You depend on reliable suppliers to keep your pumps and compressors production running smoothly. Unplanned downtime from unreliable partners leads to lost time, higher costs, and even safety risks. Customer trust grows when you deliver consistent quality, so choosing dependable suppliers helps you avoid setbacks and protect your reputation.

Key Takeaways

- Reliable suppliers deliver high-quality parts on time, helping you avoid production delays and keep your pumps and compressors running smoothly.

- Strong supplier partnerships reduce defects and warranty issues, saving you money and protecting your reputation with customers.

- Using digital tools and working closely with trusted suppliers speeds up innovation and product launches, giving you a competitive edge.

Product Quality and Consistency in Pumps and Compressors

Precision Manufacturing for Performance

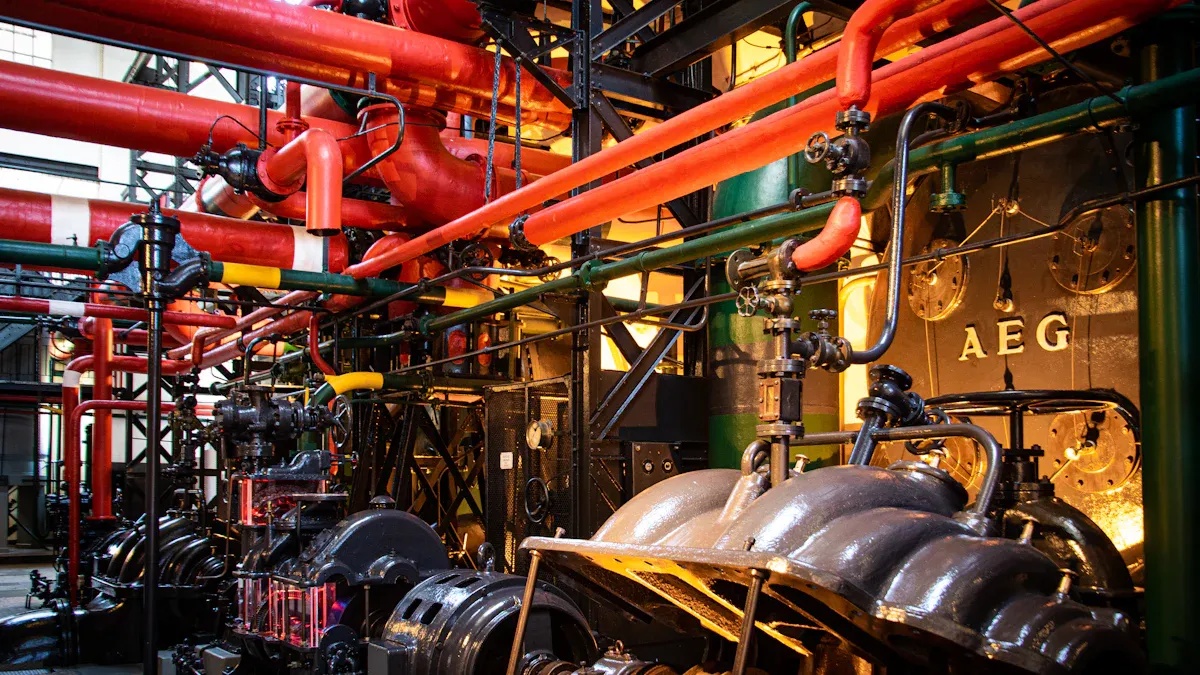

You want every pump and compressor you deliver to perform at its best. Precision manufacturing makes this possible. Reliable suppliers use advanced equipment and strict processes to create parts that fit perfectly and work smoothly. This level of accuracy helps you control fluid flow, maintain stable pressure, and keep temperatures steady. When each part meets exact specifications, your pumps and compressors run efficiently and last longer.

- Reliable suppliers provide materials with consistent chemical properties, so every diaphragm or seal matches the first one produced.

- They follow precise assembly steps, such as using the right torque and seating components correctly, to ensure uniform quality.

- Every pump goes through end-of-line testing to check flow, pressure, and vacuum levels before it leaves the factory.

- Suppliers often hold certifications like ISO 9001:2015, which shows their commitment to quality and precision.

Industry standards also play a big role. You may see requirements for ISO 9001, ASME, or even aerospace standards like AS9100. These certifications help you trust that your supplier can deliver the precision you need for pumps and compressors in any application.

Tip: Choose suppliers who invest in high-quality materials and advanced manufacturing methods. This choice leads to better performance and longer equipment life.

Reducing Defects and Warranty Issues

Defects and warranty claims can hurt your reputation and increase costs. You can avoid these problems by working with reliable suppliers who focus on quality from the start. Strong supplier relationships help you get components that meet your exact needs every time.

- Open communication with your suppliers ensures that every part meets your specifications.

- Quality control systems, including traceability and thorough inspections, catch problems before they reach your customers.

- Using standardized processes and materials keeps performance consistent across all units.

- Testing methods like prototyping, simulation, and real-world validation help you spot issues early.

- Suppliers who meet strict quality standards and use advanced engineering can offer custom solutions that fit your designs.

You also reduce risk by diversifying your supplier base and making sure each partner follows best practices. This approach keeps your production running smoothly and helps you deliver pumps and compressors that customers can trust.

Note: Building long-term partnerships with reliable suppliers supports continuous improvement and innovation, which further reduces defects and warranty issues.

Uninterrupted Production and Timely Delivery

Minimizing Downtime in Pumps and Compressors Manufacturing

You know that every minute of downtime can impact your bottom line. Reliable suppliers help you keep your production lines moving. They deliver parts on schedule and respond quickly to your needs. When you work with dependable partners, you avoid waiting for missing components or dealing with last-minute surprises.

Downtime often results from late shipments or quality issues. You can reduce these risks by choosing suppliers who use advanced planning and maintain clear communication. They track orders closely and update you about any changes. This approach helps you plan your workflow and keep your manufacturing process steady.

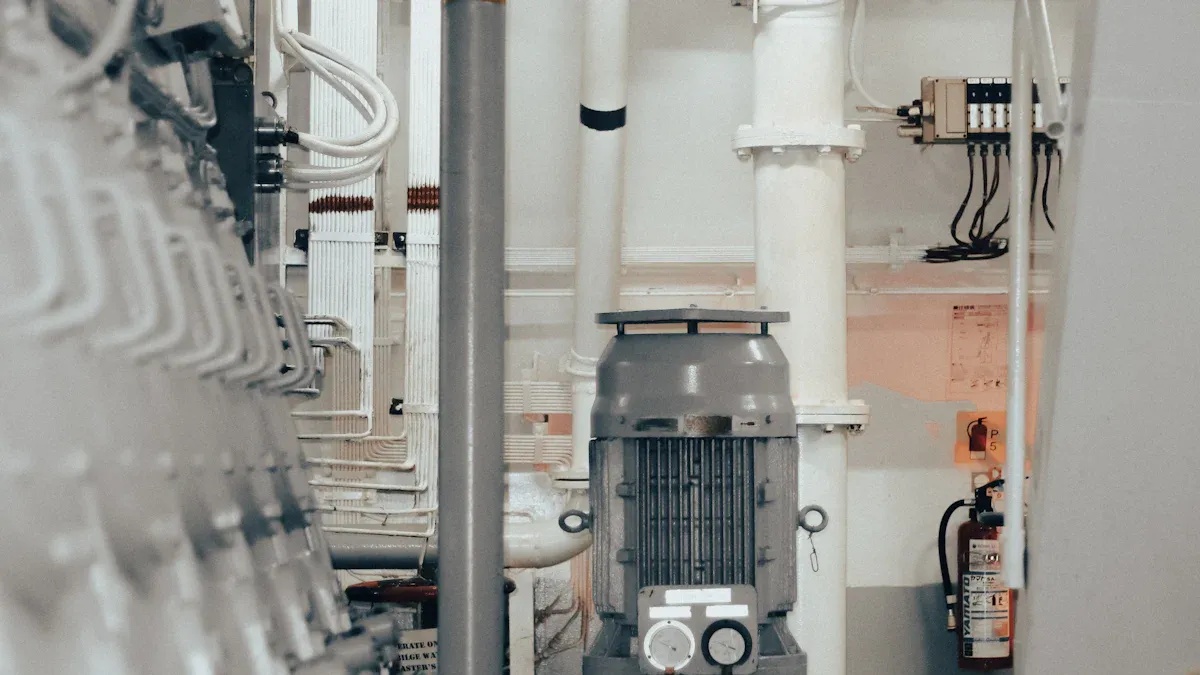

A reliable supplier also invests in technology and skilled staff. They use automated systems to monitor inventory and production. This investment allows them to spot problems early and fix them before they affect your pumps and compressors assembly.

Meeting Customer Delivery Commitments

Your customers expect you to deliver on time, even when supply chains face challenges. To meet these expectations, you need suppliers who value speed and flexibility. Many contract manufacturers now offer quick turnaround times, including next day or same day expedite options. They understand that speed and responsiveness are critical in the supply chain.

You can see how top suppliers help you meet delivery commitments:

- They provide fast shipping options when you need urgent parts.

- They communicate often to avoid delays and misunderstandings.

- They coordinate closely with your team to keep projects on track.

Global supply chain disruptions can slow down deliveries and create logistics problems. Reliable suppliers help you overcome these challenges by investing in better processes and staying prepared for changes in demand. This support lets you keep your promises to customers and build trust in your brand.

Supply Chain Resilience and Risk Mitigation

Navigating Disruptions in the Pumps and Compressors Industry

You face many risks when managing your supply chain for pumps and compressors. Disruptions can come from new regulations, rising material costs, or delays in getting parts. Understanding these risks helps you prepare for challenges and keep your production steady.

Here is a table showing some key risks and their impact:

| Key Risks to Supply Chain Resilience | Probability & Impact |

|---|---|

| Regulatory tightening on high-GWP refrigerants | High Probability, High Impact |

| Supply chain disruptions impacting component availability | Medium Probability, High Impact |

| Rising raw material costs affecting production margins | High Probability, Medium Impact |

You can see that regulatory changes and material costs have a big effect on your operations. Many companies now use digital tools to track suppliers and spot problems early. For example, digital platforms let you monitor supplier quality in real time and take quick action if issues arise. This approach helps you respond faster to disruptions and keep your supply chain strong.

Building Flexibility and Redundancy

You can build a more flexible supply chain by using several strategies. Many OEMs keep extra inventory of critical parts, such as custom motors or aluminum, to avoid running out during delays. You can also work with multiple local suppliers instead of relying on just one. This way, if one supplier faces a problem, you still have other options.

Here are some steps you can take:

- Keep safety stock at levels that cover more than twice your usual lead time.

- Source key components from several local suppliers.

- Use digital supply chain management tools for real-time monitoring.

- Invest in local production to reduce risks from tariffs and global disruptions.

Recent trends show that companies in the pumps and compressors industry are moving production closer to home and training workers to keep supply chains reliable. These actions help you adapt quickly to changes and keep your business running smoothly.

Cost Efficiency for Pumps and Compressors OEMs

Avoiding Extra Costs from Delays and Rework

You can control your costs by working with reliable suppliers who help you avoid delays and rework. When a supplier misses a deadline or delivers parts that do not meet your standards, you face extra expenses. These costs add up quickly and can hurt your bottom line.

- Supplier delays often cause downtime, which leads to lost production and financial losses for both you and your customers.

- Rework and repairs, while sometimes necessary, require extra labor and materials. This increases your expenses and can slow down your schedule.

- When you face delays, you may need to keep larger inventories or pay premium prices for urgent repairs or replacements.

- Emergency repairs and planned maintenance help you restore equipment quickly, but they also add to your costs if you rely on them too often.

You can reduce these risks by choosing suppliers who deliver on time and meet your quality standards. This approach keeps your production steady and your costs under control.

Achieving Sustainable Cost Savings

You can achieve long-term savings by partnering with reliable aluminum die casting suppliers. These suppliers use advanced tools and processes to help you understand and manage your costs.

| Cost Component | Description | Role in Quantifying ROI |

|---|---|---|

| Labor | Labor hours for moldmaking, pouring, and cleaning. | Helps you find ways to save on labor early in design. |

| Materials | Raw metal needed for each part. | Lets you estimate material costs accurately. |

| Setup | Time and cost to set up machines. | Shows how production volume affects cost per part. |

| Tooling | Costs for tool wear and replacement. | Helps you plan for long-term savings. |

| Energy | Energy used to melt metal. | Helps you understand how energy costs affect your budget. |

Reliable suppliers also use 3D scanning, non-destructive testing, and AI-supported analysis to improve quality and reduce defects. These steps lower your risk of warranty claims and rework, helping you save money over time.

Tip: Use digital costing tools and quality checks to work with your supplier on design changes. This teamwork helps you optimize costs and improve your return on investment.

Driving Innovation and Speed to Market

Collaborating on New Pumps and Compressors Designs

You can boost your innovation by working closely with reliable suppliers. These partners bring specialist advice and broad design experience to your projects. When you team up early in the design process, you gain access to advanced components like modular systems and BLDC motors. This support helps you create smaller, more efficient products that meet your customers’ needs.

Reliable suppliers also offer flexible repair and refurbishment options. You can focus on new ideas while your supplier handles operational details. This partnership reduces downtime and costs, making your design process smoother and more creative.

Here is a look at some successful collaborations:

| OEM / Supplier | Collaboration Focus | Key Outcomes |

|---|---|---|

| Atlas Copco Power Technique & RMS | Self-priming pump products sales and rental | Improved customer satisfaction, technical training, and fast parts availability |

| Copeland & HVAC OEMs | Advanced cold-climate heat pump compressors | High-efficiency performance at low temperatures, modular technology, and support for renewable energy |

| Smartnewo & Global Brands | Electric air pumps with sensor tech | Dozens of patents, rapid product launches, and global market leadership |

Tip: Early collaboration with experienced suppliers helps you reduce risks and bring better products to market faster.

Accelerating Prototyping and Product Launches

You can speed up prototyping and product launches by choosing suppliers who use digital technology. Tools like digital twins create virtual models of your products. You can test and improve designs before building physical prototypes. This approach helps you spot problems early and avoid costly delays.

Some suppliers use cloud-based AI systems to monitor equipment and predict failures. You get early warnings and expert advice, so you can plan maintenance and keep your projects on track. These digital solutions help you move from concept to launch quickly and with fewer surprises.

Note: Digital tools and reliable supplier support let you focus on innovation, reduce downtime, and deliver new products to your customers faster.

You gain a competitive edge when you prioritize supplier reliability.

- Consistent quality and in-house control build trust with your customers.

- Diversified supply chains and digital tools help you avoid disruptions and deliver on time.You face challenges like aging equipment and labor shortages, so you must evaluate suppliers carefully.

FAQ

What makes a supplier reliable for pumps and compressors OEMs?

You can trust a supplier who delivers on time, maintains consistent quality, and communicates clearly. Reliable suppliers help you avoid costly delays and production issues.

How does supplier reliability impact your production schedule?

You keep your assembly lines moving when suppliers meet deadlines. Reliable partners help you avoid downtime and ensure you deliver products to customers as promised.

Why should you choose an aluminum die casting supplier with advanced equipment?

- You get precise, high-quality parts.

- Advanced machines reduce defects.

- Modern technology supports faster production and better cost control.

Post time: Aug-01-2025