aluminiyam etyhidiweyo ibe ngundo lwentsimbi. Iimbumba zibumba isinyithi ngokuchaneka okukhulu. Iinkampani ezifanaHHXTsebenzisa obu buchwepheshe ukwenza iindawo ezinomphezulu ogudileyo kunye nobukhulu obuchanekileyo. Inkqubo isebenza ngokukhawuleza kwaye ivelisa iindawo ezininzi ngexesha elifutshane. Abasebenzi banokwenza iindonga ezibhityileyo kunye neemilo ezintsonkothileyo ezifanele izithuthi zale mihla. I-high-pressure die casting ikwanceda ukunciphisa inkunkuma kuba isebenzisa isixa esifanelekileyo semathiriyeli.

Ulawulo loMgangatho olungqongqo kunye neSiqinisekiso

Ulawulo lomgangatho ludlala indima ephambili ekuqinisekiseni ukuba indlu nganye yebhokisi yegiya ihlangabezana nemigangatho ephezulu. I-HHXT ijonga yonke imveliso kumanyathelo amaninzi ngexesha lemveliso. Abahloli bajonga iintanda, iimpazamo zobungakanani, okanye ezinye iingxaki. Basebenzisa izixhobo ezikhethekileyo ukulinganisa inxalenye nganye. Inkampani ilandela imithetho engqongqo ebekwe yi-ISO9001: 2008 kunye ne-IATF16949. Ezi ziqinisekiso zibonisa ukuba umzi-mveliso uyahlangabezana nemigangatho yehlabathi yomgangatho nokhuseleko. Abathengi bathemba iimveliso eziphumelele ezi mvavanyo kuba bayazi ukuba iindawo ziya kusebenza kakuhle koomatshini babo.

Ingcebiso: Iimveliso eziqinisekisiweyo zihlala ixesha elide kwaye zisebenza ngcono kwiimeko ezinzima.

Uyilo lokuguquguquka kunye nokwenza ngokwezifiso

Abavelisi banokutshintsha uyilo lwe-aluminiyam echanekileyo yokuphosa iibhokisi zezindlu ukuze zilungele iimfuno ezininzi. Basebenzisa imizobo yekhompyuter kunye noomatshini abaphambili ukwenza iimilo kunye nobukhulu obuqhelekileyo. I-HHXT ibonelela ngeenkonzo ze-OEM kunye ne-ODM. Abathengi banokuthumela uyilo lwabo okanye iisampuli. Umzi-mveliso ke udala izindlu zeebhokisi zegiya ezihambelana nezi zicelo. Oku bhetyebhetye kunceda abenzi beemoto kunye namanye amashishini afumane iindawo ezilungele ngokugqibeleleyo. Ukwenza ngokwezifiso kukwathetha ukuba iinkampani akufuneki zenze utshintsho olongezelelweyo ngexesha lendibano.

- Izibonelelo zokwenza ngokwezifiso:

- Ilungele iprojekthi nganye

- Amaxesha okudibanisa akhawulezayo

- Iimpazamo ezimbalwa ngexesha lofakelo

AmaBanga oMathiriyeli aSetyenziselwe kwi-Precision Aluminium yokuCasa iiBhokisi zeZindlu

Iingxube zeAluminiyam eziqhelekileyo kunye neePropati zazo

Abavelisi bakhetha ii-alloys ezithile ze-aluminiyam kwizindlu zeebhokisi zegiya kuba i-alloy nganye ibonelela ngeenzuzo ezizodwa. I-ADC1, i-ADC12, i-A380, kunye ne-AlSi9Cu3 zezinye zezona zikhethwa kakhulu. Ezi alloys zidibanisa amandla, ubunzima obulula, kunye nokumelana nokubola.

- ADC1: Le alloy inika i-castability elungileyo kunye nokuchasana okuphezulu kwi-corrosion. Isebenza kakuhle kwiindawo apho ukufuma okanye iikhemikhali zikhona.

- ADC12: Iinkampani ezininzi zeemoto zisebenzisa i-ADC12. Inika amandla abalaseleyo omatshini kunye ne-thermal conductivity entle. Le alloy iyamelana nokunxiba, okunceda ukuba iibhokisi zegiya zihlale ixesha elide.

- A380: I-A380 ibalasele ngolungelelwano lwamandla kunye nolwelo. Ivumela imilo enzima kunye neendonga ezincinci. Le alloy ikwagcina amandla ayo kumaqondo obushushu aphezulu.

- AlSi9Cu3: Le alloy iqukethe i-silicon kunye nobhedu. Inika amandla aphezulu kunye nokusebenza kakuhle. I-AlSi9Cu3 ikwabonelela ngokugqitywa komphezulu ogudileyo emva kokuphosa.

Ingcebiso: I-alloy echanekileyo inokuphucula ukusebenza kunye nobomi bebhokisi yebhokisi yezindlu.

UKhetho lweMathiriyeli eYodwa

Iinjineli zikhetha i-alloys ngokusekelwe kwiimfuno zesicelo ngasinye. Umzekelo, iibhokisi zegiya zeemoto zihlala zifuna izinto ezibamba uxinzelelo oluphezulu kunye nokusetyenziswa rhoqo. I-ADC12 kunye ne-A380 zihambelana nezi mfuno kuba zidibanisa ukuqina kunye nobunzima obulula. Usetyenziso lwe-aerospace lunokufuna izixhobo ezikhaphukhaphu, ke iinjineli zinokukhetha ialloys ezinomxholo ophezulu wesilicon ukomelela okongeziweyo kunye nobunzima obuncitshisiweyo.

Oomatshini bemizi-mveliso ngamanye amaxesha basebenza kwiimeko ezinzima. Kwezi meko, ii-alloys ezifana ne-ADC1 zibonelela ngokuxhathisa okungcono ku-corrosion. Ukukhethwa kwe-alloy kuchaphazela indlela indlu yebhokisi yegiya isebenza ngayo ngexesha. Iinkampani ezinjengeHHXT zinceda abathengi ukuba bakhethe ezona zixhobo zibalaseleyo kwiprojekthi yabo ethile.

Itheyibhile elula ibonisa indlela ii-alloys ezahlukeneyo ezidibana ngayo neemfuno ezahlukeneyo:

| Ingxubevange | Engcono Kwi | UNcedo oluPhambili |

|---|---|---|

| ADC1 | Iimeko-bume ezonakalisayo | Ukumelana nomhlwa okuphezulu |

| ADC12 | Iibhokisi zezixhobo zeemoto | Amandla kunye nokuqina |

| A380 | Iimilo ezintsonkothileyo | Ulwelo kunye namandla |

| AlSi9Cu3 | Amalungu achanekileyo | Ubuchule kunye nokugqiba |

Ukukhetha i-alloy efanelekileyo iqinisekisa ukuba indlu yebhokisi yebhokisi ihlangabezana nazo zonke iimfuno zokusebenza kunye nokhuseleko.

Usetyenziso lweLizwe lokwenyani lwe-Precision Aluminium yokuCasa iiBhokisi zeZindlu

Amabali eMpumelelo yoShishino lweemoto

Iinkampani zeemoto zixhomekeke kwinkqubela phambiliizindlu zebhokisi yegiyaukuphucula ukusebenza kwesithuthi. Iimveliso ezifana neToyota kunye ne-Audi zisebenzisa iindawo ze-aluminium ezichanekileyo eziphezulu kwiimodeli ezidumileyo ezifana ne-Corolla, i-R8, i-Q7, kunye ne-TT. Ezi zindlu zinceda iimoto zihambe kakuhle kwaye zihlale ixesha elide. Iinjineli zikhetha i-aluminiyam kuba igcina izithuthi zikhaphukhaphu kwaye zomelele. Iimoto ezikhaphukhaphu zisebenzisa amafutha amancinci kwaye zihamba ngokukhawuleza. I-HHXT ibonelela ngezindlu zebhokisi zegiya ezilungele iimodeli zemoto. Le ndlela inceda abenzi beemoto ukuhlangabezana nokhuseleko olungqongqo kunye nemigangatho yomgangatho.

Qaphela: Izindlu ezilungelelanisiweyo zinciphisa umngcipheko wokungaphumeleli kwenxalenye kwaye zenza ukulungiswa kube lula kubakhandi.

I-Aerospace kunye ne-High-Performance Sectors

Ishishini le-aerospace lifuna iindawo ezinokumelana neemeko ezinzima. Iinqwelomoya zifuna izindlu zebhokisi zegiya ezimelana nomhlwa kwaye zihlale zizinzile kwizantya eziphezulu.Iingxube zeAluminiyam, njengezo zisetyenziswa yi-HHXT, zibonelela ngomxube ochanekileyo wamandla kunye nokukhanya. Iinjineli ziyila ezi zindlu ukuze zilingane iindawo ezixineneyo kwiinqwelomoya nakwiihelikopta. Ukuphosa okuchanekileyo kuvumela iimilo ezinzima ezigcina indawo kunye nobunzima. Le teknoloji inceda iinqwelomoya ukuba zibhabhele kude kwaye zisebenzise amafutha amancinci.

Itheyibhile ibonisa ezinye iinzuzo eziphambili kwi-aerospace:

| Uphawu | Inzuzo |

|---|---|

| Ikhaphukhaphu | Ukonga amafutha angcono |

| Ii-alloys ezinamandla | Ukuphuculwa kokhuseleko |

| Uyilo oluqhelekileyo | Ilingana neendawo ezizodwa |

Oomatshini boShishino kunye neZixhobo

Imizi-mveliso neendawo zokusebenzela zisebenzisa oomatshini abasebenza iiyure ezininzi suku ngalunye. Aba matshini badinga izindlu zebhokisi zegiya ezinokuthwala imithwalo enzima kunye nokuhamba rhoqo. Izindlu zeAluminiyam zixhathisa umhlwa kunye nokuguga, nakwiindawo ezinzima. I-HHXT ibonelela ngezisombululo kwiintlobo ezininzi zezixhobo zemizi-mveliso. Ukwenza ngokwezifiso kuvumela iinkampani ukuba ziodole izindlu ezihambelana noomatshini bazo ngokugqibeleleyo. Oku kunciphisa ixesha lokuphumla kwaye igcina imigca yemveliso ihamba.

Icebiso: Ukukhetha indawo efanelekileyo yokuhlala kunceda imizi-mveliso iphephe ukulungiswa okuxabisa imali eninzi nokuchitha ixesha.

Iibhokisi ze-aluminiyam ezichanekileyo zokuphosa iibhokisi zezindlu zikhokelela kwimarike ngo-2025. Amashishini amaninzi akhetha ezi zindlu ngenxa yokusebenza kwazo okuqinileyo kunye nokugcinwa kweendleko. Iindlela zokuvelisa ezikumgangatho ophezulu kunye noluhlu olubanzi lwezixhobo zinceda ukuhlangabezana neemfuno zecandelo lezemoto, i-aerospace, kunye nezoshishino. Iinkampani zifumana ukuqina kwexesha elide kunye nokusebenza kakuhle.

Ukukhetha ezi zindlu kunika amashishini inzuzo yokwenene kwihlabathi lanamhlanje elinokhuphiswano.

FAQ

Yintoni eyenza ukuba izindlu zebhokisi ze-aluminiyam zidume ngo-2025?

Izindlu zebhokisi zeAluminiyam zinika amandla, ubunzima obukhanyayo, kunye nokuxhathisa umhlwa. Amashishini amaninzi azikhethela ukuhlala kwawo kunye nokonga imali. Iinkampani ezifanaHHXTsebenzisa itekhnoloji ephezulu ukwenza iindawo ezichanekileyo nezithembekileyo.

Ngawaphi amashishini asebenzisa izindlu zebhokisi ze-aluminiyam ezichanekileyo?

Amacandelo eemoto, i-aerospace, kunye noomatshini boshishino asebenzisa ezi zindlu. Abenzi beemoto ezifana neToyota kunye ne-Audi bathembele kubo ngokusebenza nokusebenza kakuhle. Iifektri kunye nocweyo nazo ziyaxhamla kumgangatho wazo ohlala ixesha elide.

I-HHXT iqinisekisa njani umgangatho wemveliso?

I-HHXT yenza uhlolo olungaphezulu kwesithandathu kwindlu nganye. Inkampani ilandela i-ISO9001: 2008 kunye nemigangatho ye-IATF16949. La manyathelo aqinisekisa ukuba yonke imveliso ihlangabezana neemfuno ezingqongqo zomgangatho.

Ngaba abathengi banokucela uyilo okanye ubungakanani besiko?

Ewe! Abathengi banokuthumela i-2D okanye i-3D imizobo okanye iisampuli. I-HHXT inikezelaIinkonzo ze-OEM kunye ne-ODM. Iqela lenza izindlu zeebhokisi zegiya ezihambelana neemfuno ezichanekileyo, ziqinisekisa ukufaneleka ngokufanelekileyo kwiprojekthi nganye.

Ixesha lokuposa: Jun-12-2025