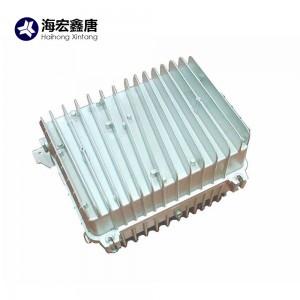

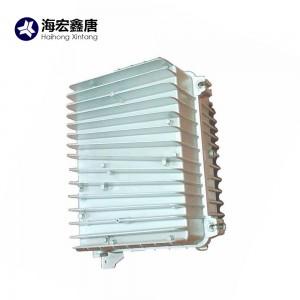

Aluminum die cast electronic spare parts truly excel across various industries. Their durability and lightweight design are impressive, enhancing the performance of modern electrical devices and making them essential for numerous applications. The precision involved in the production of these China high precision aluminum die cast electronic components ensures a perfect fit, which is crucial for reliability. For instance, I’ve observed how these parts withstand harsh environments, thanks to their excellent thermal conductivity and corrosion resistance. It’s fascinating how advancements in technology continue to elevate their quality, particularly from manufacturers like Ningbo Haihong Xintang Mechanical Co., Ltd. in China, known for their commitment to producing high precision aluminum die cast products.

Key Takeaways

- Aluminum die cast electronic spare parts are lightweight and durable, making them essential for enhancing performance in various industries.

- In the automotive sector, these parts improve fuel efficiency and reduce CO2 emissions by replacing heavier materials like steel.

- Aluminum die cast housings protect sensitive electronics in harsh environments, ensuring reliability and longevity in automotive and consumer electronics.

- These components are 100% recyclable, promoting sustainability and reducing waste in manufacturing processes.

- The precision of aluminum die casting allows for complex designs, enhancing the functionality and efficiency of devices across multiple applications.

Aluminum Die Cast Electronic Spare Parts in the Automotive Industry

When I think about the automotive industry, aluminum die cast electronic spare parts come to mind as game-changers. These parts play a crucial role in enhancing vehicle performance and efficiency.

Engine Components

Aluminum die cast engine components are essential for modern vehicles. They offer a lightweight and durable solution that significantly improves fuel efficiency. Here’s why I find them so impressive:

- Aluminum is about one-third the weight of steel, which means lighter vehicles need less energy to accelerate. This directly translates to better fuel economy.

- By replacing traditional steel engine blocks with aluminum, manufacturers can reduce weight by up to 50%. That’s a substantial improvement!

- The die casting process allows for complex shapes and precise dimensions, which is vital for engine performance.

As fuel prices rise and environmental regulations tighten, the demand for lightweight vehicles continues to grow. Using aluminum die cast parts not only helps in reducing CO2 emissions but also enhances overall vehicle performance.

Housing and Enclosures

Now, let’s talk about housing and enclosures. Aluminum die cast housings are widely used in automotive electronics. They provide protection against harsh conditions, which is crucial for the longevity of electronic components. Here are some common types of aluminum die cast housings I’ve come across:

| Type of Housing/Enclosure | Applications | Benefits |

|---|---|---|

| Electronic Covers | General electronic components | Durability, corrosion resistance, effective sealing |

| Engine Control Units | Engine management systems | Protection against vibration and extreme temperatures |

| Sensors | Various automotive sensors | Robustness against impact and harsh conditions |

| Lighting Systems | Automotive lighting | Long-term reliability in harsh environments |

| Infotainment Systems | In-car entertainment systems | Protection against contaminants and damage |

These die-cast aluminum enclosures are designed to withstand the rigors of automotive environments. They protect sensitive electronics from vibration, impact, and extreme temperatures, ensuring reliable operation.

Aluminum Die Cast Electronic Spare Parts in Consumer Electronics

When I think about consumer electronics, aluminum die cast electronic spare parts really stand out. They play a vital role in enhancing the performance and durability of devices we use every day.

Mobile Devices

Aluminum die cast components are essential in mobile devices. They contribute to the overall strength and lightweight design that we all appreciate. I’ve noticed that the remarkable strength-to-weight ratio of aluminum die castings improves performance significantly.

The aluminum alloy die casted components have advantages that other alloys don’t, which are light weight and diverse finishing options. Besides, it also has good performance in resisting high temperature and corrosion.

This means that our smartphones and tablets can be both sleek and sturdy. The high strength of aluminum die castings allows manufacturers to create complex parts that withstand demanding conditions while maintaining their structural integrity. This is crucial for devices that often face drops and impacts.

Home Appliances

Now, let’s shift gears to home appliances. Aluminum die cast electronic spare parts are becoming increasingly popular in this sector. They offer several advantages over plastic or steel alternatives. Here’s a quick look at some of these benefits:

| Advantage | Description |

|---|---|

| Strength | Aluminum die cast parts are much stronger than plastic injection moldings. |

| Durability | These parts are durable and dimensionally stable, providing a quality feel. |

| Production Efficiency | The die casting process allows for high production rates and near net shape. |

| Design Flexibility | Complex shapes can be achieved with thinner walls, enhancing design options. |

| Corrosion Resistance | Aluminum castings have good to high corrosion resistance. |

| Integral Features | Die cast parts can include integral fastening elements, reducing assembly costs. |

I find it fascinating how these components contribute to energy efficiency and product longevity. For instance, in refrigerators, aluminum parts enhance cooling mechanisms and structural integrity. In air conditioners, they improve efficiency in heat exchange components.

| Appliance Type | Contribution to Energy Efficiency and Longevity |

|---|---|

| Refrigerators | Enhances cooling mechanisms and structural integrity. |

| Air Conditioners | Improves efficiency and performance in heat exchange components. |

| Washing Machines | Contributes to durability and overall weight reduction. |

| Ovens and Microwaves | Ensures even heat distribution and withstands high temperatures. |

Aluminum Die Cast Electronic Spare Parts in Industrial Machinery

When I think about industrial machinery, aluminum die cast electronic spare parts really shine, especially in control panels and structural components. These parts enhance the reliability and safety of machinery, which is crucial in demanding environments.

Control Panels

Control panels are the nerve centers of industrial machinery. They house the electronic components that manage operations. I’ve seen firsthand how aluminum die cast parts improve these panels. Here’s why they stand out:

- Timely Support: Having reliable parts ensures seamless operations. This support prolongs the equipment’s lifespan, enhancing overall reliability.

- Safety Assurance: Authentic replacement parts keep equipment running safely. This reduces the risk of failures that could compromise safety.

- Secondary Defense: Safety rope structures act as a backup, preventing equipment from falling and reducing injury risks.

- Performance Boost: Aluminum die cast parts enhance performance and reliability across various industries, including industrial machinery.

These benefits make aluminum die cast electronic spare parts a smart choice for control panels. They not only improve functionality but also ensure that operations run smoothly and safely.

Structural Components

Now, let’s dive into structural components. I find that aluminum die cast parts offer significant advantages in heavy-duty industrial machinery. Here’s a quick look at the benefits:

| Benefit | Description |

|---|---|

| Strength and Durability | Components can withstand high stress and load levels without significant deformation, suitable for demanding applications. |

| Weight Reduction | Components are lightweight, benefiting industries like aircraft and automotive by improving fuel efficiency. |

| Precision and Complexity | Complex shapes can be created with close dimensional control, saving time and money. |

| Material Efficiency | The process consumes little material due to accurate molds, reducing waste and enhancing sustainability. |

| Economical With High Volumes | Fixed molds allow for economical mass production of die cast components. |

I’ve noticed that aluminum die cast structural components withstand harsh industrial environments better than many other materials. They offer a unique combination of strength, lightweight design, and corrosion resistance. Here’s a comparison that highlights their advantages:

| Property | Aluminum Die Cast Components | Other Materials |

|---|---|---|

| Weight | Lightweight | Heavier |

| Strength | Strong and Durable | Varies |

| Corrosion Resistance | High due to protective oxide layer | Lower in many cases |

| Surface Finish | High-quality | Varies |

| Cost-effectiveness | Cost-effective | Often more expensive |

| Environmental Impact | 100% recyclable | Varies |

With these benefits, it’s clear that aluminum die cast electronic spare parts are essential for enhancing the performance and longevity of industrial machinery. They provide the strength and reliability needed to tackle demanding tasks while maintaining efficiency.

Aluminum Die Cast Electronic Spare Parts in Telecommunications

When I think about telecommunications, aluminum die cast electronic spare parts really stand out. They play a vital role in ensuring that our communication devices work efficiently and reliably.

Equipment Housings

Aluminum die cast housings are essential for protecting telecommunications equipment. I’ve seen how these enclosures are crucial for housing devices like routers, switches, and base stations. The rapid expansion of telecommunication infrastructures and the rollout of 5G networks are driving the demand for these reliable enclosures. Here’s why I find them so effective:

- Excellent Thermal Management: Aluminum has high thermal conductivity. This helps transfer heat away from internal components, which is crucial for maintaining the lifespan of electronic devices.

- Integrated Cooling Features: The die casting process allows for complex cooling fins or heat sink structures to be built directly into the housing. This enhances thermal management even further.

- Superior Electromagnetic Shielding: These enclosures effectively block electromagnetic interference (EMI) and radio frequency interference (RFI). Their single-piece construction minimizes gaps that could allow interference, ensuring smooth operation.

Connectors and Interfaces

Now, let’s talk about connectors and interfaces. I find that aluminum die cast connectors are designed with some impressive features that enhance their performance in telecommunications. Here’s a quick look at their key specifications:

| Feature | Specification |

|---|---|

| Material | A380 aluminum alloy |

| Ultimate tensile strength | 310 MPa |

| Thermal conductivity | ~96 W/m·K |

| Density | 2.74 g/cm³ |

| Die-cast thickness | 2.0–3.2 mm |

| Surface flatness | ≤0.05 mm over 250 mm span |

These connectors not only provide a strong and durable connection but also contribute to the miniaturization of telecommunications equipment. Their lightweight nature and excellent thermal conductivity allow for efficient heat dissipation in smaller components. Plus, the advanced design capabilities of die casting enable the creation of intricate designs and thinner walls, making them perfect for compact devices.

Aluminum Die Cast Electronic Spare Parts in Aerospace

When I think about the aerospace industry, aluminum die cast electronic spare parts play a pivotal role. Their lightweight structures and high-performance engine parts are essential for modern aircraft.

Lightweight Structures

Aluminum die cast components are crucial for creating lightweight structures in aerospace applications. I’ve seen how these parts contribute to fuel efficiency and payload optimization. Here’s a quick look at some of the benefits:

| Benefit | Explanation |

|---|---|

| Reduced Fuel Consumption | Lightweight aluminum components lead to significant fuel savings, lowering operational costs. |

| Extended Flight Range | Reducing aircraft weight enables extended range, crucial for aviation. |

| Improved Payload Capacity | Weight reduction allows for increased payload capacity, essential for cargo and passenger aircraft. |

The market for aluminum die cast electronic spare parts in aerospace is projected to grow at a CAGR of 8.7% from 2025 to 2032. This growth stems from advancements in technology and the increasing demand for lightweight materials. I find it fascinating how these components enhance aircraft performance and efficiency, making them indispensable in the industry.

Engine Parts

Now, let’s talk about engine parts. Aluminum die cast engine components offer several performance advantages that I find impressive. Here’s a breakdown of their key benefits:

| Advantage | Description |

|---|---|

| High strength-to-weight ratio | Aluminum die casting provides a lightweight option without sacrificing strength. |

| Excellent corrosion resistance | Ensures longevity and durability in harsh aerospace environments. |

| Good thermal and electrical conductivity | Enhances performance in thermal management and electrical systems. |

| Ability to produce complex geometries | Allows for high precision in manufacturing intricate designs. |

I’ve noticed that aerospace-grade aluminum is vital in this sector due to its exceptional properties. These components withstand the demanding conditions of flight while remaining lightweight, which is essential for fuel efficiency and overall aircraft performance.

Aluminum die cast electronic spare parts truly make a difference across multiple industries. I’ve seen firsthand how they offer benefits like cost-effectiveness, excellent dimensional accuracy, and versatility in design. These components are lightweight yet durable, making them essential for reliability in sectors like automotive and aerospace.

The aluminum die casting process allows for creating parts that enhance performance and energy efficiency. This is crucial as we push for more energy-saving solutions in our devices.

As demand grows, I believe these parts will continue to play a vital role in advancing technology and efficiency in modern electrical devices.

FAQ

What are aluminum die cast electronic spare parts?

Aluminum die cast electronic spare parts are components made from aluminum using a die casting process. They are lightweight, durable, and precise, making them ideal for various applications in industries like automotive, aerospace, and telecommunications.

Why choose aluminum die casting over other methods?

I prefer aluminum die casting because it offers excellent dimensional accuracy and allows for complex shapes. It also provides a strong, lightweight solution that enhances performance and energy efficiency in electronic devices.

How do I know if aluminum die cast parts are right for my project?

If your project requires lightweight, durable components with precise dimensions, aluminum die cast parts are a great choice. They work well in demanding environments and can improve the overall performance of your devices.

Are aluminum die cast parts environmentally friendly?

Yes! Aluminum die cast parts are 100% recyclable. Choosing these components can help reduce waste and promote sustainability in your projects, which I find essential in today’s eco-conscious world.

How can I customize aluminum die cast parts for my needs?

You can customize aluminum die cast parts by specifying dimensions, shapes, and surface treatments. Many manufacturers, like HHXT, offer tailored solutions to meet your unique requirements, ensuring a perfect fit for your applications.

Post time: Sep-12-2025