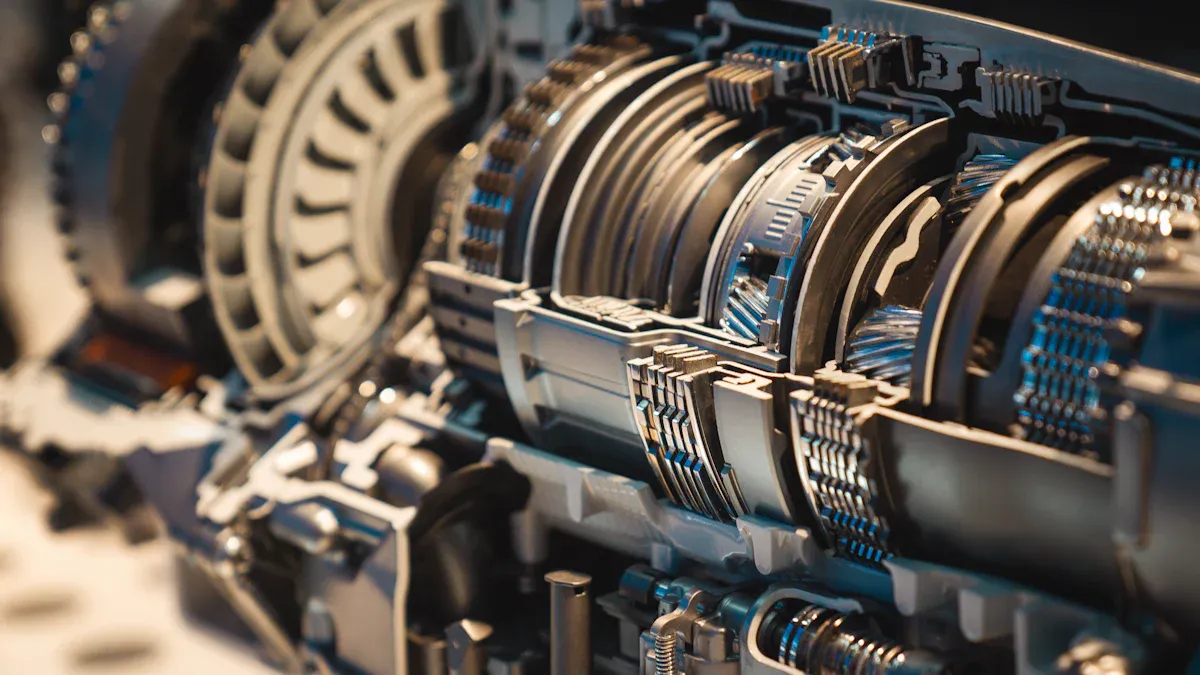

Industries in 2025 favor aluminum casting gear box solutions for their unique blend of properties. Aluminum casting gear boxes housing offers lightweight strength and durability. Customized high precision aluminum casting enables tight tolerances and consistent quality. Manufacturers choose these housings for their ability to handle demanding environments while supporting efficient, sustainable operations.

Key Takeaways

- Aluminum casting gear box housings are lightweight yet strong, improving efficiency and making machines easier to handle and maintain.

- These housings fit many industries, including automotive and heavy machinery, thanks to their flexible designs and high precision.

- Aluminum resists corrosion and harsh conditions, which helps gear boxes last longer and reduces maintenance needs.

- The material’s excellent heat management keeps gear boxes cool, improving performance and preventing costly overheating.

- Using aluminum supports sustainability by enabling recycling, lowering energy use, and cutting costs in manufacturing.

Lightweight and Versatility of Aluminum Casting Gear Box Housings

Reduced Weight for Enhanced Efficiency

Aluminum casting gear box housings offer a significant reduction in weight compared to traditional steel alternatives. This lighter design helps vehicles and machinery operate more efficiently. Engineers often select aluminum for its high strength-to-weight ratio. Lighter gear box housings reduce the overall mass of a system. This leads to better fuel economy in vehicles and lower energy consumption in industrial equipment.

Lighter components also make assembly and maintenance easier. Workers can handle and install aluminum casting gear box housings with less effort, which reduces the risk of injury and speeds up production lines.

Versatility Across Automotive and Industrial Applications

Manufacturers value the flexibility of aluminum casting gear box housings. These housings adapt to a wide range of shapes and sizes. Engineers can design complex geometries that fit specific requirements. This versatility supports use in both automotive and industrial sectors.

- In the automotive industry, aluminum casting gear box housings fit passenger cars, trucks, and commercial vehicles.

- In industrial settings, these housings support heavy machinery, robotics, and conveyor systems.

A table below highlights some common applications:

| Sector | Example Applications |

|---|---|

| Automotive | Passenger cars, trucks, EVs |

| Industrial | Robotics, conveyors, heavy machines |

This adaptability allows companies to standardize materials while customizing designs for each project.

Performance Benefits in Electric and Hybrid Vehicles

Electric and hybrid vehicles demand lightweight and efficient components. Aluminum casting gear box housings meet these needs by reducing vehicle weight and improving energy efficiency. Lower weight means electric motors require less power to move the vehicle. This extends battery life and increases driving range.

Aluminum also helps manage heat generated by electric drivetrains. Efficient heat dissipation protects sensitive components and maintains optimal performance. As a result, automakers rely on aluminum casting gear box housings to achieve the best balance of strength, weight, and thermal management.

Tip: Choosing aluminum casting gear box housings can help manufacturers meet strict emissions and efficiency standards in 2025.

Strength and Durability in Aluminum Casting Gear Box Housings

High Strength-to-Weight Ratio

Aluminum casting gear box housings deliver impressive strength while keeping weight low. Engineers select aluminum alloys for their ability to withstand heavy loads without adding unnecessary mass. This high strength-to-weight ratio supports both performance and safety. Vehicles and machines benefit from strong housings that do not slow down operation. Many industries trust aluminum casting gear box housings to protect internal components from impact and vibration.

Note: A high strength-to-weight ratio means manufacturers can design compact gear boxes that still meet strict durability standards.

Reliable Operation in Demanding Environments

Aluminum casting gear box housings perform well in harsh conditions. These housings resist damage from shock, pressure, and temperature changes. Operators rely on them in factories, construction sites, and off-road vehicles. The material’s natural toughness helps prevent cracks and deformation. Even when exposed to dust, moisture, or chemicals, aluminum casting gear box housings maintain their integrity.

- Heavy-duty trucks use these housings for reliable power transmission.

- Industrial robots depend on them for precise movement and long service life.

Longevity and Lower Maintenance Needs

Aluminum casting gear box housings last for many years with minimal upkeep. The material resists wear and tear, so parts do not need frequent replacement. Maintenance teams spend less time and money on repairs. This durability reduces downtime and keeps equipment running smoothly. Companies see lower total costs over the lifespan of their machines.

Tip: Choosing durable housings can help businesses avoid unexpected breakdowns and extend the life of their investments.

Corrosion Resistance of Aluminum Casting Gear Box Housings

Protection in Harsh Conditions

Aluminum casting gear box housings provide strong protection against corrosion. Engineers often choose aluminum because it forms a natural oxide layer. This layer shields the surface from moisture, salt, and chemicals. Many industries use these housings in places where rain, mud, or road salt can cause damage. For example, trucks and construction equipment face harsh weather every day. Aluminum casting gear box housings help keep these machines running by stopping rust and corrosion before it starts.

Note: The natural oxide layer on aluminum repairs itself if scratched, giving long-lasting protection.

Extended Service Life

Corrosion can shorten the life of metal parts. Aluminum casting gear box housings resist this problem. They last longer than steel housings in wet or salty environments. This means companies do not need to replace parts as often. Longer service life saves money and reduces waste. Many manufacturers see fewer breakdowns and less downtime when they use aluminum casting gear box housings.

- Longer life means fewer repairs.

- Machines stay in service more days each year.

- Companies spend less on replacement parts.

Reduced Risk of Failure

Corrosion weakens metal and can lead to sudden failure. Aluminum casting gear box housings lower this risk. The strong, corrosion-resistant surface keeps the housing solid and safe. Workers trust these housings in critical machines because they know the parts will not fail from rust. This reliability is important in cars, trucks, and factory equipment.

Tip: Choosing corrosion-resistant housings helps protect workers and equipment from unexpected problems.

Thermal Conductivity and Heat Management

Efficient Heat Dissipation

Aluminum casting gear box housings excel at moving heat away from internal components. The material’s high thermal conductivity allows it to transfer heat quickly. This property helps keep gearboxes cool during operation. Engineers often select aluminum for this reason. When a gearbox runs, friction creates heat. Aluminum casting gear box housings pull this heat away from gears and bearings. This process protects sensitive parts from damage.

Note: Efficient heat dissipation can extend the life of lubricants inside the gearbox.

Improved Gearbox Performance

A cooler gearbox works better. Lower temperatures help maintain the strength of the housing and the accuracy of moving parts. Operators notice smoother shifting and less noise. Machines with aluminum casting gear box housings often show higher reliability. The stable temperature inside the housing prevents warping and misalignment. This stability leads to better performance in both vehicles and industrial machines.

- Smoother operation

- Less wear on gears

- Consistent performance over time

Prevention of Overheating

Overheating can cause serious problems in gearboxes. Aluminum casting gear box housings help prevent this issue. The material’s ability to move heat away from hot spots keeps the system safe. Overheated gearboxes may fail or need costly repairs. By using aluminum, manufacturers reduce the risk of breakdowns. Workers trust these housings to keep equipment running even under heavy loads or in hot environments.

Tip: Regular checks on gearbox temperature can help spot problems early and avoid downtime.

Environmental and Cost Advantages of Aluminum Casting Gear Box Housings

Recyclability and Sustainability

Aluminum stands out as one of the most recyclable metals in the world. Manufacturers can melt down used aluminum casting gear box housings and reuse the material without losing quality. This process saves natural resources and reduces waste. Many industries choose aluminum because it supports a circular economy. When companies recycle aluminum, they help protect the environment and lower the demand for new raw materials.

Tip: Recycling aluminum uses much less energy than producing new metal from ore.

Lower Carbon Footprint and Energy Savings

Producing aluminum from recycled sources requires only a fraction of the energy needed for primary production. This energy savings leads to a much lower carbon footprint. Companies that use aluminum casting gear box housings can meet strict environmental standards more easily. Lower energy use also means fewer greenhouse gas emissions. As a result, businesses can show their commitment to sustainability and reduce their impact on the planet.

A quick look at the benefits:

- Less energy used in recycling

- Fewer emissions released

- Easier compliance with green regulations

Cost-Effectiveness and Manufacturing Flexibility

Aluminum casting gear box housings offer strong cost advantages. The casting process allows for high-volume production at a lower cost per unit. Manufacturers can create complex shapes in a single step, which reduces the need for extra machining. This flexibility helps companies respond quickly to changing market needs. Lower material and production costs make aluminum casting gear box housings a smart choice for many industries.

Note: Choosing aluminum can help companies save money while delivering high-quality products.

- Aluminum casting gear box housings offer lightweight strength, durability, and excellent heat management.

- These housings resist corrosion and support sustainable manufacturing.

- Many industries choose them for vehicles and machinery because they lower costs and improve performance.

Aluminum casting gear box housings will remain a top choice as companies focus on efficiency and environmental goals in 2025.

FAQ

What industries use aluminum casting gear box housings in 2025?

Automotive, robotics, and heavy machinery industries use aluminum casting gear box housings. These sectors value lightweight strength, durability, and cost savings. Many manufacturers choose aluminum for both electric vehicles and industrial equipment.

How does aluminum casting improve gearbox performance?

Aluminum casting provides precise shapes and tight tolerances. This accuracy helps gearboxes run smoothly and last longer. The material also manages heat well, which protects internal parts and improves overall performance.

Are aluminum casting gear box housings environmentally friendly?

Yes. Aluminum is highly recyclable. Manufacturers can reuse it many times without losing quality. Recycling aluminum saves energy and reduces waste. Companies that use aluminum help protect the environment and meet sustainability goals.

Can aluminum casting gear box housings handle harsh environments?

Aluminum casting gear box housings resist corrosion, shock, and temperature changes. The natural oxide layer protects against rust. These housings work well in wet, salty, or dirty conditions. Many industries trust them for reliable operation.

What maintenance do aluminum casting gear box housings require?

Aluminum casting gear box housings need little maintenance. The material resists wear and corrosion. Regular checks for damage or overheating help keep gearboxes in good shape. Most companies see fewer repairs and longer service life.

Post time: Jun-15-2025