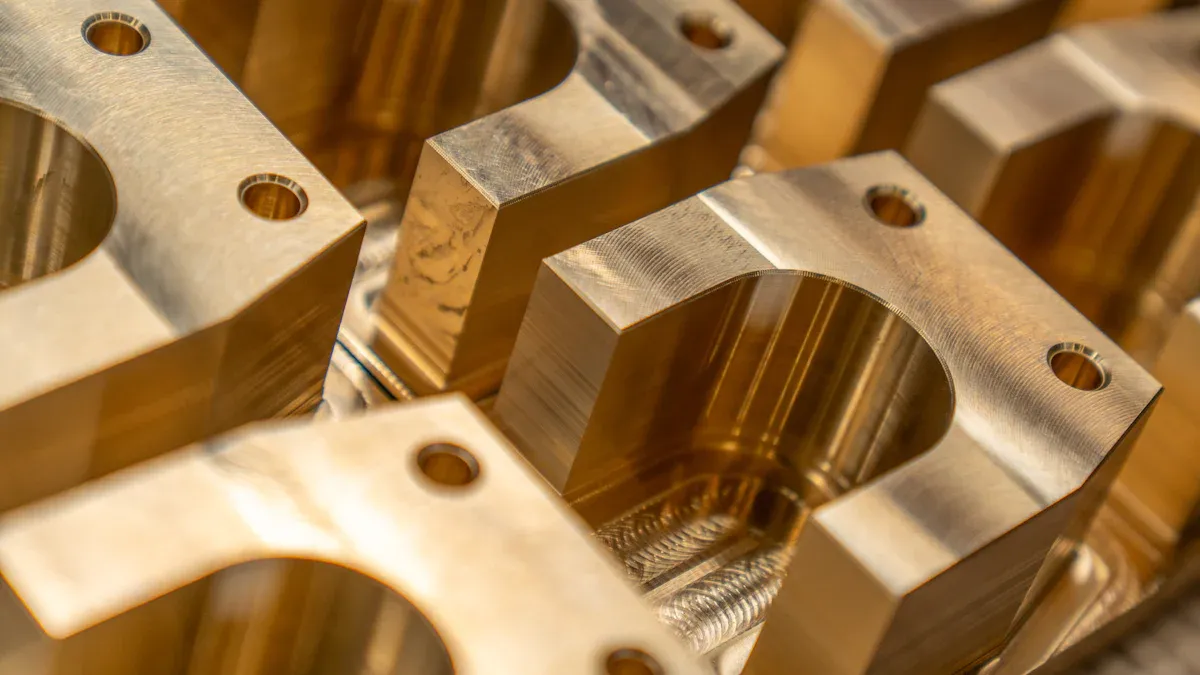

You can solve manufacturing problems quickly by choosing custom cast aluminum components. Industry reports show that cast aluminum parts deliver faster production and greater reliability than traditional materials. Whether you produce automobile parts or lighting fixtures, you gain lower costs, flexible designs, and consistent quality with cast aluminum solutions.

Key Takeaways

- Custom cast aluminum parts cut production costs by speeding up development, reducing testing, and saving energy, helping manufacturers save millions.

- Using cast aluminum boosts manufacturing speed and efficiency by enabling faster production cycles and easier machining, which lowers labor and lead times.

- Cast aluminum offers great design freedom with complex shapes and thin walls, while delivering strong, durable, and high-quality products that last longer.

Cast Aluminum: Overcoming Key Manufacturing Challenges

Reducing Production Costs

You want to keep your manufacturing costs low without sacrificing quality. Cast Aluminum helps you achieve this goal. By switching to cast aluminum components, you can reduce product development time, cut down on expensive testing, and optimize your processes. For example, Ford Motor Company saved millions by using advanced casting tools and methods. The table below shows how manufacturers benefit from cost savings:

| Aspect of Cost Savings | Description | Quantitative Impact |

|---|---|---|

| Product Development Time Reduction | Virtual Aluminum Castings (VAC) methodology speeds up development | 15–25% faster development of cylinder heads/blocks |

| Reduction in Specialized Testing | Fewer durability tests needed | Millions saved |

| Process Optimization | Lower-cost casting processes with high quality | Higher fatigue strength at lower cost |

| Heat-Treatment Cycle Time Reduction | Faster heat-treatment cycles | 2 hours saved per cycle |

| Overall Cost Savings | Improved design and manufacturing | Millions saved by Ford Motor Company |

You also save on material and energy costs. Cast Aluminum uses less energy during production compared to other metals. Its high recyclability means you spend less on raw materials and waste disposal. Advances in casting technology, like automation and simulation software, further reduce costs and improve efficiency.

Boosting Efficiency and Speed

You need to deliver products quickly to stay ahead in the market. Cast Aluminum enables faster production cycles and higher efficiency. Once you have the molds, you can produce large volumes of parts with fewer steps than machining. This method reduces lead times and labor costs, especially for high-volume runs.

Tip: Cast Aluminum’s excellent machinability and lower melting point speed up manufacturing and reduce energy use.

Case studies show dramatic improvements in production speed. For example, Monaghan Tooling achieved a 1000% productivity gain by using cast aluminum for internal recessing, cutting machining time from 270 seconds to just 27 seconds. In additive manufacturing, increasing powder layer thickness and improving laser absorption led to a fourfold increase in build rate and a threefold reduction in total production time.

Manufacturers track efficiency gains using metrics such as defect reduction rates, process capability indices, scrap reduction percentages, and supplier performance. These metrics help you measure and improve your operations, ensuring you get the most out of your investment in cast aluminum.

Expanding Design Flexibility

You want the freedom to create innovative products that stand out. Cast Aluminum gives you unmatched design flexibility. You can produce complex shapes, thin walls, and intricate internal passages that are difficult or impossible with other materials. This flexibility supports creative engineering in automotive, aerospace, and electronics industries.

- Cast Aluminum allows for:

- Complex geometries and varying wall thicknesses

- Cost-effective production of intricate designs

- Reduced tooling costs and material waste

- Near-net-shape manufacturing, minimizing finishing work

3D printing and advanced casting methods make it even easier to iterate and prototype new designs. You can quickly adjust to market demands and shorten your product development timelines. This adaptability helps you stay competitive and respond to customer needs faster.

Enhancing Quality and Durability

You expect your products to last and perform reliably. Cast Aluminum delivers superior quality and durability. It offers greater strength, dimensional stability, and heat resistance than plastic parts. Its high recyclability and resistance to corrosion make it a sustainable choice for demanding environments.

Manufacturers use strict quality control measures to ensure reliability. These include designing parts with uniform wall thickness, controlling mold temperatures, and using simulation software to predict and prevent defects. Regular inspections, 3D scanning, and CNC machining maintain tight tolerances and consistency across large production runs.

Field and laboratory tests confirm the durability of cast aluminum components. For example, fatigue tests on automotive alloys show that cast aluminum can withstand millions of cycles under stress. Proper control of porosity and microstructure ensures long service life, even in harsh industrial conditions.

Note: Cast Aluminum’s durability and recyclability support your sustainability goals and reduce lifecycle costs compared to steel or plastic alternatives.

Cast Aluminum: Practical Solutions and Real-World Results

Automotive and Industrial Applications

You can transform your automotive and industrial products by choosing cast aluminum. Leading car makers like Honda and Audi use cast aluminum for engine blocks, transmissions, and wheels. These parts offer a strong strength-to-weight ratio, resist corrosion, and handle thermal stress. When you use cast aluminum, you help your vehicles become lighter and more fuel efficient without losing durability. Tesla, Ford, and BMW have adopted large-scale aluminum casting to simplify assembly, reduce the number of parts, and boost structural rigidity. In industrial equipment, you benefit from better heat dissipation, up to 40% improved heat escape, and lower material costs. You also support environmental goals by using recyclable materials and reducing waste.

Electronics and Consumer Products

You can improve your electronics and consumer products with cast aluminum. This material gives you high strength and excellent corrosion resistance, which protects sensitive components. You get lightweight parts that make devices easier to carry and assemble. Cast aluminum’s thermal conductivity helps manage heat, making it perfect for heat sinks and enclosures. You can create thin-walled, precise parts that support miniaturization and modern design. Many top brands use cast aluminum to make their products more reliable, energy efficient, and sustainable.

Tip: Cast aluminum lets you design complex shapes and intricate details, helping your products stand out in a crowded market.

Steps for Successful Integration

You can achieve the best results by following proven steps when adding cast aluminum to your manufacturing process:

- Design molds that match your part’s geometry and function.

- Control injection pressure and temperature to avoid defects.

- Use simulation software to optimize cycle times and quality.

- Maintain your dies regularly to extend tool life.

- Apply post-processing methods like CNC machining and anodizing for better surface quality.

- Integrate automation and real-time monitoring to boost efficiency.

- Address assembly needs by choosing the right joining methods and managing material differences.

By following these steps, you ensure smooth integration and maximize the benefits of cast aluminum in your production line.

You gain a competitive edge when you choose custom cast aluminum components.

- Cast Aluminum molds last for thousands of cycles, ensuring long-term efficiency.

- Consistent dimensional accuracy and surface finish reduce post-processing.

| Benefit | Impact |

|---|---|

| Cost Savings | Up to 5.3% reduction |

| ROI | Achieved in 34 shifts |

FAQ

How do custom cast aluminum components improve your manufacturing process?

You boost efficiency and cut costs. Cast aluminum parts offer fast production, precise shapes, and reliable quality. You gain a clear advantage over traditional materials.

Can you use cast aluminum for complex designs?

- Yes! You create intricate shapes and thin walls with ease.

- Cast aluminum supports creative engineering and rapid prototyping for unique products.

What industries benefit most from cast aluminum solutions?

| Industry | Benefit |

|---|---|

| Automotive | Lightweight strength |

| Electronics | Superior heat control |

| Industrial | Cost savings |

You see results across many sectors.

Post time: Aug-21-2025