You see cast aluminum everywhere, from telecommunication equipment to machine tools. More manufacturers choose this material every year because it is strong, light, and reliable. Just look at the numbers:

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 108.45 |

| 2033 | 159.78 |

Key Takeaways

- Cast aluminum is lightweight yet strong, making it ideal for automotive and aerospace applications. This helps improve fuel efficiency and performance.

- The natural oxide layer on cast aluminum provides excellent corrosion resistance, reducing maintenance costs and extending the lifespan of parts in harsh environments.

- Cast aluminum is cost-effective, as it lowers production costs and energy use while allowing for complex shapes and designs, making it versatile for many industries.

Key Benefits of Cast Aluminum

Lightweight and High Strength

You want parts that are strong but don’t weigh you down. Cast Aluminum gives you both. Its low density means you get lightweight components that still hold up under stress. This is a huge advantage in automotive and aerospace industries. When you reduce weight, you boost fuel efficiency and performance. The Wright Brothers knew this when they built their first airplane. They cast their engine block from an aluminum and copper alloy because they needed something light and tough. Today, you see the same principle in modern cars and planes.

Tip: Lighter vehicles use less fuel and move faster, saving you money and time.

Corrosion Resistance

If you work in harsh environments, you need materials that last. Cast Aluminum forms a natural oxide layer when exposed to air. This layer protects it from rust and corrosion. You don’t have to worry about constant maintenance like you do with cast iron, which rusts easily in moist conditions. Cast Aluminum stands up to outdoor and marine environments, making it a favorite for parts that face the elements. You save on long-term costs because you don’t need extra coatings or frequent repairs.

| Material | Corrosion Resistance | Maintenance Needs |

|---|---|---|

| Cast Aluminum | Excellent | Low |

| Cast Iron | Poor | High |

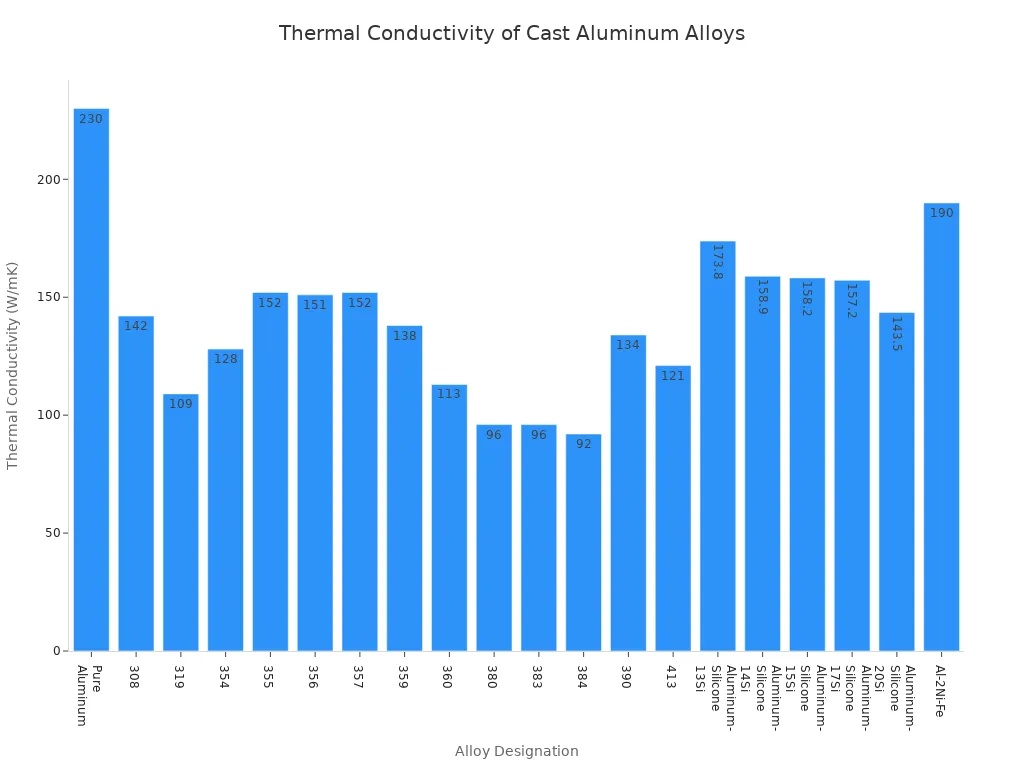

Thermal and Electrical Conductivity

You need materials that handle heat and electricity well. Cast Aluminum does both. It’s used in engine parts, electronics, and heat sinks because it moves heat away quickly. This keeps your equipment running cool and safe. Check out the thermal conductivity values for different aluminum alloys:

| Alloy Designation | General Composition | Thermal Conductivity (W/mK) |

|---|---|---|

| Pure Aluminum | 97% – 99.9% Al | 230 |

| 308 | Al – 5.5Si – 4.5Cu | 142 |

| 319 | Al – 6Si – 3.5Cu | 109 |

| 356 | Al – 7Si – 0.3Mg | 151 |

| 357 | Al – 7Si – 0.5Mg | 152 |

| 413 | Al – 12Si | 121 |

Cost-Effectiveness

You want to keep costs down without sacrificing quality. Cast Aluminum helps you do that. Bronze costs five to ten times more than aluminum. Aluminum usually makes up 40-60% of total casting costs, while iron is only 10-25%. But aluminum’s efficiency and lower maintenance needs mean you save money over time. Additive manufacturing with aluminum cuts production cycle time by about 19%, lowers processing costs by 93%, and reduces energy use by 70%. You also see a drop in carbon emissions by 71%.

- Bronze is much more expensive than aluminum.

- Aluminum casting is efficient and cost-effective.

- You save on energy and production costs.

Versatility and Workability

You want parts that fit your exact needs. Cast Aluminum lets you create complex shapes and detailed textures. You can melt it and pour it into molds for intricate designs. Die casting, permanent mold casting, and sand casting give you options for different applications. Designers love the creative freedom. You get both functional and good-looking parts. Common uses include engine parts, aerospace components, and consumer goods.

- Cast Aluminum is great for making complex shapes.

- Die casting produces high-volume, tight-tolerance parts.

- You can use it for everything from car engines to electronics.

| Characteristic | Impact on Manufacturing Lead Times and Efficiency |

|---|---|

| High fluidity | Faster mold filling, shorter cycle times |

| Excellent casting characteristics | Fewer defects, quicker production |

| Ability to produce complex shapes | Streamlined production, fewer processes |

| High dimensional accuracy | Parts fit right, less assembly time |

Environmental Sustainability

You care about the planet. Cast Aluminum supports sustainability goals. Recycling aluminum uses less than 5% of the energy needed for new production. Globally, 76% of aluminum scrap gets recycled. In 2018, 32% of all aluminum produced came from recycled materials. About 75% of all aluminum ever made is still in use today. This supports a circular economy and helps reduce carbon footprints.

| Aspect | Details |

|---|---|

| Energy Savings | Recycling uses less than 5% of the energy of new production |

| Recycling Efficiency Rate | 76% recovery rate of aluminum scrap |

| Circular Economy | 75% of aluminum ever produced is still in use |

| Carbon Reduction | Recycling supports global sustainability targets |

Note: Recycling cast aluminum is key for conserving resources and protecting the environment.

Cast Aluminum in Automotive and Industrial Applications

Automotive Components

You see cast aluminum in almost every modern car. Automakers use it because it makes vehicles lighter and more efficient. When you swap out heavier metals for cast aluminum, you get better fuel economy and lower emissions. Here are some key parts made with this material:

- Engine blocks

- Transmission housings

- Body panels

- Radiators

- Wheels

- Chassis structures

| Component | Performance Benefits |

|---|---|

| Engine blocks | High precision, cost-effectiveness, and mass production capabilities |

| Transmission housings | Lightweight, enhancing overall vehicle performance and fuel efficiency |

| Body panels | Excellent structural rigidity, corrosion resistance, and weight savings |

| Radiators | Superior heat dissipation, durability, and reduced weight |

| Wheels | Corrosion-resistant, lighter, improving fuel efficiency and vehicle handling |

| Chassis structures | Enhanced rigidity and crashworthiness, significantly reducing vehicle mass |

Did you know? The rise of electric vehicles means even more cast aluminum goes into battery housings and motor parts, helping you drive farther on a single charge.

Industrial Machinery

You find cast aluminum in many types of industrial machinery. Manufacturers choose it for its lightweight nature, corrosion resistance, and thermal conductivity. These qualities help machines run longer and more efficiently. Here’s a quick look:

| Machinery Type | Advantages of Cast Aluminum |

|---|---|

| Automotive | Lightweight, fuel efficiency |

| Aerospace | Corrosion resistance, thermal conductivity |

| Heavy Machinery | Cost-effectiveness, versatility in manufacturing |

- Lighter than steel, so machines use less energy.

- Less expensive to cast than titanium.

- Reduces stress on supporting frames.

Tip: Cast aluminum parts often last longer and need less maintenance, saving you time and money.

Broader Industry Uses

You also see cast aluminum in many other industries. It shows up in packaging machinery, medical devices, food processing equipment, and even sports gear. This material adapts to almost any need.

| Industry | Notable Applications |

|---|---|

| Packaging Machinery | Custom aluminum casted parts for machinery |

| Pharmaceutical Machinery | Equipment for drug manufacturing |

| Medical | Medical equipment and devices |

| Food Processing Equipment | Machinery for food production |

| Plastics Industry | Equipment for plastic manufacturing |

| Healthcare Industry | Specialized medical equipment |

| Material Handling Equipment | Equipment for logistics and storage |

| Tele-Communications Industry | Machinery for communication technologies |

| Sporting and Recreational Equipment | Equipment for sports and recreation |

Cast aluminum helps you get reliable, high-performance parts across many fields, from healthcare to sports.

You see why Cast Aluminum stands out in leading industries. It gives you strength, lightness, and durability. Take a look at these key attributes:

| Attribute | Description |

|---|---|

| Strength-to-Weight Ratio | High ratio means you get tough parts without extra weight. |

| Resistance to Corrosion | Natural oxide coat keeps your equipment safe in harsh conditions. |

| Thermal Conductivity | Moves heat fast, protecting electronics and machinery. |

Manufacturers keep choosing Cast Aluminum because new trends—like smart manufacturing and advanced recycling—make it even better for your future needs.

FAQ

What makes cast aluminum better for automotive parts?

You get lighter, stronger parts that improve fuel efficiency. Cast aluminum resists corrosion, so your car lasts longer with less maintenance.

Can you recycle cast aluminum easily?

Yes! You can recycle cast aluminum many times. Recycling uses less energy and helps protect the environment. ♻️

Where do you see cast aluminum outside of cars?

You find cast aluminum in electronics, medical devices, and sports equipment. It works well in many industries because it’s versatile and durable.

Post time: Aug-31-2025